ASTM E1091-98

(Specification)Standard Specification for Nonmetallic Honeycomb Core for Use in Shelter Panels

Standard Specification for Nonmetallic Honeycomb Core for Use in Shelter Panels

SCOPE

1.1 This specification is for nonmetallic honeycomb core for use in military shelter adhesively bonded sandwich panels. The materials are intended for adhesive bonding to aluminum facings using materials and processes defined by Practices E864 and E874 and Specifications E865, E866, and E990. This specification covers five main types of honeycomb for use in sandwich panels, Types I, II, III, IV, and V. Types I, II, and III honeycombs correspond to three honeycomb densities. Types IV and V are similar to Types II and III, respectively, but have lower performance requirements.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units in parentheses are provided for information only. For conversion of quantities in various systems of measurement to SI units, refer to Practice E380.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1091 – 98

Standard Specification for

Nonmetallic Honeycomb Core for Use in Shelter Panels

This standard is issued under the fixed designation E 1091; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope (SI) (the Modernized Metric System)

E 864 Practice for Surface Preparation of Aluminum Alloys

1.1 This specification is for nonmetallic honeycomb core

to be Adhesively Bonded in Honeycomb Shelter Panels

used in the manufacture of adhesively bonded sandwich panels

E 865 Specification for Structural Film Adhesives for Hon-

for tactical shelters. The materials are intended for adhesive

eycomb Sandwich Panels

bonding to aluminum facings using materials and processes

E 866 Specification for Corrosion-Inhibiting Adhesive

defined by Practices E 864 and E 874 and Specifications E 865,

Primer for Aluminum Alloys to be Adhesively Bonded in

E 866, and E 990. This specification covers five main types of

Honeycomb Shelter Panels

honeycomb for use in sandwich panels, Types I, II, III, IV, and

E 874 Practice for Adhesive Bonding of Aluminum Facings

V. Types I, II, and III honeycombs correspond to three

to Nonmetallic Honeycomb Core for Shelter Panels

honeycomb densities. Types IV and V are similar to Types II

E 990 Specification for Core-Splice Adhesive for Honey-

and III, respectively, but have lower performance require-

comb Sandwich Shelter Panels

ments.

E 1749 Terminology of Rigid Wall Relocatable Shelters

1.2 The values stated in inch-pound units are to be regarded

F 501 Test Method for Aerospace Materials Response to

as the standard. The SI units in parentheses are provided for

Flame, with Vertical Test Specimen (For Aerospace Ve-

information only. For conversion of quantities in various

hicles Standard Conditions)

systems of measurement to SI units, refer to Practice E 380.

2.2 Federal Aviation Regulation:

1.3 This standard does not purport to address all of the

FAR 25.853(a) Compartment Interiors

safety concerns, if any, associated with its use. It is the

2.3 Federal Standards:

responsibility of the user of this standard to establish appro-

FED-STD-191A Textile Test Methods

priate safety and health practices and determine the applica-

QQ-A-250/8 Aluminum Alloy 5052, Plate and Sheet

bility of regulatory limitations prior to use.

QQ-A-250/11 Aluminum Alloy 6061, Plate and Sheet

2. Referenced Documents

2.4 Military Standards:

MIL-STD-105 Sampling Procedures and Tables for Inspec-

2.1 ASTM Standards:

tion by Attributes

C 177 Test Method for Steady-State Heat Flux Measure-

MIL-STD-129 Marking for Shipment and Storage

ments and Thermal Transmission Properties by Means of

MIL-STD-401 Sandwich Constructions and Core Materials;

the Guarded-Hot-Plate Apparatus

General Test Methods

C 366 Test Methods for Measurement of Thickness of

2.5 TAPPI Standard:

Sandwich Cores

T 435-SU-68 Test Method for Hydrogen Ion Concentration

C 481 Test Method for Laboratory Aging of Sandwich

of Paper Extracts, Hot Extraction Method

Constructions

2.6 Other Publications:

C 518 Test Method for Steady-State Heat Flux Measure-

Uniform Freight Classification

ments and Thermal Transmission Properties by Means of

National Motor Freight Classification

the Heat Flow Meter Apparatus

D 3951 Practice for Commercial Packaging

E 380 Practice for Use of the International System of Units

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 04.11.

Annual Book of ASTM Standards, Vol 04.07.

Available from Federal Aviation Agency, Office of Aviation Safety, 800

This specification is under the jurisdiction of ASTM Committee E-6 on

Independence Ave., SW, Washington, DC 20591.

Performance of Building Constructionsand is the direct responsibility of Subcom-

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

mittee E06.53on Materials and Processes for Durable Rigidwall Relocatable

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Structures.

Available from the Technical Association of the Pulp and Paper Industry, 1

Current edition approved Sept. 10, 1998. Published November 1998. Originally Dunwoody Park, Atlanta, GA 30341.

published as E 1091 – 86. Last previous edition E 1091 – 94. Available from the Uniform Classification Committee, Room 1106, 222 S.

Annual Book of ASTM Standards, Vol 04.06. Riverside Plaza, Chicago, IL 60606.

3 12

Annual Book of ASTM Standards, Vol 15.03. Available from the American Trucking Associations, Inc., Traffic Department,

Annual Book of ASTM Standards, Vol 15.09. 1616 P St., NW, Washington, DC 20036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1091

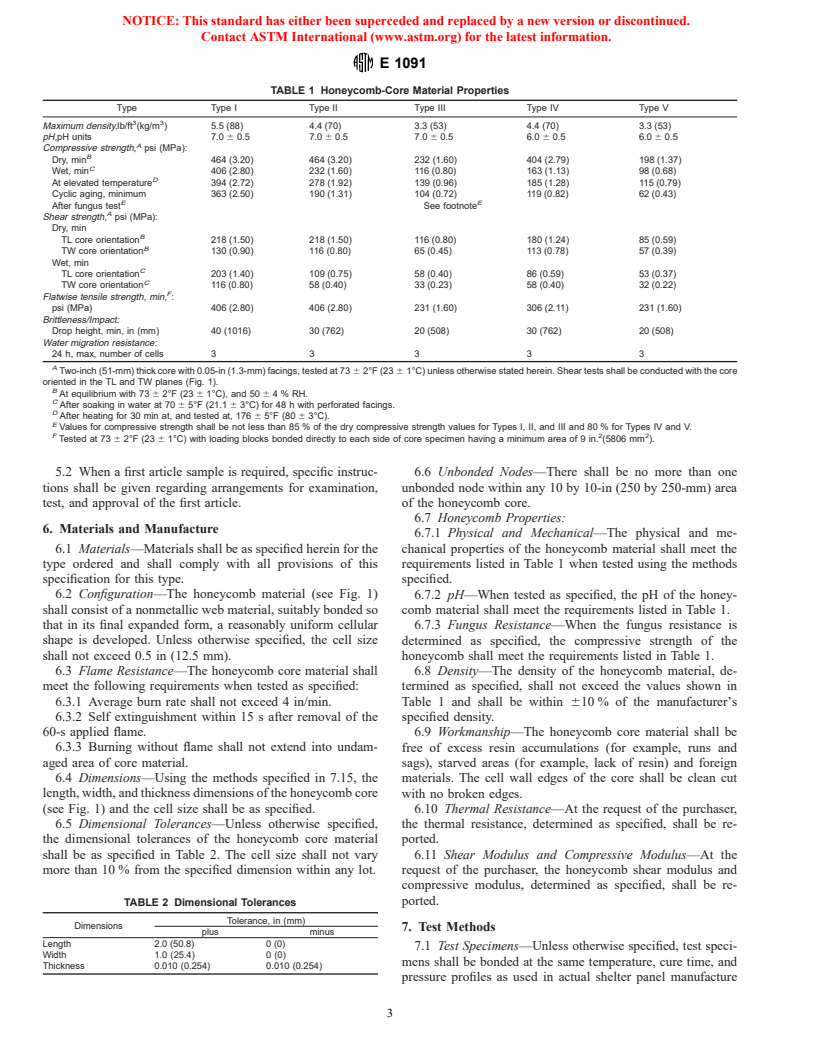

FIG. 1 Orientation of Cells in Honeycomb-Core Material

ANSI/ASQC Z1.4 – 1993, Sampling Procedures and Tables 3.2.6 sheet, n—a slice of honeycomb cut from a production

for Inspection by Attributes block.

3. Terminology

4. Classification

3.1 Definitions—See Terminology E 1749 for definitions of

4.1 Five types of nonmetallic honeycomb material are

terms used in this specification.

specified. Their required properties are given in Section 6 and

3.2 Descriptions of Terms Specific To This Standard:

in Table 1.

3.2.1 block, n—a single production unit of honeycomb

4.1.1 Type I—honeycomb for use in panels which are

before slicing.

required to have a high load-carrying capability that could not

3.2.2 cell size, n—the average distance between node

be adequately met using any of the other types.

bonds, measured along the W direction (Fig. 1), for at least 60

4.1.2 Type II—honeycomb for use in panels which are

cells, selected at random in groups containing 10 adjacent cells.

required to have a load-carrying capability that could not be

3.2.3 core material, n—a slice or sheet cut from a produc-

adequately met by using materials of any of Types III, IV, or V.

tion block that is used in a honeycomb sandwich panel. The

4.1.3 Type III—honeycomb for general use in panels where

orientation of the cells in the honeycomb core material as

the higher performances of Types I, II, and IV materials are not

produced is shown in Fig. 1. The honeycomb core materials

required.

exhibit anisotropic behavior, therefore the following notation is

4.1.4 Type IV—honeycomb similar to Type II but with

used:

slightly lower performance.

L 5 ribbon direction or longitudinal direction of core,

4.1.5 Type V—honeycomb similar to Type III but with

W 5 expanded direction or transverse direction of core, and

slightly lower performance.

T 5 core thickness or depth, and

N 5 bonded portion of the honeycomb flat sheet material;

5. Ordering Information

the honeycomb cell’s double wall.

5.1 Procurement Documents—Purchasers shall select any

3.2.4 first article, n—a sample sheet of honeycomb from the

of the desired options offered herein and the procurement

first lot produced.

documents shall specify the following:

3 3

3.2.5 lot, n—1000 ft (28.3 m ) or less of honeycomb of the

5.1.1 Title, number, and date of this specification.

same type produced during consecutive operating or working

5.1.2 Type of honeycomb required (see Section 4).

days using the same basic materials and operating conditions.

5.1.3 Dimensions required (see 6.4).

5.1.4 Cell size required (see 6.2 and 6.4).

13 5.1.5 Whether a first article sample is required (see 3.3).

Available from the American Society for Quality Control, 611 E. Wisconsin

Ave., Milwaukee, WI 53202. 5.1.6 Whether qualification is necessary (see 8.2.2).

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1091

TABLE 1 Honeycomb-Core Material Properties

Type Type I Type II Type III Type IV Type V

3 3

Maximum density,lb/ft (kg/m ) 5.5 (88) 4.4 (70) 3.3 (53) 4.4 (70) 3.3 (53)

pH,pH units 7.0 6 0.5 7.0 6 0.5 7.0 6 0.5 6.0 6 0.5 6.0 6 0.5

A

Compressive strength, psi (MPa):

B

Dry, min 464 (3.20) 464 (3.20) 232 (1.60) 404 (2.79) 198 (1.37)

C

Wet, min 406 (2.80) 232 (1.60) 116 (0.80) 163 (1.13) 98 (0.68)

D

At elevated temperature 394 (2.72) 278 (1.92) 139 (0.96) 185 (1.28) 115 (0.79)

Cyclic aging, minimum 363 (2.50) 190 (1.31) 104 (0.72) 119 (0.82) 62 (0.43)

E E

After fungus test See footnote

A

Shear strength, psi (MPa):

Dry, min

B

TL core orientation 218 (1.50) 218 (1.50) 116 (0.80) 180 (1.24) 85 (0.59)

B

TW core orientation 130 (0.90) 116 (0.80) 65 (0.45) 113 (0.78) 57 (0.39)

Wet, min

C

TL core orientation 203 (1.40) 109 (0.75) 58 (0.40) 86 (0.59) 53 (0.37)

C

TW core orientation 116 (0.80) 58 (0.40) 33 (0.23) 58 (0.40) 32 (0.22)

F

Flatwise tensile strength, min, :

psi (MPa) 406 (2.80) 406 (2.80) 231 (1.60) 306 (2.11) 231 (1.60)

Brittleness/Impact:

Drop height, min, in (mm) 40 (1016) 30 (762) 20 (508) 30 (762) 20 (508)

Water migration resistance:

24 h, max, number of cells 3 3 3 3 3

A

Two-inch (51-mm) thick core with 0.05-in (1.3-mm) facings, tested at 73 6 2°F (23 6 1°C) unless otherwise stated herein. Shear tests shall be conducted with the core

oriented in the TL and TW planes (Fig. 1).

B

At equilibrium with 73 6 2°F (23 6 1°C), and 50 6 4 % RH.

C

After soaking in water at 70 6 5°F (21.1 6 3°C) for 48 h with perforated facings.

D

After heating for 30 min at, and tested at, 176 6 5°F (80 6 3°C).

E

Values for compressive strength shall be not less than 85 % of the dry compressive strength values for Types I, II, and III and 80 % for Types IV and V.

F 2 2

Tested at 73 6 2°F (23 6 1°C) with loading blocks bonded directly to each side of core specimen having a minimum area of 9 in. (5806 mm ).

5.2 When a first article sample is required, specific instruc- 6.6 Unbonded Nodes—There shall be no more than one

tions shall be given regarding arrangements for examination, unbonded node within any 10 by 10-in (250 by 250-mm) area

test, and approval of the first article. of the honeycomb core.

6.7 Honeycomb Properties:

6. Materials and Manufacture

6.7.1 Physical and Mechanical—The physical and me-

6.1 Materials—Materials shall be as specified herein for the chanical properties of the honeycomb material shall meet the

type ordered and shall comply with all provisions of this

requirements listed in Table 1 when tested using the methods

specification for this type. specified.

6.2 Configuration—The honeycomb material (see Fig. 1)

6.7.2 pH—When tested as specified, the pH of the honey-

shall consist of a nonmetallic web material, suitably bonded so comb material shall meet the requirements listed in Table 1.

that in its final expanded form, a reasonably uniform cellular 6.7.3 Fungus Resistance—When the fungus resistance is

shape is developed. Unless otherwise specified, the cell size determined as specified, the compressive strength of the

shall not exceed 0.5 in (12.5 mm). honeycomb shall meet the requirements listed in Table 1.

6.3 Flame Resistance—The honeycomb core material shall 6.8 Density—The density of the honeycomb material, de-

meet the following requirements when tested as specified: termined as specified, shall not exceed the values shown in

6.3.1 Average burn rate shall not exceed 4 in/min. Table 1 and shall be within 610 % of the manufacturer’s

6.3.2 Self extinguishment within 15 s after removal of the specified density.

60-s applied flame. 6.9 Workmanship—The honeycomb core material shall be

6.3.3 Burning without flame shall not extend into undam- free of excess resin accumulations (for example, runs and

aged area of core material. sags), starved areas (for example, lack of resin) and foreign

6.4 Dimensions—Using the methods specified in 7.15, the materials. The cell wall edges of the core shall be clean cut

length, width, and thickness dimensions of the honeycomb core

with no broken edges.

(see Fig. 1) and the cell size shall be as specified. 6.10 Thermal Resistance—At the request of the purchaser,

6.5 Dimensional Tolerances—Unless otherwise specified,

the thermal resistance, determined as specified, shall be re-

the dimensional tolerances of the honeycomb core material ported.

shall be as specified in Table 2. The cell size shall not vary

6.11 Shear Modulus and Compressive Modulus—At the

more than 10 % from the specified dimension within any lot. request of the purchaser, the honeycomb shear modulus and

compressive modulus, determined as specified, shall be re-

ported.

TABLE 2 Dimensional Tolerances

Tolerance, in (mm)

Dimensions

7. Test Methods

plus minus

Length 2.0 (50.8) 0 (0)

7.1 Test Specimens—Unless otherwise specified, test speci-

Width 1.0 (25.4) 0 (0)

mens shall be bonded at the same temperature, cure time, and

Thickness 0.010 (0.254) 0.010 (0.254)

pressure profiles as used in actual shelter panel manufacture

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1091

and conditioned and tested under standard conditions of Test Method of MIL-STD-401. Record all individual compres-

73 6 2°F (23 6 1°C) and 50 6 4 % relative humidity (RH). sive strength values. The test is failed if two or more of the six

(See Specification E 865.) values do not meet the requirements of Table 1 or the average

value is below the value given in Table 1.

7.2 Density—Test the density of the honeycomb material

for compliance with the requirements given in Table 1. 7.4.2 Dry—Condition six specimens as specified in 7.1 for

Determine the density using the core density method of at least 48 h. Then test in accordance with the Core Compres-

MIL-STD-401 using two specimens, each at least 2.2 ft (0.2 sion Test Method of MIL-STD-401. At the option of the

m ) in area. Condition the specimens as specified for at least 48 supplier, the skins specified do not necessarily have to be

perforated. Record all individual compressive strength values.

h. Record each individual density value. Determine the average

density value of the two specimens. The test is failed if any The test is failed if two or more of the six values do not meet

the requirements of Table 1 or the average value is below Table

average density value does not meet the requirements of Table

1 and 6.8. 1.

7.3 Honeycomb Core Shear—The L by W by I dimensions 7.4.3 Elevated Temperature—Heat six specimens to

176 6 5°F (80 6 3°C) for a duration of 30 min and test

of the bo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.