ASTM D5761-96(2001)

(Practice)Standard Practice for Emulsification/Suspension of Multiphase Fluid Waste Materials

Standard Practice for Emulsification/Suspension of Multiphase Fluid Waste Materials

SCOPE

1.1 This practice covers the generation of a single-phase suspension or emulsion from multiphase samples which are primarily liquid in order to facilitate sample preparation, transfer, and analysis.

1.2 This practice is designed to keep a multiphase fluid sample in an emulsified/suspended state long enough to take a single, composite sample that is representative of the sample as a whole. The sample may reform multiple layers after standing.

1.3 The emulsion/suspension generated by following this practice can be used only for analytical procedures designed for the total sample and procedures not significantly affected by the emulsifier or the presence of an emulsion/suspension.

1.4 This practice assumes that a representative sample of not more than one litre has been obtained.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 5761 – 96 (Reapproved 2001)

Standard Practice for

Emulsification/Suspension of Multiphase Fluid Waste

Materials

This standard is issued under the fixed designation D 5761; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 multiphase fluid waste material, n—a substance or

1.1 This practice covers the generation of a single-phase

mixture of chemicals that is no longer useful for its original

suspension or emulsion from multiphase samples which are

purpose that visibly involves a solid and at least one liquid

primarily liquid in order to facilitate sample preparation,

phase or more than one liquid phase without any solid present.

transfer, and analysis.

1.2 This practice is designed to keep a multiphase fluid

4. Summary of Practice

sample in an emulsified/suspended state long enough to take a

4.1 An emulsifier is added and mixed well with a sample of

single,compositesamplethatisrepresentativeofthesampleas

multiphase fluid waste material, to produce a uniform mixture

awhole.Thesamplemayreformmultiplelayersafterstanding.

suitable for subsequent aliquoting.Asatisfactory homogeniza-

1.3 The emulsion/suspension generated by following this

tion has been attained when the sample appears to remain as a

practice can be used only for analytical procedures designed

single phase for 30 s or longer.

forthetotalsampleandproceduresnotsignificantlyaffectedby

4.2 Acalcium sulfonate emulsifier is used when the original

the emulsifier or the presence of an emulsion/suspension.

sample is primarily organic in nature; a polyethylene glycol

1.4 This practice assumes that a representative sample of

monoalky ester is used when the original sample is primarily

not more than one litre has been obtained.

aqueous in nature.Ablend of the two emulsifiers is used when

1.5 This standard does not purport to address all of the

the original sample contains roughly equal volumes of organic

safety concerns, if any, associated with its use. It is the

and aqueous material.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 This practice is intended as a solution to the difficulty of

2. Referenced Documents obtaining reproducible test results from heterogeneous

samples.

2.1 ASTM Standards:

5.2 This practice works best with multilayered liquids, but

D 4057 Practice for Manual Sampling of Petroleum and

2 can also be applied to samples with solid particles that are

Petroleum Products

sufficiently small in size to be suspended in an emulsion.

D 4177 Practice for Automatic Sampling of Petroleum and

2 5.3 The emulsified/suspended sample can be used for all

Petroleum Products

bulk property testing such as microwave digestion/inductively

2.2 EPA Standard:

coupled argon plasma (ICAP), ion chromatography, heat of

SW846 Test Methods for Evaluating Solid Waste, Physical/

3 combustion, ash content, water, nonvolatile residue, and pH. It

Chemical Methods

may be prudent to retain a portion of the sample in its original,

3. Terminology multiphase form for some types of analyses.

3.1 Definitions:

6. Interferences

3.1.1 emulsion, n—a suspension of fine particles or glob-

6.1 Not all samples can be emulsified, due to varying

ules, or both, of one or more liquids in another liquid.

chemical reactions with the surfactants. If the emulsion is not

stable for at least 30 s after shaking, it may not be suitable for

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

testing as an emulsion.

Products and Lubricants and is the direct responsibility of Subcommittee D02.03 on

6.2 Duetotheirphysicalcomposition,somesamplesarenot

Elemental Analysis.

Current edition approved Apr. 10, 1996. Published June 1996. suitable for splitting and, as a result, cannot be emulsified if a

Annual Book of ASTM Standards, Vol 05.02.

nonemulsified retain is required. For example, excessive

Available from the Environmental Protection Agency, 401 M Street, SW,

amountsofsolidsandsemisolidsortarsdonotpermitsplitting.

Washington, DC 20460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

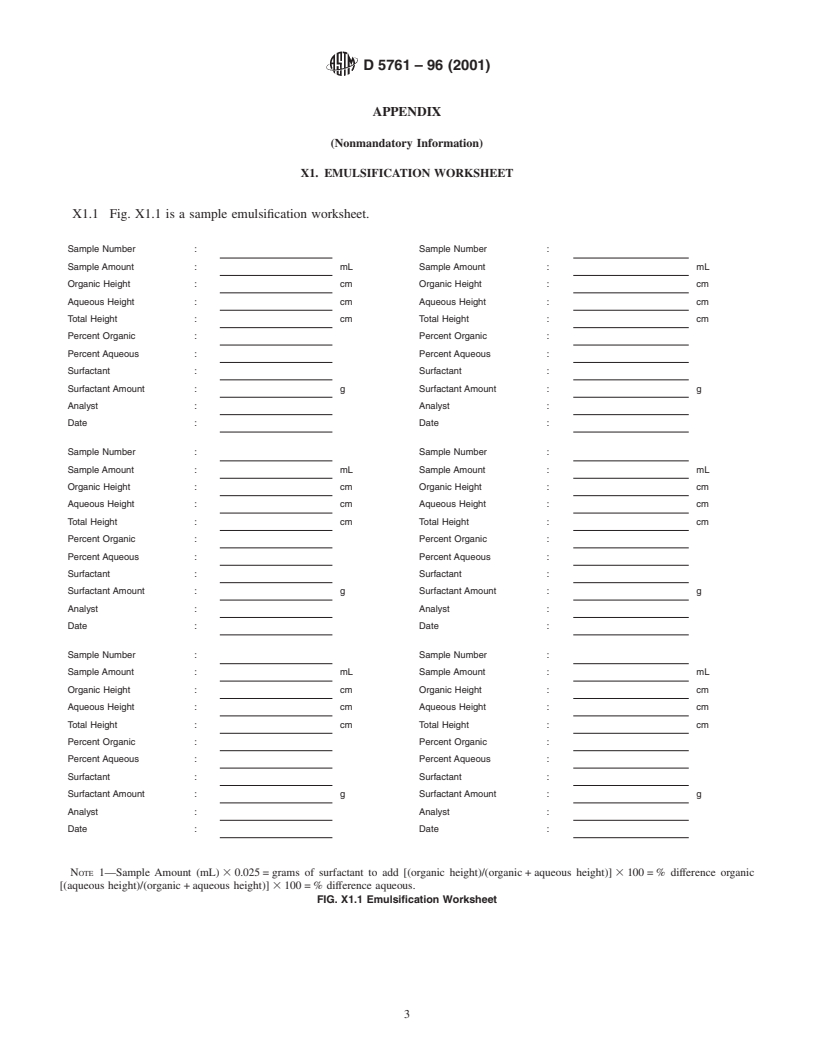

D 5761 – 96 (2001)

6.3 In some instances, the amount of sample submitted may 9.2 Vigorously shake multiphase samples by hand, or by

not be sufficient for splitting and, as a result, cannot be mechanicalmeans,forupto30s.Ifwithin1minaftershaking,

emulsified if some unemulsified sample must be retained. the sample appears to separate and each of the layers consists

6.4 Erroneous results can be obtained if precautions are not of at least 10 % by volume of the total, and if there is a

taken to avoid the loss of volatile material. Do not open sufficientsampleavailablebasedonsubsequenttestingrequire-

containers unnecessarily. Results for samples from leaky con- ments, then the sample is a candidate for the emulsification

tainersmustbemarkedtoindicatethatthesampleintegritywas procedure.

not maintained during shipping/storage. 9.3 (Optional.) If some unemulsified sample is to be re-

tained, split the sample into two separate samples using the

7. Apparatus

splitter funnel shown in Fig. 1.

9.4 Tentatively classify any liquid phase, using information

7.1 Funnel, Splitting—2-L separatory funnel fitted with

known about the sample, as organic or aqueous and determine

twin 0.7-mm inside diameter glass discharge tubes as shown in

their volume percentages relati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.