ASTM A890/A890M-10

(Specification)Standard Specification for Castings, Iron-Chromium-Nickel-Molybdenum Corrosion-Resistant, Duplex (Austenitic/Ferritic) for General Application

Standard Specification for Castings, Iron-Chromium-Nickel-Molybdenum Corrosion-Resistant, Duplex (Austenitic/Ferritic) for General Application

ABSTRACT

This specification covers castings, iron-chromium-nickel-molybdenum corrosion-resistant, duplex(austenitic/ferritic) for general application. Castings shall be heat treated in accordance with the required procedure and heat-treat temperature. Proper heat treatment of these alloys is usually necessary to enhance corrosion resistance and in some cases to meet mechanical properties. Minimum heat-treat temperatures are specified; however, it is sometimes necessary to heat-treat at higher temperatures, hold for some minimum time at temperature and then rapidly cool the castings in order to enhance the corrosion resistance and meet the required mechanical properties. The steel shall conform to the required chemical composition for carbon, manganese, silicon, phosphorus, sulfur, chromium, nickel, molybdenum, copper, tungsten, and nitrogen. Castings shall be marked for material identification with the specification designation and grade.

SCOPE

1.1 This specification covers a group of cast duplex stainless steels (austenitic/ferritic).

1.2 The duplex stainless steel alloys offer a combination of enhanced mechanical properties and corrosion resistance when properly balanced in composition and properly heat treated. Ferrite levels are not specified, but these alloys will develop a range of approximately 30 to 60 % ferrite with the balance austenite.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3.1 Within the text, the SI units are shown in brackets.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A890/A890M – 10

Standard Specification for

Castings, Iron-Chromium-Nickel-Molybdenum Corrosion-

Resistant, Duplex (Austenitic/Ferritic) for General

1

Application

This standard is issued under the fixed designationA890/A890M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E1245 Practice for Determining the Inclusion or Second-

Phase Constituent Content of Metals by Automatic Image

1.1 Thisspecificationcoversagroupofcastduplexstainless

Analysis

steels (austenitic/ferritic).

1.2 The duplex stainless steel alloys offer a combination of

3. Ordering Information

enhanced mechanical properties and corrosion resistance when

3.1 Orders for material to this specification shall include the

properly balanced in composition and properly heat treated.

following, as required, to describe the material adequately:

Ferrite levels are not specified, but these alloys will develop a

3.1.1 Description of casting by pattern or drawing number

range of approximately 30 to 60 % ferrite with the balance

(dimensional tolerance shall be included on the casting draw-

austenite.

ing),

1.3 The values stated in either SI units or inch-pound units

3.1.2 Specification designation and grade including year of

are to be regarded separately as standard. The values stated in

issue,

each system may not be exact equivalents; therefore, each

3.1.3 Options in the specification (See 9.1), and

system shall be used independently of the other. Combining

3.1.4 Supplementary requirements desired, including the

values from the two systems may result in non-conformance

standards of acceptance.

with the standard.

1.3.1 Within the text, the SI units are shown in brackets.

4. Process

4.1 The steel shall be made by the electric furnace process

2. Referenced Documents

2 with or without separate refining such as argon-oxygen-

2.1 ASTM Standards:

decarburization (AOD).

A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

5. Heat Treatment

A732/A732M Specification for Castings, Investment, Car-

5.1 Castings shall be heat treated in accordance with the

bon and Low Alloy Steel for General Application, and

requirements in Table 1.

Cobalt Alloy for High Strength at Elevated Temperatures

A781/A781M Specification for Castings, Steel and Alloy,

NOTE 1—Proper heat treatment of these alloys is usually necessary to

Common Requirements, for General Industrial Use enhance corrosion resistance and in some cases to meet mechanical

properties. Minimum heat-treat temperatures are specified; however, it is

E29 Practice for Using Significant Digits in Test Data to

sometimes necessary to heat-treat at higher temperatures, hold for some

Determine Conformance with Specifications

minimum time at temperature and then rapidly cool the castings in order

E562 Test Method for Determining Volume Fraction by

to enhance the corrosion resistance and meet mechanical properties.

Systematic Manual Point Count

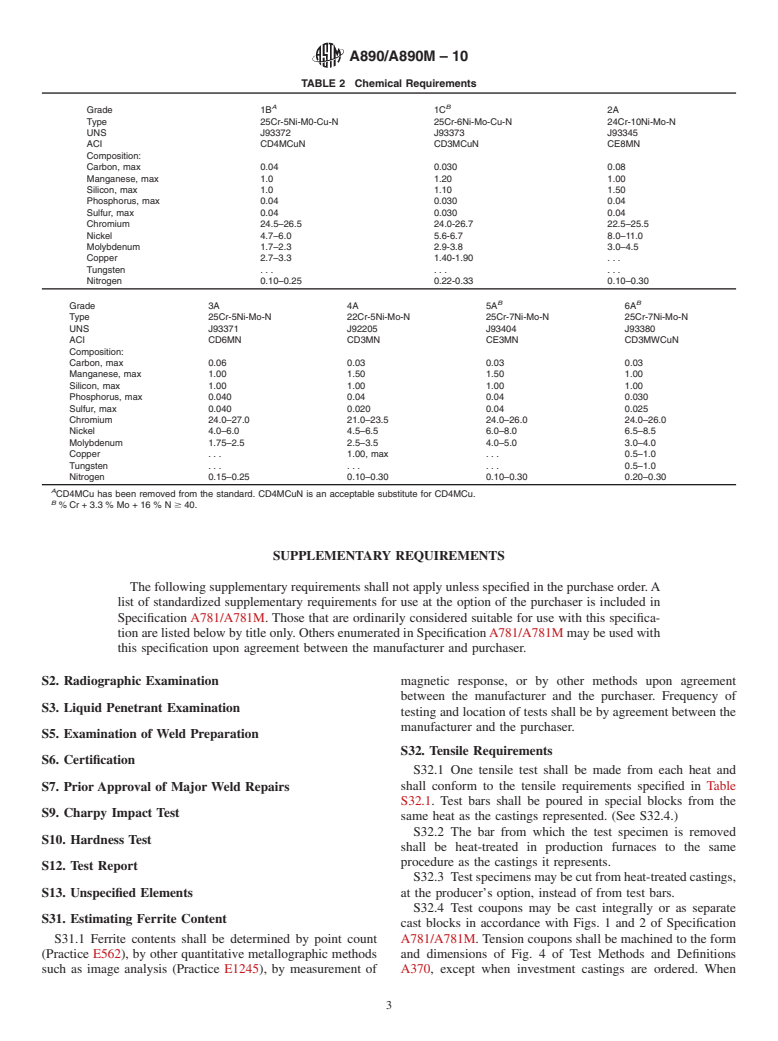

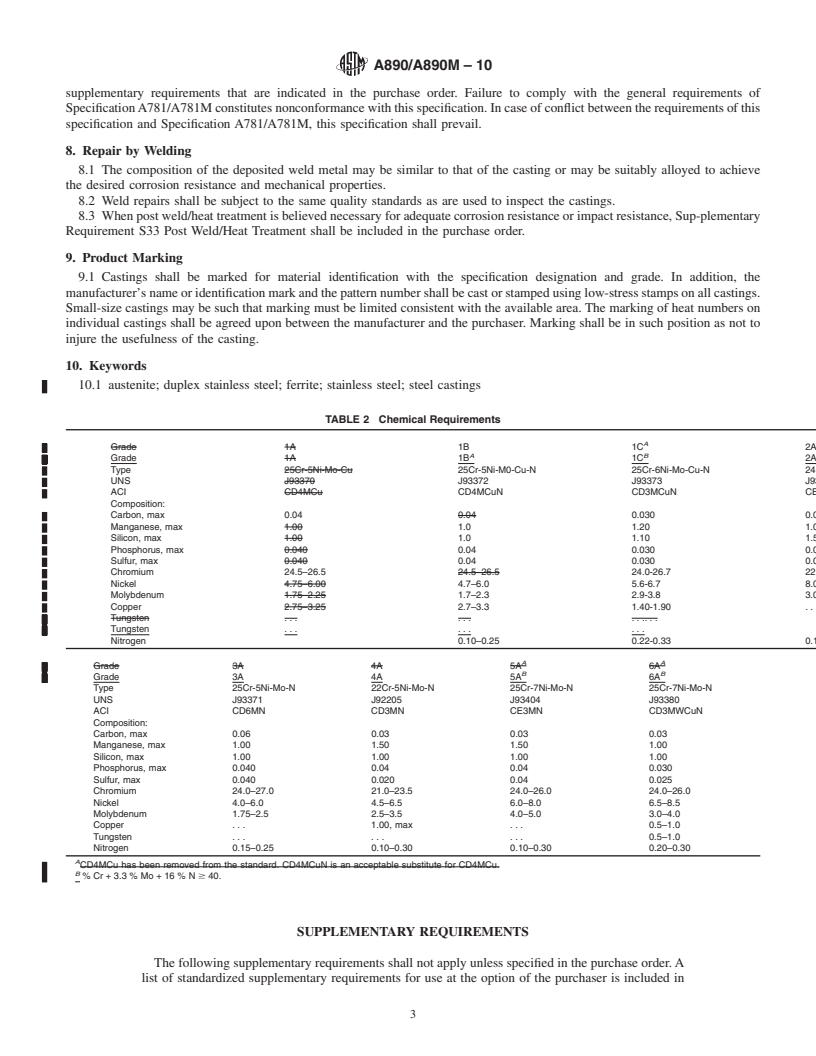

6. Chemical Composition

6.1 The steel shall conform to the requirements as to

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

chemical composition prescribed in Table 2.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.18 on Castings.

7. General Requirements

Current edition approved April 1, 2010. Published May 2010. Originally

7.1 Material furnished to this specification shall conform to

approved in 1988. Last previous edition approved in 2007 as A890/A890M – 99

(2007). DOI: 10.1520/A0890_A0890M-10.

the requirements of SpecificationA781/A781M, including any

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

supplementary requirements that are indicated in the purchase

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

order. Failure to comply with the general requirements of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Specification A781/A781M constitutes nonconformance with

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A890/A890M – 10

TABLE 1 Heat Treatment Requirements

8.2 Weld repairs shall be subject to the same quality

standards as are used to inspect the castings.

Grade Heat Treatment

8.3 When post weld/heat treatment is believed necessary for

1B, 1C Heat to 1900°F [1040°C] minimum, hold for sufficient time to

adequate corrosion resistance or impact resistance, Sup-

heat casting uniformly to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A890/A890M–99 (Reapproved 2007) Designation: A890/A890M – 10

Standard Specification for

Castings, Iron-Chromium-Nickel-Molybdenum Corrosion-

Resistant, Duplex (Austenitic/Ferritic) for General

1

Application

This standard is issued under the fixed designationA890/A890M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers a group of cast duplex stainless steels (austenitic/ferritic).

1.2 The duplex stainless steel alloys offer a combination of enhanced mechanical properties and corrosion resistance when

properly balanced in composition and properly heat treated. Ferrite levels are not specified, but these alloys will develop a range

of approximately 30 to 60 % ferrite with the balance austenite.

1.3 The values stated in either inch-poundSI units or metric (SI) inch-pound units are to be regarded separately as standard.

Within the text the metric (SI) units are shown in brackets. The values stated in each system aremay not be exact equivalents;

therefore, each system mustshall be used independently of the other. Combining values from the two systems may result in

non-conformance with the specification. standard.

1.3.1 Within the text, the SI units are shown in brackets.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A732/A732M Specification for Castings, Investment, Carbon and Low Alloy Steel for General Application, and Cobalt Alloy

for High Strength at Elevated Temperatures

A781/A781M Specification for Castings, Steel and Alloy, Common Requirements, for General Industrial Use

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E562 Test Method for Determining Volume Fraction by Systematic Manual Point Count

E1245 Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis

3. Ordering Information

3.1 Orders for material to this specification shall include the following, as required, to describe the material adequately:

3.1.1 Description of casting by pattern or drawing number (dimensional tolerance shall be included on the casting drawing),

3.1.2 Specification designation and grade including year of issue,

3.1.3 Options in the specification (See 9.1), and

3.1.4 Supplementary requirements desired, including the standards of acceptance.

4. Process

4.1 The steel shall be made by the electric furnace process with or without separate refining such as argon-oxygen-

decarburization (AOD).

5. Heat Treatment

5.1 Castings shall be heat treated in accordance with the requirements in Table 1.

NOTE 1—Proper heat treatment of these alloys is usually necessary to enhance corrosion resistance and in some cases to meet mechanical properties.

Minimum heat-treat temperatures are specified; however, it is sometimes necessary to heat-treat at higher temperatures, hold for some minimum time at

temperature and then rapidly cool the castings in order to enhance the corrosion resistance and meet mechanical properties.

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.18

on Castings.

Current edition approved Nov.April 1, 2007.2010. Published November 2007.May 2010. Originally approved in 1988. Last previous edition approved in 20032007 as

A890/A890M – 99 (2003).(2007). DOI: 10.1520/A0890_A0890M-99R07.10.1520/A0890_A0890M-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A890/A890M – 10

TABLE 1 Heat Treatment Requirements

Grade Heat Treatment

1A, 1B, 1C Heat to 1900°F [1040°C] minimum, hold for sufficient time to

heat casting uniformly to temperature, quench in water or rapid

cool by other means.

1B, 1C Heat to 1900°F [1040°C] minimum, hold for sufficient time to

heat casting uniformly to temperature, quenc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.