ASTM F1548-01(2006)

(Specification)Standard Specification for the Performance of Fittings for Use with Gasketed Mechanical Couplings Used in Piping Applications

Standard Specification for the Performance of Fittings for Use with Gasketed Mechanical Couplings Used in Piping Applications

ABSTRACT

This specification defines classification, materials, test requirements, inspection certification, marking and packaging of fittings for use with gasketed mechanical couplings used in piping applications. These fittings are classified into the following design types: Type I and Type II. The design of the fittings may be qualified by mathematical analysis in accordance with piping codes.

SCOPE

1.1 This specification defines classification, materials, test requirements, inspection certification, marking and packaging of fittings for use with gasketed mechanical couplings complying to Specification F1476.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1548 – 01 (Reapproved 2006)

Standard Specification for

Performance of Fittings for Use with Gasketed Mechanical

Couplings Used in Piping Applications

This standard is issued under the fixed designation F1548; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

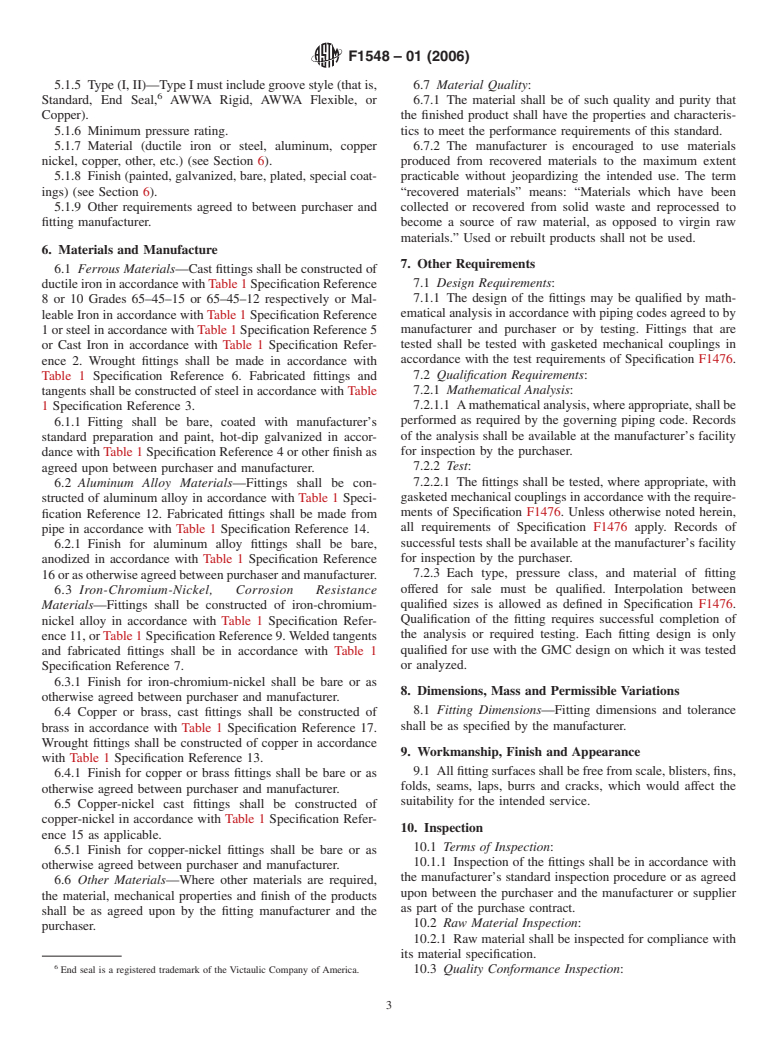

TABLE 1 Specification Equivalency Table

1. Scope

1.1 This specification defines classification, materials, test

Spec. Ref. U.S. Designation British ISO

requirements, inspection certification, marking and packaging

Number ASTM Standard Standard

of fittings for use with gasketed mechanical couplings com-

1 A47/A47M 6681 5922

2 A48/A48M 1452 —

plying to Specification F1476.

3 A53/A53M 3601 —

4 A153/A153M 729 1459, 1460, 1461

2. Referenced Documents

5 A216/A216M 3100 —

6 A234/A234M 1640 Pt. 1 —

2.1 ASTM Standards:

7 A312/A312M 3605 —

NOTE 1—See Table 1 for equivalency listing of applicable, equivalent 8 A395/A395M ——

9 A403/A403M 1640 Pt. 2 —

specifications.

10 A536 4772 2531, 4179, 8179

A47/A47M Specification for Ferritic Malleable Iron Cast-

11 A743/A743M 3100 —

ings

12 B26/B26M 1490 3522, 7722

13 B75 2871 —

A48/A48M Specification for Gray Iron Castings

14 B210 1471 209

A53/A53M Specification for Pipe, Steel, Black and Hot-

15 B369 3071 —

Dipped, Zinc-Coated, Welded and Seamless

16 B580 ——

17 B584 1400 —

A153/A153M Specification for Zinc Coating (Hot-Dip) on

18 B633 1706 2081

Iron and Steel Hardware

A216/A216M Specification for Steel Castings, Carbon,

ANSI

Suitable for Fusion Welding, for High-Temperature Ser-

19 B 36.10 3600 4200

vice

20 B 36.19 3600 4200

A234/A234M Specification for Piping Fittings of Wrought

21 Z 540.1 5781 —

Carbon Steel and Alloy Steel for Moderate and High

ANSI/AWWA

Temperature Service

A312/A312M Specification for Seamless, Welded, and

22 C151/A21.51 4772 2531, 4179, 8179

23 C606–87 ——

Heavily Cold Worked Austenitic Stainless Steel Pipes

A395/A395M Specification for Ferritic Ductile Iron

Pressure-Retaining Castings for Use at Elevated Tempera-

tures

A743/A743M Specification for Castings, Iron-Chromium,

A403/A403M Specification for Wrought Austenitic Stain-

Iron-Chromium-Nickel, Corrosion Resistant, for General

less Steel Piping Fittings

Application

A536 Specification for Ductile Iron Castings

B26/B26M Specification for Aluminum-Alloy Sand Cast-

ings

B75 Specification for Seamless Copper Tube

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

B210 Specification for Aluminum and Aluminum-Alloy

Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Drawn Seamless Tubes

Machinery and Piping Systems.

B369 Specification for Copper-Nickel Alloy Castings

Current edition approved Dec. 1, 2006. Published January 2007. Originally

B580 Specification for Anodic Oxide Coatings on Alumi-

approved in 1994. Last previous edition approved in 2001 as F1548 – 01. DOI:

10.1520/F1548-01R06.

num

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

B584 Specification for Copper Alloy Sand Castings for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

General Applications

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1548 – 01 (2006)

B633 Specification for Electrodeposited Coatings of Zinc Area—Gravimetric Method

on Iron and Steel

1461 Metallic Coatings—Hot Dipped Galvanized Coatings

F1476 Specification for Performance of Gasketed Mechani-

on Fabricated Ferrous Products—Requirements

cal Couplings for Use in Piping Applications

2081 Metallic Coatings—Electroplated Coatings of Zinc on

Iron or Steel

2.2 ANSI Standards:

2531 Ductile Iron Pipes, Fittings and Accessories for Pres-

B 36.10 Welded and Seamless Wrought Steel Pipe

B 36.19 Stainless Steel Pipe sure Pipe Lines

Z 540.1 Calibration Laboratories in Measuring Test Equip- 3522 Cast Aluminum Alloys—Chemical Composition and

ment

Mechanical Properties

2.3 ANSI/AWWA Standards:

4179 Ductile Iron Pipes for Pressure and Non-Pressure

C151/A21.51 Ductile-IronPipe,CentrifugallyCastinMetal

Pipelines—Centrifugal Cement Mortar Lining—General

Molds or Sand-Lined Molds, for Water and Other Liquids

Requirements

C606–87 Grooved and Shouldered Joints

4200 Plain End Steel Tubes, Welded and Seamless—

2.4 British Standards:

General Tables of Dimensions and Masses Per Unit

BS 729 Specification for Hot Dip Galvanized Coatings on

Length

Iron and Steel Articles

5922 Malleable Cast Iron

BS 1400 Specification for Copper Alloy Ingots and Copper

7722 AluminumAlloy Castings Produced by Gravity, Sand,

Alloy and High Conductivity Copper Castings

or Chill Casting, or by Related Processes—General Con-

BS 1452 Specification for Flake Graphite Cast Iron

ditions for Inspection and Delivery

BS 1471 Specification for Wrought Aluminum and Alumi-

8179 Ductile Iron Pipes—External Zinc Coating

num Alloys for General Engineering Purposes—Drawn

Tube

3. Terminology

BS 1490 Specification for Aluminum and Aluminum Alloy

3.1 Definitions:

Ingots and Castings for General Engineering Purposes

3.1.1 fabricated fitting—a fitting constructed by welding

BS 1640 Pt. 1 Wrought Carbon and Ferritic Alloy Steel

together sections of pipe or tube.

Fittings

3.1.2 fitting—a device used in a piping system to change

BS 1640 Pt. 2 Wrought and Cast Austenitic Chromium—

pipe direction, size, split or combine flows, or adapt to other

Nickel Steel Fittings

joining methods.

BS 1706 Method for Specifying Electroplated Coatings of

3.1.3 grooved end—type of fitting or pipe end having a

Zinc and Cadmium on Iron and Steel

groove for use with grooved mechanical couplings (Type I) as

BS 2871 Specification for Copper and Copper Alloys—

defined in F1476.

Tubes

3.1.4 pipe—hollow tubular product conforming to Table 1

BS 3071 Specification for Nickel—Copper Alloy Castings

Specification Reference Nos. 19, 20, 22 and 13, Nominal

BS 3100 Specification for Steel Castings for General Engi-

Dimensions, or O.D. tube.

neering Purposes

3.1.5 plain end—type of fitting or pipe end for use with a

BS 3600 Specification for Dimensions of Steel Pipe for the

gasketed mechanical coupling (Type II) that is plain end as

Petroleum Industry

defined in Specification F1476.

BS 3601 Specification for Carbon Steel Pipes and Tubes

3.1.6 tangent—a section of straight pipe or tube integral to

with Specified Room Temperature Properties for Pressure

or welded to the end(s) of a fitting.

Purposes

3.1.7 wrought fitting—a fitting made by shaping or shaping

BS 3605 Austenitic Stainless Steel Pipes and Tubes for

and welding.

Pressure Purposes

BS 4772 Specification for Ductile Iron Pipes and Fittings

4. Classification

BS 5781 Measurement and Calibration System

BS 6681 Specification for Malleable Cast Iron

4.1 These fittings are classified into the following design

2.5 International Standards Organization:

types:

209 Composition of Wrought Products of Aluminum and

4.1.1 Type I—Grooved end.

Aluminum Alloys. Chemical Composition (Percent)

4.1.2 Type II—Plain end.

1459 Metallic Coatings—Protection Against Corrosion by

Hot Dip Galvanizing—Guiding Principles

5. Ordering Information

1460 Metallic Coatings—Hot Dip Galvanized Coatings on

5.1 Orders for fittings under this specification shall include

Ferrous Materials—Determination of the Mass Per Unit

the following:

5.1.1 Specification designation, title, number and year of

issue.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org.

5.1.2 Quantity.

Available from British Standards Institute (BSI), 389 Chiswick High Rd.,

5.1.3 Size and appropriate suffix (Example 8 in. IPS, 76.1

London W4 4AL, U.K., http://www.bsi-global.com.

mm O.D.).

Available from International Organization for Standardization (ISO), 1 rue de

Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch. 5.1.4 Fitting description (90° Elbow, Tee

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.