ASTM D7572-09

(Guide)Standard Guide for Recovery of Aqueous Cyanides by Extraction from Mine Rock and Soil After Remediation of Process Releases

Standard Guide for Recovery of Aqueous Cyanides by Extraction from Mine Rock and Soil After Remediation of Process Releases

SIGNIFICANCE AND USE

This practice is intended as a means for obtaining an extract from mine rock and soil samples to verify the effectiveness of cyanide release remediation. Cyanide is analyzed in mine rock and soil extracts after remediation of process spills, to demonstrate regulatory compliance; however, improper sample collection and extraction can result in significant positive or negative bias, potentially resulting in unnecessary permit violations or undetected cyanide releases into the environment.

This practice is designed to mobilize aqueous cyanides present in the solids, so that the resulting extract can be used to assess leachate that could potentially be produced from remediated mine rock or soil in the field.

This practice is not intended to simulate actual site leaching conditions.

This practice produces extracts that are amenable to the determination of minor (trace) constituents. When minor constituents are being determined, it is especially important that precautions be taken in sample preservation, storage and handling to avoid possible contamination of the extracts.

This practice uses a comparative test method and is intended for use as a routine method for monitoring remediated mine rock and soils after process releases and remediation. It is assumed that all who use this practice will be trained analysts capable of performing it skillfully and safely. It is expected that work will be performed in a properly equipped laboratory applying appropriate quality control practices such as those described in Guide D 3856.

SCOPE

1.1 This guide is applicable for the collection, extraction and preservation of extracts from mine rock and soil samples after remediation of cyanide process releases for the analysis of cyanide in the extracts. Responsibilities of field sampling personnel and the laboratory are indicated.

1.2 The sampling, preservation and extraction procedures described in this practice are recommended for the analysis of total cyanide, available cyanide, weak acid dissociable cyanide, and free cyanide by Test Methods D 2036, D 4282, D 4374, D 6888, D 6994, D 7237, and D 7284. The information supplied in this practice can also be applied to other analytical methods for cyanide, for example, US EPA Method 335.4.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7572–09

Standard Guide for

Recovery of Aqueous Cyanides by Extraction from Mine

Rock and Soil After Remediation of Process Releases

This standard is issued under the fixed designation D7572; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4282 Test Method for Determination of Free Cyanide in

Water and Wastewater by Microdiffusion

1.1 This guide is applicable for the collection, extraction

D4374 Test Methods for Cyanides in Water—Automated

and preservation of extracts from mine rock and soil samples

Methods for Total Cyanide, Weak Acid Dissociable Cya-

afterremediationofcyanideprocessreleasesfortheanalysisof

nide, and Thiocyanate

cyanide in the extracts. Responsibilities of field sampling

D4840 Guide for Sample Chain-of-Custody Procedures

personnel and the laboratory are indicated.

D5847 Practice for Writing Quality Control Specifications

1.2 The sampling, preservation and extraction procedures

for Standard Test Methods for Water Analysis

described in this practice are recommended for the analysis of

D4841 Practice for Estimation of Holding Time for Water

total cyanide, available cyanide, weak acid dissociable cya-

Samples Containing Organic and Inorganic Constituents

nide,andfreecyanidebyTestMethodsD2036,D4282,D4374,

D6888 Test Method for Available Cyanide with Ligand

D6888, D6994, D7237, and D7284. The information supplied

Displacement and Flow InjectionAnalysis (FIA) Utilizing

in this practice can also be applied to other analytical methods

Gas Diffusion Separation and Amperometric Detection

for cyanide, for example, US EPA Method 335.4.

D6994 Test Method for Determination of Metal Cyanide

1.3 The values stated in SI units are to be regarded as

Complexes in Wastewater, Surface Water, Groundwater

standard.

and Drinking Water UsingAnion Exchange Chromatogra-

1.4 This standard does not purport to address all of the

phy with UV Detection

safety concerns, if any, associated with its use. It is the

D6696 Guide for Understanding Cyanide Species

responsibility of the user of this standard to establish appro-

D7237 Test Method for Aquatic Free Cyanide with Flow

priate safety and health practices and determine the applica-

Injection Analysis (FIA) Utilizing Gas Diffusion Separa-

bility of regulatory limitations prior to use.

tion and Amperometric Detection

2. Referenced Documents

D7284 Test Method for Total Cyanide in Water by Micro

Distillation followed by Flow InjectionAnalysis with Gas

2.1 ASTM Standards:

Diffusion Separation and Amperometric Detection

D75 Practice for Sampling Aggregates

D7365 Practice for Sampling, Preservation and Mitigating

D1129 Terminology Relating to Water

Interferences in Water Samples for Analysis of Cyanide

D1193 Specification for Reagent Water

D7511 Test Method for Total Cyanide by Segmented Flow

D1293 Test Methods for pH of Water

Injection Analysis, In-Line Ultraviolet Digestion and Am-

D2036 Test Methods for Cyanides in Water

perometric Detection

D3694 Practices for Preparation of Sample Containers and

E877 Practice for Sampling and Sample Preparation of Iron

for Preservation of Organic Constituents

Ores and Related Materials for Determination of Chemical

D3856 Guide for Good Laboratory Practices in Laborato-

Composition

ries Engaged in Sampling and Analysis of Water

2.2 U.S. EPA Methods:

EPA OIA-1677 Available Cyanide in Water

This practice is under the jurisdiction of ASTM Committee D19 on Water and

EPAMethod 335.2 Cyanide,Total (Titrimetric; Spectropho-

is the direct responsibility of Subcommittee D19.06 on Methods for Analysis for

tometric)

Organic Substances in Water.

EPA Method 335.4 Determination of Total Cyanide by

Current edition approved Oct. 1, 2009. Published October 2009. DOI: 10.1520/

D7572-09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from United States Environmental Protection Agency (EPA), Ariel

Standards volume information, refer to the standard’s Document Summary page on Rios Bldg., 1200 Pennsylvania Ave., NW, Washington, DC 20460, http://

the ASTM website. www.epa.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7572–09

Semi-Automated Colorimetry 6.2 Unless otherwise specified, samples must be extracted

within 72 hours and the extracts must be analyzed within 14

3. Terminology

days; however, it is recommended to estimate the actual

3.1 Definitions: For definitions of terms used in this prac-

holding time for each new sample matrix as described in

tice, refer to Terminology D1129 and Guide D6696. Practice D4841. Certain sample matrices may require imme-

3.2 Definitions of Terms Specific to This Standard:

diate analysis to avoid cyanide degradation due to interfer-

3.2.1 refrigeration, n—storingthesamplebetweenitsfreez- ences.Aholding time study is required if there is evidence that

ing point and 6°C.

cyanide degradation occurs from interferences which would

3.2.2 mine rock, n—ore, waste rock or overburden exca- cause the holding time to be less than specified in this practice

vated in order to construct an ore-processing site, or recover

or Practice D7365. Potential interferences for cyanide analyti-

metals or minerals during mining operations; or coarse pro- cal methods are shown in Table 1.

cessed ore such as heap-leach spoils.

7. Apparatus

4. Summary of Guide

7.1 Agitation Equipment, of any type that rotates the extrac-

4.1 Samples are collected in appropriate containers at the

tion vessel in an end-over-end fashion at a rate of 30 6 2 r/min

remediation site, refrigerated and transported to the laboratory

such that the axis of rotation is horizontal and it passes through

where they are weighed, sub-sampled, the moisture is deter-

the center of the bottle (see Fig. 1).

mined and cyanides are extracted prior to analysis. Results of

7.2 Drying Pans or Dishes, for moisture content determina-

the analysis of the extract are applied to the original solid

tions, 500 g to 8 kg capacity.

sample to determine the apparent concentration of cyanides

7.3 Drying Oven—Any thermostatically controlled drying

dissolved in water present in the solids as the result of the

oven capable of maintaining a steady temperature of 62°C in

process release.

a range of 100 to 110°C.

7.4 Extraction Vessels, cylindrical, wide-mouth, of a com-

5. Significance and Use

position suitable to the nature of the mine rock or soil and

5.1 This practice is intended as a means for obtaining an

cyanide analyses to be performed, constructed of materials that

extract from mine rock and soil samples to verify the effec-

will not allow sorption of the constituents of interest, and

tivenessofcyanidereleaseremediation.Cyanideisanalyzedin

sturdy enough to withstand the impact of the falling sample

mine rock and soil extracts after remediation of process spills,

fragments. The size of the container should be selected so that

to demonstrate regulatory compliance; however, improper

the sample, plus extraction fluid occupy approximately

sample collection and extraction can result in significant

50–95 % of the container in order to provide good mixing

positive or negative bias, potentially resulting in unnecessary

without overfilling. The containers must have water-tight

permit violations or undetected cyanide releases into the

closures of sufficient diameter to fill with the samples.

environment.

7.5 Filtration Device, pressure or vacuum of a composition

5.2 This practice is designed to mobilize aqueous cyanides

suitable to the nature of the analyses to be performed and

present in the solids, so that the resulting extract can be used to

equipped with a pre-washed glass wool or equivalent filter.An

assess leachate that could potentially be produced from reme-

assembly for pre-filtration or a centrifuge may be required if

diated mine rock or soil in the field.

filtration is difficult. Warning—Avoid passing excessive

5.3 This practice is not intended to simulate actual site

amounts of air through the sample during filtration to prevent

leaching conditions.

liberation of toxic hydrogen cyanide or cyanogen chloride gas.

5.4 This practice produces extracts that are amenable to the

7.6 Laboratory Balance, capable of weighing to 1.0 g.

determination of minor (trace) constituents. When minor con-

7.7 pH Meter, with a readability of 0.01 units and an

stituents are being determined, it is especially important that

accuracy of at least 60.1 units at 25°C.

precautions be taken in sample preservation, storage and

handling to avoid possible contamination of the extracts. 8. Reagents

5.5 This practice uses a comparative test method and is

8.1 Purity of Reagents—Reagent grade chemicals shall be

intendedforuseasaroutinemethodformonitoringremediated

used in this practice. Unless otherwise indicated, it is intended

mine rock and soils after process releases and remediation. It is

that all reagents shall conform to the specifications of the

assumed that all who use this practice will be trained analysts

Committee on Analytical Reagents of the American Chemical

capableofperformingitskillfullyandsafely.Itisexpectedthat

Society, where such specifications are available. Other grades

work will be performed in a properly equipped laboratory

may be used, provided it is first ascertained that the reagent is

applying appropriate quality control practices such as those

of sufficiently high purity to permit its use without lessening

described in Guide D3856.

the accuracy of the determination.

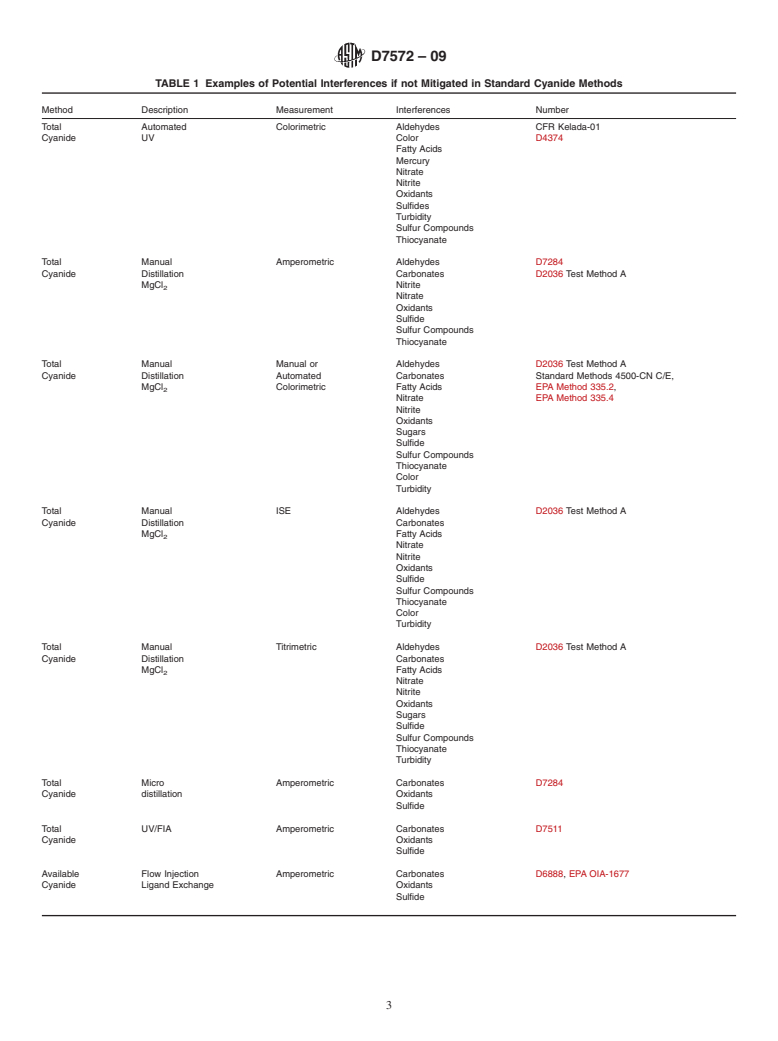

6. Interferences

6.1 Many interferences are known for the analysis of

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

cyanide and could effect the results of the analysis of extracts

listed by the American Chemical Society, see Annual Standards for Laboratory

produced using this practice. Refer to Practice D7365 for

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

proper handling of the extracts during sampling, mitigation of

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

interferences and preservation prior to cyanide analysis. MD.

D7572–09

TABLE 1 Examples of Potential Interferences if not Mitigated in Standard Cyanide Methods

Method Description Measurement Interferences Number

Total Automated Colorimetric Aldehydes CFR Kelada-01

Cyanide UV Color D4374

Fatty Acids

Mercury

Nitrate

Nitrite

Oxidants

Sulfides

Turbidity

Sulfur Compounds

Thiocyanate

Total Manual Amperometric Aldehydes D7284

Cyanide Distillation Carbonates D2036 Test Method A

MgCl Nitrite

Nitrate

Oxidants

Sulfide

Sulfur Compounds

Thiocyanate

Total Manual Manual or Aldehydes D2036 Test Method A

Cyanide Distillation Automated Carbonates Standard Methods 4500-CN C/E,

MgCl Colorimetric Fatty Acids EPA Method 335.2,

Nitrate EPA Method 335.4

Nitrite

Oxidants

Sugars

Sulfide

Sulfur Compounds

Thiocyanate

Color

Turbidity

Total Manual ISE Aldehydes D2036 Test Method A

Cyanide Distillation Carbonates

MgCl Fatty Acids

Nitrate

Nitrite

Oxidants

Sulfide

Sulfur Compounds

Thiocyanate

Color

Turbidity

Total Manual Titrimetric Aldehydes D2036 Test Method A

Cyanide Distillation Carbonates

MgCl Fatty Acids

Nitrate

Nitrite

Oxidants

Sugars

Sulfide

Sulfur Compounds

Thiocyanate

Turbidity

Total Micro Amperometric Carbonates D7284

Cyanide distillation Oxidants

Sulfide

Total UV/FIA Amperometric Carbonates D7511

Cyanide Oxidants

Sulfide

Available Flow Injection Amperometric Carbonates D6888, EPA OIA-1677

Cyanide Ligand Exchange Oxidants

Sulfide

D7572–09

TABLE 1 Continued

Method Description Measurement Interferences Number

Cyanide Alkaline Manual Aldehydes D2036 Test Method B

Amenable to Chlorination and Colorimetric Carbonates

Chlorination Manual Fatty Acids

Distillations Nitrate

Nitrite

Oxidants

Sulfide

Sulfur Compounds

Thiocyanate

Color

Turbidity

Unknowns that cause negative

results

Weak Acid Buffered Manual Aldehydes D2036 Test Method C

Dissociable Distillation Colorimetric Carbonates

Cyanide Fatty Acids

Nitrate

Nitrite

Oxidants

Sugars

Sulfide

Sulfur Compounds

Thiocyanate

Turbidity

Weak Acid Automated Automated Aldehydes D4374

Dissociable Method Colorimetric Color

Cyanide Fatty Acids

Mercury

Nitrate

Nitrite

Oxidants

Sulfides

Turbidity

Weak Acid Buffered ISE Aldehydes D2036 Test Method C

Dissociable Distillation Carbonates

Cyanide Fatty Acids

Nitrate

Nitrite

Oxidants

Sugars

Sulfide

Sulfur Compounds

Thiocyanate

Turbidity

Weak Acid Buffered Titrimetric Aldehydes D2036 Test Method C

Dissociable Distillation Carbonates

Cyanide Fatty Acids

Nitrate

Nitrite

Oxidants

Sugars

Sulfide

Sulfur Compounds

Thiocyanate

Turbidity

Weak Acid Manual Aldehydes D2036 Test Method B

Dissociable Colorimetric Carbonates

Cyanide Fatty Acids

Nitrite

Nitrate

Oxidants

Sugars

Sulfide

Sulfur Compounds

Thiocyanate

Volatile Compounds

D7572–09

TABLE 1 Continued

Method Description Measurement Interferences Number

Metal Ion UV Carbonate D6994

Cyanide Chromatography Dissolved Solids

Complexes Metal Anions

Metal Cations

Oxidants

Photodecomposition

Free Cyanide Flow Injection Amperometric Carbonate D7237

Oxidants

Sulfide

Free Cyanide Microdiffusion Colorimetric Aldehydes D4282

Oxidants

Sulfide

Sulfur Compounds

FIG. 1 Extractors

D7572–09

8.2 Purity of Water—Unless otherwise indicated, references 10.4.1 Sample and extract containers shall be made of

to water shall be understood to mean reagent water that meets materials that will not contaminate the sample, vapor barrier

the purity specifications of Type I or Type II water, presented bags and bottles need to be cleaned thoroughly to remove all

in D1193. extraneous surface contamination prior to use, if necessary.

8.3 Concentrated Sodium Hydroxide Solution (0.4 M)—In a Chemically resistant rigid plastic containers, such as those

1-Lvolumetric flask, dissolve 16 g NaOH in reagent water and made of high density polyethelene (HDPE) are suitable.

dilute to volume. Samples should be collected and stored in opaque containers

8.4 Dilute Sodium Hydroxide Solution Extraction Fluid and sealed in vapor barrier bags to minimize exposure to

(0.04 M)—In a 1-L volumetric flask, add 100 mL of 0.4 M ultraviolet radiation and loss of moisture and hydrogen cya-

NaOH in reagent water and di

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.