ASTM G165-99(2005)

(Practice)Standard Practice for Determining Rail-to-Earth Resistance

Standard Practice for Determining Rail-to-Earth Resistance

SIGNIFICANCE AND USE

Low resistance between the rails and earth could result in large magnitudes of stray earth currents with the attendant corrosion damage to underground metallic structures.

These measurements are of a low voltage type and are not designed to evaluate the high voltage dielectric characteristics of the rail insulating elements.

Sections of track with rail-to-earth resistances less than acceptable minimums must be tested in greater detail to determine the reason(s) for this condition. Determination of the reason(s) for any low rail-to-earth resistance may require the use of special testing techniques or special instruments, or both, beyond the scope of this practice.

The electrical tests call for the use of electric meters that have varying characteristics depending on cost, manufacture, and generic type. It is assumed that any person employing the test procedures contained herein will know how to determine and apply proper correction factors and that they will have sufficient knowledge to ensure reasonable accuracy in the data obtained.

This practice does not encompass all possible field conditions to obtain rail-to-earth resistance characteristics. No general set of test procedures will be applicable to all situations.

SCOPE

1.1 This practice covers the procedures necessary to follow for measuring resistance-to-earth of the running rails which are used as the conductors for returning the train operating current to the substation in electric mass transit systems.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G165–99 (Reapproved 2005)

Standard Practice for

Determining Rail-to-Earth Resistance

This standard is issued under the fixed designation G165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This practice covers the procedures necessary to follow 4.1 Low resistance between the rails and earth could result

for measuring resistance-to-earth of the running rails which are in large magnitudes of stray earth currents with the attendant

used as the conductors for returning the train operating current corrosion damage to underground metallic structures.

to the substation in electric mass transit systems. 4.2 These measurements are of a low voltage type and are

1.2 The values stated in SI units are to be regarded as the not designed to evaluate the high voltage dielectric character-

standard. The values given in parentheses are for information istics of the rail insulating elements.

only. 4.3 Sections of track with rail-to-earth resistances less than

1.3 This standard does not purport to address all of the acceptable minimums must be tested in greater detail to

safety concerns, if any, associated with its use. It is the determinethereason(s)forthiscondition.Determinationofthe

responsibility of the user of this standard to establish appro- reason(s) for any low rail-to-earth resistance may require the

priate safety and health practices and determine the applica- use of special testing techniques or special instruments, or

bility of regulatory limitations prior to use. both, beyond the scope of this practice.

4.4 The electrical tests call for the use of electric meters that

2. Referenced Documents

have varying characteristics depending on cost, manufacture,

2.1 ASTM Standards: and generic type. It is assumed that any person employing the

G15 Terminology Relating to Corrosion and Corrosion

test procedures contained herein will know how to determine

Testing and apply proper correction factors and that they will have

sufficient knowledge to ensure reasonable accuracy in the data

3. Terminology

obtained.

3.1 Definitions of Terms Specific to This Standard:

4.5 This practice does not encompass all possible field

3.1.1 cross bond—insulated copper cables that connected

conditions to obtain rail-to-earth resistance characteristics. No

between adjacent sections of track to ensure electrical conti-

general set of test procedures will be applicable to all situa-

nuity between them.

tions.

3.1.2 direct fixation fastener—a device for fastening run-

5. Equipment

ning rails to their support structures.

3.1.3 impedance bond—a device connected to running rails

5.1 Indicating dc; high impedance (minimum ten megohm)

for automatic train operations. voltmeter (two required); multi-scale, capable of reading posi-

3.1.4 The terminology used herein, if not specifically de-

tive and negative values without removing test leads; and

fined otherwise, shall be in accordance with Terminology G15. covering at least the following full scale ranges:

Definitions provided herein, and not given in Terminology

5.1.1 0 to 10 mV,

G15, are limited to this practice. 5.1.2 0 to 100 mV,

5.1.3 0 to 1 V,

1 5.1.4 0 to 10 V, and

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.10 on Corrosion in 5.1.5 0 to 100 V.

Soils.

5.1.6 Meters shall be accurate within 1 % of full scale.

Current edition approved May 1, 2005. Published May 2005. Originally

5.2 Direct current ammeter, multi-scale, covering the fol-

approved in 1999. Last previous edition approved in 1999 as G165 – 99. DOI:

lowing full scale ranges:

10.1520/G0165-99R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2.1 0 to 1 A,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2.2 0 to 10 A, and

Standards volume information, refer to the standard’s Document Summary page on

5.2.3 0 to 100 A.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G165–99 (2005)

NOTE 1—Switches within substation can be opened.

5.3 Direct current milliammeter, multi-scale, covering the

following full scale ranges:

7.2 Ensure electrical continuity between the rails within the

5.3.1 0 to 15 mA,

insulated track section being tested by the use of the existing

5.3.2 0 to 150 mA, and

cables at impedance bonds or by installing temporary wire

5.3.3 0 to 1500 mA,

connections between the rails.

5.4 An alternative to the ammeter and milliammeter is a

7.3 Track-to-earthresistancemeasurementswillbeobtained

millivolt meter and external shunts covering the listed current

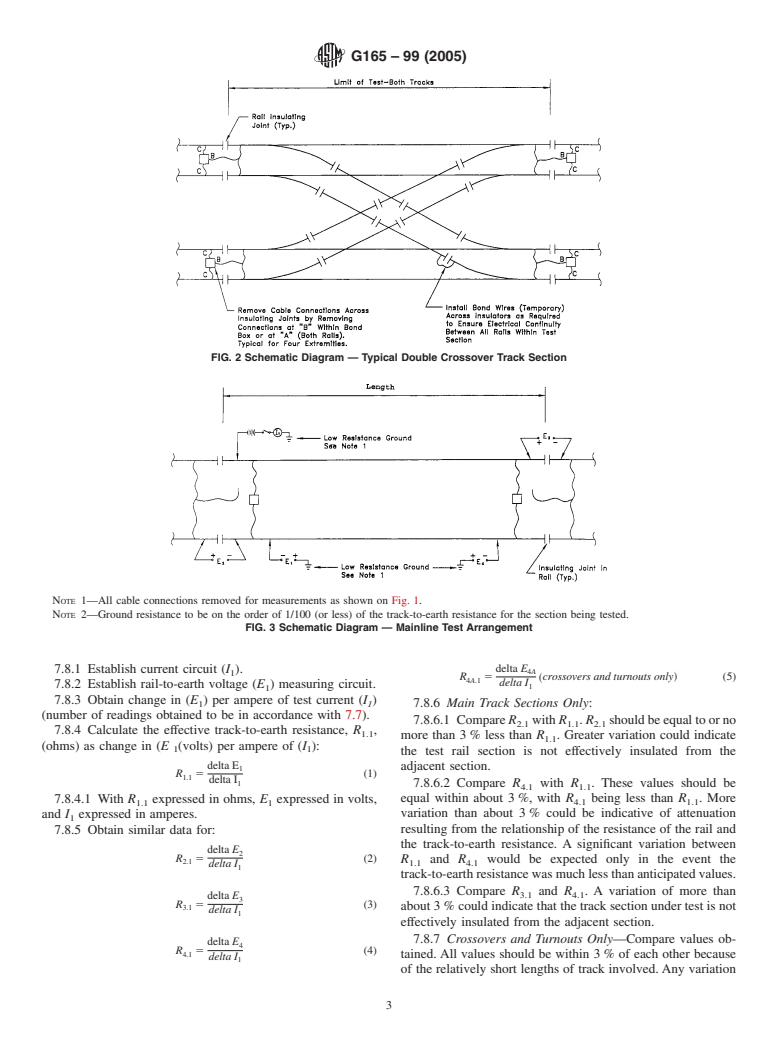

as shown on Fig. 3 for main track sections and as shown on

ranges. Meters (and shunt combinations if used) shall be

Fig. 4 for main track sections containing double crossovers.

accurate to within 1 % of full scale.

Measurements on track sections containing turnouts and single

5.5 Direct current power source with control circuits. Gen-

crossovers will be similar to that shown on Fig. 4 with the

erally, 6 or 12 V automotive type wet cell batteries will suffice.

number of test points being determined by the electrical

5.6 Test wires, assorted lengths and sizes, to suit field

configuration of insulating joints and bonding cables.

conditions. Wires should have minimum 600 V insulation in

7.4 The track-to-earth resistance measurements for the track

perfect condition (no visible cuts or abrasions) and be multi-

in the train storage yards will require special consideration for

strand copper conductors for flexibility.

each section to be tested because of the number and location of

5.7 Miscellaneous tools as required for making wire con-

insulating joints resulting from the type of signal system being

nections, splicing, and so forth.

used within the yard area and because of the number of cross

5.8 Vehicle to transport equipment and personnel along

bonds and other bonding cables used within the yard.

track to facilitate testing.

7.5 All data shall be recorded.

6. Visual Inspection 7.6 A sketch showing location of the test and the electrical

test set-up used shall be included.

6.1 The track section to be tested should be visually

7.7 The number of readings taken to determine an electrical

examined to ensure the insulating components have been

constant or property must be sufficient to ensure that random

installed and there is no debris, water, or other conductive

factors due to human error in reading the instruments and

material in electrical contact with the metallic track compo-

transient disturbances in the electrical network have negligible

nents that could result in the lowering of the effective track-

influence on final results.Aminimum of three readings should

to-earth resistance thus producing incorrect data.

be obtained but additional readings may be required depending

7. Electrical Tests

upon the exact circumstances of the test. The adequacy of data

generally can be established by the tester. Once the specified

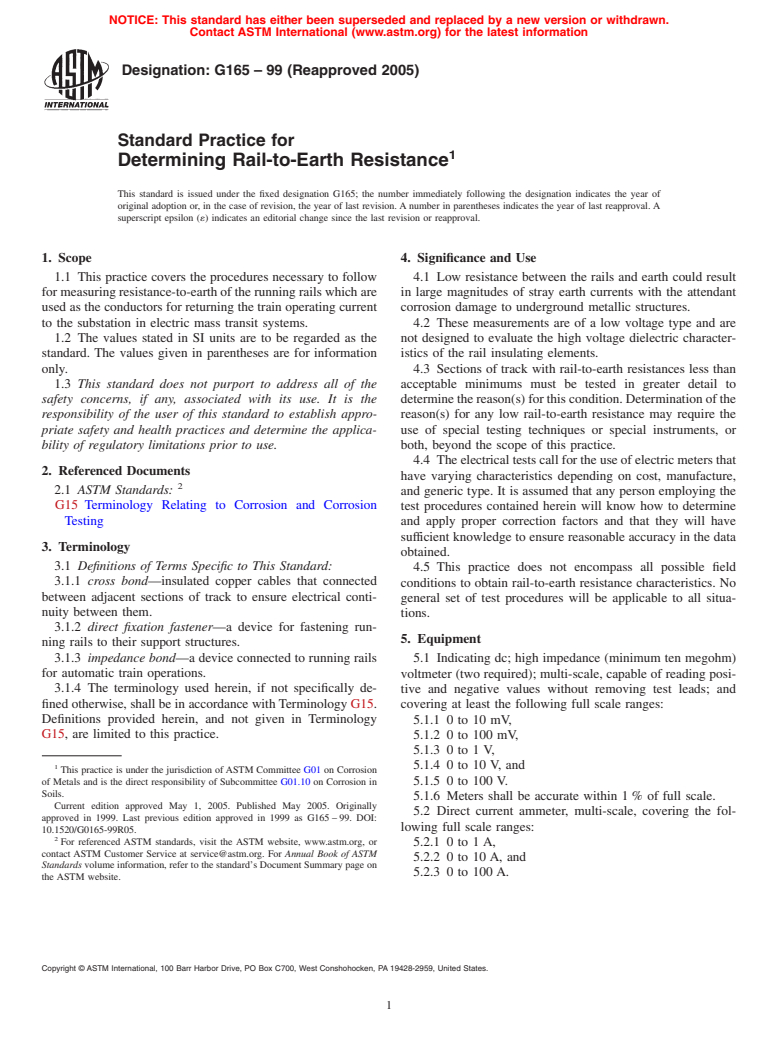

7.1 Electricallyisolatesectionsoftrack(seetypicalarrange-

minimum number of readings have been obtained, data should

ments in Figs. 1 and 2). Length of track section to be tested is

be examined to see that removal of neither the highest nor the

dependent upon the locations of rail insulators. Rail insulators

lowest value will alter the arithmetic average of group by more

are found at the ends of turnouts and single and double

than 3 %. If the average is altered by more than 3 %, one more

crossovers. The lengths of the track sections will vary within

complete set of data should be taken and the results combined

the general range of 60 to 2750 m (200 to 9000 ft).

with the first set. If the test of the data still produces a change

7.1.1 Remove cable connections from across rail insulators.

in the average value greater than 3 %, it may indicate an

7.1.2 Disconnect cross bonds within section of track being

unstable condition in the system.

tested and other track.

7.1.3 Disconnect power traction substation negative feeder 7.8 Measurements Procedure—(Fig. 3 for main track

cables from track section being tested. section, Fig. 4 for crossovers and turnouts).

FIG. 1 Schematic Diagram — Typical Mainline Track Section

-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.