ASTM D6258-09

(Test Method)Standard Test Method for Determination of Solvent Red 164 Dye Concentration in Diesel Fuels

Standard Test Method for Determination of Solvent Red 164 Dye Concentration in Diesel Fuels

SIGNIFICANCE AND USE

This test method was developed to provide for the enforcement of 26 CFR 48.4082-1(b), which mandates that all tax-exempt diesel fuels be dyed with an amount of Solvent Red 164 at a concentration that is spectrally equivalent to 3.9 lb/103 bbl (11.1 mg/L) of Solvent Red 26. It is employed to verify that the correct amount of Solvent Red 164 is being added to tax-exempt product at terminals or refineries prior to sale, and to detect the presence of Solvent Red 164 in taxed product intended for on-road use.

Solvent Red 26 is the azo dye shown in Fig. 1. It is the standard against which the concentration of Solvent Red 164 is measured because it is available in a certified pure form. Solvent Red 164 is identical in structure to Solvent Red 26 except that it has hydrocarbon (alkyl) chains incorporated to increase its solubility in diesel and burner fuels. The exact composition of Solvent Red 164 will vary from manufacturer to manufacturer and lot to lot depending upon the extent of alkylation that occurs during production; however, its visible spectrum is virtually identical to the spectrum of Solvent Red 26. Solvent Red 164 is employed in the field (instead of Solvent Red 26) to dye tax-exempt diesel and burner fuels because of its higher solubility and relatively low cost.

FIG. 1 Structure of Solvent Red 26

SCOPE

1.1 This test method covers the procedure for determining the concentration of dye Solvent Red 164 in commercially available diesel and burner fuels using visible spectroscopy.

Note 1—This test method is suitable for all No. 1 and No. 2 grades in Specifications D 396 and D 975 and for grades DMA and DMB in Specification D 2069.

1.2 The concentration ranges specified for the calibration standards are established in response to the Internal Revenue Service dyeing requirements which state that tax-exempt diesel fuel satisfies the dyeing requirement only if it contains the dye Solvent Red 164 (and no other dye) at a concentration spectrally equivalent to 3.9 lb of the solid dye standard Solvent Red 26 per thousand bbl (11.1 mg/L) of diesel fuel.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6258 − 09

StandardTest Method for

Determination of Solvent Red 164 Dye Concentration in

1

Diesel Fuels

This standard is issued under the fixed designation D6258; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E131 Terminology Relating to Molecular Spectroscopy

E169 PracticesforGeneralTechniquesofUltraviolet-Visible

1.1 This test method covers the procedure for determining

Quantitative Analysis

the concentration of dye Solvent Red 164 in commercially

E275 Practice for Describing and Measuring Performance of

available diesel and burner fuels using visible spectroscopy.

Ultraviolet and Visible Spectrophotometers

NOTE 1—This test method is suitable for all No. 1 and No. 2 grades in

E288 Specification for Laboratory Glass Volumetric Flasks

Specifications D396 and D975 and for grades DMA and DMB in

E691 Practice for Conducting an Interlaboratory Study to

Specification D2069.

Determine the Precision of a Test Method

1.2 The concentration ranges specified for the calibration

E969 Specification for Glass Volumetric (Transfer) Pipets

standards are established in response to the Internal Revenue

2.2 Federal Regulation:

Servicedyeingrequirementswhichstatethattax-exemptdiesel

26 CFR 48.4082-1(b) Federal Excise Tax Regulation

fuel satisfies the dyeing requirement only if it contains the dye

Solvent Red 164 (and no other dye) at a concentration

3. Terminology

spectrally equivalent to 3.9 lb of the solid dye standard Solvent

3.1 Definitions:

Red 26 per thousand bbl (11.1 mg/L) of diesel fuel.

3.1.1 For definitions of terms used in this test method, refer

1.3 The values stated in SI units are to be regarded as

to Terminology E131.

standard. No other units of measurement are included in this

standard.

4. Summary of Test Method

1.4 This standard does not purport to address all of the

4.1 The absorbance of each sample is recorded over a

safety concerns, if any, associated with its use. It is the

specified wavelength range, and the scan is analyzed using

responsibility of the user of this standard to establish appro-

derivative analysis software to determine the dye concentra-

priate safety and health practices and determine the applica-

tion.

bility of regulatory limitations prior to use.

4.2 Derivative analysis methodology is employed to mini-

2. Referenced Documents

mize interferences caused by variations in the color and

2

composition of the fuel samples regularly tested using this test

2.1 ASTM Standards:

method.

D396 Specification for Fuel Oils

4.2.1 Naturally occurring diesel test fuels range in color

D975 Specification for Diesel Fuel Oils

3 from water white to nearly black, and many of the samples

D2069 Specification for Marine Fuels (Withdrawn 2003)

tested using this test method have also had used oils and other

D3699 Specification for Kerosine

products blended with them. These variations in color and

D4057 Practice for Manual Sampling of Petroleum and

composition have a significant effect upon absorbance charac-

Petroleum Products

teristics of the samples in the region of the visible spectrum

where azo dyes absorb. Standard operating procedures to

1

This test method is under the jurisdiction of ASTM Committee D02 on

correct for these background variations would involve running

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

a neat (undyed) sample and subtracting out the background

Current edition approved March 1, 2009. Published March 2009. Originally

absorbance. In most situations involved with the application of

approved in 1998. Last previous edition approved in 2004 as D6258–04. DOI:

this test method, however, neat material is not available, so no

10.1520/D6258-09.

2

background corrections can be made.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

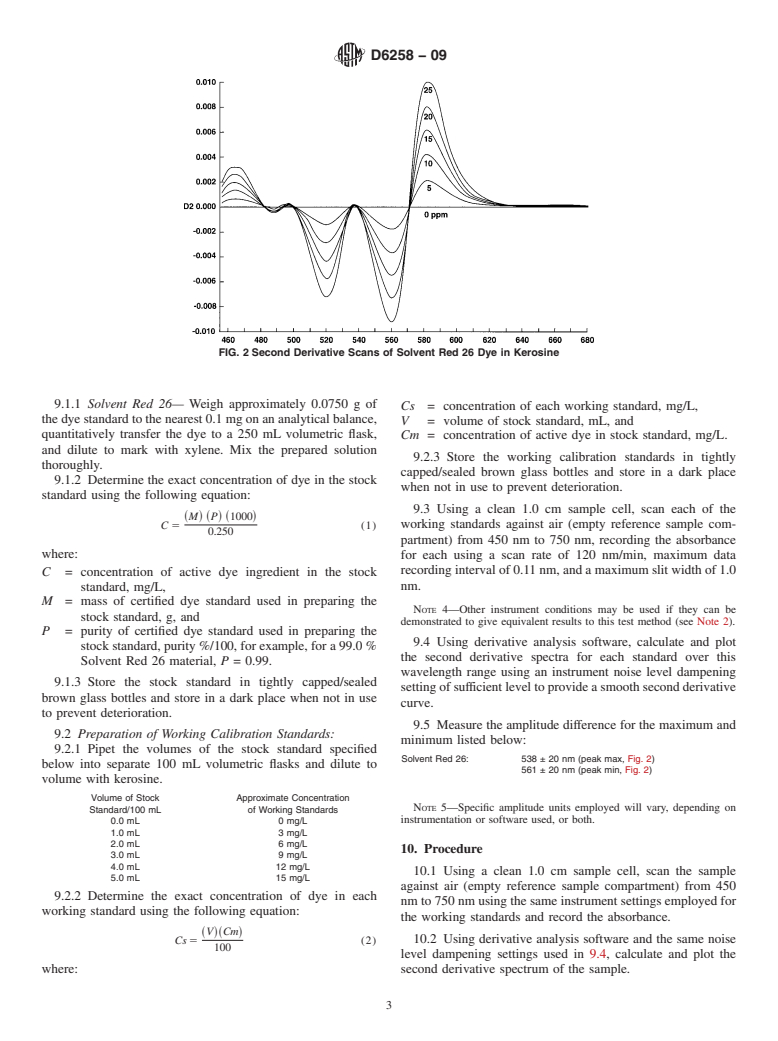

4.2.2 The second derivative of the absorbance of these dyes

Standards volume information, refer to the standard’s Document Summary page on

in the visible region is a function of the fine structure of the

the ASTM website.

3 dye’s absorbance peak (versus its height or area) and is

The last approved version of this historical standard is referenced on

www.astm.org. relatively unaffected by changes in background absorbance.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D6258–04 Designation:D6258–09

Standard Test Method for

Determination of Solvent Red 164 Dye Concentration in

1

Diesel Fuels

This standard is issued under the fixed designation D 6258; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the procedure for determining the concentration of dye Solvent Red 164 in commercially available

diesel and burner fuels using visible spectroscopy.

NOTE 1—This test method is suitable for all No. 1 and No. 2 grades in Specifications D 396 and D 975 and for grades DMAand DMB in Specification

D 2069.

1.2 The concentration ranges specified for the calibration standards are established in response to the Internal Revenue Service

dyeingrequirementswhichstatethattax-exemptdieselfuelsatisfiesthedyeingrequirementonlyifitcontainsthedyeSolventRed

164 (and no other dye) at a concentration spectrally equivalent to 3.9 lb of the solid dye standard Solvent Red 26 per thousand

bbl (11.1 mg/L) of diesel fuel.

1.3The values stated in SI units are to be regarded as the standard.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 396 Specification for Fuel Oils

D 975 Specification for Diesel Fuel Oils

D 2069 Specification for Marine Fuels

D 3699 Specification for Kerosine

D 4057 Practice for Manual Sampling of Petroleum and Petroleum Products

E 131 Terminology Relating to Molecular Spectroscopy

E 169 Practices for General Techniques of Ultraviolet-Visible Quantitative Analysis

E 275 Practice for Describing and Measuring Performance of Ultraviolet, Visible, Ultraviolet and Near-InfraredVisible

Spectrophotometers

E 288 Specification for Laboratory Glass Volumetric Flasks

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E 969 Specification for Glass Volumetric (Transfer) PipettesPipets

2.2 Other Document: Federal Regulation:

26 CFR 48.4082-1(b) Federal Excise Tax Regulation

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminology E 131.

4. Summary of Test Method

4.1 The absorbance of each sample is recorded over a specified wavelength range, and the scan is analyzed using derivative

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.05 on

Properties of Fuels, Petroleum Coke and Carbon Material.

´1

Current edition approved Nov. 1, 2004. Published November 2004. Originally approved in 1998. Last previous edition approved in 2003 as D6258–98(2003) .

Current edition approved March 1, 2009. Published March 2009. Originally approved in 1998. Last previous edition approved in 2004 as D 6258–04.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6258–09

analysis software to determine the dye concentration.

4.2 Derivative analysis methodology is employed to minimize interferences caused by variations in the color and composition

of the fuel samples regularly tested using this test method.

4.2.1 Naturally occurring diesel test fuels range in color from water white to nearly black, and many of the samples tested using

this test method have also had used oils and other products blended with them. These variations in color and composition have

a significant effect upon absorbance characteristics of the samples in the region of the visible spectrum where azo dyes absorb.

Standard operating procedures to correct for these background v

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.