ASTM D6032-96

(Test Method)Standard Test Method for Determining Rock Quality Designation (RQD) of Rock Core

Standard Test Method for Determining Rock Quality Designation (RQD) of Rock Core

SCOPE

1.1 This test method covers the determination of the rock quality designation (RQD) as a standard parameter in drill core logging.

1.2 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound units are approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6032 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determining Rock Quality Designation (RQD) of Rock Core

This standard is issued under the fixed designation D 6032; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope excavation for foundations of structures. The RQD values also

can serve to identify potential problems related to bearing

1.1 This test method covers the determination of the rock

capacity, settlement, erosion, or sliding in rock foundations.

quality designation (RQD) as a standard parameter in drill core

The RQD can provide an indication of rock quality in quarries

logging.

for concrete aggregate, rockfill, or large riprap.

1.2 The values stated in SI units are to be regarded as the

4.3 The RQD has been widely used as a warning indicator

standard. The values stated in inch-pound units are approxi-

of low-quality rock zones that may need greater scrutiny or

mate.

require additional borings or other investigational work.

1.3 This standard does not purport to address all of the

4.4 The RQD is a basic component of many rock mass

safety concerns, if any, associated with its use. It is the

classification systems for engineering purposes.

responsibility of the user of this standard to establish appro-

4.5 Used alone, The RQD is not sufficient to provide an

priate safety and health practices and determine the applica-

adequate description of rock mass quality. The RQD does not

bility of regulatory limitations prior to use.

account for joint orientation, tightness, continuity, and gouge

2. Referenced Documents material. The RQD must be used in combination with other

geological and geotechnical input.

2.1 ASTM Standards:

4.6 The RQD is sensitive to the orientation of joint sets with

D 2113 Practice for Diamond Core Drilling for Site Inves-

respect to the orientation of the core. That is, a joint set parallel

tigation

to the core axis will not intersect the core, unless the drill hole

D 5079 Practices for Preserving and Transporting Rock

happens to run along the joint. A joint set perpendicular to the

Core Samples

core axis will intersect the core axis at intervals equal to the

E 691 Practice for Conducting an Interlaboratory Study to

joint spacing. For intermediate orientations, the spacing of joint

Determine the Precision of a Test Method

intersections with the core will be a cosine function of angle

3. Summary of Test Method

between joints and the core axis.

4.7 Core sizes from BQ to PQ with core diameters of 36.5

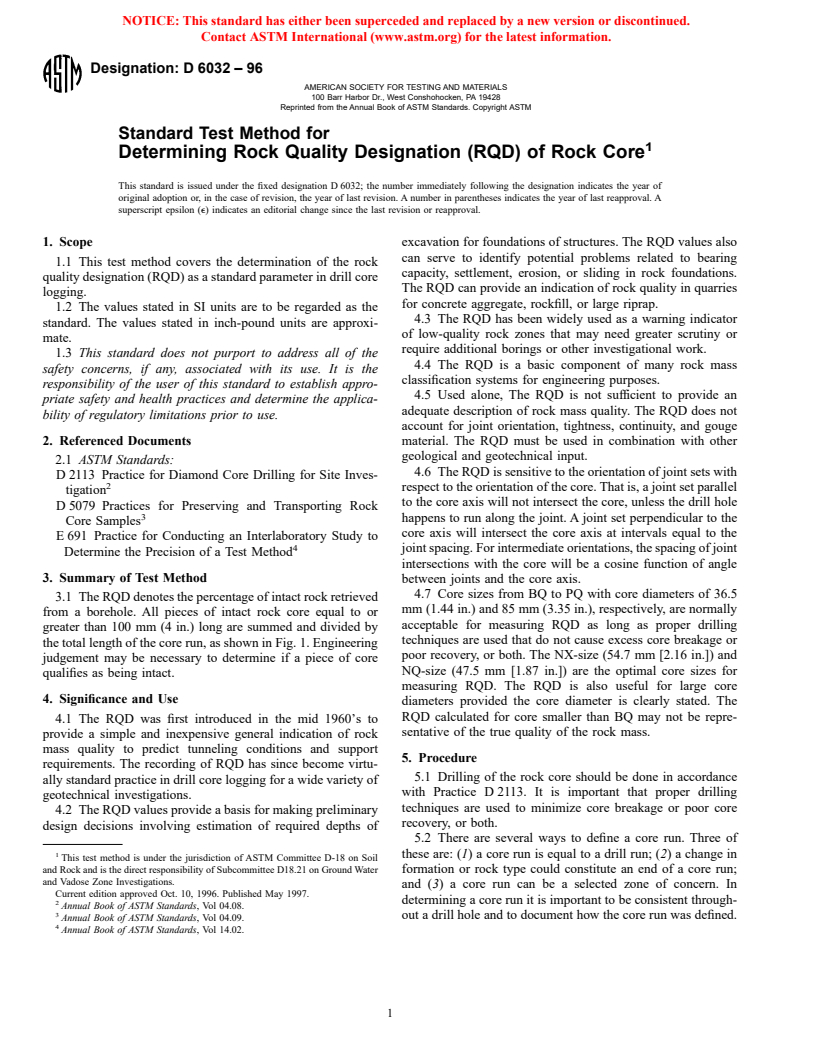

3.1 The RQD denotes the percentage of intact rock retrieved

mm (1.44 in.) and 85 mm (3.35 in.), respectively, are normally

from a borehole. All pieces of intact rock core equal to or

acceptable for measuring RQD as long as proper drilling

greater than 100 mm (4 in.) long are summed and divided by

techniques are used that do not cause excess core breakage or

the total length of the core run, as shown in Fig. 1. Engineering

poor recovery, or both. The NX-size (54.7 mm [2.16 in.]) and

judgement may be necessary to determine if a piece of core

NQ-size (47.5 mm [1.87 in.]) are the optimal core sizes for

qualifies as being intact.

measuring RQD. The RQD is also useful for large core

4. Significance and Use

diameters provided the core diameter is clearly stated. The

RQD calculated for core smaller than BQ may not be repre-

4.1 The RQD was first introduced in the mid 1960’s to

sentative of the true quality of the rock mass.

provide a simple and inexpensive general indication of rock

mass quality to predict tunneling conditions and support

5. Procedure

requirements. The recording of RQD has since become virtu-

5.1 Drilling of the rock core should be done in accordance

ally standard practice in drill core logging for a wide variety of

with Practice D 2113. It is important that proper drilling

geotechnical investigations.

techniques are used to minimize core breakage or poor core

4.2 The RQD values provide a basis for making preliminary

recovery, or both.

design decisions involving estimation of required depths of

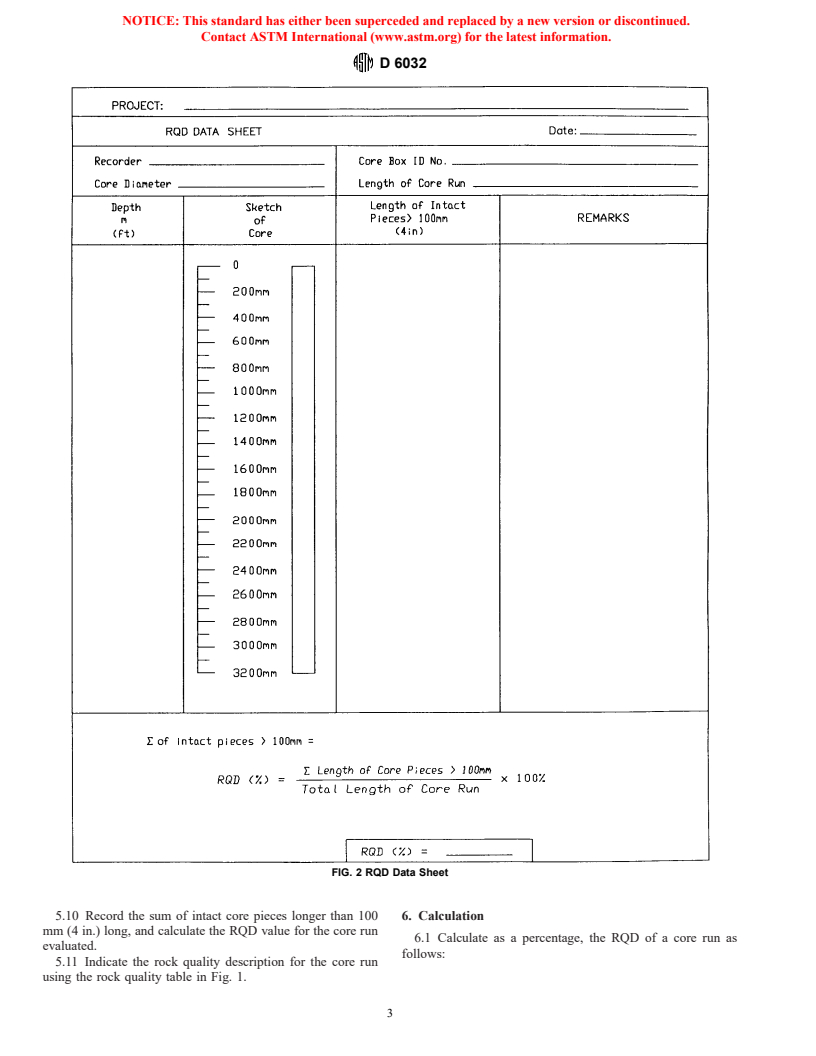

5.2 There are several ways to define a core run. Three of

1 these are: (1) a core run is equal to a drill run; (2) a change in

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

formation or rock type could constitute an end of a core run;

and Rock and is the direct responsibility of Subcommittee D18.21 on Ground Water

and Vadose Zone Investigations.

and (3) a core run can be a selected zone of concern. In

Current edition approved Oct. 10, 1996. Published May 1997.

determining a core run it is important to be consistent through-

Annual Book of ASTM Standards, Vol 04.08.

out a drill hole and to document how the core run was defined.

Annual Book of ASTM Standards, Vol 04.09.

Annual Book of ASTM Standards, Vol 14.02.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6032

FIG. 1 RQD Logging

NOTE 1—Centerline measurements ensure that the RQD value resulting

5.3 Retrieval, preservation, transportation, storage, and

from the measurements is not dependent on the core diameter. Centerline

cataloging of the rock core should be done in accordance with

measurements also avoid unduly penalizing resulting RQD values for

Practices D 5079. The RQD should be logged on site when the

cases where fractures parallel the core axis (that is, vertical fractures).

core is retrieved because some rocks can disintegrate, due to

5.6 Only those pieces of rock formed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.