ASTM B825-13

(Test Method)Standard Test Method for Coulometric Reduction of Surface Films on Metallic Test Samples (Withdrawn 2018)

Standard Test Method for Coulometric Reduction of Surface Films on Metallic Test Samples (Withdrawn 2018)

SIGNIFICANCE AND USE

4.1 The present trend in environmental testing of materials with electrically conductive surfaces is to produce, under accelerated laboratory conditions, corrosion and film-forming reactions that are similar to those that cause failures in service environments. In many of these procedures the parts under test are exposed for days or weeks to controlled quantities of both water vapor and pollutant gases, which may be present in extremely dilute concentrations.Note 2—Descriptions of such tests can be found in Practice B827.

4.2 Many of these environmental test methods require monitoring of the conditions within the chamber during the test in order to confirm that the intended environmentally related reactions are actually taking place. The most common type of monitor consists of copper, silver, or other thin metallic coupons of a few square centimeters that are placed within the test chamber and that react with the corrosive environment in much the same way as the significant surfaces of the parts under test.

4.3 In practice, a minimum number of control coupons are placed in each specified location (see Test Method B810) within the chamber for a specified exposure time, depending upon the severity of the test environment. At the end of this time interval, the metal samples are removed and analyzed by the coulometric reduction procedure.

4.4 Other corrosion film evaluation techniques for metallic coupons are also available. The most common of these is mass gain, which is nondestructive to the surface films, but is limited to the determination of the total amount of additional mass acquired by the metal as a result of the environmental attack. The most common is weighing using high performance microbalances or for purposes of real-time monitoring, quartz crystal microbalances (see Specification B808).Note 3—Detailed instructions for conducting such weighings, as well as coupon cleaning and surface preparation procedures, are included as part of Test Method B810...

SCOPE

1.1 This test method covers procedures and equipment for determining the relative buildup of corrosion and tarnish films (including oxides) on metal surfaces by the constant-current coulometric technique, also known as the cathodic reduction method.

1.2 This test method is designed primarily to determine the relative quantities of tarnish films on control coupons that result from gaseous environmental tests, particularly when the latter are used for testing components or systems containing electrical contacts used in customer product environments.

1.3 This test method may also be used to evaluate test samples that have been exposed to indoor industrial locations or other specific application environments. (See 4.6 for limitations.)

1.4 This test method has been demonstrated to be applicable particularly to copper and silver test samples (see (1)).2 Other metals require further study to prove their applicability within the scope of this test method.

1.5 The values stated in SI units are the preferred units. The values provided in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers procedures and equipment for determining the relative buildup of corrosion and tarnish films (including oxides) on metal surfaces by the constant-current coulometric technique, also known as the cathodic reduction method.

Formerly under the jurisdiction of Committee B02 on Nonferrous Metals and Alloys, this test method was withdrawn in Novem...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B825 −13

Standard Test Method for

Coulometric Reduction of Surface Films on Metallic Test

1

Samples

This standard is issued under the fixed designation B825; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

1.1 This test method covers procedures and equipment for 2.1 ASTM Standards:

determining the relative buildup of corrosion and tarnish films B808TestMethodforMonitoringofAtmosphericCorrosion

(including oxides) on metal surfaces by the constant-current Chambers by Quartz Crystal Microbalances

coulometric technique, also known as the cathodic reduction B809Test Method for Porosity in Metallic Coatings by

method. Humid Sulfur Vapor (“Flowers-of-Sulfur”)

B810TestMethodforCalibrationofAtmosphericCorrosion

1.2 This test method is designed primarily to determine the

Test Chambers by Change in Mass of Copper Coupons

relative quantities of tarnish films on control coupons that

B827Practice for Conducting Mixed Flowing Gas (MFG)

result from gaseous environmental tests, particularly when the

Environmental Tests

latter are used for testing components or systems containing

D1193Specification for Reagent Water

electrical contacts used in customer product environments.

3. Summary of Test Method

1.3 This test method may also be used to evaluate test

samples that have been exposed to indoor industrial locations

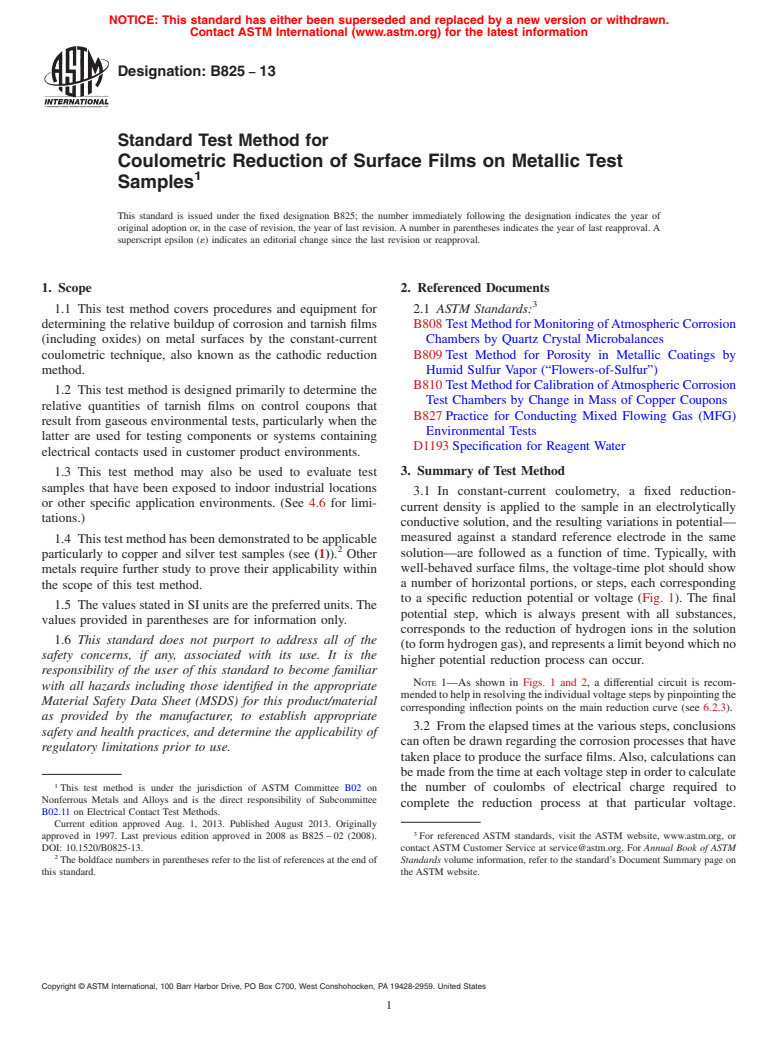

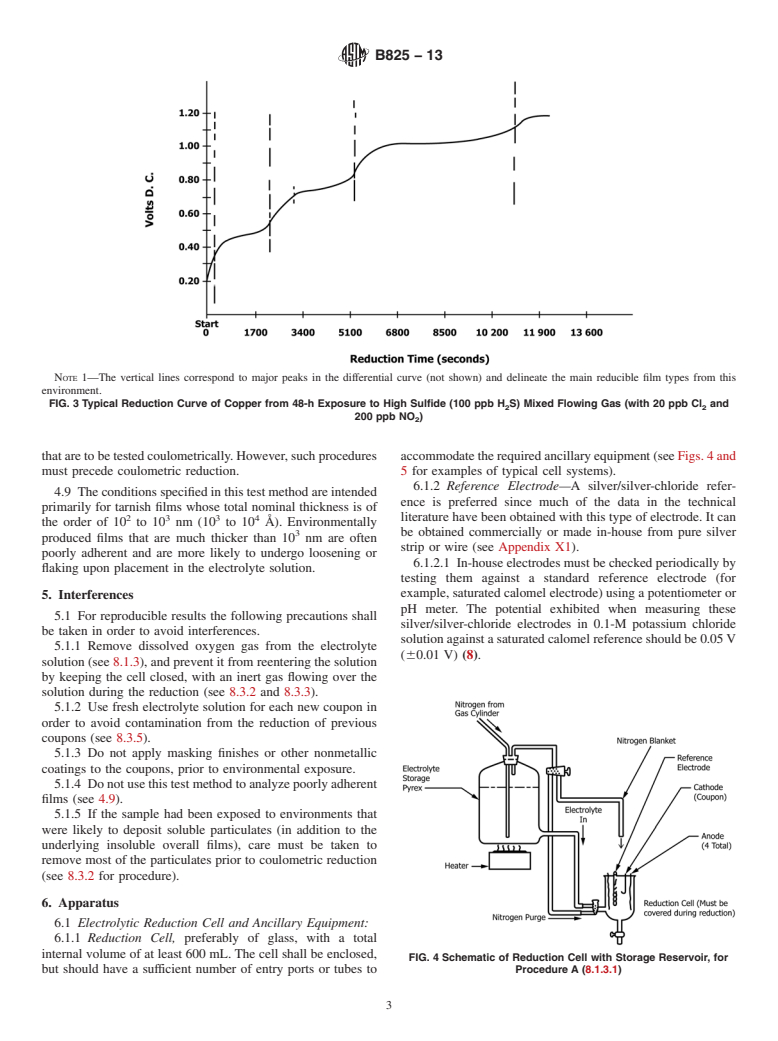

3.1 In constant-current coulometry, a fixed reduction-

or other specific application environments. (See 4.6 for limi-

current density is applied to the sample in an electrolytically

tations.)

conductive solution, and the resulting variations in potential—

measured against a standard reference electrode in the same

1.4 Thistestmethodhasbeendemonstratedtobeapplicable

2

solution—are followed as a function of time. Typically, with

particularly to copper and silver test samples (see (1)). Other

well-behaved surface films, the voltage-time plot should show

metals require further study to prove their applicability within

a number of horizontal portions, or steps, each corresponding

the scope of this test method.

to a specific reduction potential or voltage (Fig. 1). The final

1.5 ThevaluesstatedinSIunitsarethepreferredunits.The

potential step, which is always present with all substances,

values provided in parentheses are for information only.

corresponds to the reduction of hydrogen ions in the solution

1.6 This standard does not purport to address all of the

(toformhydrogengas),andrepresentsalimitbeyondwhichno

safety concerns, if any, associated with its use. It is the

higher potential reduction process can occur.

responsibility of the user of this standard to become familiar

NOTE 1—As shown in Figs. 1 and 2, a differential circuit is recom-

with all hazards including those identified in the appropriate

mendedtohelpinresolvingtheindividualvoltagestepsbypinpointingthe

Material Safety Data Sheet (MSDS) for this product/material

corresponding inflection points on the main reduction curve (see 6.2.3).

as provided by the manufacturer, to establish appropriate

3.2 Fromtheelapsedtimesatthevarioussteps,conclusions

safety and health practices, and determine the applicability of

canoftenbedrawnregardingthecorrosionprocessesthathave

regulatory limitations prior to use.

takenplacetoproducethesurfacefilms.Also,calculationscan

bemadefromthetimeateachvoltagestepinordertocalculate

1

This test method is under the jurisdiction of ASTM Committee B02 on the number of coulombs of electrical charge required to

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

complete the reduction process at that particular voltage.

B02.11 on Electrical Contact Test Methods.

Current edition approved Aug. 1, 2013. Published August 2013. Originally

3

approved in 1997. Last previous edition approved in 2008 as B825–02 (2008). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/B0825-13. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B825−13

4.2 Many of these environmental test methods require

monitoringoftheconditionswithinthechamberduringthetest

in order to confirm that the intended environmentally related

reactions are actually taking place. The most common type of

monitor consis

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B825 − 02 (Reapproved 2008) B825 − 13

Standard Test Method for

Coulometric Reduction of Surface Films on Metallic Test

1

Samples

This standard is issued under the fixed designation B825; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers procedures and equipment for determining the relative buildup of corrosion and tarnish films

(including oxides) on metal surfaces by the constant-current coulometric technique, also known as the cathodic reduction method.

1.2 This test method is designed primarily to determine the relative quantities of tarnish films on control coupons that result

from gaseous environmental tests, particularly when the latter are used for testing components or systems containing electrical

contacts.contacts used in customer product environments.

1.3 This test method may also be used to evaluate test samples that have been exposed to indoor industrial locations or other

specific application environments. (See 4.6 for limitations.)

2

1.4 This test method has been demonstrated to be applicable particularly to copper and silver test samples (see (1)). Other

metals require further study to prove their applicability within the scope of this test method.

1.5 The values stated in SI units are the preferred units. The values provided in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

B808 Test Method for Monitoring of Atmospheric Corrosion Chambers by Quartz Crystal Microbalances

B809 Test Method for Porosity in Metallic Coatings by Humid Sulfur Vapor (“Flowers-of-Sulfur”)

B810 Test Method for Calibration of Atmospheric Corrosion Test Chambers by Change in Mass of Copper Coupons

B827 Practice for Conducting Mixed Flowing Gas (MFG) Environmental Tests

D1193 Specification for Reagent Water

3. Summary of Test Method

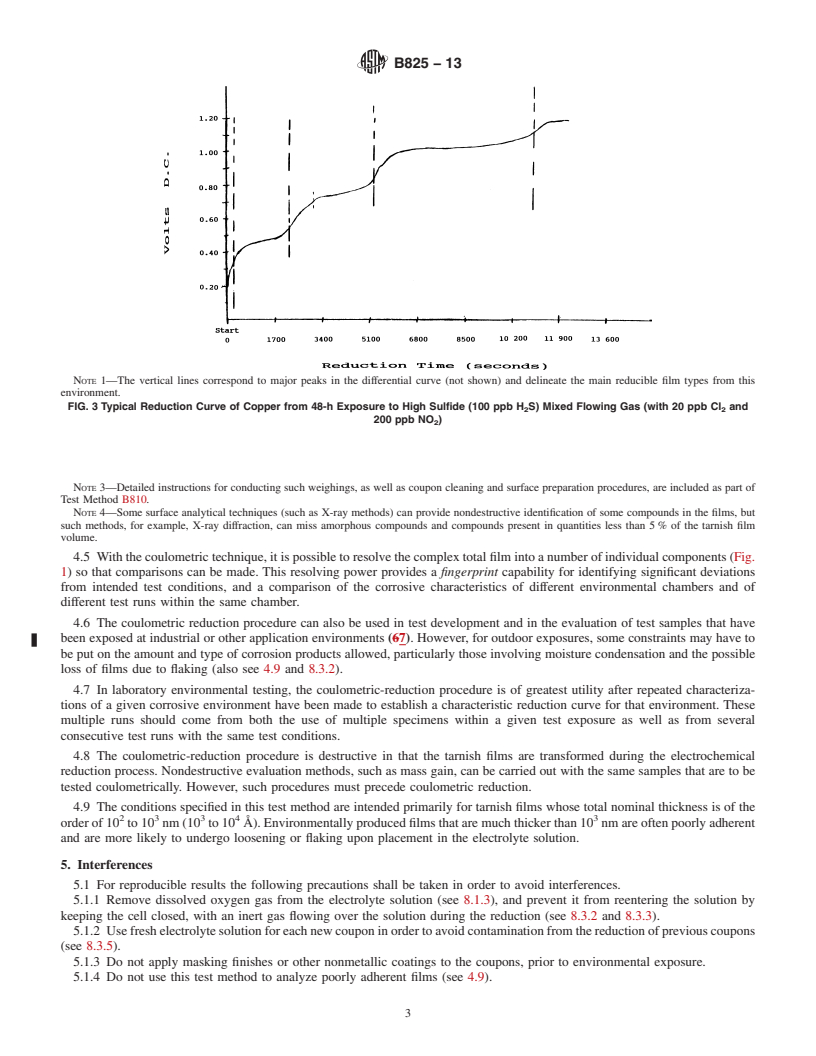

3.1 In constant-current coulometry, a fixed reduction-current density is applied to the sample in an electrolytically conductive

solution, and the resulting variations in potential—measured against a standard reference electrode in the same solution—are

followed as a function of time. Typically, with well-behaved surface films, the voltage-time plot should show a number of

horizontal portions, or steps, each corresponding to a specific reduction potential or voltage (Fig. 1). The final potential step, which

is always present with all substances, corresponds to the reduction of hydrogen ions in the solution (to form hydrogen gas), and

represents a limit beyond which no higher potential reduction process can occur.

NOTE 1—As shown in Figs. 1 and 2, a differential circuit is recommended to help in resolving the individual voltage steps by pinpointing the

corresponding inflection points on the main reduction curve (see 6.2.3).

1

This test method is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.11 on

Electrical Contact Test Methods.

Current edition approved March 1, 2008Aug. 1, 2013. Published March 2008August 2013. Originally approved in 1997. Last previous edition approved in 20022008 as

B825 - 02.B825 – 02 (2008). DOI: 10.1520/B0825-02R08.10.1520/B0825-13.

2

The boldface numbers in parentheses refer to the list of references at the end of this standard.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B825 − 13

FIG. 1 Ideal Reduction Behavior of Oxide and Sulfide Films on Copper (from Ref 1)

FIG. 2 Typical Reduction Behavior of Films on C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.