ASTM D6621-21

(Practice)Standard Practice for Performance Testing of Process Analyzers for Aromatic Hydrocarbon Materials

Standard Practice for Performance Testing of Process Analyzers for Aromatic Hydrocarbon Materials

SIGNIFICANCE AND USE

5.1 Performance testing of on-line analyzers is critical to their proper performance within predictable levels of precision and accuracy. This practice can affect production efficiency and certification of aromatic hydrocarbon materials.

SCOPE

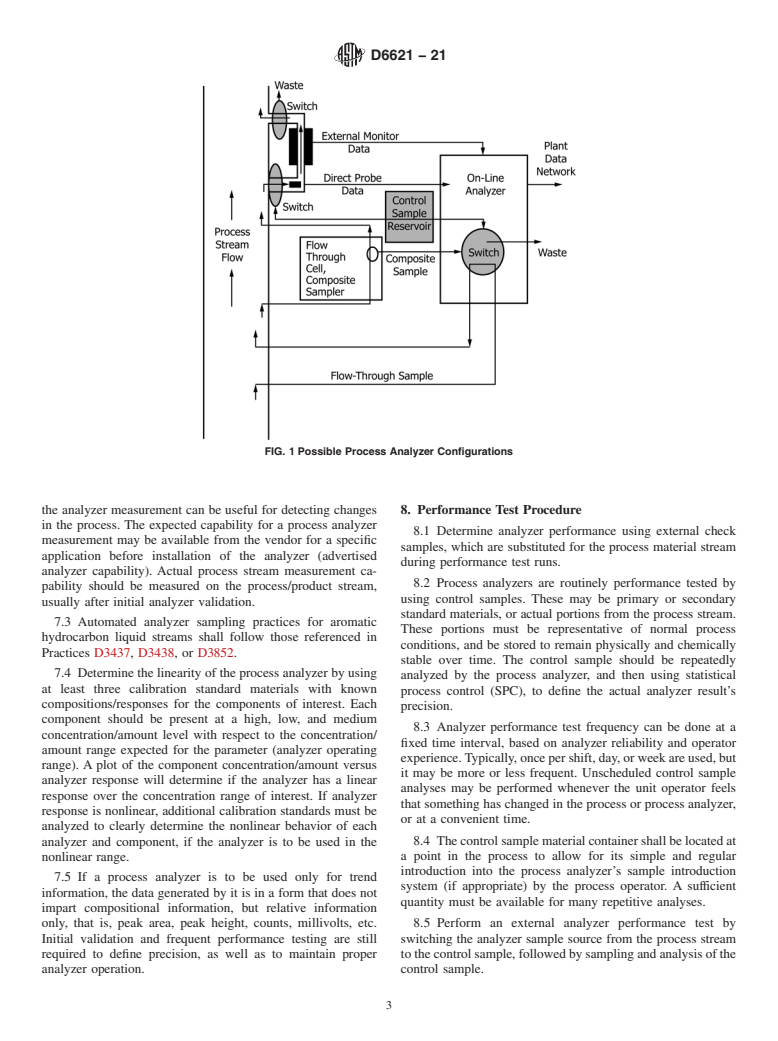

1.1 This practice serves as a practical guide for the performance testing of process stream analyzers specifically for measuring chemical or physical characteristics of liquid aromatic hydrocarbon materials for production or certification of these materials. The practice may be applicable to other hydrocarbon stream analyzers as well.

1.2 Only external methods (complete substitution of the process stream with a standard) of control sample introduction are included. Internal methods are beyond the scope of this practice.

1.3 Methods for resetting key operational parameters of analyzers to match predefined limits are provided by vendors and are not included in this practice.

1.4 Analyzer validation procedures are covered in Practices D3764 and D6122, not in this practice.

1.5 Procedures for statistically interpreting data from automatic sampling process stream analyzers are outlined.

1.6 The implementation of this practice requires that the analyzer be installed according to APIRP-550 (1),2 and be in agreement with the analyzer supplier’s recommendations. Also, it assumes that the analyzer is designed to monitor the specific material parameter of interest, and that at the time of initial or periodic validation, the analyzer was operating at the conditions specified by the manufacturer and consistently with the primary test method.

1.7 The units of measure used in this practice shall be the same as those applicable to the test primary method used for analyzer validation.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6621 − 21

Standard Practice for

Performance Testing of Process Analyzers for Aromatic

1

Hydrocarbon Materials

This standard is issued under the fixed designation D6621; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* priate safety, health, and environmental practices, and deter-

mine the applicability of regulatory limitations prior to use.

1.1 This practice serves as a practical guide for the perfor-

1.9 This international standard was developed in accor-

mance testing of process stream analyzers specifically for

dance with internationally recognized principles on standard-

measuring chemical or physical characteristics of liquid aro-

ization established in the Decision on Principles for the

matic hydrocarbon materials for production or certification of

Development of International Standards, Guides and Recom-

these materials. The practice may be applicable to other

mendations issued by the World Trade Organization Technical

hydrocarbon stream analyzers as well.

Barriers to Trade (TBT) Committee.

1.2 Only external methods (complete substitution of the

process stream with a standard) of control sample introduction

2. Referenced Documents

are included. Internal methods are beyond the scope of this

3

2.1 ASTM Standards:

practice.

D3437Practice for Sampling and Handling Liquid Cyclic

1.3 Methods for resetting key operational parameters of

Products

analyzers to match predefined limits are provided by vendors

D3438Practice for Sampling and Handling Naphthalene,

and are not included in this practice.

Maleic Anhydride, and Phthalic Anhydride

1.4 Analyzer validation procedures are covered in Practices D3764PracticeforValidationofthePerformanceofProcess

D3764 and D6122, not in this practice.

Stream Analyzer Systems

D3852Practice for Sampling and Handling Phenol, Cresols,

1.5 Procedures for statistically interpreting data from auto-

and Cresylic Acid

matic sampling process stream analyzers are outlined.

D6122Practice for Validation of the Performance of Multi-

1.6 The implementation of this practice requires that the

variate Online, At-Line, Field and Laboratory Infrared

2

analyzer be installed according to APIRP-550 (1), and be in

Spectrophotometer, and Raman Spectrometer BasedAna-

agreement with the analyzer supplier’s recommendations.

lyzer Systems

Also, it assumes that the analyzer is designed to monitor the

E456Terminology Relating to Quality and Statistics

specific material parameter of interest, and that at the time of

E1655 Practices for Infrared Multivariate Quantitative

initial or periodic validation, the analyzer was operating at the

Analysis

conditions specified by the manufacturer and consistently with

the primary test method.

3. Terminology

1.7 The units of measure used in this practice shall be the

3.1 Definitions:

same as those applicable to the test primary method used for

3.1.1 accuracy, n—closeness of agreement between a test

analyzer validation.

result and an accepted reference value.

1.8 This standard does not purport to address all of the

3.1.2 analyzer output, n—signal that is proportional to the

safety concerns, if any, associated with its use. It is the

quality parameter being measured and suitable for input to

responsibility of the user of this standard to establish appro-

readout instrumentation.

3.1.2.1 Discussion—It may be pneumatic, electrical, digital,

etc., and expressed as psi, mv, sec., etc.

1

This practice is under the jurisdiction ofASTM Committee D16 on Aromatic,

Industrial, Specialty and Related Chemicals and is the direct responsibility of

Subcommittee D16.09 on On-Line Analysis.

Current edition approved Nov. 1, 2021. Published December 2021. Originally

3

approved in 2000. Last previous edition approved in 2017 as D6621–00 (2017). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/D6621-21. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Standards volume information, refer to the standard’s Document Summary page on

this practice. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6621 − 21

3.1.3 analyzer result, n—numerical estimate of a physical, 3.1.15 validation o

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6621 − 00 (Reapproved 2017) D6621 − 21

Standard Practice for

Performance Testing of Process Analyzers for Aromatic

1

Hydrocarbon Materials

This standard is issued under the fixed designation D6621; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice serves as a practical guide for the performance testing of process stream analyzers specifically for measuring

chemical or physical characteristics of liquid aromatic hydrocarbon materials for production or certification of these materials. The

practice may be applicable to other hydrocarbon stream analyzers as well.

1.2 Only external methods (complete substitution of the process stream with a standard) of control sample introduction are

included. Internal methods are beyond the scope of this practice.

1.3 Methods for resetting key operational parameters of analyzers to match predefined limits are provided by vendors and are not

included in this practice.

1.4 Analyzer validation procedures are covered in Practices D3764 and D6122, not in this practice.

1.5 Procedures for statistically interpreting data from automatic sampling process stream analyzers are outlined.

2

1.6 The implementation of this practice requires that the analyzer be installed according to APIRP-550 (1), and be in agreement

with the analyzer supplier’s recommendations. Also, it assumes that the analyzer is designed to monitor the specific material

parameter of interest, and that at the time of initial or periodic validation, the analyzer was operating at the conditions specified

by the manufacturer and consistently with the primary test method.

1.7 The units of measure used in this practice shall be the same as those applicable to the test primary method used for analyzer

validation.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices, and determine the

applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This practice is under the jurisdiction of ASTM Committee D16 on Aromatic, Industrial, Specialty and Related Chemicals and is the direct responsibility of Subcommittee

D16.09 on On-Line Analysis.

Current edition approved July 1, 2017Nov. 1, 2021. Published July 2017December 2021. Originally approved in 2000. Last previous edition approved in 20122017 as

D6621 – 00 (2012).(2017). DOI: 10.1520/D6621-00R17.10.1520/D6621-21.

2

The boldface numbers in parentheses refer to the list of references at the end of this practice.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6621 − 21

2. Referenced Documents

3

2.1 ASTM Standards:

D3437 Practice for Sampling and Handling Liquid Cyclic Products

D3438 Practice for Sampling and Handling Naphthalene, Maleic Anhydride, and Phthalic Anhydride

D3764 Practice for Validation of the Performance of Process Stream Analyzer Systems

D4177D3852 Practice for Automatic Sampling of Petroleum and Petroleum Productsand Handling Phenol, Cresols, and Cresylic

Acid

D6122 Practice for Validation of the Performance of Multivariate Online, At-Line, Field and Laboratory Infrared

Spectrophotometer, and Raman Spectrometer Based Analyzer Systems

E456 Terminology Relating to Quality and Statistics

E1655 Practices for Infrared Multivariate Quantitative Analysis

3. Terminology

3.1 Definitions:

3.1.1 accuracy, n—closeness of agreement between a test result and an accepted reference value.

3.1.2 analyzer output, n—signal that is proportional to the quality parameter being measured and suitable for input to readout

instrumentation.

3.1.2.1 Discussion—

It may be pneumatic, electrical, digital, etc., and expressed as psi, mv, sec., etc.

3.1.3 analyzer result, n—numerical es

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.