ASTM C162-05(2010)

(Terminology)Standard Terminology of Glass and Glass Products

Standard Terminology of Glass and Glass Products

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C162 − 05(Reapproved 2010)

Standard Terminology of

Glass and Glass Products

This standard is issued under the fixed designation C162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Abbe´ value 5 ~n 2 1!/~n 2 n !

d F C

where n is the refractive index for the helium line at

d

1.1 This terminology defines terms generally used in the

587.6 nm and n and n are the refractive indices for the

F C

glass industry.

hydrogen lines at 486.1 and 656.3 nm, respectively. See syn-

onymous term nu-value and related term dispersion.

1.2 In some cases in which a usage is specific to a certain

industry, that is spelled out within the definition. For complete-

acid polishing—the polishing of a glass surface by acid

ness and historical purposes, terms that are outdated are listed

treatment.

as being archaic. The reader is cautioned that some companies

air bells—bubbles of irregular shape formed generally during

or industries may define or use terms differently than the way

the pressing or molding operations in the manufacture of

these terms are defined within this terminology.

optical glass.

1.3 Other sources of glass glossaries are Glass Association

of North America’s Glazing Manual, Engineering Standards

alabaster glass—a milky-white glass that diffuses light with-

Manual for Tempered Glass, Laminated Glass Design Guide,

out fiery color.

and ASTM Committee C-14 standards.

alcove—a narrow channel to convey molten glass from refiner

to forehearth or to the revolving pot where it is gathered by

2. Referenced Documents

the Owens machine.

2.1 ASTM Standards:

C148 Test Methods for Polariscopic Examination of Glass

alkali—an industrial term for the oxide of sodium or potas-

Containers

sium; less frequently of lithium.

C336 Test Method for Annealing Point and Strain Point of

ampoule—aglasscontainerdesignedtobefilledandsealedby

Glass by Fiber Elongation

fusion of the glass neck.

C338 Test Method for Softening Point of Glass

C598 Test Method for Annealing Point and Strain Point of

anneal—to attain acceptably low stresses, or desired structure,

Glass by Beam Bending

or both, in glass by controlled cooling from a suitable

C1048 Specification for Heat-Strengthened and Fully Tem-

temperature.

pered Flat Glass

C1172 Specification for Laminated Architectural Flat Glass annealing—a controlled cooling process for glass designed to

reduceresidualstresstoacommerciallyacceptableleveland

3. Terminology

modify structure.

Abbé value—the reciprocal dispersive power, a value used in

annealing point (A.P.)—thattemperaturecorrespondingeither

optical design, expressed mathematically as:

to a specific rate of elongation of a glass fiber when

measured by Test Method C336, or a specific rate of

midpoint deflection of a glass beam when measured by Test

This terminology is under the jurisdiction of ASTM Committee C14 on Glass

Method C598. At the annealing point of glass, internal

and Glass Products and is the direct responsibility of Subcommittee C14.01 on

stresses are substantially relieved in a matter of minutes.

Nomenclature and Definitions.

Current edition approved March 1, 2010. Published March 2010. Originally

annealing range—the range of glass temperature in which

approved in 1941. Last previous edition approved in 2005 as C162 – 05. DOI:

10.1520/C0162-05R10.

stress in glass can be relieved at a commercially practical

Available from Glass Association of North America (GANA), 2945 SW

rate. For purposes of comparing glasses, the annealing range

Wanamaker Drive, Ste A, Topeka, KS 66614-5321. http://www.glasswebsite.com.

is assumed to correspond with the temperature between the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM annealing point (A.P.) and the strain point (St.P.).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. antimony—an industrial term for an oxide of antimony.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C162 − 05 (2010)

arch, n—a part of a melter; a crown. bent glass—flat glass that has been shaped while hot into a

body having curved surfaces.

arch, v—to heat a pot in a pot arch.

beveling—the process of edge finishing flat glass to a bevel

arrest mark—See dwell mark.

angle.

arsenic—an industrial term for an oxide of arsenic.

bicheroux process—{archaic} an intermittent process for

aventurine—glass containing colored, opaque spangles of

making plate glass, in which the glass is cast between rolls,

nonglassy material.

onto driven conveyer rolls, or a flat moving table.

back wall—the wall at the charging end of a melter.

binder—(1) for a continuous filament process, a constituent of

a fiber glass sizing that couples the fiber to the composite

baffle—a mold part used to close the delivery or baffle hole in

matrix.

a blank mold.

(2)forinsulation,materialappliedtoglassfiberstohold

baffle mark—amarkorseamonabottleresultingfromamold

them in a desired arrangement.

joint between blank mold and baffle.

blank—(1)apreliminaryshapefromwhichafinishedarticleis

baffle wall—a wall used to deflect gases or flames in a melter.

further formed, molded, or cut.

See shadow wall.

(2) a semi-finished piece of glass for making an optical

element, such as a lens or prism. Also known as a pressing.

baghouse—achambercontainingbagfiltersfortheremovalof

particles from a process exhaust stream.

blanket feed—a method for charging batch designed to

produce an even distribution of batch across the width of the

bait—the tool dipped into molten glass to start any drawing

melter.

operation.

blank mold—the metal mold that first shapes the glass in the

barrel, glass container—{archaic} See sidewall, glass con-

manufacture of hollow ware.

tainer.

base—{archaic} the bottom of a bottle.

blending-batch—{archaic} stepwise changes in batch compo-

sition to arrive at the final change in finished glass.

basic fiber—unprocessed glass fibers directly from the form-

ing equipment.

blister—a relatively large gaseous inclusion in glass.

batch—(1) the recipe of batch ingredients.

bloach—{archaic} an imperfection resulting from incom-

(2) the raw materials weighed but unmixed.

pletely grinding plate glass, caused by a low place in the

(3) the raw materials, properly proportioned and mixed,

plate which retains part of the original rough surface.

for delivery to the furnace.

blocking—(1) shaping a gather of glass in a cavity of wood or

batch charger—a mechanical device for introducing batch to

metal.

the melter.

(2) archaic, promoting mixing and fining of glass by

immersion of a wooden block or other object to create

batch feeder—See batch charger.

bubbles.

batch house—the place where batch materials are received,

(3) reprocessing to remove surface imperfections.

handled, weighed, and mixed.

(4) archaic, mounting of glass for grinding and polish-

bath—synonymous with float bath. ing.

(5 ) archaic, idling a furnace at reduced temperatures.

bead—(1) an enlarged, rounded raised section on a glass

See hot hold.

article.

(2) a small piece of glass tubing bonded around a wire block mold—a one-piece mold.

lead.

block reek, rake—{archaic} a scratch imperfection caused by

(3) in fiber glass, a tear drop-shaped glass mass which

cullet lodged in the felt in the polishing operation.

forms as a result of the interruption of the fiber forming

process below an orifice.

bloom—(1) a visible surface film resulting from attack by the

atmosphere or from the deposition of particulate or vapor

bearer arch—See rider arch.

condensates. (See also smoked.)

bearing surface—the outside surface of an item of glassware

(2) a blemish in float glass appearing on the bottom (tin

on which it rests when in its normal upright position.

contact) surface after reheating as a result of the presence of

beltmarks—See chain marks. tin diffused into the surface.

bench—See siege.

blow-and-blow process—the process of forming hollow ware

bending stress—a stress system that simultaneously imposes a

in which both the preliminary and final shapes are formed by

compressive component at one surface, graduating to an

air pressure.

imposed tensile component at the opposite surface of a glass

section. blower—one who forms glass by blowing. (See also gaffer.)

C162 − 05 (2010)

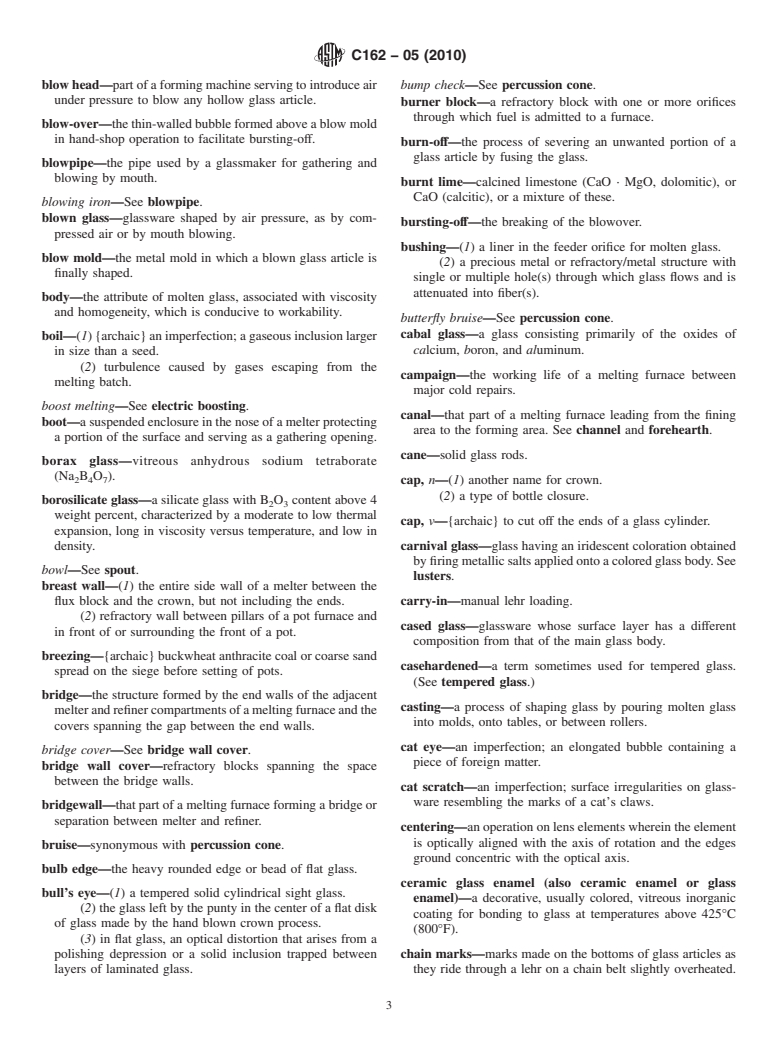

blow head—partofaformingmachineservingtointroduceair bump check—See percussion cone.

under pressure to blow any hollow glass article.

burner block—a refractory block with one or more orifices

through which fuel is admitted to a furnace.

blow-over—thethin-walled bubble formed above ablowmold

in hand-shop operation to facilitate bursting-off.

burn-off—the process of severing an unwanted portion of a

glass article by fusing the glass.

blowpipe—the pipe used by a glassmaker for gathering and

blowing by mouth.

burnt lime—calcined limestone (CaO · MgO, dolomitic), or

CaO (calcitic), or a mixture of these.

blowing iron—See blowpipe.

blown glass—glassware shaped by air pressure, as by com-

bursting-off—the breaking of the blowover.

pressed air or by mouth blowing.

bushing—(1) a liner in the feeder orifice for molten glass.

blow mold—the metal mold in which a blown glass article is

(2) a precious metal or refractory/metal structure with

finally shaped.

single or multiple hole(s) through which glass flows and is

attenuated into fiber(s).

body—the attribute of molten glass, associated with viscosity

and homogeneity, which is conducive to workability.

butterfly bruise—See percussion cone.

cabal glass—a glass consisting primarily of the oxides of

boil—(1) {archaic} an imperfection; a gaseous inclusion larger

calcium, boron, and aluminum.

in size than a seed.

(2) turbulence caused by gases escaping from the

campaign—the working life of a melting furnace between

melting batch.

major cold repairs.

boost melting—See electric boosting.

canal—that part of a melting furnace leading from the fining

boot—a suspended enclosure in the nose of a melter protecting

area to the forming area. See channel and forehearth.

a portion of the surface and serving as a gathering opening.

cane—solid glass rods.

borax glass—vitreous anhydrous sodium tetraborate

(Na B O ).

2 4 7

cap, n—(1) another name for crown.

(2) a type of bottle closure.

borosilicate glass—a silicate glass with B O content above 4

2 3

weight percent, characterized by a moderate to low thermal

cap, v—{archaic} to cut off the ends of a glass cylinder.

expansion, long in viscosity versus temperature, and low in

carnival glass—glass having an iridescent coloration obtained

density.

byfiringmetallicsaltsappliedontoacoloredglassbody.See

bowl—See spout.

lusters.

breast wall—(1) the entire side wall of a melter between the

flux block and the crown, but not including the ends. carry-in—manual lehr loading.

(2) refractory wall between pillars of a pot furnace and

cased glass—glassware whose surface layer has a different

in front of or surrounding the front of a pot.

composition from that of the main glass body.

breezing—{archaic} buckwheat anthracite coal or coarse sand

casehardened—a term sometimes used for tempered glass.

spread on the siege before setting of pots.

(See tempered glass.)

bridge—the structure formed by the end walls of the adjacent

casting—a process of shaping glass by pouring molten glass

melterandrefinercompartmentsofameltingfurnaceandthe

into molds, onto tables, or between rollers.

covers spanning the gap between the end walls.

cat eye—an imperfection; an elongated bubble containing a

bridge cover—See bridge wall cover.

piece of foreign matter.

bridge wall cover—refractory blocks spanning the space

between the bridge walls.

cat scratch—an imperfection; surface irregularities on glass-

ware resembling the marks of a cat’s claws.

bridgewall—that part of a melting furnace forming a bridge or

separation between melter and refiner.

centering—an operation on lens elements wherein the element

is optically aligned with the axis of rotation and the edges

bruise—synonymous with percussion cone.

ground concentric with the optical axis.

bulb edge—the heavy rounded edge or bead of flat glass.

ceramic glass enamel (also ceramic enamel or glass

bull’s eye—(1) a tempered solid cylindrical sight glass.

enamel)—a decorative, usually colored, vitreous inorganic

(2) the glass left by the punty in the center of a flat disk

coating for bonding to glass at temperatures above 425°C

of glass made by the hand blown crown process.

(800°F).

(3) in flat glass, an optical distortion that arises from a

polishing depression or a solid inclusion trapped between chain marks—marks made on the bottoms of glass articles as

layers of laminated glass. they ride through a lehr on a chain belt slightly overheated.

C162 − 05 (2010)

channel—(1)incontainerglass,thatpartofaforehearthwhich contact stress—the tensile stress component imposed at a

carries the glass from the melter to the flow spout and in glass surface immediately surrounding the contact area

which temperature adjustments are made. between the glass surface and an object generating a locally

(2) in fiber glass, the structure to deliver glass from the applied force.

melter to the refiner or forehearth.

continuous filament—a single glass fiber of sufficiently small

diametertobeflexibleenoughfortextileuses andofgreator

charge, n—See batch (3).

indefinite length.

charge, v—to add batch to a melter.

continuous furnace—synonymous with melter.

chatter sleek—{archaic} See frictive track.

cooling-down period—{archaic} (1) the time elapsing after a

check—an imperfection; a surface crack in a glass article.

covered pot is opened before the glass is cool enough to

checkers—(1) an open structure of firebrick serving as a heat

work.

exchanger.

(2) period between fining stage and the removal of the

(2) slang for regenerators of this type.

glass from the furnace.

(3) slang for refractory brick used in such a construc-

cooling rate—See setting rate.

tion.

cord—a generally attenuated glassy inclusion with properties

chemical durability—the lasting quality (both physical and

differing from those of the surrounding glass.

chemical) of a glass surface. It is frequently evaluated, after

corrugated glass—glass rolled to produce a corrugated con-

prolonged weathering or storing, in terms of chemical and

tour.

physical changes in the glass surface, or in terms of changes

in the contents of a vessel.

crackled—glassware, the surface of which has been intention-

ally cracked

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.