ASTM D5236-01

(Test Method)Standard Test Method for Distillation of Heavy Hydrocarbon Mixtures (Vacuum Potstill Method)

Standard Test Method for Distillation of Heavy Hydrocarbon Mixtures (Vacuum Potstill Method)

SCOPE

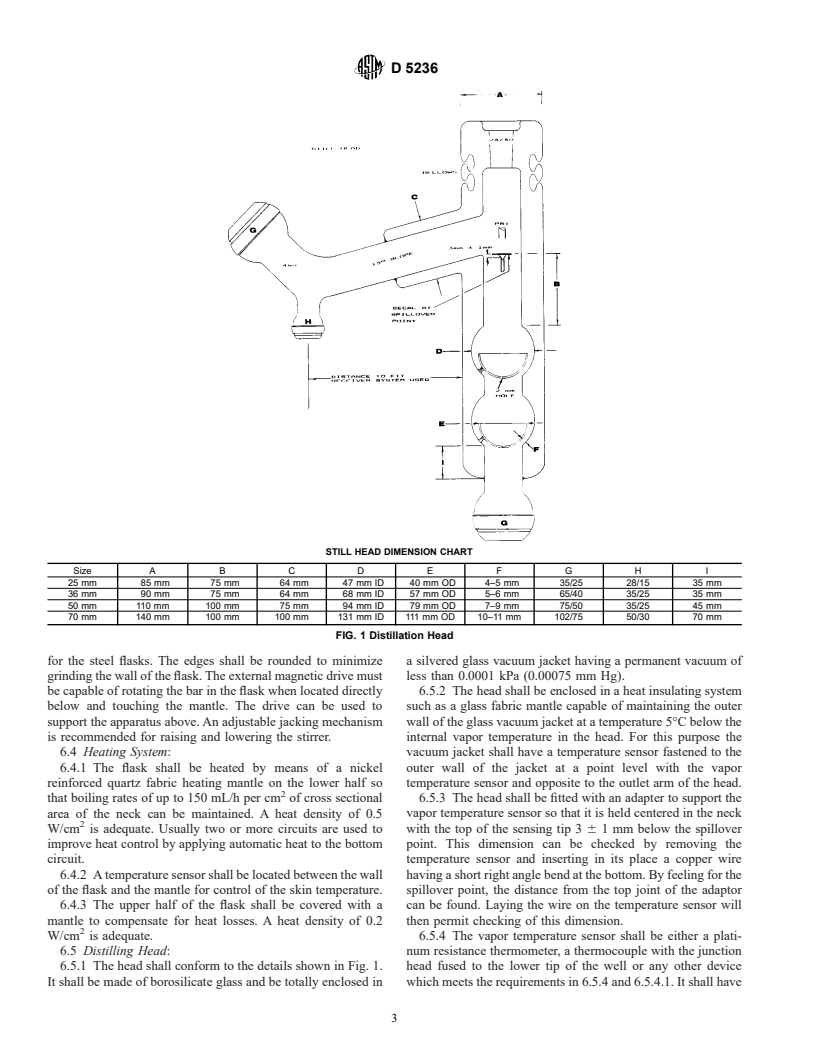

1.1 This test method covers the procedure for distillation of heavy hydrocarbon mixtures having initial boiling points greater than 150°C (300°F), such as heavy crude oils, petroleum distillates, residues, and synthetic mixtures. It employs a potstill with a low pressure drop entrainment separator operated under total takeoff conditions. Distillation conditions and equipment performance criteria are specified and typical apparatus is illustrated.

1.2 This test method details the procedures for the production of distillate fractions of standardized quality in the gas oil and lubricating oil range as well as the production of standard residua. In addition, it provides for the determination of standard distillation curves to the highest atmospheric equivalent temperature possible by conventional distillation.

1.3 The maximum achievable atmospheric equivalent temperature (AET) is dependent upon the heat tolerance of the charge. For most samples, a temperature up to 565°C (10570°F) can be attained. This maximum will be significantly lower for heat sensitive samples (for example, heavy residues) and might be somewhat higher for nonheat sensitive samples.

1.4 The recommended distillation method for crude oils up to cutpoint 400°C (752°F) AET is Test Method D 2892. This test method can be used for heavy crude oils with initial boiling points greater than 150—C (302°F). However, distillation curves and fraction qualities obtained by these methods are not comparable.

1.5 This test method contains the following annexes:

1.5.1 Annex A1—Test Method for Determination of the Temperature Response Time,

1.5.2 Annex A2—Practice for Calibration of Sensors,

1.5.3 Annex A3—Test Method for Dehydration of a Wet Sample of Oil,

1.5.4 Annex A4—Practice for Conversion of Observed Vapor Temperature to Atmospheric Equivalent Temperature (AET), and

1.5.5 Annex A5—Test Method for Determination of Wettage.

1.6 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are provided for information purposes only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warnings see 6.5.4.2, 6.5.6.3, 6.9.3, 9.5, 9.6 and A2.3.1.3.

General Information

Relations

Standards Content (Sample)

An American National Standard

Designation: D 5236 – 01

Standard Test Method for

Distillation of Heavy Hydrocarbon Mixtures (Vacuum Potstill

1

Method)

This standard is issued under the fixed designation D 5236; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 The values stated in SI units are to be regarded as the

standard. The inch-pound units given in parentheses are

1.1 This test method covers the procedure for distillation of

provided for information purposes only.

heavy hydrocarbon mixtures having initial boiling points

1.7 This standard does not purport to address all of the

greater than 150°C (300°F), such as heavy crude oils, petro-

safety concerns, if any, associated with its use. It is the

leum distillates, residues, and synthetic mixtures. It employs a

responsibility of the user of this standard to establish appro-

potstill with a low pressure drop entrainment separator oper-

priate safety and health practices and determine the applica-

ated under total takeoff conditions. Distillation conditions and

bility of regulatory limitations prior to use. For specific

equipment performance criteria are specified and typical appa-

warnings see 6.5.4.2, 6.5.6.3, 6.9.3, 9.5, 9.6, and A2.3.1.3.

ratus is illustrated.

1.2 This test method details the procedures for the produc-

2. Referenced Documents

tion of distillate fractions of standardized quality in the gas oil

2.1 ASTM Standards:

and lubricating oil range as well as the production of standard

D 941 Test Method for Density and Relative Density (Spe-

residua. In addition, it provides for the determination of

cific Gravity) of Liquids by Lipkin Bicapillary Pycnom-

standard distillation curves to the highest atmospheric equiva-

2

eter

lent temperature possible by conventional distillation.

D 1160 Test Method for Distillation of Petroleum Products

1.3 The maximum achievable atmospheric equivalent tem-

3

at Reduced Pressure

perature (AET) is dependent upon the heat tolerance of the

D 1217 Test Method for Density and Relative Density

charge. For most samples, a temperature up to 565°C

3

(Specific Gravity) of Liquids by Bingham Pycnometer

(10570°F) can be attained. This maximum will be significantly

D 1250 Guide for Petroleum Measurement Tables (Descrip-

lower for heat sensitive samples (for example, heavy residues)

3

tion only; tables published separately in 12 volumes)

and might be somewhat higher for nonheat sensitive samples.

D 1298 Test Method for Density, Relative Density (Specific

1.4 The recommended distillation method for crude oils up

Gravity), or API Gravity of Crude Petroleum and Liquid

to cutpoint 400°C (752°F) AET is Test Method D 2892. This

3

Petroleum Products by Hydrometer Method

test method can be used for heavy crude oils with initial boiling

D 1480 Test Method for Density and Relative Density

points greater than 150°C (302°F). However, distillation curves

(Specific Gravity) of Viscous Materials by Bingham Pyc-

and fraction qualities obtained by these methods are not

3

nometer

comparable.

D 2892 Test Method for Distillation of Crude Petroleum

1.5 This test method contains the following annexes:

4

(15-Theoretical Plate Column)

1.5.1 Annex A1—Test Method for Determination of the

D 4057 Practice for Manual Sampling of Petroleum and

Temperature Response Time,

4

Petroleum Products

1.5.2 Annex A2—Practice for Calibration of Sensors,

D 4177 Practice for Automatic Sampling of Petroleum and

1.5.3 Annex A3—Test Method for Dehydration of a Wet

4

Petroleum Products

Sample of Oil,

D 5002 Test Method for Density and Relative Density of

1.5.4 Annex A4—Practice for Conversion of Observed Va-

5

Crude Oils by Digital Density Analyzer

por Temperature to Atmospheric Equivalent Temperature

(AET), and

3. Terminology

1.5.5 Annex A5—Test Method for Determination of Wet-

3.1 Definitions of Terms Specific to This Standard:

tage.

3.1.1 boil-up rate, n—the quantity of vapor entering the

1

This test method is under the jurisdiction of ASTM Committee D02 on

2

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee Discontinued; see 1993 Annual Book of ASTM Standards, Vol 05.01.

3

D02.08.0C on Crude Distillation. Annual Book of ASTM Standards, Vol 05.01.

4

Current edition approved Dec. 10, 2001. Published February 2002. Originally Annual Book of ASTM Standards, Vol 05.02.

e1 5

published as D 5236 – 92. Last previous edition D 5236 – 99a . Annual Book of ASTM Standards, Vol 05.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5236

distillation head per unit time. 5. Significance and Use

3.1.1.1 Discussion—It is approximately equal to the takeoff

5.1 This test method

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.