ASTM A707/A707M-02(2007)

(Specification)Standard Specification for Forged Carbon and Alloy Steel Flanges for Low-Temperature Service

Standard Specification for Forged Carbon and Alloy Steel Flanges for Low-Temperature Service

ABSTRACT

This specification covers forged carbon and alloy steel flanges intended primarily for petroleum and gas pipelines in areas subject to low ambient temperatures. Eight grades, four yield-strength classes, and three different notch toughness levels are included. All material shall be heat treated by annealing, normalizing, precipitation hardening, quenching-and-tempering, normalizing-and-tempering, normalizing-and-precipitation hardening, or quenching-and-precipitation hardening. A chemical heat analysis shall be made and conform to the requirements as to chemical composition specified. The material in the weld neck shall conform to the mechanical property requirements specified. Hardness test, impact test, ultrasonic test, tension test, and hydrostatic test shall be made to conform to the specified requirements.

SCOPE

1.1 This specification covers forged carbon and alloy steel flanges intended primarily for petroleum and gas pipelines in areas subject to low ambient temperatures. Included are flanges to specified dimensions or to dimensional standards such as those MSS, ASME, and API specifications that are referenced in Section 2.

1.2 Supplementary requirements are provided for use when additional requirements are desired. These shall apply only when specified individually by the purchaser in the order.

1.3 Eight grades, four yield-strength classes, and three different notch toughness levels are included.

1.4 The availability of a particular size of flange of a specific grade and class is limited only by the capability of the composition to meet the specified mechanical property requirements. However, current practice normally limits the following:(a) Grade L1 to Classes 1 and 2, (b) Grade L2 to Classes 1, 2, and 3, (c) Grade L3 to Classes 1, 2, and 3,(d) Grade L4 to Classes 1, 2, and 3,(e) Grade L7 to Classes 1 and 2, and (f) Grades L5, L6, and L8 are generally available in any class.

1.5 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished to inch-pound units.

1.6 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A707/A707M – 02 (Reapproved 2007)

Standard Specification for

Forged Carbon and Alloy Steel Flanges for Low-

Temperature Service

This standard is issued under the fixed designationA707/A707M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers forged carbon and alloy steel 2.1 In addition to those reference documents listed in

flanges intended primarily for petroleum and gas pipelines in Specification A961/A961M, the following list of standards

areassubjecttolowambienttemperatures.Includedareflanges apply to this specification:

to specified dimensions or to dimensional standards such as 2.2 ASTM Standards:

those MSS, ASME, and API specifications that are referenced A388/A388M Practice for Ultrasonic Examination of Steel

in Section 2. Forgings

1.2 Supplementary requirements are provided for use when A788/A788M Specification for Steel Forgings, General Re-

additional requirements are desired. These shall apply only quirements

when specified individually by the purchaser in the order. A961/A961M Specification for Common Requirements for

1.3 Eight grades, four yield-strength classes, and three SteelFlanges,ForgedFittings,Valves,andPartsforPiping

different notch toughness levels are included. Applications

1.4 The availability of a particular size of flange of a 2.3 MSS Standards:

specific grade and class is limited only by the capability of the SP 44 Steel Pipeline Flanges

compositiontomeetthespecifiedmechanicalpropertyrequire- 2.4 API Standard:

ments. However, current practice normally limits the follow- 605 Large Diameter Carbon Steel Flanges

ing: 2.5 ASME Boiler and Pressure Vessel Code:

(a) Grade L1 to Classes 1 and 2, Section VIII Division I, Part UG-84

(b) Grade L2 to Classes 1, 2, and 3, Section IX Welding Qualifications

(c) Grade L3 to Classes 1, 2, and 3, 2.6 ASME Standard:

(d) Grade L4 to Classes 1, 2, and 3, B 16.5 Dimensional Standards for Steel Pipe Flanges and

(e) Grade L7 to Classes 1 and 2, and Flanged Fittings

(f) Grades L5, L6, and L8 are generally available in any 2.7 AWS Standards:

class. A 5.1 Mild Steel Covered Electrodes

1.5 This specification is expressed in both inch-pound units A 5.5 Low-Alloy Steel Covered Arc-Welding Electrodes

and in SI units. However, unless the order specifies the

3. Terminology

applicable “M” specification designation (SI units), the mate-

3.1 Definitions:

rial shall be furnished to inch-pound units.

1.6 The values stated in either inch-pound units or SI units

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

system are not exact equivalents; therefore, each system must For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

be used independently of the other. Combining values from the

Standards volume information, refer to the standard’s Document Summary page on

two systems may result in nonconformance with the specifi-

the ASTM website.

cation.

AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

hq.com.

1 4

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Available from American Petroleum Institute (API), 1220 L. St., NW, Wash-

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee ington, DC 20005-4070, http://api-ec.api.org.

A01.22 on Steel Forgings and Wrought Fittings for PipingApplications and Bolting Available from American Society of Mechanical Engineers (ASME), ASME

Materials for Piping and Special Purpose Applications. International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

Current edition approved March 1, 2007. Published April 2007. Originally www.asme.org.

approved in 1974. Last previous edition approved in 2002 as A707/A707M – 02. Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

DOI: 10.1520/A0707_A0707M-02R07. Miami, FL 33126, http://www.aws.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A707/A707M – 02 (2007)

3.1.1 flakes—short discontinuous internal fissures attributed 6. Manufacture

to stresses produced by localized transformation and decreased

6.1 ThesteelshallmeetthemeltingpracticeofSpecification

solubility of hydrogen during cooling after hot working.

A961/A961M.

3.1.2 linear surface imperfection (or indication)—animper-

6.2 The finished product shall be a forging as defined by 3

fection or indication with a length at least three times its width.

(only) of Specification A788/A788M.

4. Ordering Information

7. Heat Treatment

4.1 It is the purchaser’s responsibility to specify in the

purchase order all ordering information necessary to purchase

7.1 After forging and before reheating for heat treatment,

the needed material. In addition to the ordering information

the forging shall be allowed to cool substantially below the

guide lines in Specification A961/A961M, orders should in-

transformation range. The method of cooling shall be such as

clude the following information:

to ensure against the development of cracks, flakes, etc.

4.1.1 Additional requirements (see Table 1 footnotes, 9.2.2,

7.2 All material shall be heat treated by annealing, normal-

9.3, 11.5, 17.1, 21.1, and 21.2).

izing, precipitation hardening, quenching-and-tempering,

normalizing-and-tempering, normalizing-and-precipitation

5. General Requirements

hardening, or quenching-and-precipitation hardening.

5.1 Product furnished to this specification shall conform to

7.2.1 The procedures for the various heat treatments are as

the requirements of SpecificationA961/A961M, including any

given in Specification A961/A961M except as defined in the

supplementary requirements that are indicated in the purchase

following:

order. Failure to comply with the general requirements of

7.2.1.1 Precipitation Hardening—Consists of heating to a

Specification A961/A961M constitutes nonconformance with

this specification. In case of conflict between the requirements temperature between 1000 and 1250°F [538 and 677°C],

holding at temperature for not less than ⁄2 h, and then cooling

of this specification and Specification A961/A961M, this

specification shall prevail. at any convenient rate.

TABLE 1 Chemical Requirements

Grade

Element

A A B

L1 L2 L3 L4 L5 L6 L7 L8

Carbon, max, %

Heat analysis 0.20 0.30 0.22 0.18 0.07 0.07 0.20 0.20

Product analysis 0.23 0.33 0.25 0.20 0.09 0.09 0.22 0.22

Manganese, %

Heat analysis 0.60-1.50 0.60-1.35 1.15–1.50 0.45–0.65 0.40–0.70 1.85–2.20 0.90 max 0.20–0.40

Product analysis 0.55-1.60 0.55-1.45 1.05–1.60 0.40–0.70 0.35–0.75 1.75–2.30 1.00 max 0.15–0.45

Phosphorus, max, %

Heat analysis 0.030 0.030 0.025 0.025 0.025 0.025 0.025 0.020

Product analysis 0.035 0.035 0.030 0.030 0.030 0.030 0.030 0.025

Sulfur, max, %

Heat analysis 0.030 0.030 0.025 0.025 0.025 0.025 0.025 0.020

Product analysis 0.040 0.040 0.035 0.035 0.035 0.035 0.035 0.025

Silicon, max, %

Heat analysis 0.35 0.35 0.30 0.35 0.35 0.15 0.35 0.35

Product analysis 0.37 0.37 0.32 0.37 0.37 0.17 0.37 0.37

Chromium, %

Heat analysis 0.30 max 0.30 max 0.30 max 0.30 max 0.60–0.90 0.30 max 0.30 max 1.50–2.00

Product analysis 0.34 max 0.34 max 0.34 max 0.34 max 0.56–0.94 0.34 max 0.34 max 1.44–2.06

Nickel, %

Heat analysis 0.40 max 0.40 max 0.40 max 1.65–2.00 0.70–1.00 0.40 max 3.2–3.7 2.8–3.9

Product analysis 0.43 max 0.43 max 0.43 max 1.60–2.05 0.67–1.03 0.43 max 3.18–3.82 2.68–3.97

Molybdenum, %

Heat analysis 0.12 max 0.12 max 0.12 max 0.20–0.30 0.15–0.25 0.25–0.35 0.12 max 0.40–0.60

Product analysis 0.13 max 0.13 max 0.13 max 0.19–0.33 0.14–0.28 0.22–0.38 0.13 max 0.35–0.65

Vanadium, %

Heat analysis 0.05 max 0.05 max 0.04–0.11 0.05 max 0.05 max 0.05 max 0.05 max 0.05 max

Product analysis 0.06 max 0.06 max 0.03–0.13 0.06 max 0.06 max 0.06 max 0.06 max 0.06 max

Nitrogen, %

Heat analysis . . 0.010–0.030 . . . . .

Product analysis . . 0.005–0.035 . . . . .

Copper, %

C

Heat analysis 0.40 max 0.40 max 0.20 min 0.40 max 1.00–1.30 0.40 max 0.40 max 0.40 max

C

Product analysis 0.43 max 0.43 max 0.18 min 0.43 max 0.95–1.35 0.43 max 0.43 max 0.43 max

Columbium, %

Heat analysis 0.02 max 0.02 max 0.02 max 0.02 max 0.03 min 0.06–0.10 0.02 max 0.02 max

Product analysis 0.03 max 0.03 max 0.03 max 0.03 max 0.02 min 0.05–0.11 0.03 max 0.03 max

A

The sum of copper, nickel, chromium, and molybdenum shall not exceed 1.00 % on heat analysis.

B

The sum of chromium, molybdenum and vanadium shall not exceed 0.32 % on heat analysis.

C

When specified.

A707/A707M – 02 (2007)

8. Chemical Composition 11.2 For the purpose of determining conformance with

Table 2, specimens shall be obtained from production flanges

8.1 A chemical heat analysis in accordance with Specifica-

after heat treatment or from separately forged test blanks

tion A961/A961M shall be made and conform to the require-

prepared from the stock used to make the forgings. Such test

ments as to chemical composition prescribed in Table 1.

blanks shall conform to the requirements of Specification

Leaded steels shall not be permitted.

A961/A961M.

11.3 Specimens shall be obtained from a location on the

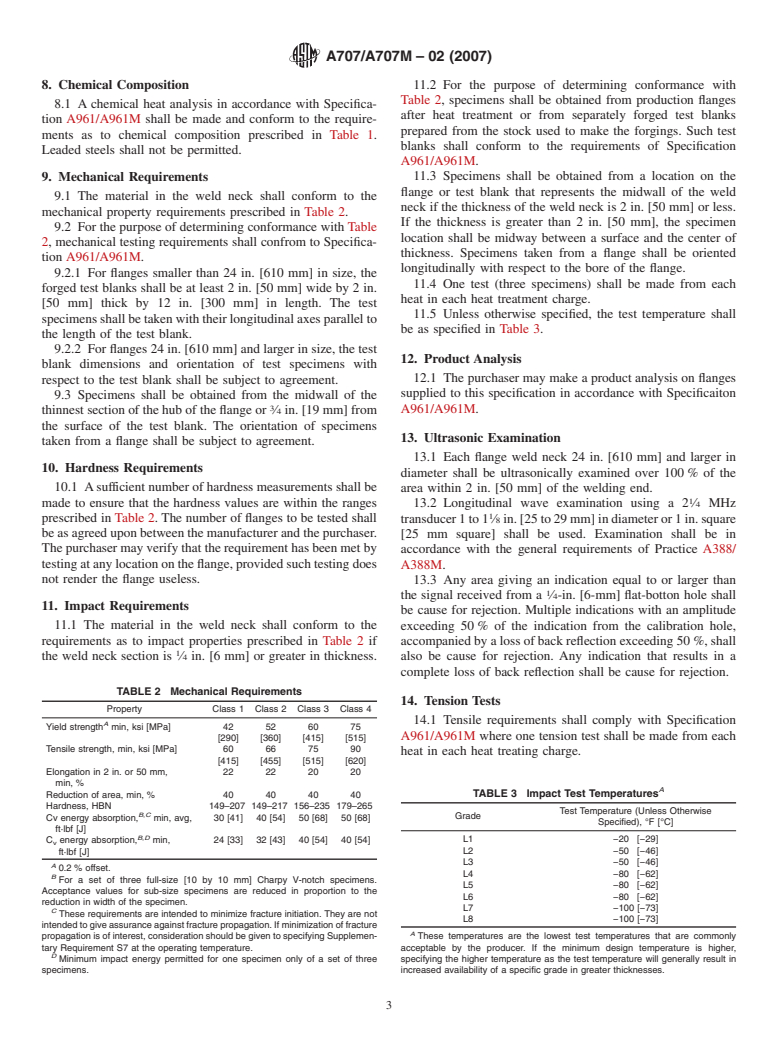

9. Mechanical Requirements

flange or test blank that represents the midwall of the weld

9.1 The material in the weld neck shall conform to the

neck if the thickness of the weld neck is 2 in. [50 mm] or less.

mechanical property requirements prescribed in Table 2.

If the thickness is greater than 2 in. [50 mm], the specimen

9.2 For the purpose of determining conformance with Table

location shall be midway between a surface and the center of

2, mechanical testing requirements shall confrom to Specifica-

thickness. Specimens taken from a flange shall be oriented

tion A961/A961M.

longitudinally with respect to the bore of the flange.

9.2.1 For flanges smaller than 24 in. [610 mm] in size, the

11.4 One test (three specimens) shall be made from each

forged test blanks shall be at least 2 in. [50 mm] wide by 2 in.

heat in each heat treatment charge.

[50 mm] thick by 12 in. [300 mm] in length. The test

11.5 Unless otherwise specified, the test temperature shall

specimensshallbetakenwiththeirlongitudinalaxesparallelto

be as specified in Table 3.

the length of the test blank.

9.2.2 For flanges 24 in. [610 mm] and larger in size, the test

12. Product Analysis

blank dimensions and orientation of test specimens with

12.1 The purchaser may make a product analysis on flanges

respect to the test blank shall be subject to agreement.

supplied to this specification in accordance with Specificaiton

9.3 Specimens shall be obtained from the midwall of the

A961/A961M.

thinnest section of the hub of the flange or ⁄4 in. [19 mm] from

the surface of the test blank. The orientation of specimens

13. Ultrasonic Examination

taken from a flange shall be subject to agreement.

13.1 Each flange weld neck 24 in. [610 mm] and larger in

10. Hardness Requirements

diameter shall be ultrasonically examined over 100 % of the

10.1 Asufficient number of hardness measurements shall be

area within 2 in. [50 mm] of the welding end.

made to ensure that the hardness values are within the ranges

13.2 Longitudinal wave examination using a 2 ⁄4 MHz

prescribed in Table 2. The number of flanges to be tested shall

transducer1to1 ⁄8in.[25to29mm]indiameteror1in.square

beasagreeduponbetweenthemanufacturerandthepurchaser. [25 mm square] shall be used. Examination shall be in

Thepurchasermayverify that the requirement has beenmetby

accordance with the general requirements of Practice A388/

testingatanylocationontheflange,providedsuchtestingdoes A388M.

not render the flange useless.

13.3 Any area giving an indication equal to or larger than

the signal received from a ⁄4-in. [6-mm] flat-botton hole shall

11. Impact Requirements

be cause for rejection. Multiple indications with an amplitude

11.1 The material in the weld neck shall conform to the exceeding 50 % of the indication from the calibration hole,

requirements as to impact properties prescribed in Table 2 if accompanied by a loss of back reflection exceeding 50 %, shall

the weld neck section is ⁄4 in. [6 mm] or greater in thickness. also be cause for rejection. Any indication that results in a

complete loss of back reflection shall be cause for rejection.

TABLE 2 Mechanical Requirements

14. Tension Tests

Property Class 1 Class 2 Class 3 Class 4

14.1 Tensile requirements shall comply with Specification

A

Yield strength min, ksi [MPa] 42 52 60 75

A961/A961M where one tension test shall be made from each

[290] [360] [415] [515]

Tensile strength, min, ksi [MPa] 60 66 75 90

heat in each heat treating charge.

[415] [455] [515] [620]

Elongation in 2 in. or 50 mm, 22 22 20 20

min, %

A

Reduction of area, min, % 40 40 40 40 TABLE 3 Impact Test Temperatures

Hardness, HBN 149–207 149–217 156–235 179–265

Test Temperature (Unless Otherwise

B,C

Grade

Cv energy absorption, min, avg, 30 [41] 40 [54] 50 [68] 50 [68]

Specified), °F [°C]

ft·lbf [J]

B,D

L1 −20 [−29]

C energy absorption, min, 24 [33] 32 [43] 40 [54] 40 [54]

v

ft·lbf [J] L2 −50 [−46]

L3 −50 [−46]

A

0.2 % offset.

L4 −80 [−62]

B

For a set of three full-size [10 by 10 mm] Charpy V-notch specimens.

L5 −80 [−62]

Acceptance values for sub-size specimens are reduced in proportion to the

L6 −80 [−62]

reduction in width of the specimen.

L7 −100 [−73]

C

These requirements are intended to minimize fracture initiation. They are not

L8 −100 [−73]

intended to give assurance against fracture propagation. If minimization of fracture

A

propagation is of interest, consideration should be given to specifying Supplemen- These temperatures are the lowest test temperatures that are commonly

tary Requirement S7 at the operating temperature. acceptable by the producer. If the minimum design temperature is higher,

D

Minimum impact energy permitted for one specimen only of a set of three specifying the higher temperature as the test temperature will generally result in

specimens. increased availability of a specific grade in greater thicknesses.

A707/A707M – 02 (2007)

14.1.1 Whentheheattreatingtemperaturesarethesameand 19. Inspection

the furnaces (either batch or continuous type) are controlled

19.1 Inspection provisions of Specification A961/A961M

within 625°F [614°C] and equipped with recording pyrom-

apply.

ete

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.