ASTM D3246-96

(Test Method)Standard Test Method for Sulfur in Petroleum Gas by Oxidative Microcoulometry

Standard Test Method for Sulfur in Petroleum Gas by Oxidative Microcoulometry

SCOPE

1.1 This test method covers determination of sulfur in the range from 1.5 to 100 mg/kg (ppm by mass) by weight in hydrocarbon products that are gaseous at normal room temperature and pressure.

Note 1-The test method has been tested cooperatively only on high-purity ethylene gas. Precision data have not been developed for other products.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3246–96

Standard Test Method for Sulfur in Petroleum Gas by

1

Oxidative Microcoulometry

This standard is issued under the fixed designation D3246; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope about 80% oxygen and 20% inert gas (for example, nitrogen,

argon, etc.). Oxidative pyrolysis converts the sulfur to sulfur

1.1 This test method covers determination of sulfur in the

dioxide which then flows into a titration cell where it reacts

range from 1.5 to 100 mg/kg (ppm by mass) by weight in

with triiodide ion present in the electrolyte. The triiodide thus

hydrocarbon products that are gaseous at normal room tem-

consumed, is coulometrically replaced and the total current

perature and pressure.

required to replace it is a measure of the sulfur present in the

NOTE 1—The test method has been tested cooperatively only on

sample injected.

high-purityethylenegas.Precisiondatahavenotbeendevelopedforother

3.2 The reaction occurring in the titration cell as sulfur

products.

dioxide enters is:

1.2 The values stated in SI units are to be regarded as the

2 2 1

I 1 SO 1H O→SO 13I 12H (1)

3 2 2 3

standard.

1.3 This standard does not purport to address all of the The triiodide ion consumed in the above reaction is gener-

safety concerns, if any, associated with its use. It is the ated coulometrically thus:

responsibility of the user of this standard to establish appro-

2 2 2

3I →I 12e (2)

3

priate safety and health practices and determine the applica-

3.3 Thesemicroequivalentsoftriiodide(iodine)areequalto

bility of regulatory limitations prior to use.

the number of microequivalents of titratable sample ion enter-

2. Referenced Documents ing the titration cell.

3.4 A liquid blend containing a known amount of sulfur is

2.1 ASTM Standards:

used for calibration.

D1265 Practice for Sampling Liquified Petroleum (LP)

2

Gases—Manual Method

4. Significance and Use

3

D1193 Specification for Reagent Water

4.1 Trace quantities of sulfur compounds in hydrocarbon

D3120 Test Method forTrace Quantities of Sulfur in Light

products can be harmful to many catalytic chemical processes

Liquid Petroleum Hydrocarbons by Oxidative Microcou-

2

in which these products are used. Maximum permissible levels

lometry

of total sulfur are normally included in specifications for such

F307 PracticeforSamplingPressurizedGasforGasAnaly-

4

hydrocarbons. It is recommended that this test method be used

sis

to provide a basis for agreement between two laboratories

2.2 Other Standards:

when the determination of sulfur in hydrocarbon gases is

Compressed Gas Association Booklets G-4 and G-4-1 on

5 important.

the Use of Oxygen.

4.2 On liquefied petroleum gas, total volatile sulfur is

3. Summary of Test Method measured on an injected gas sample. For such material a liquid

sample must be used to measure total sulfur.

3.1 Asample is injected into a combustion tube maintained

at about 800°C having a flowing stream of gas containing

5. Interferences

5.1 This test method is applicable in the presence of total

1

This test method is under the jurisdiction of ASTM Committee D02 on halideconcentrationsofupto10timesthesulfurlevelandtotal

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

nitrogen content of up to 1.0%. Free nitrogen does not

D02.03 on Elemental Analysis.

interfere.

Current edition approved Nov. 10, 1996. Published January 1997. Originally

5.2 This test method is not applicable in the presence of

published as D3246–73T. Last previous edition D3246–92.

2

Annual Book of ASTM Standards, Vol 05.01.

total heavy metal concentrations (for example, Ni, V, Pb, etc.)

3

Annual Book of ASTM Standards, Vol 11.01.

in excess of 500 mg/kg.

4

Annual Book of ASTM Standards, Vol 15.03.

5

Available from Compressed Gas Association, 1235 Jefferson Davis Hwy.,

Arlington, VA 22202.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

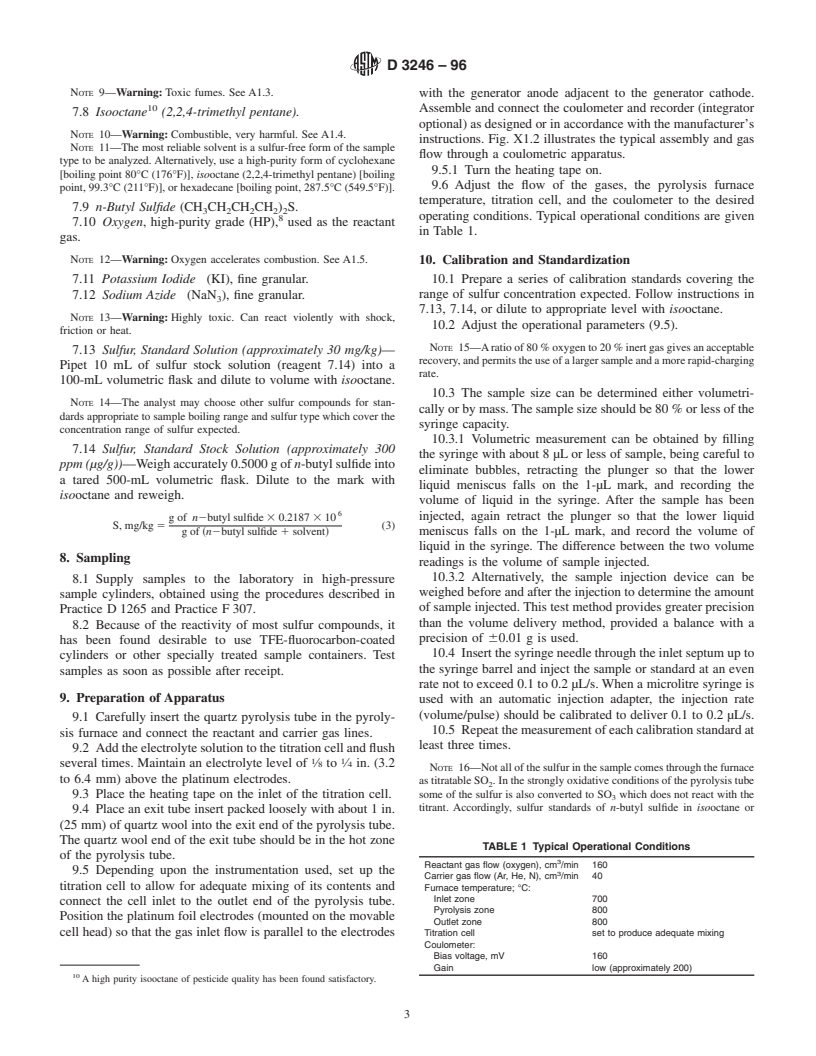

D3246–96

NOTE 2—To attain the quantitative detectability that the method is

6.5 Recorder, having a sensitivity of at least 0.1 mV/25 mm

capable of, stringent techniques should be employed and all possible

with chart speeds of 12 to 25 mm/min. Use of a suitable

sources of sulfur contamination must be eliminated.

electronic or mechanical integrator is recommended but op-

tional.

,

6 7

6. Apparatus

6.6 Sampling Syringe for Liquid—A microlitre syringe of

6.1 Pyrolysis Furnace—The sample should be pyrolyzed in

10-µL capacity capable of accurately delivering

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.