ASTM D7872-13

(Test Method)Standard Test Method for Determining the Concentration of Pipeline Drag Reducer Additive in Aviation Turbine Fuels

Standard Test Method for Determining the Concentration of Pipeline Drag Reducer Additive in Aviation Turbine Fuels

SIGNIFICANCE AND USE

5.1 DRA is frequently added into multiproduct pipelines to increase throughput or reduce energy requirements of fuel movement. Although these additives are not used in jet fuel, contamination can occur from other products if proper batching guidelines are not followed or by other cases of human error. CRC Report No. 642 reviewed the impact of DRA on jet fuel fit-for-purpose performance and concluded that the fuel spray angle and atomization capability of several engine-type fuel nozzles can be adversely affected impacting high altitude relight performance at elevated concentrations. A method that accurately quantifies the amount of DRA in jet fuel can be useful in confirming the absence of significant contamination to protect the safety of aviation operations. This test method is designed to measure down to sub-100 µg/L levels of DRA in aviation fuel.

SCOPE

1.1 This test method covers the measurement of high molecular weight polymers, in particular pipeline drag reducer additive (DRA), in aviation turbine fuels with a 72 µg/L lower detection limit. The method cannot differentiate between different polymers types. Thus, any non-DRA high molecular weight polymer will cause a positive measurement bias. Further investigation is required to confirm the polymer detected is DRA.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 Warning—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website — http://www.epa.gov/mercury/faq.htm — for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7872 − 13 An American National Standard

Standard Test Method for

Determining the Concentration of Pipeline Drag Reducer

1

Additive in Aviation Turbine Fuels

This standard is issued under the fixed designation D7872; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4177 Practice for Automatic Sampling of Petroleum and

Petroleum Products

1.1 This test method covers the measurement of high

molecular weight polymers, in particular pipeline drag reducer 2.2 Other Reference:

additive (DRA), in aviation turbine fuels with a 72 µg/L lower CRC Report No. 642 Investigation of Pipeline Drag Reduc-

detection limit. The method cannot differentiate between dif- ers in Aviation Turbine Fuels

ferent polymers types. Thus, any non-DRA high molecular

weight polymer will cause a positive measurement bias. 3. Terminology

Further investigation is required to confirm the polymer

3.1 Definitions:

detected is DRA.

3.1.1 bumping, v—violent boiling which displaces liquid

1.2 The values stated in SI units are to be regarded as

into the distillation flask.

standard. No other units of measurement are included in this

3.1.2 drag reducing additive (DRA), n—a material com-

standard.

prised of very high molecular weight hydrocarbon polymers

1.3 Warning—Mercury has been designated by many regu- that is soluble in petroleum products and used to reduce the

latory agencies as a hazardous material that can cause central fluid friction during pipeline transportation.

nervous system, kidney and liver damage. Mercury, or its

3.1.3 rotary evaporation, n—a distillation process utilizing

vapor, may be hazardous to health and corrosive to materials.

heat, reduced pressure and a rotating flask which evaporates

Caution should be taken when handling mercury and mercury

fluid to reduce the volume of a sample of material.

containing products. See the applicable product Material

3.1.3.1 Discussion—The apparatus, consisting of a round-

Safety Data Sheet (MSDS) for details and EPA’s website —

bottomed flask in a heated bath, is operated under vacuum

http://www.epa.gov/mercury/faq.htm — for additional infor-

(reduced pressure) to lower the boiling point of the fluid, and

mation. Users should be aware that selling mercury and/or

the rotational motion accelerates evaporation of the liquid by

mercury containing products into your state or country may be

creating additional surface area of the fluid being distilled off.

prohibited by law.

3.1.4 sheared DRA, n—the very long hydrocarbon polymers

1.4 This standard does not purport to address all of the

of drag reducing agent that have been shortened by severe

safety concerns, if any, associated with its use. It is the

physical processes such that the resulting material is no longer

responsibility of the user of this standard to establish appro-

effective at reducing fluid friction.

priate safety and health practices and determine the applica-

3.1.4.1 Discussion—Severe physical and mechanical pro-

bility of regulatory limitations prior to use.

cesses include large pressure changes which can occur at

control valves, pumps, meters, reductions in pipe diameter

2. Referenced Documents

which affect fluid velocity, and ultrasonication in a laboratory

2

2.1 ASTM Standards:

process, resulting in shorter polymeric chains which are still

D4057 Practice for Manual Sampling of Petroleum and

very large compared to the fuel molecules and are non-

Petroleum Products

distillable.

3.1.5 total exclusion, n—polymers larger than the pore size

1

This test method is under the jurisdiction of ASTM Committee D02 on

cannot enter the pores and elute together as the first peak in the

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

chromatogram.

Subcommittee D02.J0.01 on Jet Fuel Specifications.

Current edition approved June 15, 2013. Published September 2013. DOI:

3.2 Abbreviations:

10.1520/D7872-13.

3.2.1 DRA—drag reducing additive

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.2 GPC—gel permeation chromatography

Standards volume information, refer to the standard’s Document Summary page on

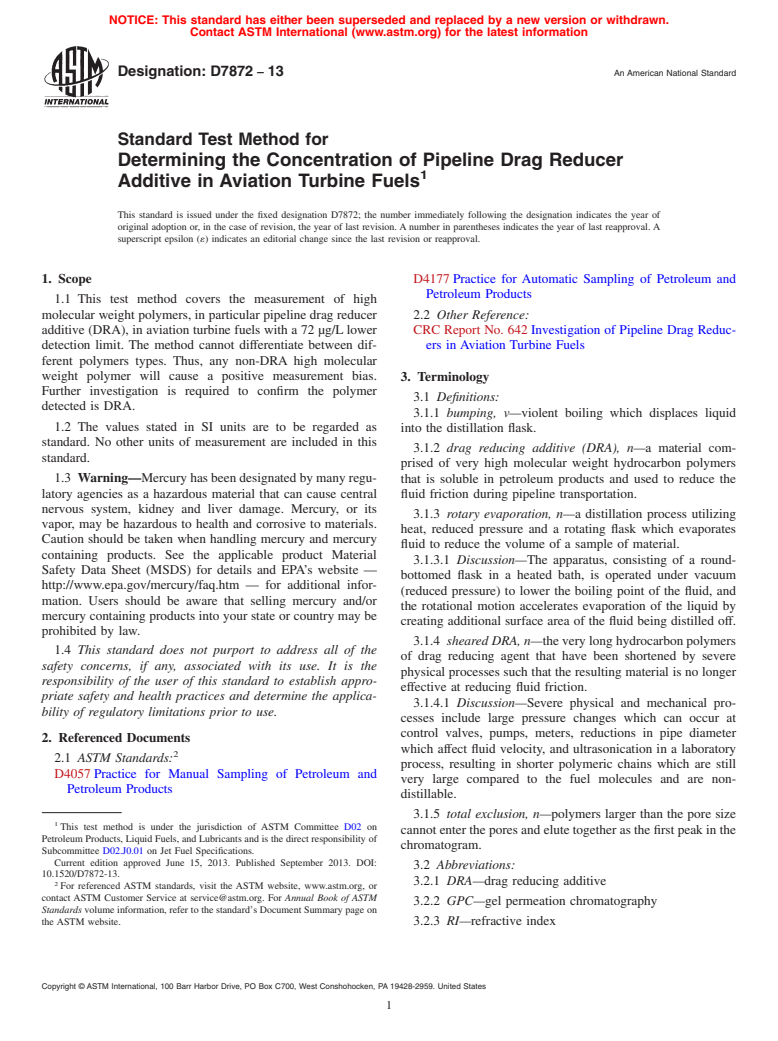

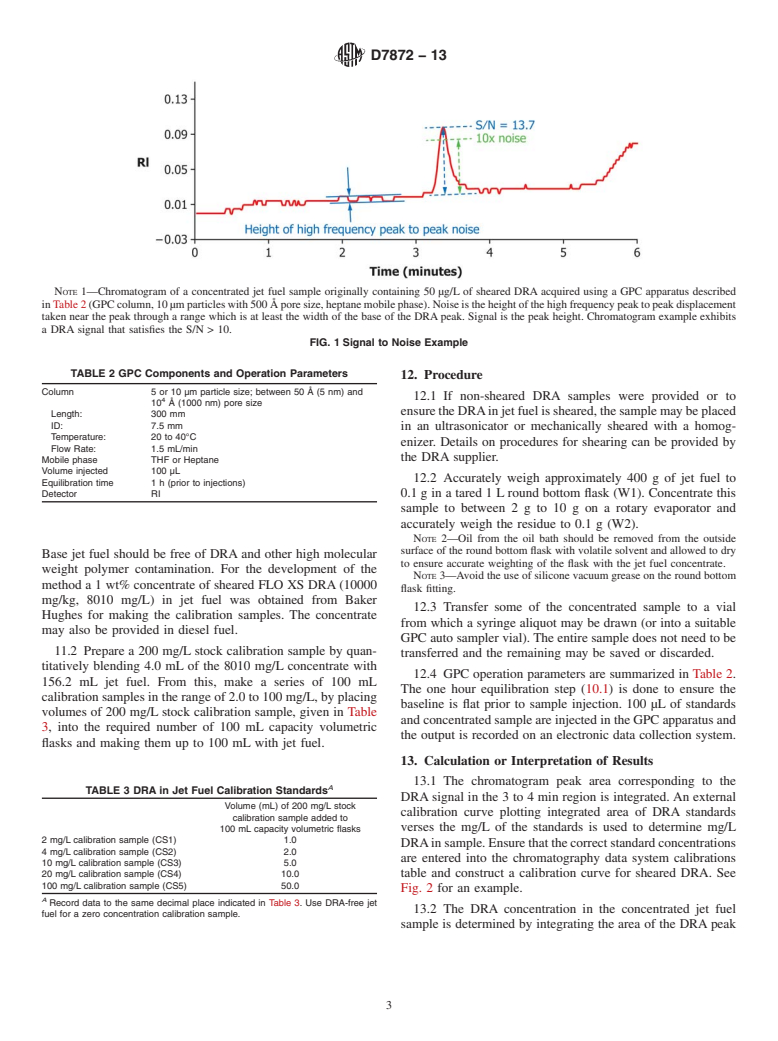

the ASTM website. 3.2.3 RI—refractive index

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7872 − 13

3.2.4 THF—tetrahydrofuran 7.2 Rotary evaporator, equipped with a silicone oil heating

bath that can accommodate flasks capable of holding 400 g of

4. Summary of Test Method

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.