ASTM D6376-10(2017)e1

(Test Method)Standard Test Method for Determination of Trace Metals in Petroleum Coke by Wavelength Dispersive X-ray Fluorescence Spectroscopy

Standard Test Method for Determination of Trace Metals in Petroleum Coke by Wavelength Dispersive X-ray Fluorescence Spectroscopy

SIGNIFICANCE AND USE

5.1 The presence and concentration of sulfur and various metallic elements in a petroleum coke are major factors determining the suitability of a coke for various purposes. This test method provides rapid means for measuring sulfur and commercially important metallic elements in coke samples.

5.2 This test method provides a guide for determining conformance to material specifications for use by buyers and sellers in a commercial transfer of petroleum coke.

5.3 Sulfur contents can be used to evaluate the potential formation of sulfur oxides (SOx), a source of atmospheric pollution.

SCOPE

1.1 This test method covers the X-ray fluorescence spectrometric determination of total sulfur and trace metals in samples of raw or calcined petroleum coke. Elements determined using this test method are listed in Table 1.

1.2 Detection limits, sensitivity, and optimal element ranges will vary with matrices, spectrometer type, analyzing crystal, and other instrument conditions and parameters.

1.3 All analytes are determined as the element and reported as such. These include all elements listed in Table 1. This test method may be applicable to additional elements or concentration ranges if sufficient standards are available to produce proper calibration equations.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D6376 − 10 (Reapproved 2017)

Standard Test Method for

Determination of Trace Metals in Petroleum Coke by

Wavelength Dispersive X-ray Fluorescence Spectroscopy

This standard is issued under the fixed designation D6376; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units formatting was corrected editorially in February 2017.

1. Scope D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.1 This test method covers the X-ray fluorescence spectro-

D5056 Test Method for Trace Metals in Petroleum Coke by

metricdeterminationoftotalsulfurandtracemetalsinsamples

Atomic Absorption

of raw or calcined petroleum coke. Elements determined using

D5600 Test Method for Trace Metals in Petroleum Coke by

this test method are listed in Table 1.

Inductively Coupled Plasma Atomic Emission Spectrom-

1.2 Detection limits, sensitivity, and optimal element ranges

etry (ICP-AES)

will vary with matrices, spectrometer type, analyzing crystal,

D6969 Practice for Preparation of Calcined Petroleum Coke

and other instrument conditions and parameters.

Samples for Analysis

1.3 All analytes are determined as the element and reported

D6970 Practice for Collection of Calcined Petroleum Coke

as such. These include all elements listed in Table 1. This test

Samples for Analysis

method may be applicable to additional elements or concen-

E11 Specification for Woven Wire Test Sieve Cloth and Test

tration ranges if sufficient standards are available to produce

Sieves

proper calibration equations.

3. Terminology

1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3.1 Definitions:

standard.

3.1.1 calcined petroleum coke, n—petroleum coke that has

1.5 This standard does not purport to address all of the

been thermally treated to drive off the volatile matter and to

safety concerns, if any, associated with its use. It is the

develop crystalline structure.

responsibility of the user of this standard to establish appro-

3.1.2 green petroleum coke, n—same as raw petroleum

priate safety and health practices and determine the applica-

coke.

bility of regulatory limitations prior to use.

3.1.3 petroleum coke, n—a solid, carbonaceous residue

2. Referenced Documents

produced by thermal decomposition of heavy petroleum frac-

tions or cracked stocks, or both

2.1 ASTM Standards:

D346 Practice for Collection and Preparation of Coke

3.1.4 raw petroleum coke, n—petroleum coke that has not

Samples for Laboratory Analysis

been calcined.

D1552 Test Method for Sulfur in Petroleum Products by

3.2 Definitions of Terms Specific to This Standard:

High Temperature Combustion and Infrared (IR) Detec-

3.2.1 alpha, n—correction factor used to compensate for

tion or Thermal Conductivity Detection (TCD)

interferences.

3.2.2 analytical sample, n—a representative fraction taken

This test method is under the jurisdiction of ASTM Committee D02 on

from a larger mass of petroleum coke and reduced by grinding

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

to pass a 75 µm (U.S. No. 200 mesh) sieve.

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial.

Current edition approved Jan. 1, 2017. Published February 2017. Originally

3.2.3 pellet, n—a blend of dried sample and binder milled

approved in 1999. Last previous edition approved in 2010 as D6376 – 10. DOI:

together and then formed into a pellet by pressure.

10.1520/D6376-10R17E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.4 reference samples, n—samples of known concentra-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tions to be used in the calibration of the X-ray fluorescence

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. spectrometer.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6376 − 10 (2017)

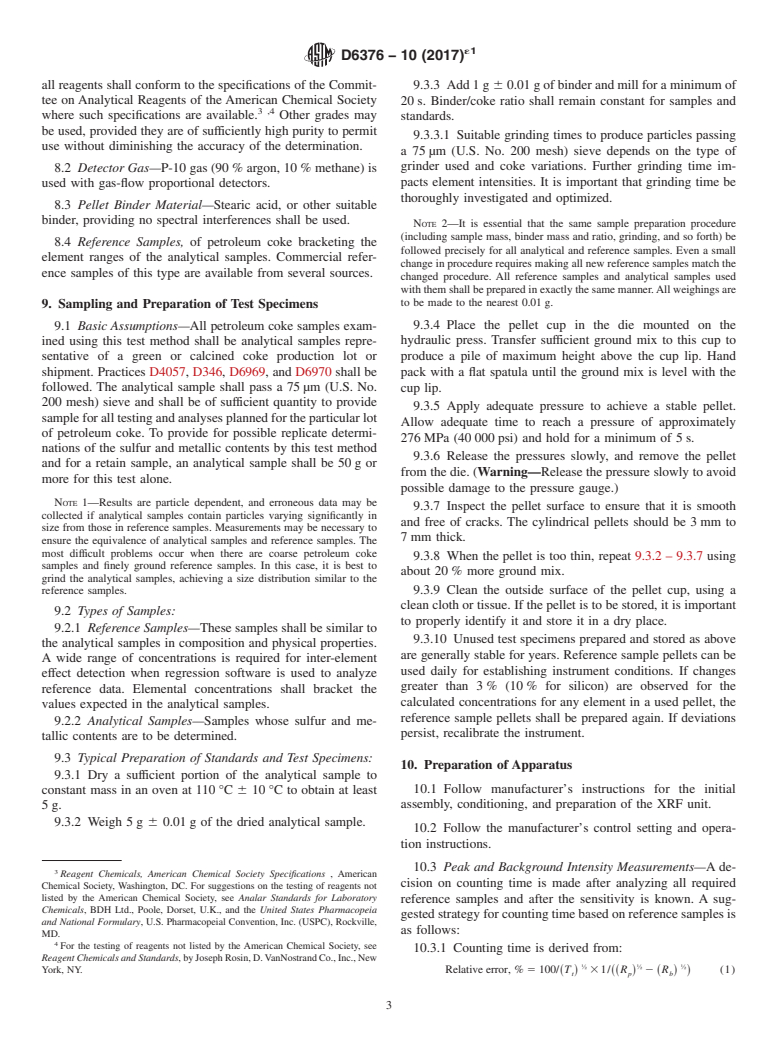

TABLE 1 Applicable Concentration Ranges TABLE 2 Suitable Instrument Operating Conditions

Element Concentration Range, (mg/kg) 2Θ Angle, Background, Analyzing

Element

A A A

Degrees Degrees Crystal

Na 50–500

Al 50–500 Sodium 25.05 26.75, 24.35 Multilayer, 2d ;50Å

Si 20–500 Aluminum 145.13 143.13 PET

S, % 0.10–7.0 Silicon 144.95 147.05, 142.85 InSb

Ca 20–500 Sulfur 110.68 113.18 Ge

Ti 10–200 Calcium 113.08 116.00 LiF (200)

V 20–2000 Titanium 86.13 84.13 LiF (200)

Mn 10–200 Vanadium 76.93 78.93 LiF (200)

Fe 20–1000 Manganese 62.97 60.97 LiF (200)

Ni 20–500 Iron 57.52 59.02 LiF (200)

Nickel 48.66 49.92, 47.40 LiF (200)

A

The wavelength angles and analyzing crystals listed are suitable due to their

sensitivityandgeneralindustryacceptance.Thesechoicesaremadebasedonthe

4. Summary of Test Method

elementtobedetermined.Otherinstrumentoperatingconditionscanbeused,but

an attempt should always be made to use only those conditions yielding optimal

4.1 A representative sample of petroleum coke is dried to

sensitivity with minimum interferences. The instrument manufacturer should be

constant mass at 110 °C 6 10 °C and then crushed to pass a

consulted for recommendations on optimal targets, crystal options, and any

75 µm (U.S. No. 200 mesh) sieve. A weighed portion of this

concentration limit restrictions on your unit.

analytical sample is mixed with stearic acid, or other suitable

binder, and then milled and compressed into a small, smooth

pellet suitable for analysis. The pellet is irradiated by an X-ray

beam. The characteristic X rays of the elements analyzed are

7.2 Hydraulic Press, capable of exerting a force of not less

excited, separated, and detected by the wavelength-dispersive

than 276 MPa (40 000 psi).

X-ray spectrometer. These measured X-ray intensities are

7.3 Mill or Grinder, capable of reducing 20 g of petroleum

converted to elemental concentration through the use of a

coke to a sample passing 75 µm (U.S. No. 200 mesh) in less

calibration equation derived from analyses of standard materi-

than 10 min, without introducing contamination.

als. This calibration equation defines the sensitivity and back-

7.4 Mixer/Mill, for blending sample and binder.

ground associated with a particular X-ray spectrometer.

7.5 Pellet Cup, Aluminum (optional), tapered to hold

4.2 The K-alpha spectral lines are used for all of the

pressed pellets.

elements determined by this test method.

7.6 Pelletizing Die, for forming pellets of a diameter suit-

5. Significance and Use

able for use in the spectrometer.

5.1 The presence and concentration of sulfur and various

7.7 Sieves, 75 µm (U.S. No. 200 mesh) as specified in

metallic elements in a petroleum coke are major factors

Specification E11.

determining the suitability of a coke for various purposes.This

7.8 Drying Oven, capable of maintaining a minimum tem-

test method provides rapid means for measuring sulfur and

perature of 110 °C 6 10 °C.

commercially important metallic elements in coke samples.

7.9 X-ray Spectrometer,equippedforsoftX-raydetectionof

5.2 This test method provides a guide for determining

the K-alpha spectral lines for all of the elements determined by

conformance to material specifications for use by buyers and

this test method. For increased sensitivity, this instrument shall

sellers in a commercial transfer of petroleum coke.

be equipped with the following:

5.3 Sulfur contents can be used to evaluate the potential

7.9.1 Analyzing Crystals—This choice is made based on the

formation of sulfur oxides (SO ), a source of atmospheric

x

element to be determined. The crystal selected should yield

pollution.

optimal sensitivity with minimum interferences. The same

crystal shall be used for both standards and unknowns. See

6. Interferences

Table 2 for recommended crystals.

6.1 Review all potential spectral interferences for the ele-

7.9.2 Detector, suitable for the determination of elements in

ments listed in Table 2. Follow your manufacturer’s operating

question. Choices include gas-flow proportional, sealed

guide to develop and apply alphas to compensate for these

proportional, and scintillation detectors.

interferences.

7.9.3 Optical Path, in a vacuum.

6.2 Compensate for inter-element effects by using alphas as

7.9.4 Pulse-Height Analyzer, or other means of energy

part of the regression procedure provided with spectrometer

discrimination.

software.

7.9.5 Suitable X-ray Tube—Chromium, molybdenum,

platinum, rhodium, or tungsten target and dual targets have

6.3 Changesinthesulfurconcentrationinthesampleaffects

been found suitable. The scandium tube is very advantageous

analyte X-ray intensities. Therefore, determine the magnitude

for light elements.

of the sulfur effect on each metallic element and apply in

appropriate correction.

8. Reagents and Materials

7. Apparatus

8.1 Purity of Reagents—Reagent grade chemicals shall be

7.1 Balance, capable of weighing 50 g 6 0.01 g. used in all tests. Unless otherwise indicated, it is intended that

´1

D6376 − 10 (2017)

all reagents shall conform to the specifications of the Commit- 9.3.3 Add 1 g 6 0.01 g of binder and mill for a minimum of

tee on Analytical Reagents of the American Chemical Society 20 s. Binder/coke ratio shall remain constant for samples and

3,4

where such specifications are available. Other grades may

standards.

be used, provided they are of sufficiently high purity to permit

9.3.3.1 Suitable grinding times to produce particles passing

use without diminishing the accuracy of the determination.

a 75 µm (U.S. No. 200 mesh) sieve depends on the type of

grinder used and coke variations. Further grinding time im-

8.2 Detector Gas—P-10 gas (90 % argon, 10 % methane) is

used with gas-flow proportional detectors. pacts element intensities. It is important that grinding time be

thoroughly investigated and optimized.

8.3 Pellet Binder Material—Stearic acid, or other suitable

binder, providing no spectral interferences shall be used.

NOTE 2—It is essential that the same sample preparation procedure

(including sample mass, binder mass and ratio, grinding, and so forth) be

8.4 Reference Samples, of petroleum coke bracketing the

followed precisely for all analytical and reference samples. Even a small

element ranges of the analytical samples. Commercial refer-

change in procedure requires making all new reference samples match the

ence samples of this type are available from s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.