ASTM E494-20

(Practice)Standard Practice for Measuring Ultrasonic Velocity in Materials by Comparative Pulse-Echo Method

Standard Practice for Measuring Ultrasonic Velocity in Materials by Comparative Pulse-Echo Method

ABSTRACT

This practice covers a test procedure for measuring ultrasonic velocities in materials with conventional ultrasonic pulse echo flaw detection equipment in which results are displayed in an A-scan display, and describes a method whereby unknown ultrasonic velocities in a material sample are determined by comparative measurements using a reference material whose ultrasonic velocities are accurately known. The ultrasonic testing system that shall be used shall consist of the test instrument, search unit, couplant, and the standard reference blocks. The test procedure shall include both longitudinal and transverse wave velocity measurements, which should conform to the theoretical values of the parameters.

SIGNIFICANCE AND USE

5.1 This practice describes a test procedure for the application of conventional ultrasonic methods to determine unknown ultrasonic velocities in a material sample by comparative measurements using a reference material whose ultrasonic velocities are accurately known.

5.2 Although not all methods described in this practice are applied equally or universally to all velocity measurements in different materials, it does provide flexibility and a basis for establishing contractual criteria between users, and may be used as a general guideline for preparing a detailed procedure or specification for a particular application.

5.3 This practice is directed towards the determination of longitudinal and shear wave velocities using the appropriate sound wave form. This practice also outlines methods to determine elastic modulus and can be applied in both contact and immersion mode.

SCOPE

1.1 This practice covers a test procedure for measuring ultrasonic velocities in materials with conventional ultrasonic pulse echo flaw detection equipment in which results are displayed in an A-scan display. This practice describes a method whereby unknown ultrasonic velocities in a material sample are determined by comparative measurements using a reference material whose ultrasonic velocities are accurately known.

1.2 This procedure is intended for solid materials 5 mm (0.2 in.) thick or greater. The surfaces normal to the direction of energy propagation shall be parallel to at least ±3°. Surface finish for velocity measurements shall be 3.2 μm (125 μin.) root-mean-square (rms) or smoother.

Note 1: Sound wave velocities are cited in this practice using the fundamental units of meters per second, with inches per second supplied for reference in many cases. For some calculations, it is convenient to think of velocities in units of millimeters per microsecond. While these units work nicely in the calculations, the more natural units were chosen for use in the tables in this practice. The values can be simply converted from m/s to mm/μs by moving the decimal point three places to the left, that is, 3500 m/s becomes 3.5 mm/μs.

1.3 Ultrasonic velocity measurements are useful for determining several important material properties. Young's modulus of elasticity, Poisson's ratio, acoustic impedance, and several other useful properties and coefficients can be calculated for solid materials with the ultrasonic velocities if the density is known (see Appendix X1).

1.4 More accurate results than those obtained using this method can be obtained with more specialized ultrasonic equipment, auxiliary equipment, and specialized techniques. Some of the supplemental techniques are described in Appendix X2. (Material contained in Appendix X2 is for informational purposes only.)

Note 2: Factors including techniques, equipment, types of material, and operator variables will result in variations in absolute velocity readings, sometimes by as much as ±5 %. Relative results with a single combination of the above factors can be expected to be much more accurate (probably within a 1 % tolerance).

1.5 Units—The values stated in SI units are to be regarded as standard. The values given in parentheses after SI uni...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E494 − 20

Standard Practice for

Measuring Ultrasonic Velocity in Materials by Comparative

1

Pulse-Echo Method

This standard is issued under the fixed designation E494; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

NOTE 2—Factors including techniques, equipment, types of material,

1. Scope*

and operator variables will result in variations in absolute velocity

1.1 This practice covers a test procedure for measuring

readings, sometimes by as much as 65%. Relative results with a single

ultrasonic velocities in materials with conventional ultrasonic combination of the above factors can be expected to be much more

accurate (probably within a 1% tolerance).

pulse echo flaw detection equipment in which results are

displayed in an A-scan display. This practice describes a

1.5 Units—The values stated in SI units are to be regarded

method whereby unknown ultrasonic velocities in a material

as standard. The values given in parentheses after SI units are

sample are determined by comparative measurements using a

providedforinformationonlyandarenotconsideredstandard.

reference material whose ultrasonic velocities are accurately

1.6 This standard does not purport to address all of the

known.

safety concerns, if any, associated with its use. It is the

1.2 This procedure is intended for solid materials 5 mm

responsibility of the user of this standard to establish appro-

(0.2in.) thick or greater. The surfaces normal to the direction priate safety, health, and environmental practices and deter-

of energy propagation shall be parallel to at least 63°. Surface

mine the applicability of regulatory limitations prior to use.

finish for velocity measurements shall be 3.2 µm (125 µin.) 1.7 This international standard was developed in accor-

root-mean-square (rms) or smoother.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

NOTE 1—Sound wave velocities are cited in this practice using the

Development of International Standards, Guides and Recom-

fundamental units of meters per second, with inches per second supplied

mendations issued by the World Trade Organization Technical

for reference in many cases. For some calculations, it is convenient to

think of velocities in units of millimeters per microsecond. While these

Barriers to Trade (TBT) Committee.

units work nicely in the calculations, the more natural units were chosen

for use in the tables in this practice. The values can be simply converted

2. Referenced Documents

from m/s to mm/µs by moving the decimal point three places to the left,

2

that is, 3500 m/s becomes 3.5 mm/µs.

2.1 ASTM Standards:

1.3 Ultrasonic velocity measurements are useful for deter- C597Test Method for Pulse Velocity Through Concrete

E317PracticeforEvaluatingPerformanceCharacteristicsof

miningseveralimportantmaterialproperties.Young’smodulus

Ultrasonic Pulse-Echo Testing Instruments and Systems

of elasticity, Poisson’s ratio, acoustic impedance, and several

without the Use of Electronic Measurement Instruments

other useful properties and coefficients can be calculated for

E543Specification forAgencies Performing Nondestructive

solid materials with the ultrasonic velocities if the density is

Testing

known (see Appendix X1).

E797Practice for Measuring Thickness by Manual Ultra-

1.4 More accurate results than those obtained using this

sonic Pulse-Echo Contact Method

method can be obtained with more specialized ultrasonic

E1316Terminology for Nondestructive Examinations

equipment, auxiliary equipment, and specialized techniques.

3

2.2 ASNT Documents:

Some of the supplemental techniques are described in Appen-

SNT-TC-1A Recommended Practice for Nondestructive

dix X2. (Material contained in Appendix X2 is for informa-

Testing Personnel Qualification and Certification

tional purposes only.)

1 2

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

structive Testing and is the direct responsibility of Subcommittee E07.06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Ultrasonic Method. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2020. Published January 2021. Originally the ASTM website.

3

approved in 1973.

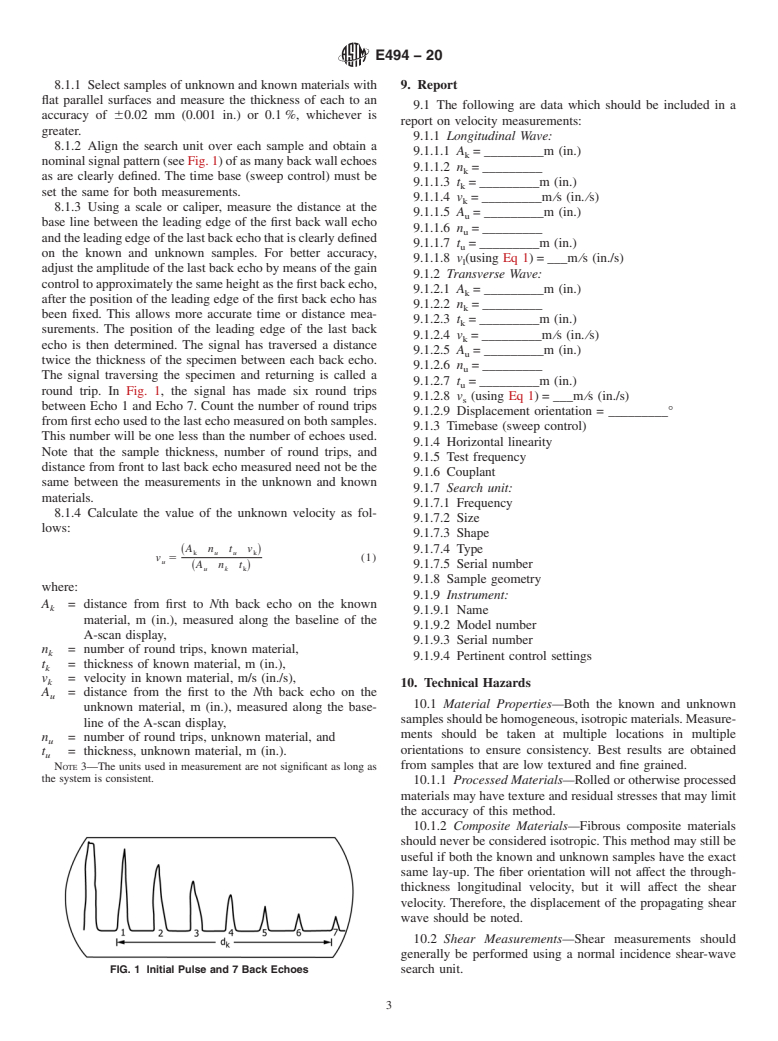

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E494 − 15 E494 − 20

Standard Practice for

Measuring Ultrasonic Velocity in Materials by Comparative

1

Pulse-Echo Method

This standard is issued under the fixed designation E494; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This practice covers a test procedure for measuring ultrasonic velocities in materials with conventional ultrasonic pulse echo

flaw detection equipment in which results are displayed in an A-scan display. This practice describes a method whereby unknown

ultrasonic velocities in a material sample are determined by comparative measurements using a reference material whose ultrasonic

velocities are accurately known.

1.2 This procedure is intended for solid materials 5 mm (0.2 in.) thick or greater. The surfaces normal to the direction of energy

propagation shall be parallel to at least 63°. Surface finish for velocity measurements shall be 3.2 μm (125 μin.) root-mean-square

(rms) or smoother.

NOTE 1—Sound wave velocities are cited in this practice using the fundamental units of metresmeters per second, with inches per second supplied for

reference in many cases. For some calculations, it is convenient to think of velocities in units of millimetresmillimeters per microsecond. While these

units work nicely in the calculations, the more natural units were chosen for use in the tables in this practice. The values can be simply converted from

m/s to mm/μs by moving the decimal point three places to the left, that is, 3500 m/s becomes 3.5 mm/μs.

1.3 Ultrasonic velocity measurements are useful for determining several important material properties. Young’s modulus of

elasticity, Poisson’s ratio, acoustic impedance, and several other useful properties and coefficients can be calculated for solid

materials with the ultrasonic velocities if the density is known (see Appendix X1).

1.4 More accurate results than those obtained using this method can be obtained with more specialized ultrasonic equipment,

auxiliary equipment, and specialized techniques. Some of the supplemental techniques are described in Appendix X2. (Material

contained in Appendix X2 is for informational purposes only.)

NOTE 2—Factors including techniques, equipment, types of material, and operator variables will result in variations in absolute velocity readings,

sometimes by as much as 5 %.65 %. Relative results with a single combination of the above factors can be expected to be much more accurate (probably

within a 1 % tolerance).

1.5 Units—The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided

for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic Method.

Current edition approved Dec. 1, 2015Dec. 1, 2020. Published December 2015January 2021. Originally approved in 1973. Last previous edition approved in 20102015

as E494 - 10.E494 – 15. DOI: 10.1520/E0494-15.10.1520/E0494-20.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E494 − 20

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C597 Test Method for Pulse Velocity Through Concrete

E317 Practice for Evaluating Performance Characteristics of Ultrasonic Pulse-Echo Testing Instruments and Systems without the

Use of Electronic Measurement Instruments

E543 S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.