ASTM E2041-99

(Test Method)Standard Method for Estimating Kinetic Parameters by Differential Scanning Calorimeter Using the Borchardt and Daniels Method

Standard Method for Estimating Kinetic Parameters by Differential Scanning Calorimeter Using the Borchardt and Daniels Method

SCOPE

1.1 This test method covers the determination of the kinetic parameters of activation energy, Arrhenius frequency factor, and reaction order using the Borchardt and Daniels treatment of data obtained by differential scanning calorimetry. This test method is applicable to the temperature range from 170 to 870 K (-100 to 600oC).

1.2 This treatment is applicable only to smooth exothermic reactions with no shoulders, discontinuous changes, or shifts in baseline. It is applicable only to reactions with reaction order n 2. It is not applicable to autocatalyzed reactions and, therefore, is not applicable to the determination of kinetic parameters for most thermoset curing reactions or to crystallization reactions.

1.3 Electronic instrumentation or automated data analysis systems or treatments equivalent to this test method may be used.

Note 1--The user is advised that all electronic data treatment may not be equivalent. It is the responsibility of the user of such electronic data treatment to verify applicability to this test method.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This test method is similar, but not equivalent to, ISO Method 11357, Part 5, which contains provisions for additional information not supplied by this test method.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 2041 – 99

Standard Method for

Estimating Kinetic Parameters by Differential Scanning

Calorimeter Using the Borchardt and Daniels Method

This standard is issued under the fixed designation E 2041; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 967 Practice for Temperature Calibration of Differential

Scanning Calorimeters and Differential Thermal Analyz-

1.1 This test method covers the determination of the kinetic

ers

parameters of activation energy, Arrhenius frequency factor,

E 968 Practice for Heat Flow Calibration of Differential

and reaction order using the Borchardt and Daniels treatment

Scanning Calorimeters

of data obtained by differential scanning calorimetry. This test

E 1142 Terminology Relating to Thermophysical Proper-

method is applicable to the temperature range from 170 to

ties

870 K (−100 to 600°C).

E 1145 Terminology Relating to Hazardous Properties of

1.2 This treatment is applicable only to smooth exothermic

Chemicals

reactions with no shoulders, discontinuous changes, or shifts in

E 1970 Practice for Statistical Treatment of Thermoanalyti-

baseline. It is applicable only to reactions with reaction order

cal Data

n # 2. It is not applicable to autocatalyzed reactions and,

2.2 ISO Standards:

therefore, is not applicable to the determination of kinetic

ISO 11357 Part 5: Determination of Temperature and/or

parameters for most thermoset curing reactions or to crystalli-

,

3 4

Time of Reaction and Reaction Kinetics

zation reactions.

1.3 Electronic instrumentation or automated data analysis

3. Terminology

systems or treatments equivalent to this test method may be

3.1 Definitions—Specific technical terms used in this test

used.

method are defined in Terminologies E 473, E 1142 and

NOTE 1—The user is advised that all electronic data treatment may not

E 1445.

be equivalent. It is the responsibility of the user of such electronic data

treatment to verify applicability to this test method.

4. Summary of Test Method

1.4 The values stated in SI units are to be regarded as the

4.1 A test specimen is heated at a linear rate in a differential

standard.

scanning calorimeter or other suitable calorimeter through a

1.5 This test method is similar, but not equivalent to, ISO

region of exothermic reaction behavior. The rate of heat

Method 11357, Part 5, which contains provisions for additional

evolution, developed by a chemical reaction, is proportional to

information not supplied by this test method.

the rate of reaction. Integration of the heat flow as a function of

1.6 This standard does not purport to address all of the

time yields the total heat of a reaction.

safety concerns, if any, associated with its use. It is the

4.2 The Borchardt and Daniels data treatment is used to

responsibility of the user of this standard to establish appro-

derive the kinetic parameters of activation energy, Arrhenius

priate safety and health practices and determine the applica-

frequency factor, and reaction order from the heat flow and

bility of regulatory limitations prior to use.

total heat of reaction information obtained in 4.1 (see Section

5).

2. Referenced Documents

5. Basis of Methodology

2.1 ASTM Standards:

E 473 Terminology Relating to Thermal Analysis

5.1 Kinetic reactions may be modeled with a number of

E 537 Test Method for Assessing the Thermal Stability of

suitable equations. The Borchardt and Daniels method makes

Chemicals by Methods of Differential Thermal Analysis

use of the general rate equation to describe the dependence of

E 698 Test Method for Arrhenius Kinetic Constants for

the rate of reaction on the amount of material present.

Thermally Unstable Materials

n

da/dt 5 k~T! ~12a! (1)

This test method is under the jurisdiction of ASTM Committee E-37 on

Thermal Measurements and the direct responsibility of Subcommittee E37.01 on

Test Methods and Recommended Practices. Annual Book of ASTM Standards, Vol 14.02.

Current edition approved Sept. 10, 1999. Published November 1999. Available from American National Standards Institute, 11 W. 42nd St., 13th

Borchardt, H.J., Daniels, F., J. Amer. Chem. Soc. Vol 79, pp.41–46 (1957). Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 2041

(where y [ ln[k(T)], m [ E/R, x 1/T and b [ ln[Z]) where a

where:

−1

plot of the logarithm of the reaction rate constant (ln[k(T)])

da/dt 5 reaction rate (min )

versus the reciprocal of absolute temperature (l/T) produces a

a5 fraction reacted (dimensionless),

−1

k(T) 5 rate constant at temperature T (min ), and straight line, the slope of which is equal to −E/R and the

n 5 reaction order (dimensionless)

intercept of which is ln[Z].

5.2 For a reaction conducted at temperature (T), the rate

5.5 As an alternate to Eq 2 and 4, the rate and Arrhenius

equation of 5.1, may be cast in its logarithmic form:

equations may be combined and cast in its logarithmic form:

ln da/dt 5 ln k T 1 nln 12a (2)

@ # @ ~ !# @ #

ln@da/dt# 5 ln@Z# 1 nln@12a# 2 E/RT (5)

This equation has the form of a straight line, y 5 mx + b,

The resultant equation has the form z 5 a + bx + cy (where

where a plot of the logarithm of the reaction rate (ln[da/dt])

z [ ln[da/dt], ln[Z] [ a, b [ n, x [ ln[1− a], c [ E/R, and

versus the logarithm of the fraction remaining (ln[1− a])

y [ l/T) and may be solved using multiple linear regression

yields a straight line, the slope of which is equal to n and the

data treatment.

intercept is equal to ln[k(T)].

5.6 The values for da/dt,(1− a) and T needed to solve Eq

5.3 The Borchardt and Daniels model also makes use of the

2, Eq 4 and Eq 5, are experimental parameters obtained from

Arrhenius equation to describe how the reaction rate changes

a single linear heating rate DSC experiment scanning through

as a function of temperature:

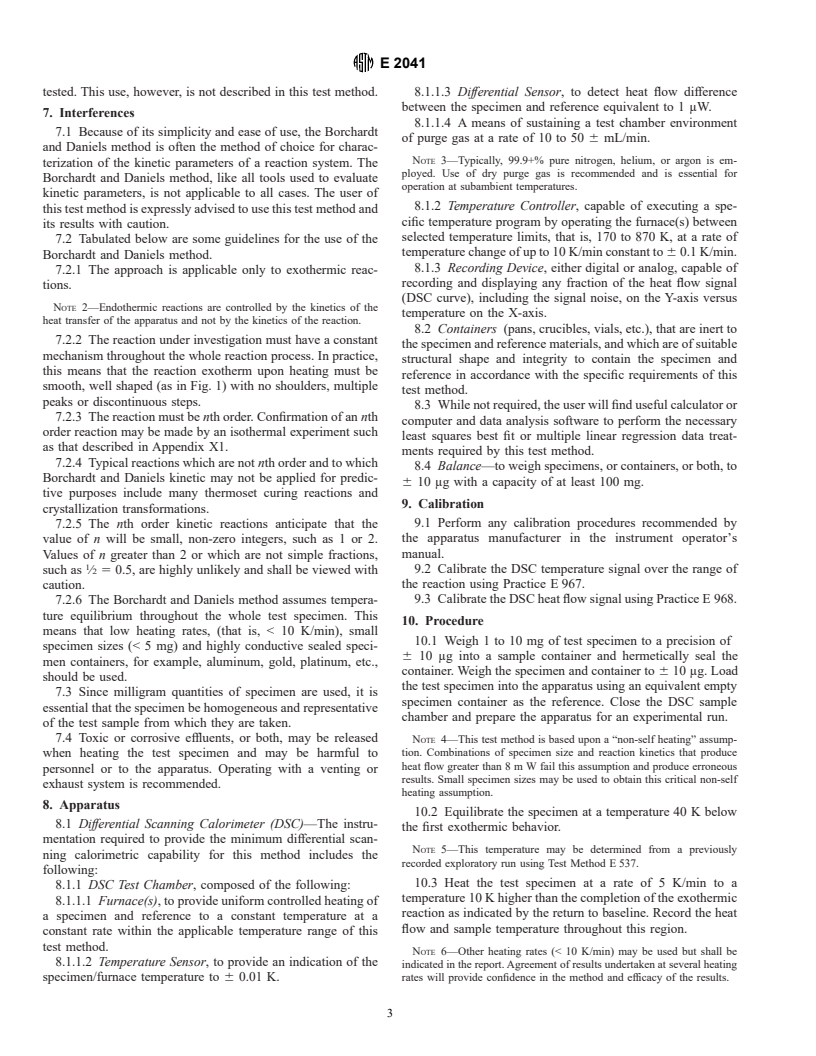

the temperature region of the reaction exotherm as shown in

·E/RT

Fig. 1.

k~T! 5 Ze (3)

5.7 Kinetic results obtained by this test method may be

where:

compared with those obtained by E 698.

−1

Z 5 Arrhenius frequency factor (time ),

E 5 Activation energy (J/mol),

6. Significance and Use

T 5 Absolute temperature (K), and

6.1 This test method is useful in research, development,

R 5 Gas constant 5 8.314 J/mol • K).

quality assurance, and for specification acceptance purposes.

5.4 The Arrhenius equation Eq 3 also may be cast in its

6.2 The determination of the appropriate model for a chemi-

logarithmic form:

cal reaction or transformation and the values associated with its

ln@k~T!# 5 ln@Z# 2 E/RT (4)

kinetic parameters may be used in the estimation of reaction

The equation has the form of a straight line, y 5 mx + b, performance at temperatures or time conditions not easily

FIG. 1 Idealized DSC Curve

E 2041

tested. This use, however, is not described in this test method. 8.1.1.3 Differential Sensor, to detect heat flow difference

between the specimen and reference equivalent to 1 μW.

7. Interferences

8.1.1.4 A means of sustaining a test chamber environment

7.1 Because of its simplicity and ease of use, the Borchardt

of purge gas at a rate of 10 to 50 6 mL/min.

and Daniels method is often the method of choice for charac-

NOTE 3—Typically, 99.9+% pure nitrogen, helium, or argon is em-

terization of the kinetic parameters of a reaction system. The

ployed. Use of dry purge gas is recommended and is essential for

Borchardt and Daniels method, like all tools used to evaluate

operation at subambient temperatures.

kinetic parameters, is not applicable to all cases. The user of

8.1.2 Temperature Controller, capable of executing a spe-

this test method is expressly advised to use this test method and

cific temperature program by operating the furnace(s) between

its results with caution.

selected temperature limits, that is, 170 to 870 K, at a rate of

7.2 Tabulated below are some guidelines for the use of the

temperature change of up to 10 K/min constant to 6 0.1 K/min.

Borchardt and Daniels method.

8.1.3 Recording Device, either digital or analog, capable of

7.2.1 The approach is applicable only to exothermic reac-

recording and displaying any fraction of the heat flow signal

tions.

(DSC curve), including the signal noise, on the Y-axis versus

NOTE 2—Endothermic reactions are controlled by the kinetics of the

temperature on the X-axis.

heat transfer of the apparatus and not by the kinetics of the reaction.

8.2 Containers (pans, crucibles, vials, etc.), that are inert to

7.2.2 The reaction under investigation must have a constant

the specimen and reference materials, and which are of suitable

mechanism throughout the whole reaction process. In practice,

structural shape and integrity to contain the specimen and

this means that the reaction exotherm upon heating must be

reference in accordance with the specific requirements of this

smooth, well shaped (as in Fig. 1) with no shoulders, multiple

test method.

peaks or discontinuous steps.

8.3 While not required, the user will find useful calculator or

7.2.3 The reaction must be nth order. Confirmation of an nth

computer and data analysis software to perform the necessary

order reaction may be made by an isothermal experiment such

least squares best fit or multiple linear regression data treat-

as that described in Appendix X1.

ments required by this test method.

7.2.4 Typical reactions which are not nth order and to which

8.4 Balance—to weigh specimens, or containers, or both, to

Borchardt and Daniels kinetic may not be applied for predic-

6 10 μg with a capacity of at least 100 mg.

tive purposes include many thermoset curing reactions and

9. Calibration

crystallization transformations.

7.2.5 The nth order kinetic reactions anticipate that the 9.1 Perform any calibration procedures recommended by

the apparatus manufacturer in the instrument operator’s

value of n will be small, non-zero integers, such as 1 or 2.

Values of n greater than 2 or which are not simple fractions, manual.

9.2 Calibrate the DSC temperature signal over the range of

such as ⁄2 5 0.5, are highly unlikely and shall be viewed with

caution. the reaction using Practice E 967.

9.3 Calibrate the DSC heat flow signal using Practice E 968.

7.2.6 The Borchardt and Daniels method assumes tempera-

ture equilibrium throughout the whole test specimen. This

10. Procedure

means that low heating rates, (that is, < 10 K/min), small

10.1 Weigh 1 to 10 mg of test specimen to a precision of

specimen sizes (< 5 mg) and highly conductive sealed speci-

6 10 μg into a sample container and hermetically seal the

men containers, for example, aluminum, gold, platinum, etc.,

container. Weigh the specimen and container to 6 10 μg. Load

should be used.

the test specimen into the apparatus using an equivalent empty

7.3 Since milligram quantities of specimen are used, it is

specimen container as the reference. Close the DSC sample

essential that the specimen be homogeneous and representative

chamber and prepare the apparatus for an experimental run.

of the test sample from which they are taken.

7.4 Toxic or corrosive effluents, or both, may be released

NOTE 4—This test method is based upon a “non-self heating” assump-

tion. Combinations of specimen size and reaction kinetics that produce

when heating the test specimen and may be harmful to

heat flow greater than 8 m W fail this assumption and produce erroneous

personnel or to the apparatus. Operating with a venting or

results. Small specimen sizes may be used to obtain this critical non-self

exhaust system is recommended.

heating assumption.

8. Apparatus

10.2 Equilibrate the specimen at a temperature 40 K below

8.1 Differential Scanning Calorimeter (DSC)—The instru-

the first exothermic behavior.

mentation required to provide the minimum differential scan-

NOTE 5—This temperature may be determined from a previously

ning calorimetric capability for this method includes the

recorded exploratory run using Test Method E 537.

following:

10.3 Heat the test specimen at a rate of 5 K/min to a

8.1.1 DSC Test Chamber, composed of the following:

temperature 10 K higher than the completion of the exothermic

8.1.1.1 Furnace(s), to provide uniform controlled heating of

reaction as indicated by the return to baseline. Record the heat

a specimen and reference to a constant temperature at a

flow and sample temperature throughout this region.

constant rate within the applicable temperature range of this

test method.

NOTE 6—Other heating rates (< 10 K/min) may be used but shall be

8.1.1.2 Temperature Sensor, to provide an indication of the

indicated in the report. Agreement of results undertaken at several heating

specimen/furnace temperature to 6 0.01 K. rates will provide confidence in the method and efficacy of the results.

E 2041

NOTE 11—The uncertainty introduced into results by linearizing non-

10.4 Cool the specimen container to ambient temperature

linear data are discussed in J. Chem. Ed.,74, 1001 (1997).

and reweigh. Record and report any change in mass from that

observed in 10.1 prior to the test.

11.13.1 This plot should result in a straight line. If it does

10.5 Calculate reaction order (n), activation energy (E), and

not, assume a new value for n and repeat the steps in

Arrhenius frequency factor (Z) according to the procedures in

11.11-11.13 until a straight line is obtained. Report the value of

Section 11.

n, which yields a straight line. A curve that is concave upward

indicates that the value of n is too large while one that is

11. Calculation

concave downward indicates that n is too small.

11.14 Using a least squares best fit technique (see Practice

11.1 Construct a linear baseline from a point on the baseline

before the reaction exotherm to a point on the baseline after the E 1970), determine a slope (m), intercept (b), standard devia-

tion in slope (s ) and standard deviation in intercept (s ) for

reaction.

m b

11.2 Construct a perpendicular line from the baseline to the this straight line. The slopes m and s have the units of 1/kK.

m

Intercepts b and s are dimensionless.

peak of the thermal curve and record this value in mW. Only

b

results for which the maximum heat flow (as expressed by this 11.15 Calculate the value for activation energy and standard

deviation in activation energy (s ) using the following equa-

line) are less than 8 mW shall be used in these calculations. If

E

the heat flow at the peak maximum is greater than 8 mW, tions:

reduce the specimen size or heating rate and rerun the

E52 m • R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.