ASTM F423-95

(Specification)Standard Specification for Polytetrafluoroethylene (PTFE) Plastic-Lined Ferrous Metal Pipe, Fittings, and Flanges (Withdrawn 2002)

Standard Specification for Polytetrafluoroethylene (PTFE) Plastic-Lined Ferrous Metal Pipe, Fittings, and Flanges (Withdrawn 2002)

SCOPE

1.1 This specification covers factory-made polytetrafluoroethylene (PTFE) plastic-lined ferrous metal pipe, fittings, and flanges primarily intended for conveying corrosive fluids. Included are requirements for material, workmanship, dimensions, working pressure and temperature, design, fabrication, test methods, marking, as well as qualification requirements. Note 1-This specification does not include products coated with PTFE.

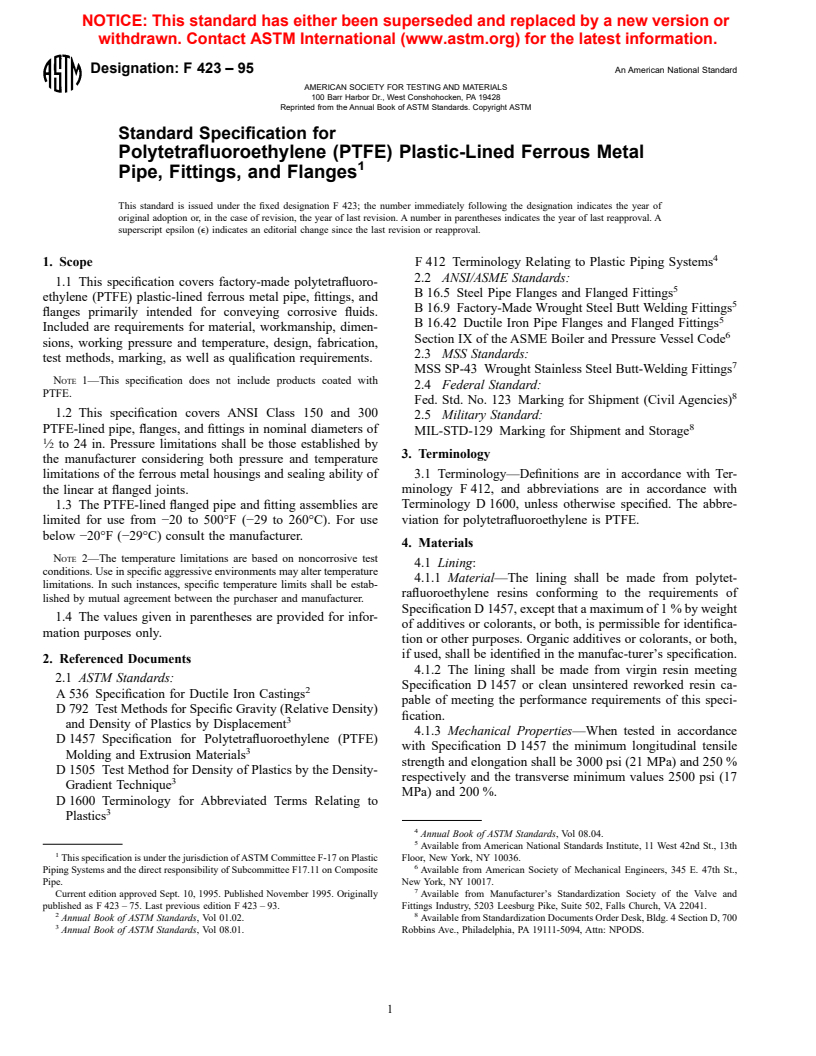

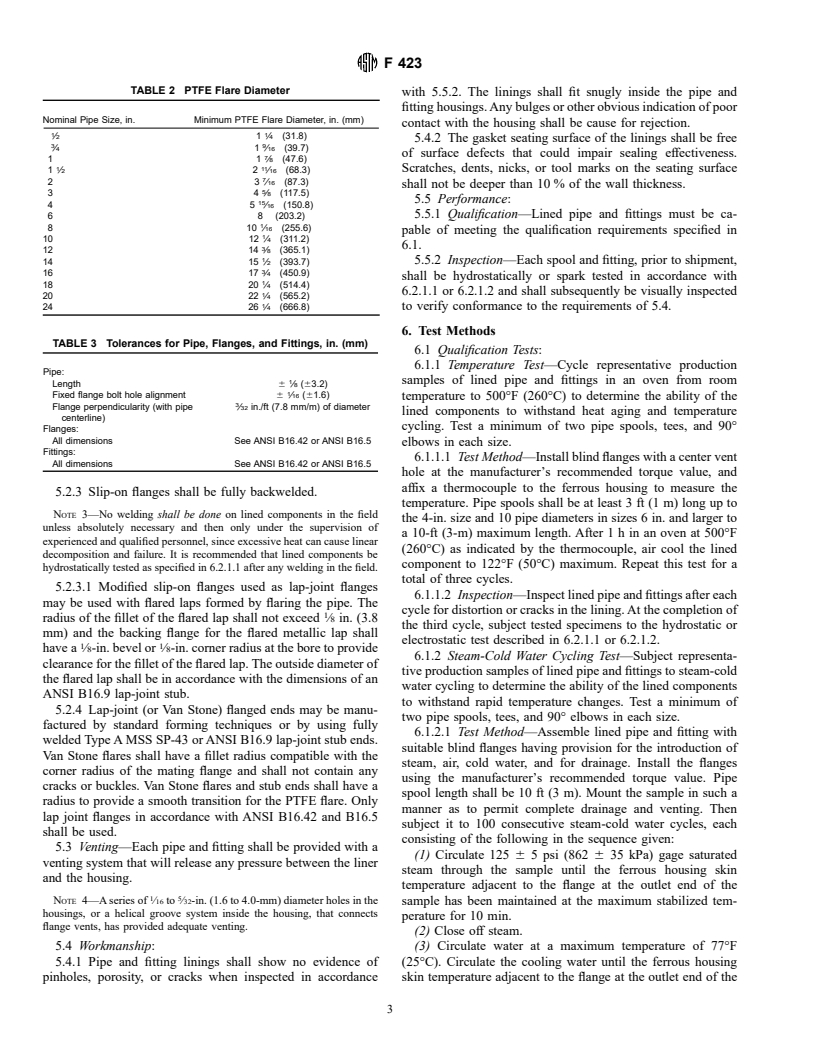

1.2 This specification covers ANSI Class 150 and 300 PTFE-lined pipe, flanges, and fittings in nominal diameters of 1/2 to 24 in. Pressure limitations shall be those established by the manufacturer considering both pressure and temperature limitations of the ferrous metal housings and sealing ability of the linear at flanged joints.

1.3 The PTFE-lined flanged pipe and fitting assemblies are limited for use from -20 to 500°F (-29 to 260°C). For use below -20°F (-29°C) consult the manufacturer. Note 2-The temperature limitations are based on noncorrosive test conditions. Use in specific aggressive environments may alter temperature limitations. In such instances, specific temperature limits shall be established by mutual agreement between the purchaser and manufacturer.

1.4 The values given in parentheses are provided for information purposes only.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: F 423 – 95 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Polytetrafluoroethylene (PTFE) Plastic-Lined Ferrous Metal

1

Pipe, Fittings, and Flanges

This standard is issued under the fixed designation F 423; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

4

1. Scope F 412 Terminology Relating to Plastic Piping Systems

2.2 ANSI/ASME Standards:

1.1 This specification covers factory-made polytetrafluoro-

5

B 16.5 Steel Pipe Flanges and Flanged Fittings

ethylene (PTFE) plastic-lined ferrous metal pipe, fittings, and

5

B 16.9 Factory-Made Wrought Steel Butt Welding Fittings

flanges primarily intended for conveying corrosive fluids.

5

B 16.42 Ductile Iron Pipe Flanges and Flanged Fittings

Included are requirements for material, workmanship, dimen-

6

Section IX of the ASME Boiler and Pressure Vessel Code

sions, working pressure and temperature, design, fabrication,

2.3 MSS Standards:

test methods, marking, as well as qualification requirements.

7

MSS SP-43 Wrought Stainless Steel Butt-Welding Fittings

NOTE 1—This specification does not include products coated with

2.4 Federal Standard:

PTFE.

8

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.2 This specification covers ANSI Class 150 and 300

2.5 Military Standard:

8

PTFE-lined pipe, flanges, and fittings in nominal diameters of

MIL-STD-129 Marking for Shipment and Storage

1

⁄2 to 24 in. Pressure limitations shall be those established by

3. Terminology

the manufacturer considering both pressure and temperature

limitations of the ferrous metal housings and sealing ability of 3.1 Terminology—Definitions are in accordance with Ter-

minology F 412, and abbreviations are in accordance with

the linear at flanged joints.

1.3 The PTFE-lined flanged pipe and fitting assemblies are Terminology D 1600, unless otherwise specified. The abbre-

viation for polytetrafluoroethylene is PTFE.

limited for use from −20 to 500°F (−29 to 260°C). For use

below −20°F (−29°C) consult the manufacturer.

4. Materials

NOTE 2—The temperature limitations are based on noncorrosive test

4.1 Lining:

conditions. Use in specific aggressive environments may alter temperature

4.1.1 Material—The lining shall be made from polytet-

limitations. In such instances, specific temperature limits shall be estab-

rafluoroethylene resins conforming to the requirements of

lished by mutual agreement between the purchaser and manufacturer.

Specification D 1457, except that a maximum of 1 % by weight

1.4 The values given in parentheses are provided for infor-

of additives or colorants, or both, is permissible for identifica-

mation purposes only.

tion or other purposes. Organic additives or colorants, or both,

if used, shall be identified in the manufac-turer’s specification.

2. Referenced Documents

4.1.2 The lining shall be made from virgin resin meeting

2.1 ASTM Standards:

Specification D 1457 or clean unsintered reworked resin ca-

2

A 536 Specification for Ductile Iron Castings

pable of meeting the performance requirements of this speci-

D 792 Test Methods for Specific Gravity (Relative Density)

fication.

3

and Density of Plastics by Displacement

4.1.3 Mechanical Properties—When tested in accordance

D 1457 Specification for Polytetrafluoroethylene (PTFE)

with Specification D 1457 the minimum longitudinal tensile

3

Molding and Extrusion Materials

strength and elongation shall be 3000 psi (21 MPa) and 250 %

D 1505 Test Method for Density of Plastics by the Density-

respectively and the transverse minimum values 2500 psi (17

3

Gradient Technique

MPa) and 200 %.

D 1600 Terminology for Abbreviated Terms Relating to

3

Plastics

4

Annual Book of ASTM Standards, Vol 08.04.

5

Available from American National Standards Institute, 11 West 42nd St., 13th

1

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

Floor, New York, NY 10036.

6

Piping Systems and the direct responsibility of Subcommittee F17.11 on Composite

Available from American Society of Mechanical Engineers, 345 E. 47th St.,

Pipe. New York, NY 10017.

7

Current edition approved Sept. 10, 1995. Published November 1995. Originally Available from Manufacturer’s Standardization Society of the Valve and

published as F 423 – 75. Last previous edition F 423 – 93. Fittings Industry, 5203 Leesburg Pike, Suite 502, Falls Church, VA 22041.

2 8

Annual Book of ASTM Standards, Vol 01.02. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

3

Annual Book of ASTM Standar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.