ASTM D5235-18(2024)

(Test Method)Standard Test Method for Microscopic Measurement of Dry Film Thickness of Coatings on Wood Products

Standard Test Method for Microscopic Measurement of Dry Film Thickness of Coatings on Wood Products

SIGNIFICANCE AND USE

5.1 As a base for calibration adjustment or accuracy verification of dry film coating thickness measuring instruments.

5.2 The dry film thickness of coatings on wood or wood-based products is specified in written product warranties for proper decorative and protective performance of coatings on wood or wood-based products.

5.3 The minimum and maximum dry film thickness of coatings is recommended by coating companies for satisfactory decorative and protective performance on wood or wood-based products.

5.4 The average dry film thickness of coatings on wood or wood-based material may be used by manufacturing companies to estimate the theoretical cost of applied coatings.

5.5 The ratio of minimum to maximum dry film thickness on textured products is used as an indication of coating uniformity.

5.6 Specific coated product requirements may dictate certain film thickness determinations to be made. Agreement between buyer and seller may be advisable to accommodate product needs relative to dry film thickness.

SCOPE

1.1 This test method covers the measurement of dry film thickness of coatings applied to a smooth, textured or curved rigid substrate of wood or a wood-based product.

1.2 This test method covers the preparation of wood or wood-based specimens for the purpose of microscopic measurement of dry film thickness.

1.3 This test method suggests an analysis of dry film thickness of coatings on wood or wood-based products using a microscopic measurement.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5235 − 18 (Reapproved 2024)

Standard Test Method for

Microscopic Measurement of Dry Film Thickness of

Coatings on Wood Products

This standard is issued under the fixed designation D5235; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the measurement of dry film

thickness of coatings applied to a smooth, textured or curved

3. Terminology

rigid substrate of wood or a wood-based product.

3.1 Definitions of Terms Specific to This Standard:

1.2 This test method covers the preparation of wood or

3.1.1 dry film thickness or DFT, n—the thickness of dried,

wood-based specimens for the purpose of microscopic mea-

cured coating film on the substrate surface which may include

surement of dry film thickness.

attached fibers but excludes free fibers that are encapsulated in

1.3 This test method suggests an analysis of dry film

the layer itself.

thickness of coatings on wood or wood-based products using a

3.1.2 edge face, n—that part of the specimen that is a plane

microscopic measurement.

perpendicular to the surface showing a cross section of the

1.4 The values stated in either SI units or inch-pound units

coating and substrate.

are to be regarded separately as standard. The values stated in

3.1.3 soak in, n—refers to a coating on a porous (wood)

each system are not necessarily exact equivalents; therefore, to

where the coating does not lie essentially on the surface of the

ensure conformance with the standard, each system shall be

wood or wood-based product, but has penetrated into the fiber

used independently of the other, and values from the two

structure of the wood or wood-based material.

systems shall not be combined.

3.1.3.1 Discussion—Wood or wood-based products are gen-

1.5 This standard does not purport to address all of the

erally of a porous nature; sometimes exhibiting uniform

safety concerns, if any, associated with its use. It is the

absorption of coatings. Frequently absorption of coatings is of

responsibility of the user of this standard to establish appro-

a non-uniform nature and influenced by localized surface

priate safety, health, and environmental practices and deter-

density differences or wood pore size. These conditions of

mine the applicability of regulatory limitations prior to use.

coating absorption are commonly referred to as soak in.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Summary of Test Method

ization established in the Decision on Principles for the

4.1 A specimen of coated wood or wood-based product is

Development of International Standards, Guides and Recom-

cut to convenient size and edge face with the coating film

mendations issued by the World Trade Organization Technical

cross-section is prepared by polishing or cutting with a sharp

Barriers to Trade (TBT) Committee.

blade.

2. Referenced Documents

4.2 The prepared edge of the specimen is imaged by a

2.1 ASTM Standards:

calibrated imaging system with known magnification in order

E177 Practice for Use of the Terms Precision and Bias in

to measure the dry film thickness using an image analysis

ASTM Test Methods

computer program.

4.3 Suggestions regarding interpretation of dry film thick-

This test method is under the jurisdiction of ASTM Committee D01 on Paint

ness on porous wood or wood-based material are offered.

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.52 on Factory Coated Wood Products.

Current edition approved Feb. 1, 2024. Published February 2024. Originally 5. Significance and Use

approved in 1992. Last previous edition approved in 2018 as D5235 – 18. DOI:

5.1 As a base for calibration adjustment or accuracy verifi-

10.1520/D5235-18R24.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or cation of dry film coating thickness measuring instruments.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 The dry film thickness of coatings on wood or wood-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. based products is specified in written product warranties for

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5235 − 18 (2024)

proper decorative and protective performance of coatings on 8. Procedure

wood or wood-based products.

8.1 Specimen Preparation—Select the area to be measured

for coating thickness and remove it from the coated wood or

5.3 The minimum and maximum dry film thickness of

wood-based material by a suitable method. Methods of sawing,

coatings is recommended by coating companies for satisfactory

core drilling, chiseling etc., can be used. Avoid collection of

decorative and protective performance on wood or wood-based

samples near the edges of sheeting material or the ends of

products.

boards, particularly those coated in vacuum coaters, unless

5.4 The average dry film thickness of coatings on wood or

defective coating application is being investigated. For tex-

wood-based material may be used by manufacturing compa-

tured surfaces, areas representative of varying degrees of

nies to estimate the theoretical cost of applied coatings.

texture (average, extreme, minimal or non-existent) should be

5.5 The ratio of minimum to maximum dry film thickness

selected. Take care that areas of interest are not damaged.

on textured products is used as an indication of coating Cutting across wood grains is preferable in exposure of area of

uniformity.

the interest and must be conducted when a coated rough wood

surface is being tested. Inspection of the surface of interest for

5.6 Specific coated product requirements may dictate cer-

excessive damage, as well as preliminary assessment of coat-

tain film thickness determinations to be made. Agreement

ing conditions and uniformity of application should be con-

between buyer and seller may be advisable to accommodate

ducted under a microscope. Appropriate areas for coating dry

product needs relative to dry film thickness.

film thickness measurements should be selected based on

testing purpose.

6. Apparatus

8.1.1 Frequently the purpose of testing is the measurement

6.1 Microscope with Attached Digital Camera (see Note 1),

of the average coating dry film thickness for coating spread

providing sufficient magnification and image quality in the

assessment or identification of areas with excessively thick or

field of view; generally 100× to 200× magnification is suffi-

thin coating dry film thickness.

cient.

8.2 Specimen Surface Preparation—Two methods are de-

NOTE 1—Certain digital cameras can provided sufficient magnification

scribed for specimen surface preparation due to the variability

and image quality of the coating cross-section without a microscope.

in the properties of wood coatings. Method A is recommended

6.2 Source of Oblique Illumination, for the microscope.

to be used for hard coatings, for example, melamine furniture

coating or polyester coating, which are brittle at room tem-

6.3 Image Analysis Program, with capabilities for lines to

perature and could shatter in contact with a sharp blade.

be drawn along the coating/substrate interface and the coating

Method B is recommended for flexible, exterior finishes, which

surface and for calculation of the average distance between

would smear in contact with sandpaper. Such smearing may

these lines on the specimen image.

mask the appearance of voids or fracture lines in the coating

6.4 Microscope Image Calibration Tool.

and substrate and may eliminate coating/wood substrate inter-

6.5 Cutoff Saw. face details, thereby increasing measurement error.

6.6 Belt or Disc Sander. 8.3 Method A:

8.3.1 Select the desired coated area of a wood or wood-

6.7 C-Type Clamp.

based material that is to be measured for dry film thickness.

6.8 Sharp Utility Knife or Razor Blade.

With the cutoff saw, cut off a sample at least 38.1 mm [1 ⁄2 in.]

wide from this area for mounting and encapsulation in casting

7. Materials

resin (Note 2).

7.1 200 and 600-Grit Sand Paper.

NOTE 2—Some specimens could be satisfactorily prepared and tested

without mounting. Mounting may be omitted, if careful microscopic

7.2 Mould, such as a paper cup, aluminum weighing dish, or

inspection of the sanded specimen does not show any damage to the area

a 50.8 mm [2 in.] or larger diameter plastic pipe that is at least

of interest or coating edge distortion.

25.4 mm [1 in.] high.

8.3.2 Cut this specimen to a length that is at least 12.7 mm

[ ⁄2 in.] less than the inside diameter of the mold to be used.

7.3 Source of Sanding Adhesive, which is used as encapsu-

lating medium such as: 8.3.3 Place the specimen, with the sample edge to be

measured, face down and approximately centered in the mold.

7.3.1 Hot Melt Glue,

8.3.4 Prepare the sanding adhesive according to the manu-

7.3.2 Fast-Cure Acrylic Mounting Kit, or

facturer’s directions for use. A dispersed pigment may be

7.3.3 Epoxy.

added to the adhesive for better microscopic contrast between

7.4 Solvent-borne Tint Dispersion, which is compatible with

the dry film and the adhesive.

the sanding adhesive.

8.3.5 Pour the sanding adhesive around the sample in the

mold and allow to harden according to the manufacturer’s

7.5 Mineral Oil.

directions.

7.6 Automotive Red Transmission Oil.

8.3.6 Remove the mold from the hardened and encapsulated

7.7 Zinc Stearate Powder. specimen edge.

D5235 − 18 (2024)

8.3.7 Using a disc sander, belt sander or 200-grit sandpaper 8.5 Dry Film Thickness Measurement From the Image of the

mounted on a glass plate, sand the edge face of the encapsu- Edge Face of the Specimen:

lated specimen until the edge face is relatively smooth. 8.5.1 Place the polished or clean cut edge face under the

Maintain the edge face of the specimen as flat as possible microscope lens.

during sanding. Avoid heat buildup of the sanding adhesive by 8.5.2 Adjust the illuminating light at a convenient oblique

intermittent sanding if necessary. angle. Proper light angle adjustment is helpful in obtaining

8.3.8 Polish the edge face of the rough sanded specimen as good contrast along the coating surface edge, inter-coat

follows: boundaries, and coating/wood interface. This is particularly

8.3.8.1 Mount a piece of 600-grit sandpaper on a flat glass important when measuring transparent coating DFT.

plate. Rub the edge face of the rough sanded specimen over the 8.5.3 Adjust magnification. Generally 100× magnification is

600-grit sandpaper in one direction, then reverse direction by sufficient for coating DFT above 50 μm and 200× magnifica-

180° for several more rubs. Zinc stearate powder can be tion is sufficient for coating DFT above 25 μm. Lower

sprinkled on the 600-grit sandpaper or the 600-grit sandpaper magnification allows for a larger field of view which is

can be wetted with mineral oil to produce a highly polished beneficial when measuring a coating applied to rough wood

edge face free of scratches. containing peaks and valleys.

8.3.8.2 Some laboratories find that a mold for the specimen 8.5.4 Adjust contrast and lighting for best imaging of the

encapsulation with sanding adhesive is not necessary. In this coating surface edge and coating/wood interface.

case two specimens are prepared with the cutoff saw. The 8.5.5 To improve contrast between wood and coating inter-

sanding adhesive after proper mixing is generously applied to face light coat of mineral oil or automotive red transmission

the coated face of each specimen, the specimens are placed fluid may be applied.

together and a C-clamp is used to squeeze out some of the 8.5.6 Capture image of the edge face of the specimen

sanding adhesive. The C-clamp is not removed until sanding preferably with the coating film cross-section in the centre of

adhesive has hardened. the field of view.

8.5.7 Capture calibration image (Note 3) at the same mag-

8.4 Method B:

nification.

8.4.1 Select the desired area of coated wood or wood-based

material that is to be measured for dry film thickness and obtain

NOTE 3—A certified silicon test specimen, with a 10 micron grid and

1.9 micron dividing lines, for imaging system calibration could be used.

a suitable sample using the cutoff saw or other appropriate tool

Such a specimen can be supplied by Agar Scientific. Other objects with

cut off a suitable sample. There is a handling advantage if the

known dimensions measured with certified tools could also be used for

sample to be tested has a rectangular shape.

imaging and calibration.

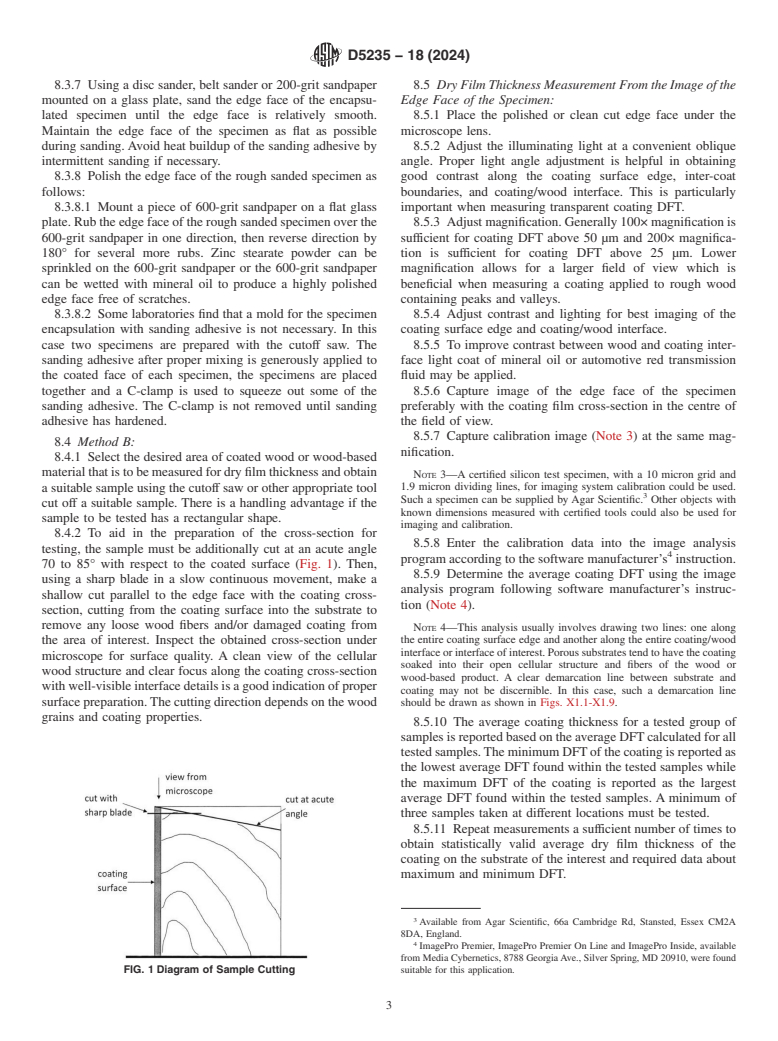

8.4.2 To aid in the preparation of the cross-section for

8.5.8 Enter the calibration data into the image analysis

testing, the sample must be additionally cut at an acute angle

program according to the software manufacturer’s instruction.

70 to 85° with respect to the coated surface (Fig. 1). Then,

8.5.9 Determine the average coating DFT using the image

using a sharp blade in a slow continuous movement, make a

analysis program following software manufacturer’s instruc-

shallow cut parallel to the edge face with the coating cross-

tion (Note 4).

section, cutting from the coating surface into the substrate to

remove any loose wood fibers and/or damaged coating from

NOTE 4—This analysis usually involves drawing two lines: one along

the entire coating surface edge and another along the entire coating/wood

the area of interest. Inspect the obtained cross-section under

interface or interface of interest. Porous substrates tend to have the coating

microscope for surface quality. A clean view of the cellular

soaked into their open cellular structure and fibers of the wood or

wood structure and clear focus along the coating cross-section

wood-based product. A clear demarcation line between substrate and

with well-visible interface details is a good indication of proper

coating may not be discernible. In this case, such a demarcation line

surface preparation. The cutting direction depends on the wood

should be drawn as shown in Figs. X1.1-X1.9.

grains and coating properties.

8.5.10 The average coating thickness for a tested group of

samples is reported based on the average DFT calculated for all

tested samples. The minimum DFT of the coating is reported as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.