ASTM D5056-04(2010)

(Test Method)Standard Test Method for Trace Metals in Petroleum Coke by Atomic Absorption

Standard Test Method for Trace Metals in Petroleum Coke by Atomic Absorption

SIGNIFICANCE AND USE

The presence and concentration of various metallic elements in a petroleum coke are major factors in the suitability of the coke for various uses. This test method provides a means of measuring the amounts of those metallic elements in the coke sample.

The test method provides a standard procedure for use by the purchaser and seller in the commercial transfer of petroleum coke to determine whether the lot of coke meets the specifications of the purchasing party.

SCOPE

1.1 This test method covers the analysis for the commonly determined trace metals (aluminum, calcium, iron, nickel, silicon, sodium, and vanadium) in laboratory analysis samples of raw and calcined petroleum coke by atomic absorption spectroscopy.

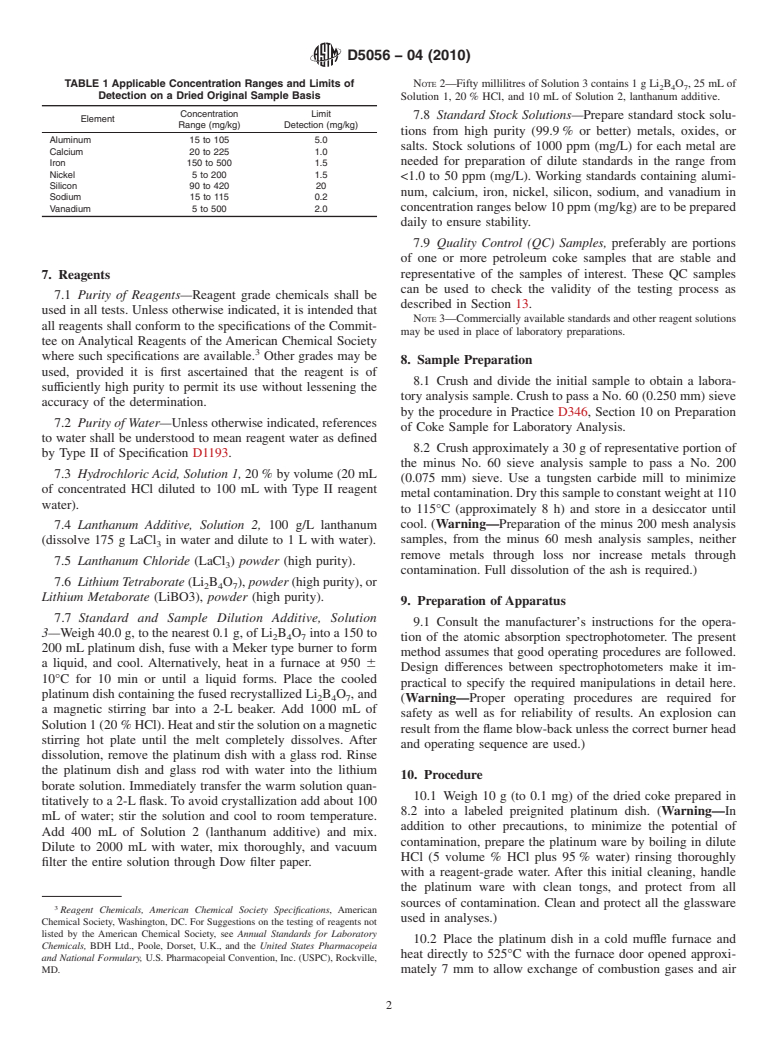

1.2 The elemental concentration ranges for which this test method is applicable and the limits of detection of this test method are listed in Table 1.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5056 − 04(Reapproved 2010)

Standard Test Method for

Trace Metals in Petroleum Coke by Atomic Absorption

This standard is issued under the fixed designation D5056; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope copy for the following elements: aluminum, calcium, iron,

nickel, silicon, sodium, and vanadium.

1.1 This test method covers the analysis for the commonly

determined trace metals (aluminum, calcium, iron, nickel,

4. Significance and Use

silicon, sodium, and vanadium) in laboratory analysis samples

4.1 The presence and concentration of various metallic

of raw and calcined petroleum coke by atomic absorption

elementsinapetroleumcokearemajorfactorsinthesuitability

spectroscopy.

ofthecokeforvarioususes.Thistestmethodprovidesameans

1.2 The elemental concentration ranges for which this test

of measuring the amounts of those metallic elements in the

method is applicable and the limits of detection of this test

coke sample.

method are listed in Table 1.

4.2 The test method provides a standard procedure for use

1.3 The values stated in SI units are to be regarded as the

by the purchaser and seller in the commercial transfer of

standard.

petroleum coke to determine whether the lot of coke meets the

1.4 This standard does not purport to address all of the

specifications of the purchasing party.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 5. Interferences

priate safety and health practices and determine the applica-

5.1 Spectral interferences can occur when using other than

bility of regulatory limitations prior to use. For warning

the recommended wavelength for analysis or when using

statements, see Sections 8-10.

multi-elemental hollow cathode lamps.

2. Referenced Documents

6. Apparatus

2.1 ASTM Standards:

6.1 Furnace, electric, capable of regulation of temperature

D346 Practice for Collection and Preparation of Coke

at 525°C 6 10°C.

Samples for Laboratory Analysis

6.2 Magnetic Stirring Hot Plate.

D6299 Practice for Applying Statistical Quality Assurance

and Control Charting Techniques to Evaluate Analytical 6.3 Platinum Dish, 50 to 58-mL capacity.

Measurement System Performance

6.4 Platinum Dish, 150 to 200-mL capacity.

D1193 Specification for Reagent Water

6.5 Platinum-Tipped Tongs.

3. Summary of Test Method

6.6 Furnace, electric, capable of regulation of temperature

at 950 6 10°C or a Meker type forced air burner.

3.1 A representative sample of the petroleum coke is ashed

at 525°C under specified conditions. The ash is fused with

6.7 Atomic Absorption Spectrophotometer (AAS), equipped

lithium tetraborate (Li B O ), or lithium metaborate (LiBO ).

2 4 7 3

as follows:

Themeltisdissolvedindilutehydrochloricacid(HCl),andthe

6.7.1 Background Correction, using either a deuterium (D )

resultant solution is analyzed by atomic absorption spectros-

arc background corrector or other comparable simultaneous

background correction system.

6.7.2 Burner Head, capable of supporting a nitrous oxide-

This test method is under the jurisdiction of ASTM Committee D02 on

acetylene flame.

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

6.7.3 Burner Head, single or multiple-slot, capable of sup-

Current edition approved May 1, 2010. Published May 2010. Originally

porting an air-acetylene flame.

approved in 1990. Last previous edition approved in 2004 as D5056–04. DOI:

6.7.4 Hollow Cathode Lamps, one for each of the elements

10.1520/D5056-04R10.

to be analyzed: aluminum, calcium, iron, nickel, silicon,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sodium, and vanadium.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. NOTE 1—Multi-elemental lamps can also be used; however, spectral

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5056 − 04(Reapproved 2010)

interferences are possible (see 5.1).

D5056 − 04 (2010)

TABLE 1 Applicable Concentration Ranges and Limits of NOTE 2—Fifty millilitres of Solution 3 contains1gLi B O ,25mLof

2 4 7

Detection on a Dried Original Sample Basis

Solution 1, 20 % HCl, and 10 mL of Solution 2, lanthanum additive.

Concentration Limit

7.8 Standard Stock Solutions—Prepare standard stock solu-

Element

Range (mg/kg) Detection (mg/kg)

tions from high purity (99.9 % or better) metals, oxides, or

Aluminum 15 to 105 5.0

salts. Stock solutions of 1000 ppm (mg/L) for each metal are

Calcium 20 to 225 1.0

Iron 150 to 500 1.5 needed for preparation of dilute standards in the range from

Nickel 5 to 200 1.5

<1.0 to 50 ppm (mg/L). Working standards containing alumi-

Silicon 90 to 420 20

num, calcium, iron, nickel, silicon, sodium, and vanadium in

Sodium 15 to 115 0.2

concentration ranges below 10 ppm (mg/kg) are to be prepared

Vanadium 5 to 500 2.0

daily to ensure stability.

7.9 Quality Control (QC) Samples, preferably are portions

of one or more petroleum coke samples that are stable and

representative of the samples of interest. These QC samples

7. Reagents

can be used to check the validity of the testing process as

7.1 Purity of Reagents—Reagent grade chemicals shall be

described in Section 13.

used in all tests. Unless otherwise indicated, it is intended that

NOTE 3—Commercially available standards and other reagent solutions

all reagents shall conform to the specifications of the Commit-

may be used in place of laboratory preparations.

tee on Analytical Reagents of the American Chemical Society

where such specifications are available. Other grades may be

8. Sample Preparation

used, provided it is first ascertained that the reagent is of

8.1 Crush and divide the initial sample to obtain a labora-

sufficiently high purity to permit its use without lessening the

tory analysis sample. Crush to pass a No. 60 (0.250 mm) sieve

accuracy of the determination.

by the procedure in Practice D346, Section 10 on Preparation

7.2 Purity of Water—Unless otherwise indicated, references

of Coke Sample for Laboratory Analysis.

to water shall be understood to mean reagent water as defined

8.2 Crush approximately a 30 g of representative portion of

by Type II of Specification D1193.

the minus No. 60 sieve analysis sample to pass a No. 200

7.3 Hydrochloric Acid, Solution 1, 20 % by volume (20 mL

(0.075 mm) sieve. Use a tungsten carbide mill to minimize

of concentrated HCl diluted to 100 mL with Type II reagent

metalcontamination.Drythissampletoconstantweightat110

water).

to 115°C (approximately 8 h) and store in a desiccator until

cool. (Warning—Preparation of the minus 200 mesh analysis

7.4 Lanthanum Additive, Solution 2, 100 g/L lanthanum

samples, from the minus 60 mesh analysis samples, neither

(dissolve 175 g LaCl in water and dilute to 1 L with water).

remove metals through loss nor increase metals through

7.5 Lanthanum Chloride (LaCl ) powder (high purity).

contamination. Full dissolution of the ash is required.)

7.6 Lithium Tetraborate (Li B O ), powder (high purity), or

2 4 7

Lithium Metaborate (LiBO3), powder (high purity).

9. Preparation of Apparatus

7.7 Standard and Sample Dilution Additive, Solution

9.1 Consult the manufacturer’s instructions for the opera-

3—Weigh 40.0 g, to the nearest 0.1 g, of Li B O into a 150 to

2 4 7

tion of the atomic absorption spectrophotometer. The present

200 mL platinum dish, fuse with a Meker type burner to form

method assumes that good operating procedures are followed.

a liquid, and cool. Alternatively, heat in a furnace at 950 6

Design differences between spectrophotometers make it im-

10°C for 10 min or until a liquid forms. Place the cooled

practical to specify the required manipulations in detail here.

platinum dish containing the fused recrystallized Li B O , and

2 4 7

(Warning—Proper operating procedures are required for

a magnetic stirring bar into a 2-L beaker. Add 1000 mL of

safety as well as for reliability of results. An explosion can

Solution1(20 %HCl).Heatandstirthesolutiononamagnetic

result from the flame blow-back unless the correct burner head

stirring hot plate until the melt completely dissolves. After

and operating sequence are used.)

dissolution, remove the platinum dish with a glass rod. Rinse

the platinum dish and glass rod with water into the lithium

10. Procedure

borate solution. Immediately transfer the warm solution quan-

10.1 Weigh 10 g (to 0.1 mg) of the dried coke prepared in

titatively to a 2-L flask. To avoid crystallization add about 100

8.2 into a labeled preignited platinum dish. (Warning—In

mL of water; stir the solution and cool to room temperature.

addition to other precautions, to minimize the potential of

Add 400 mL of Solution 2 (lanthanum additive) and mix.

contamination, prepare the platinum ware by boiling in dilute

Dilute to 2000 mL with water, mix thoroughly, and vacuum

HCl (5 volume % HCl plus 95 % water) rinsing thoroughly

filter the entire solution through Dow filter paper.

with a reagent-grade water. After this initial cleaning, handle

the platinum ware with clean tongs, and protect from all

sources of contamination. Clean and protect all the glassware

Reagent Chemicals, American Chemical Society Specifications, American

used in analyses.)

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory

10.2 Place the platinum dish in a cold muffle fur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.