ASTM A596/A596M-95(2009)e1

(Test Method)Standard Test Method for Direct-Current Magnetic Properties of Materials Using the Ballistic Method and Ring Specimens

Standard Test Method for Direct-Current Magnetic Properties of Materials Using the Ballistic Method and Ring Specimens

SIGNIFICANCE AND USE

Test methods using suitable ring-type specimens are the preferred methods of determining the basic magnetic properties of a material caused by the absence of demagnetizing effects and are well suited for specification acceptance, service evaluation, and research and development.

Provided the test specimen is representative of the bulk material as is usually the case for thin strip and wire, this test is also suitable for design purposes.

When the test specimen is not necessarily representative of the bulk material such as a ring machined from a large forging or casting, the results of this test method may not be an accurate indicator of the magnetic properties of the bulk material. In such instances, the test results when viewed in context of past performance history will be useful for judging the suitability of the current material for the intended application.

SCOPE

1.1 This test method covers dc ballistic testing for the determination of basic magnetic properties of materials in the form of ring, toroidal, link, double-lapped Epstein cores, or other standard shapes which may be cut, stamped, machined, or ground from cast, compacted, sintered, forged, or rolled materials. It includes tests for normal induction and hysteresis taken under conditions of steep wavefront reversals of the direct-current magnetic field strength.

1.2 This test method shall be used in conjunction with Practice A34/A34M.

1.3 This test method is suitable for a testing range from very low magnetic field strength up to 200 or more Oe [15.9 or more kA/m]. The lower limit is determined by integrator sensitivity and the upper limit by heat generation in the magnetizing winding. Special techniques and short duration testing may extend the upper limit of magnetic field strength.

1.4 Testing under this test method is inherently more accurate than other methods. When specified dimensional or shape requirements are observed, the measurements are a good approximation to absolute properties. Test accuracy available is primarily limited by the accuracy of instrumentation. In most cases, equivalent results may be obtained using Test Method A773/A773M or the test methods of IEC Publication 60404-4.

1.5 This test method permits a choice of test specimen to permit measurement of properties in any desired direction relative to the direction of crystallographic orientation without interference from external yoke systems.

1.6 The symbols and abbreviated definitions used in this test method appear in Fig. 1 and Sections 5, 6, 9, and 10. For the official definitions see Terminology A340. Note that the term flux density used in this document is synonymous with the term magnetic induction.

1.7 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.8 The values stated in either customary (cgs-emu and inch-pound) units or SI units are to be regarded separately as standard. Within this test method, the SI units are shown in brackets except for the sections concerning calculations where there are separate sections for the respective unit systems. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this method.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the ...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: A596/A596M − 95(Reapproved 2009)

Standard Test Method for

Direct-Current Magnetic Properties of Materials Using the

Ballistic Method and Ring Specimens

This standard is issued under the fixed designationA596/A596M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Updated IEC information editorially in November 2009.

1. Scope 1.7 Warning—Mercury has been designated by EPA and

many state agencies as a hazardous material that can cause

1.1 This test method covers dc ballistic testing for the

central nervous system, kidney, and liver damage. Mercury, or

determination of basic magnetic properties of materials in the

its vapor, may be hazardous to health and corrosive to

form of ring, toroidal, link, double-lapped Epstein cores, or

materials.Cautionshouldbetakenwhenhandlingmercuryand

other standard shapes which may be cut, stamped, machined,

mercury-containing products. See the applicable product Ma-

or ground from cast, compacted, sintered, forged, or rolled

terial Safety Data Sheet (MSDS) for details and EPA’s website

materials. It includes tests for normal induction and hysteresis

(http://www.epa.gov/mercury/faq.htm)foradditionalinforma-

taken under conditions of steep wavefront reversals of the

tion. Users should be aware that selling mercury or mercury-

direct-current magnetic field strength.

containingproducts,orboth,inyourstatemaybeprohibitedby

1.2 This test method shall be used in conjunction with

state law.

Practice A34/A34M.

1.8 The values stated in either customary (cgs-emu and

1.3 Thistestmethodissuitableforatestingrangefromvery

inch-pound) units or SI units are to be regarded separately as

lowmagneticfieldstrengthupto200ormoreOe[15.9ormore

standard. Within this test method, the SI units are shown in

kA/m]. The lower limit is determined by integrator sensitivity

brackets except for the sections concerning calculations where

and the upper limit by heat generation in the magnetizing

there are separate sections for the respective unit systems. The

winding. Special techniques and short duration testing may

values stated in each system are not exact equivalents;

extend the upper limit of magnetic field strength.

therefore,eachsystemshallbeusedindependentlyoftheother.

1.4 Testing under this test method is inherently more accu- Combiningvaluesfromthetwosystemsmayresultinnoncon-

rate than other methods. When specified dimensional or shape formance with this method.

requirements are observed, the measurements are a good

1.9 This standard does not purport to address all of the

approximationtoabsoluteproperties.Testaccuracyavailableis

safety concerns, if any, associated with its use. It is the

primarily limited by the accuracy of instrumentation. In most

responsibility of the user of this standard to establish appro-

cases, equivalent results may be obtained using Test Method

priate safety and health practices and determine the applica-

A773/A773M or the test methods of IEC Publication 60404-4.

bility of regulatory limitations prior to use.

1.5 This test method permits a choice of test specimen to

2. Referenced Documents

permit measurement of properties in any desired direction

relative to the direction of crystallographic orientation without

2.1 ASTM Standards:

interference from external yoke systems.

A34/A34MPractice for Sampling and Procurement Testing

of Magnetic Materials

1.6 Thesymbolsandabbreviateddefinitionsusedinthistest

A340Terminology of Symbols and Definitions Relating to

method appear in Fig. 1 and Sections 5, 6, 9, and 10. For the

Magnetic Testing

official definitions see Terminology A340. Note that the term

A341/A341MTest Method for Direct Current Magnetic

fluxdensityusedinthisdocumentissynonymouswiththeterm

Properties of Materials Using D-C Permeameters and the

magnetic induction.

Ballistic Test Methods

This test method is under the jurisdiction of ASTM Committee A06 on

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2009. Published January 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1969. Last previous edition approved in 2004 as A596/ Standards volume information, refer to the standard’s Document Summary page on

´1

A596M–95(2004) . DOI: 10.1520/A0596_A0596M-95R09E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A596/A596M − 95 (2009)

context of past performance history will be useful for judging

the suitability of the current material for the intended applica-

tion.

4. Interferences

4.1 This test method has several important requirements.

Unless adequate inside diameter to outside diameter ratios are

maintained in the test specimens, the magnetic field strength

will be excessively nonuniform throughout the test specimen

andthemeasuredparameterscannotberepresentedasmaterial

properties.

4.2 The basic quality of materials having directionally

sensitivepropertiescannotbetestedsatisfactorilywithringsor

laminations. With them it is necessary to use Epstein speci-

mens cut with their lengths in the direction of specific interest

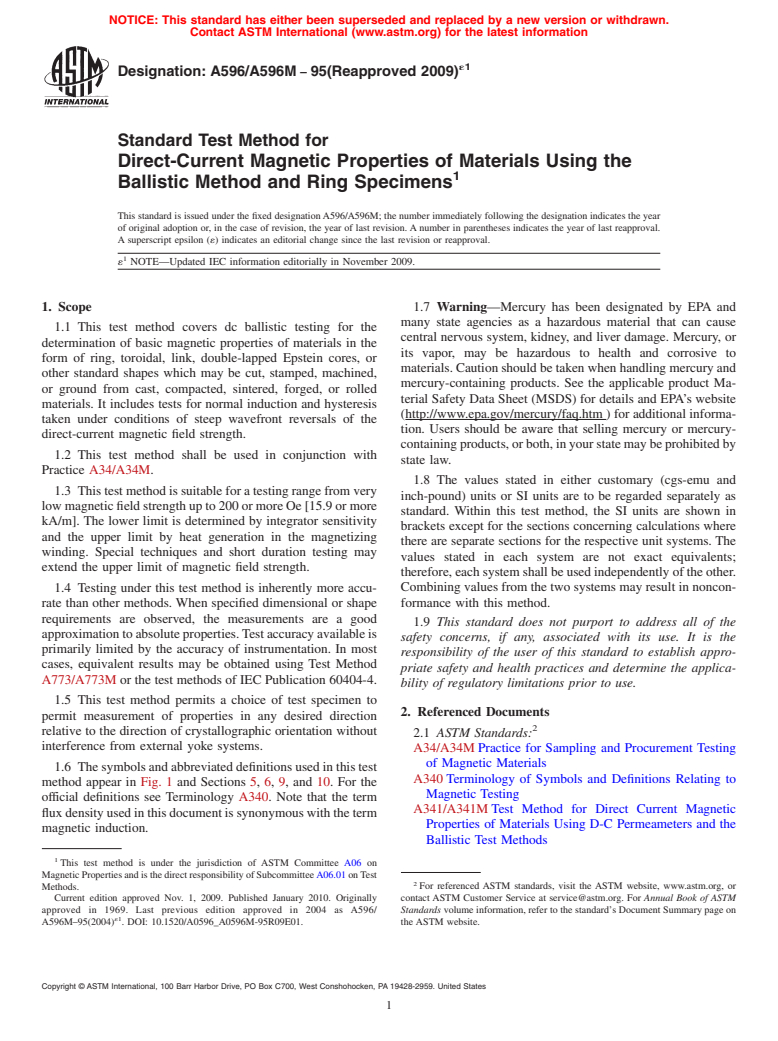

NOTE 1—

or to use long link-shaped or spirally wound toroidal core test

A —Multirange ammeter, main-magnetizing current circuit

specimens whose long dimensions are similarly located. The

A —Multirange ammeter, hysteresis-current circuit

acceptableminimumwidthofstripusedinsuchtestspecimens

N —Magnetizing (primary) winding

is also sensitive to the material under test. At present, it is

N —Flux-sensing (secondary) winding

F—Electronic integrator believed that the grain-oriented silicon steels should have a

R —Main current control rheostat

1 strip width of at least 3 cm [30 mm].

R —Hysteresis current control rheostat

4.3 Unlessringspecimensarelargeindiameter,itisdifficult

S —Reversing switch

S —Shunting switch for hysteresis current control rheostat toprovideasufficientnumberofprimaryturnsneededtoreach

FIG. 1 Basic Circuit Using Ring-Type Cores

the highest magnetic field strength. In general, magnetic

materials tend to have nonuniform properties throughout the

body of the test specimen; for this reason, uniformly distrib-

A343/A343MTest Method for Alternating-Current Mag-

uted test windings and uniform specimen cross-sectional area

netic Properties of Materials at Power Frequencies Using

are highly desirable to suppress nonuniform behavior to a

Wattmeter-Ammeter-Voltmeter Method and 25-cm Ep-

tolerable degree.

stein Test Frame

A773/A773MTest Method for dc Magnetic Properties of

5. Apparatus

Materials Using Ring and Permeameter Procedures with

dc Electronic Hysteresigraphs

5.1 The apparatus shall consist of as many of the compo-

2.2 IEC Standard:

nents described in 5.2-5.10 as are required to perform the

Publication 60404-4Ed. 2.2, Magnetic Materials—Part 4:

desired test. The basic circuit is shown in Fig. 1.

Methods of Measurement of the D-C Magnetic Properties

5.2 Balance and Scales:

of Magnetically Soft Materials, IEC, 2008

5.2.1 The balance used to weigh the test specimen shall be

capable of weighing to an accuracy of better than 0.1%.

3. Significance and Use

5.2.2 The micrometer, caliper, or other length-measuring

3.1 Test methods using suitable ring-type specimens are

device used in the determination of magnetic path length and

the preferred methods of determining the basic magnetic

cross-sectional area shall be capable of measuring to an

properties of a material caused by the absence of demagnetiz-

accuracy of better than 0.1%.

ing effects and are well suited for specification acceptance,

5.3 dc Power Supply—The preferred source of dc current is

service evaluation, and research and development.

a high quality linear power supply of either unipolar or bipolar

3.2 Provided the test specimen is representative of the bulk

operation. The power supply must exhibit high stability and

material as is usually the case for thin strip and wire, this test

very low ripple to achieve the most accurate results. Program-

is also suitable for design purposes.

mable bipolar operational amplifier power supplies have

3.3 Whenthetestspecimenisnotnecessarilyrepresentative

proven to be very satisfactory for this type of testing. Other

of the bulk material such as a ring machined from a large

stable sources of dc current such as storage batteries are

forgingorcasting,theresultsofthistestmethodmaynotbean

permitted.

accurate indicator of the magnetic properties of the bulk

5.4 Main-Current-Control Rheostat R —When nonpro-

material. In such instances, the test results when viewed in

grammable sources of dc current such as storage batteries are

used, rheostats must be used to control the current. These

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

rheostatsmusthavesufficientpowerratingandheat-dissipating

4th Floor, New York, NY 10036.

capabilitytohandlethelargesttestcurrentwithoutundesirable

Lloyd, M. G., “Errors in Magnetic Testing with Ring Specimens,’’ Technical

changes in resistance and, therefore, magnetizing current

News Bulletin, National Institute for Standards andTechnology,Vol 5, 1909, p. 435

(S108). during conduct of the test.

´1

A596/A596M − 95 (2009)

5.5 Hysteresis-Current-Control Rheostat R —The 6. Test Specimen

hysteresis-current-control rheostat, when required, must have

6.1 When the test specimen represents a test lot of material,

the same power rating and resistance as the main-current-

its selection shall conform to the requirements of Practice

control rheostat.

A34/A34M or of an individual specification.

5.6 Main-Current Ammeter A —Measurement of the mag- 6.2 To qualify as a test specimen suitable for evaluation of

netizing current can be accomplished with either a dc ammeter material properties the effective ratio of mean diameter to

radialwidthshallbenotlessthan10to1(oraninsidediameter

oracombinationofaprecisionshuntresistoranddcvoltmeter.

to outside diameter ratio not less than 0.82). When the test

The meters and shunt resistor, if used, must have an accuracy

specimen has smaller ratios than the above requirements, the

of at least 0.25%. To improve test accuracy multirange digital

testresultsshouldnotberepresentedasmaterialpropertiesbut

ammeters or voltmeters are preferred. Autoranging capability

should be called core properties because of nonuniform flux

is desirable for convenience but is not essential for this test

distribution.

method.Ifanalogmetersareused,therangesmustbesuchthat

all test readings are made in the upper two thirds of the scale. 6.3 When link, oval-shaped, or rectangular test specimen

forms are used, the requirements of 6.2 apply to the end or

5.7 Hysteresis-CurrentAmmeter,A —Thehysteresis-current

corner sections where flux crowding occurs. When straight-

measuring system shall conform to the requirements in 5.6.In

sided test specimens are very long relative to the length of the

general, a separate measuring system is not required since the

corner or end sections, they are suitable for basic material

main current ammeter ( A ) can also be used to measure the

properties evaluation with relatively unoriented materials pro-

hysteresis current.

vided the uncertainty in determination of true-path (effective)

length is less than 5% of the total path length. When this

5.8 Reversing Switch, S —Because of the low resistance

uncertainty in path length (shortest or longest relative to the

nature of the magnetizing circuit, it is imperative that high

mean-path length) exceeds 5%, the test values should be

quality switches be used. Changes in switch resistance upon

reported as core properties and not basic material properties.

reversal will cause deviation from the cyclically magnetized

6.4 The test specimen may be constructed of solid, lami-

condition which, if excessive, will impair test accuracy and

nated, or strip materials and in any of the shapes described in

precision. Experience has shown that mercury switches are the

1.1.

best suited for this application. Knife blade switches or

mechanical or electrically operated contractors can also be

6.5 Test specimen cores made from strip may be laminated,

used provided the requirement for uniform and equal contact machined, spirally wound, or Epstein specimens (the method

resistance can be maintained. Because of the presence of

of selection for Epstein specimens is described inTest Method

leakagecurrentsintheopencondition,solidstaterelaysarenot A343/A343M, Annex A3). When the material is to be tested

permitted. The difficulties inherent in the use of main current half transverse and half longitudinal, the material shall be cut

into Epstein strips or square laminations of adequate dimen-

reversing switches can be minimized by use of linear power

sional ratio.

supplies capable of accepting a remote programming signal.

Such power supplies are permitted provided that the magne-

6.6 Test specimens used for basic material evaluation shall

tizingcurrentisequal(towithin0.1%)ineitherpolaritywhen

be cut, machined, ground, slit, or otherwise formed to have a

normal induction testing is conducted, current reversals can be

cross section that remains sufficiently uniform that its nonuni-

conductedwithnoovershootoroscillationandthemagnetizing formity will not materially affect the accuracy of establishing

current is truly zero for the zero current programming signal. andmeasuringfluxdensity, B,ormagneticfieldstrength, H,in

the test specimen.

5.9 Hysteresis Switch, S (When Required)—This switch

6.7 When required for material properties development, the

should conform to requirements in 5.8.

test specimen shall have received a stress relief or other heat

5.10 Integrator, F—Because of their superior accuracy,

treatment after preparation. This heat treatment is subject to

stability, and ease of operation, electronic charge integrators

agreementbetweenmanufacturerandpurchaser,manufacturers

are the preferred means of measuring magnetic flux. Integra-

recommendation,ortherecommendedheattreatmentprovided

tors using either operational amplifier and capacitor feedback by the appropriate ASTM standard for the material. The heat

(analog integrator) or pulse counting are permitted. The accu- treatment used shall be reported with the magnetic test results.

racy of the integrator must be better than 1% full scale. If

7. Calibration of Integrator

analog display meters are use

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.