ASTM D1665-98(2014)

(Test Method)Standard Test Method for Engler Specific Viscosity of Tar Products

Standard Test Method for Engler Specific Viscosity of Tar Products

SIGNIFICANCE AND USE

5.1 This test method is useful in characterizing the consistency of tar and tar distillates by measuring their flow properties. It is applicable to materials that are readily liquid at temperatures up to 100°C.

SCOPE

1.1 This test method covers the determination of specific viscosity of tars and their fluid products. It does not determine absolute viscosity, but is an empirical flow test. Only by conforming strictly to requirements of the test method are reproducible results obtained.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1665 −98 (Reapproved 2014)

Standard Test Method for

1

Engler Specific Viscosity of Tar Products

This standard is issued under the fixed designation D1665; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers the determination of specific

4.1 The time, in s, is measured for a fixed volume of liquid

viscosity of tars and their fluid products. It does not determine

material to flow through an efflux tube under an accurately

absolute viscosity, but is an empirical flow test. Only by

reproducible head and at a closely controlled temperature. The

conforming strictly to requirements of the test method are

Engler specific viscosity is then calculated by dividing the

reproducible results obtained.

efflux time by the viscometer calibration factor as determined

by making the same efflux measurement for water.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

5. Significance and Use

standard.

1.3 This standard does not purport to address all of the

5.1 This test method is useful in characterizing the consis-

safety concerns, if any, associated with its use. It is the

tency of tar and tar distillates by measuring their flow proper-

responsibility of the user of this standard to establish appro-

ties. It is applicable to materials that are readily liquid at

priate safety and health practices and determine the applica-

temperatures up to 100°C.

bility of regulatory limitations prior to use.

6. Apparatus

2. Referenced Documents

6.1 Engler ViscosimeterasshowninFig.1,consistingofthe

2

2.1 ASTM Standards:

following:

D140 Practice for Sampling Bituminous Materials

6.1.1 Cup—This is a gold-plated cylindrical brass vessel of

E1 Specification for ASTM Liquid-in-Glass Thermometers

106.0 6 1.0 mm, A, inside diameter, closed at the top by a

E11 Specification for Woven Wire Test Sieve Cloth and Test

double walled lid. To the rounded bottom is attached a

Sieves

metal-encased tapered platinum efflux tube 20.0 6 0.1 mm, H,

long with an inside diameter of 2.90 6 0.02 mm, E, at the top

3. Terminology

and 2.80 6 0.02 mm, F, at the bottom. The efflux tube shall

3.1 Definitions:

project through and extend 3.0 6 0.2 mm, G, below a jacket

3.1.1 Engler specific viscosity—the ratio obtained by divid-

that surrounds the cup and shall have a bottom outside

ing the time of flow, in s, of 50 mLof material using an Engler

diameter, including its surrounding metal, of 4.5 6 0.2 mm, I.

viscosimeter at a selected temperature by a factor representing

Three metal measuring points, spaced equidistantly around the

thetimeofflow,ins,foranequalvolumeofwaterat25°C.The

circumference of the cup, are fastened to the sides and extend

usualtemperaturesfordeterminationofspecificviscosityoftar

inwardlyapproximately7mm,thenturnupatarightangleand

materials are 25°C, 40°C, 50°C, and 100°C, and generally the

end in sharp points which are located 52.0 6 0.5 mm, D,

temperatureissoselectedthatthespecificviscosityisnotmore

verticallyabovethelowerendoftheeffluxtubeand25.0 61.0

than 45.

mm, C, above the lowest portion of the cylindrical sidewall of

the cup. They serve both for indicating when the instrument is

level and for measuring the charge of material, which is

1 approximately 250 mL.

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.43 on

6.1.2 Jacket—The cup is surrounded by a jacket which

Specifications and Test for Tar and Tar Products.

holds water or other suitable liquid serving as a constant

Current edition approved June 1, 2014. Published October 2014. Originally

temperature bath. In the type illustrated, the jacket is provided

approved in 1959. Last previous edition approved in 2009 as D1665 – 98 (2009).

DOI: 10.1520/D1665-98R14.

with a thermometer clamp and stirring device. A tripod

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

supports the apparatus and also carries a ring burner by means

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of which the bath is heated.Adjustable legs on the tripod serve

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. to level the instrument. Other arrangements of outer baths,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

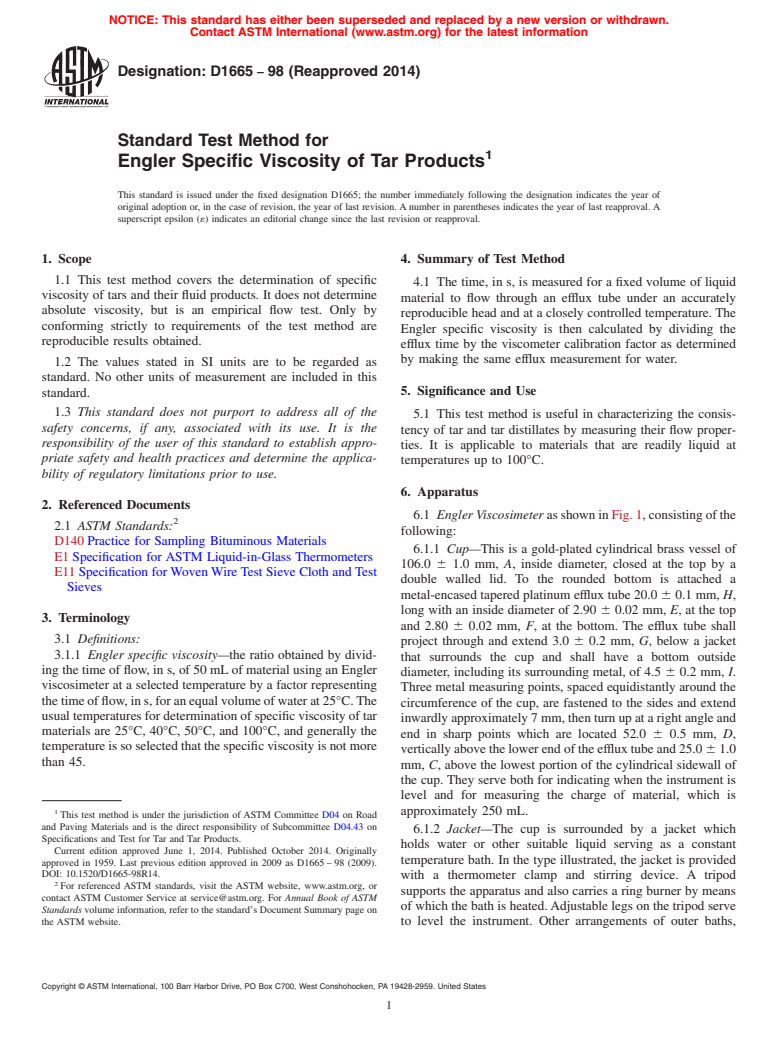

---------------------- Page: 1 ----------------------

D1665−98 (2014)

FIG. 1 Engler Viscosimeter

supports,andstirri

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1665 − 98 (Reapproved 2009) D1665 − 98 (Reapproved 2014)

Standard Test Method for

1

Engler Specific Viscosity of Tar Products

This standard is issued under the fixed designation D1665; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of specific viscosity of tars and their fluid products. It does not determine absolute

viscosity, but is an empirical flow test. Only by conforming strictly to requirements of the test method are reproducible results

obtained.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D140 Practice for Sampling Bituminous Materials

E1 Specification for ASTM Liquid-in-Glass Thermometers

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Terminology

3.1 Definitions:

3.1.1 Engler specific viscosity—the ratio obtained by dividing the time of flow, in s, of 50 mL of material using an Engler

viscosimeter at a selected temperature by a factor representing the time of flow, in s, for an equal volume of water at 25°C. The

usual temperatures for determination of specific viscosity of tar materials are 25°C, 40°C, 50°C, and 100°C, and generally the

temperature is so selected that the specific viscosity is not more than 45.

4. Summary of Test Method

4.1 The time, in s, is measured for a fixed volume of liquid material to flow through an efflux tube under an accurately

reproducible head and at a closely controlled temperature. The Engler specific viscosity is then calculated by dividing the efflux

time by the viscometer calibration factor as determined by making the same efflux measurement for water.

5. Significance and Use

5.1 This test method is useful in characterizing the consistency of tar and tar distillates by measuring their flow properties. It

is applicable to materials that are readily liquid at temperatures up to 100°C.

6. Apparatus

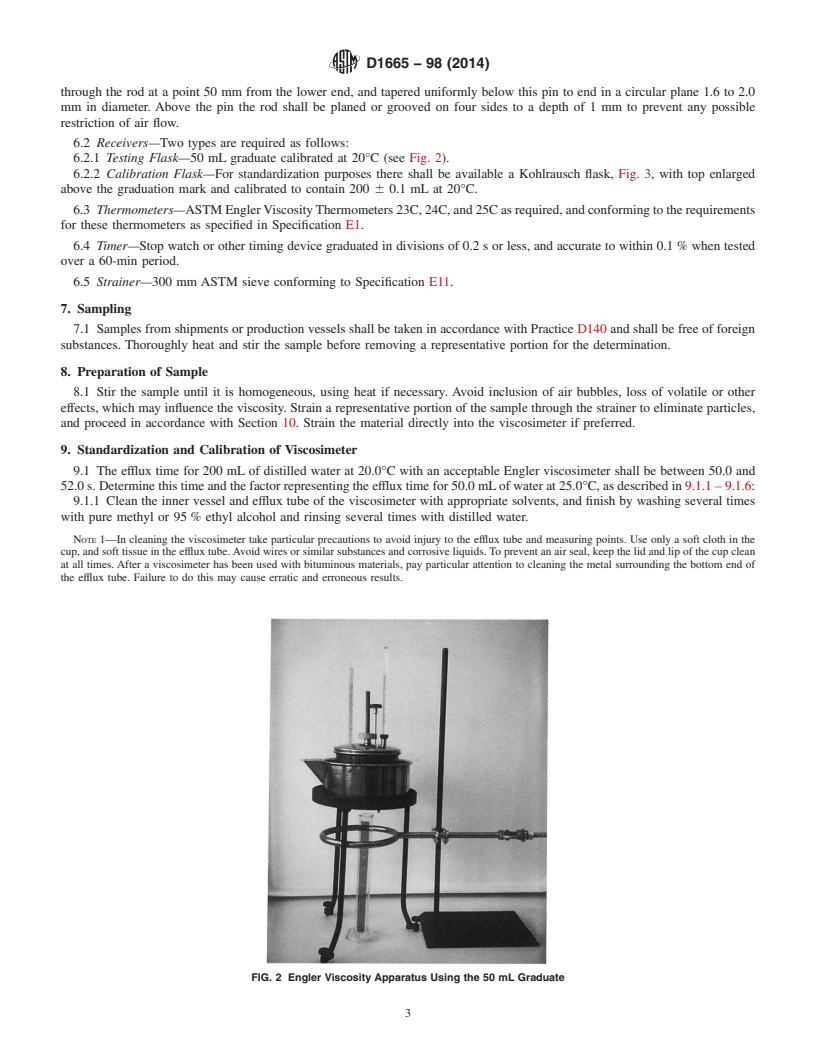

6.1 Engler Viscosimeter as shown in Fig. 1, consisting of the following:

6.1.1 Cup—This is a gold-plated cylindrical brass vessel of 106.0 6 1.0 mm, A, inside diameter, closed at the top by a double

walled lid. To the rounded bottom is attached a metal-encased tapered platinum efflux tube 20.0 6 0.1 mm, H, long with an inside

diameter of 2.90 6 0.02 mm, E, at the top and 2.80 6 0.02 mm, F, at the bottom. The efflux tube shall project through and extend

3.0 6 0.2 mm, G, below a jacket that surrounds the cup and shall have a bottom outside diameter, including its surrounding metal,

1

This test method is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.43 on

Specifications and Test for Tar and Tar Products.

Current edition approved Dec. 1, 2009June 1, 2014. Published January 2010October 2014. Originally approved in 1959. Previous Last previous edition approved in

20032009 as D1665 – 98 (2003).(2009). DOI: 10.1520/D1665-98R09.10.1520/D1665-98R14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1665 − 98 (2014)

FIG. 1 Engler Viscosimeter

of 4.5 6 0.2 mm, I. Three metal measuring points, spaced equidistantly around the circumference of the cup, are fastened to the

sides and extend inwardly approximately 7 mm, then turn up at a right angle and end in sharp points which are located 52.0 6

0.5 mm, D, vertically above the lower end of the efflux tube and 25.0 6 1.0 mm, C, above the lowest portion of the cylindrical

sidewall of the cup. They serve both for indicating when the instrument is level and for measuring the charge of material, which

is approximately 250 mL.

6.1.2 Jac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.