ASTM E2382-04

(Guide)Guide to Scanner and Tip Related Artifacts in Scanning Tunneling Microscopy and Atomic Force Microscopy

Guide to Scanner and Tip Related Artifacts in Scanning Tunneling Microscopy and Atomic Force Microscopy

SCOPE

1.1 All microscopes are subject to artifacts. The purpose of this document is to provide a description of commonly observed artifacts in scanning tunneling microscopy (STM) and atomic force microscopy (AFM) relating to probe motion and geometric considerations of the tip and surface interaction, provide literature references of examples and, where possible, to offer an interpretation as to the source of the artifact. Because the scanned probe microscopy field is a burgeoning one, this document is not meant to be comprehensive but rather to serve as a guide to practicing microscopists as to possible pitfalls one may expect. The ability to recognize artifacts should assist in reliable evaluation of instrument operation and in reporting of data.

1.2 A limited set of terms will be defined here. A full description of terminology relating to the description, operation, and calibration of STM and AFM instruments is beyond the scope of this document.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2382 − 04

Guideto

Scanner and Tip Related Artifacts in Scanning Tunneling

Microscopy and Atomic Force Microscopy

This standard is issued under the fixed designation E2382; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope remain constant during the generation of the image. The

“image” is therefore a contour plot of a constant value of the

1.1 All microscopes are subject to artifacts. The purpose of

surface property under study (for example, tunneling current in

this document is to provide a description of commonly

STM or lever deflection in AFM).

observed artifacts in scanning tunneling microscopy (STM)

and atomic force microscopy (AFM) relating to probe motion

3.1.3 tip—the physical probe used in either STM or AFM.

and geometric considerations of the tip and surface interaction,

For STM the tip is made from a conductive metal wire (for

provide literature references of examples and, where possible,

example, tungsten or Pt/Ir) while for AFM the tip can be

to offer an interpretation as to the source of the artifact.

conductive (for example, doped silicon) or non-conductive (for

Because the scanned probe microscopy field is a burgeoning

example, silicon nitride). The important performance param-

one,thisdocumentisnotmeanttobecomprehensivebutrather

eters for tips are the aspect ratio, the radius of curvature, the

to serve as a guide to practicing microscopists as to possible

opening angle, the overall geometrical shape, and the material

pitfalls one may expect. The ability to recognize artifacts

of which they are made.

should assist in reliable evaluation of instrument operation and

3.1.4 cantilever or lever—the flexible beam onto which the

in reporting of data.

AFM tip is placed at one end with the other end anchored

1.2 A limited set of terms will be defined here. A full

rigidly to the microscope. The important performance param-

description of terminology relating to the description,

eters for cantilevers are the force constant (expressed in N/m)

operation, and calibration of STM and AFM instruments is

and resonance frequency (expressed in kHz typically). These

beyond the scope of this document.

values will depend on the geometry and material properties of

the lever.

2. Referenced Documents

3.1.5 scanner—the device used to position the sample and

2.1 ASTM Standards:

tip relative to one another. Generally either the tip or sample is

E1813 Practice for Measuring and Reporting Probe Tip

scanned in either STM or AFM. The scanners are typically

Shape in Scanning Probe Microscopy

made from piezoelectric ceramics. Tripod scanners use three

independent piezo elements to provide motion in x, y, and z.

3. Terminology

Tube scanners are single element piezo materials that provide

3.1 Definitions of Terms Specific to This Standard:

coupled x,y,z motion. The important performance parameters

3.1.1 artifact—any feature of an image generated by an

for scanners are the distance of movement per applied volt

AFM or STM that deviates from the true surface.Artifacts can

(expressed as nm/V) and the lateral and vertical scan ranges

have origins in sample preparation, instrument hardware/

(expressed in microns).

software, operation, post processing of data, etc.

3.1.6 scan angle—the angle of rotation of the x scan axis

3.1.2 image—surface topography represented by plotting

relative to the x-axis of the sample

the z value for feature height as a function of x and y position.

Typically the z height value is derived from the necessary z

3.1.7 tip characterizer—a special sample used to determine

voltage applied to the scanner to allow the feedback value to the geometry of the tip.The tip in question is used to image the

characterizer.Theimagethenbecomesaninputtoanalgorithm

for determining the tip geometry.

This guide is under the jurisdiction of ASTM Committee E42 on Surface

Analysis and is the direct responsibility of Subcommittee E42.14 on STM/AFM.

3.2 Abbreviations Used in this Document:

Current edition approved Aug. 1, 2004. Published September 2004. DOI:

10.1520/E2382-04. 3.2.1 AFM—atomic force microscopy (microscope). We

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

refer here to contact mode AFM as opposed to non-contact

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

techniques.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 3.2.2 STM—scanning tunneling microscopy (microscope).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2382 − 04

4. Significance and Use

4.1 This compilation is limited to artifacts observed in

scanning tunneling microscopes and contact-mode atomic

force microscopes. In particular, this document focuses on

artifacts related to probe motion and geometrical consider-

ations of the tip and surface interaction. Many of the artifacts

described here extend to other scanned probe microscopies

where piezoscanners are used as positioning elements or where

tips of similar geometries are used. These are not the only

artifacts associated with measurements obtained by STM or

AFM. Artifacts can also arise from the following: control

electronics (for example, improper feedback gains); noise

(mechanical, acoustic, or electronic); drift (thermal or me-

chanical); problems unique to signal detection methods (for

example, laser spillover in optical lever schemes); improper

use of image processing (real time or post processed); sample

preparation, environment (for example, humidity) and tip-

surface interaction (for example, excessive electrostatic,

adhesive, shear, and compressive forces). It is suggested that

these other types of artifacts form the basis of future ASTM

guides.

5. Artifacts in STM and AFM

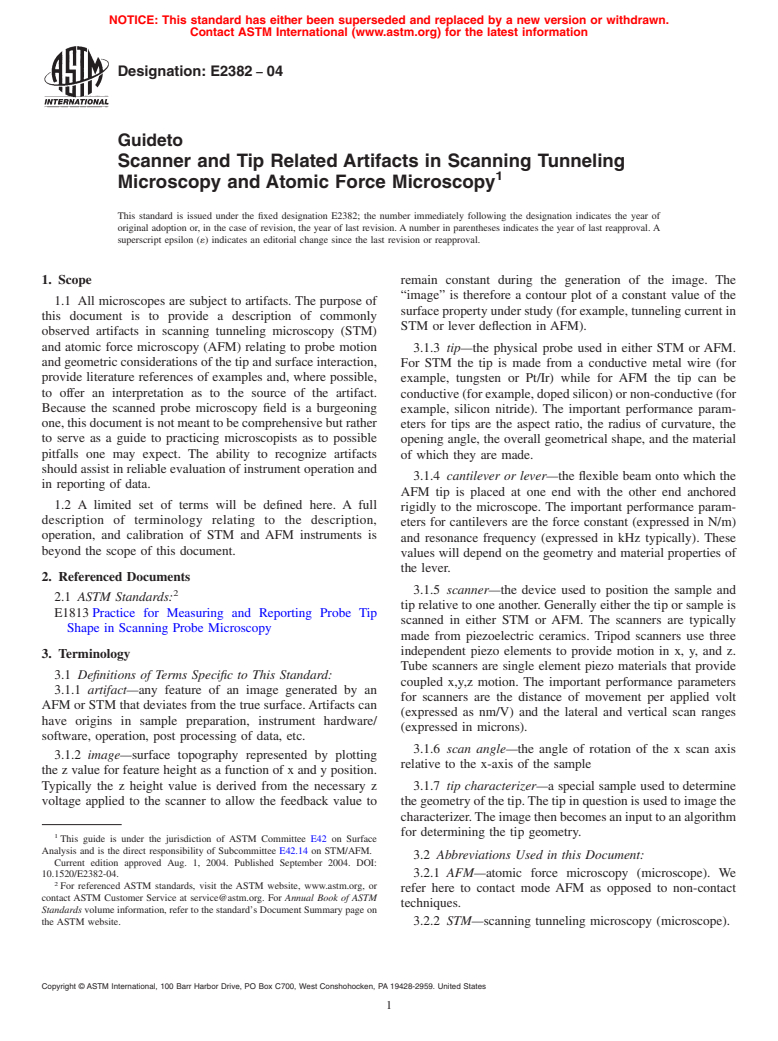

FIG. 1 Ideal behavior of a piezoelectric scanner in one dimension

(either x, y, or z).

5.1 Artifacts arising from Scanner Motion— Scanners are

made from piezoelectric ceramic materials used to accurately

position the tip relative to the surface on the nanometer scale.

They exhibit an inverse piezoelectric effect where the material

will undergo dimensional change in an applied electric field.

Ideal behavior is often assumed when using these devices in

STM or AFM microscopes. Ideal behavior implies: 1) linear

response in dimensional change per applied volt; 2) no

dependence of the dimensional response on the direction of the

voltage change, the magnitude of the voltage change, or the

rate of the voltage change (Fig. 1). The motions of these

devices are subject to deviations that include non-linearity,

hysteresis, and creep (1-5). In addition to these non-ideal

motions which are characteristic of independent scanner axes,

artifacts may arise as a consequence of coupling between the

axes.

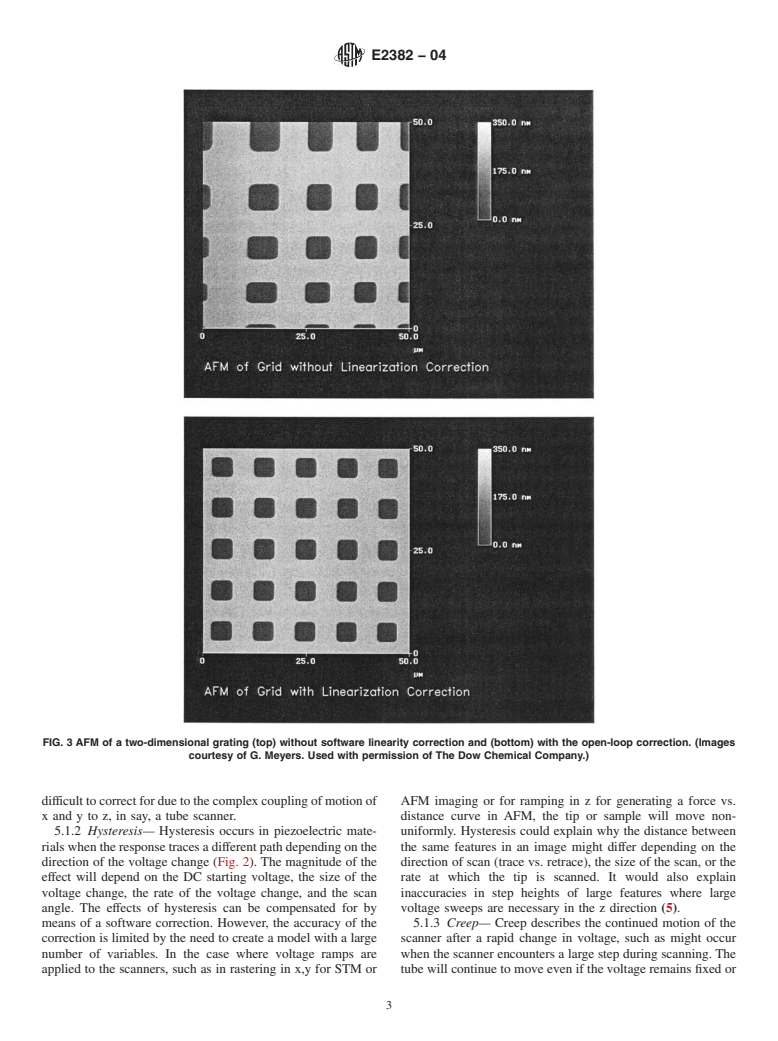

5.1.1 Non-linearity— Non-linearity means that the response

of the scanner in nm/V changes as a function of applied

voltage.Typically the response deviates more at larger positive

or negative voltages than near zero applied volts (2) (Fig. 2).

Non-linear effects in the lateral direction (x,y) can be observed

most clearly when scanning a periodic structure with known

spatial frequencies such as a diffraction grating . Since the

scanner does not move linearly with applied voltage, the

FIG. 2 Non-ideal behavior in a piezoelectric scanner. Non-linear

measurement points will not be equally spaced. The observed

extension in response to linear applied voltage and hysteresis

spacings will vary over the image and some linear features will

where the sensitivity varies depending on direction of applied

appear curved. While obvious for test structures, this effect voltage.

could go unnoticed on other samples that do not have evenly

spaced surface features. This effect can be compensated for in

additionalpositionsensorsuchasacapacitorplate(closedloop

software by applying a non-linear voltage ramp during scan-

method) (5).An example of the open loop correction method is

ning based on prior calibration (open loop method) or by

given in Fig. 3. Non-linear effects in z or height measurements

independently measuring the position of the scanner using an

are less obvious but can be detected using vertical height

standards (4).Theyaremostnoticeablewhentryingtomeasure

small features (small changes in V) and large features (large

The boldface numbers in parentheses refer to a list of references at the end of

this standard. changes in V) within the same scan. They are also more

E2382 − 04

FIG. 3 AFM of a two-dimensional grating (top) without software linearity correction and (bottom) with the open-loop correction. (Images

courtesy of G. Meyers. Used with permission of The Dow Chemical Company.)

difficulttocorrectforduetothecomplexcouplingofmotionof AFM imaging or for ramping in z for generating a force vs.

x and y to z, in say, a tube scanner. distance curve in AFM, the tip or sample will move non-

5.1.2 Hysteresis— Hysteresis occurs in piezoelectric mate- uniformly. Hysteresis could explain why the distance between

rialswhentheresponsetracesadifferentpathdependingonthe the same features in an image might differ depending on the

direction of the voltage change (Fig. 2). The magnitude of the direction of scan (trace vs. retrace), the size of the scan, or the

effect will depend on the DC starting voltage, the size of the rate at which the tip is scanned. It would also explain

voltage change, the rate of the voltage change, and the scan inaccuracies in step heights of large features where large

angle. The effects of hysteresis can be compensated for by voltage sweeps are necessary in the z direction (5).

means of a software correction. However, the accuracy of the 5.1.3 Creep— Creep describes the continued motion of the

correction is limited by the need to create a model with a large scanner after a rapid change in voltage, such as might occur

number of variables. In the case where voltage ramps are when the scanner encounters a large step during scanning. The

applied to the scanners, such as in rastering in x,y for STM or tube will continue to move even if the voltage remains fixed or

E2382 − 04

sample. Some systems correct for this in real time by using a

line by line planefit of the data. Alternatively a polynomial

plane can be fit to and subtracted from the data set after image

capture. As with dynamic range effects the bowing artifact is

more common for long range scanners.

5.1.5.2 Abbe Offset Error —Another artifact related to

coupled motion is the Abbe offset error. When the point of

interest on the sample surface is displaced from the true

measuring system (that is, the undeflected scanner tube z-axis),

an angular error exists in the positioning system and, therefore,

the measured displacement. The magnitude of this error is

directly proportional to the length of the ‘lever arm’times the

angular offset in radians. In a scanned sample configuration the

lever length is estimated by the sum of the tube length plus the

distance to the sample surface. This sum is typically tens of

millimeters while the scanning displacement is only a few

micronssotheangularoffsetsaretypically<<0.0001(radians).

A good example of this effect is in the measurement of lattice

spacings in cleaved mica using a short tube scanner in contact

mode (6). As the sample height is increased the measured

lattice spacings decrease for the same xy scan size.

5.1.6 Ringing —Ringing occurs when the feedback ampli-

FIG. 4 Creep in a piezoelectric scanner is another non-ideal be-

fier gain or filter frequency is too high. This causes the tube to

havior. The scanner exhibits a delay in response to sudden volt-

oscillate or ring at high frequency and the image becomes

age changes (used with permission from ThermoMicroscopes,

dominated by noise. In extreme cases the ringing is audible.

now Veeco Instruments, Inc.).

Sometimes optimum imaging occurs with PID settings set just

below the onset of ringing, however, once other parameters are

changes sign.This is a time dependent effect and its magnitude

changed, for example, scan speed or size, the ringing may

will depend on the size of the voltage change and the rate of

return. Horizontal ringing is responsible for the turnaround

voltage change (Fig. 4). Creep accounts for the initial lateral

effect at image edges where the scanner reverses direction

drift apparent after zooming or moving to a new area which

during scanning.

will settle out after several scan lines have been recorded (Fig.

5.2 Artifacts Caused by the Tip —Artifacts derived from the

5a). Creep accounts for the overshoot and slopes at both the

STM or AFM probe tip is the most common sort of artifact

plateaus and bases in line profiles of periodic, tall features that

observed with scanned probe microscopes. Consideration of

have been recorded at a fast scan rate. It is also very noticeable

the geometry and shape, material of construction, and the

in generatingAFM force vs. distance curves where the x and y

possible presence of structural defects and contamination,

scans are disabled and the z element voltage is ramped. Both

assists in recognizing tip artifacts. The heights and depths of

hysteresis and creep account for the higher force seen in the

major surface features determine what portion of the tip

unloadingvs.loadingportionofthecurvesforthesamesample

interacts with the surface (and therefore which portion of the

displacement (so called “reverse-path” effect ()3) seen in Fig.

tipneedstobeconsideredasasourceofartifacts).Fig.6shows

5b.

an idealized tip characterized by an opening half-angle, α (α =

5.1.4 Dynamic Range— The maximum extension of a

30° in the example), an aspect ratio (length to base width (L/W

piezoceramic scanner in x, y, or z will depend on the response

= 1 in the example), and a spherical shape at the apex. The

of the piezo material, the size and shape of the scanner, and the

spherical tip described in Fig. 6 is idealized and one of many

maximum voltages that can be applied to the piezo electrodes.

possible or real descriptions of actual tips.

Each scanner has a stated range of x, y and z motion. Features

Table 1 summarizes the important performance parameters

in an image can appear clipped if the vertical height exceeds

for STM and AFM tips commercially available at this time. A

the available range of z motion prescribed for the scanner in

detailed description of analytical tip shapes and the means by

use. If the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.