ASTM A1001-01(2006)

(Specification)Standard Specification for High Strength Steel Castings in Heavy Sections

Standard Specification for High Strength Steel Castings in Heavy Sections

ABSTRACT

This specification covers cast alloy steels in the normalized and tempered or quenched and tempered condition, suitable for high strain gradient conditions. One test block for each heat is required. The test block configuration and size are specified. Tension and Charpy impact tests and oxygen, nitrogen, and hydrogen gas content tests shall be performed. The steel shall be made by electric furnace process with methods, such as argon-oxygen-decarburization, to conform to the maximum gas level. Heat treatment procedure shall be done. Multiple austenitizing and tempering are permitted. The chemistry grade shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, and aluminum. Residual elements include: zirconium, copper, titanium, tungsten, vanadium, columbium, and boron. A product analysis shall be made for specification conformance. Casting shell and core depth zone shall be established and examined. Repair methods such as grinding and welding are detailed.

SCOPE

1.1 This specification covers cast alloy steels in the normalized and tempered or quenched and tempered condition, in section sizes through 37 in. (940 mm), suitable for high strain gradient conditions such as those encountered in hooks, shackles, support frames, and other lifting devices. The classes of steel in this specification are weldable only with qualified procedures.

1.2 Section range and class selection will depend on design and service conditions. Users should note that this specification contemplates mechanical property gradients.

1.3 The values stated in inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in non-conformities with the specification. Inch-pound units are applicable for material ordered to this Specification and SI units for material ordered to this Specification.

1.4 If, by agreement, castings are to be supplied in a partially completed condition, that is, all of the provisions of the product specification have not been filled, then the material marking (see Section 15) and certification (see Section ) are to reflect the extent to which the product specification requirements have been met.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A1001 – 01 (Reapproved 2006)

Standard Specification for

1

High Strength Steel Castings in Heavy Sections

This standard is issued under the fixed designation A1001; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E709 Guide for Magnetic Particle Testing

E1019 Test Methods for Determination of Carbon, Sulfur,

1.1 This specification covers cast alloy steels in the normal-

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

ized and tempered or quenched and tempered condition, in

Alloys by Various Combustion and Fusion Techniques

section sizes through 37 in. (940 mm), suitable for high strain

E1447 Test Method for Determination of Hydrogen in

gradient conditions such as those encountered in hooks, shack-

Titanium and Titanium Alloys by Inert Gas Fusion Ther-

les, support frames, and other lifting devices. The classes of

mal Conductivity/Infrared Detection Method

steel in this specification are weldable only with qualified

E1806 Practice for Sampling Steel and Iron for Determina-

procedures.

tion of Chemical Composition

1.2 Section range and class selection will depend on design

2.2 Manufacturers Standardization of the Value and Fit-

andserviceconditions.Usersshouldnotethatthisspecification

tings Industry Standards:

contemplates mechanical property gradients.

MSS SP-55 Quality Standard for Steel Castings – Visual

1.3 The values stated in inch-pound units or SI units are to

2

Method

beregardedseparatelyasstandard.Withinthetext,theSIunits

areshowninbrackets.Thevaluesstatedineachsystemarenot

3. General Conditions for Delivery

exact equivalents; therefore, each system must be used inde-

3.1 Materials furnished to this Specification shall conform

pendentlyoftheother.Combiningvaluesfromthetwosystems

to the applicable requirements of Specification A703/A703M,

may result in non-conformities with the specification. Inch-

includingthesupplementaryrequirementsthatareindicatedon

pound units are applicable for material ordered to this Speci-

the purchase order.

fication and SI units for material ordered to this Specification.

3.2 Terminology and test methods shall be in accordance

1.4 If, by agreement, castings are to be supplied in a

with Test Methods and Definitions A370.

partially completed condition, that is, all of the provisions of

3.3 In the case of conflict between requirements of this

theproductspecificationhavenotbeenfilled,thenthematerial

specification and referenced specifications, the former shall

marking (see Section 15) and certification (see Section 14) are

prevail.

to reflect the extent to which the product specification require-

ments have been met.

4. Ordering Information

4.1 It shall be the responsibility of the purchaser to specify

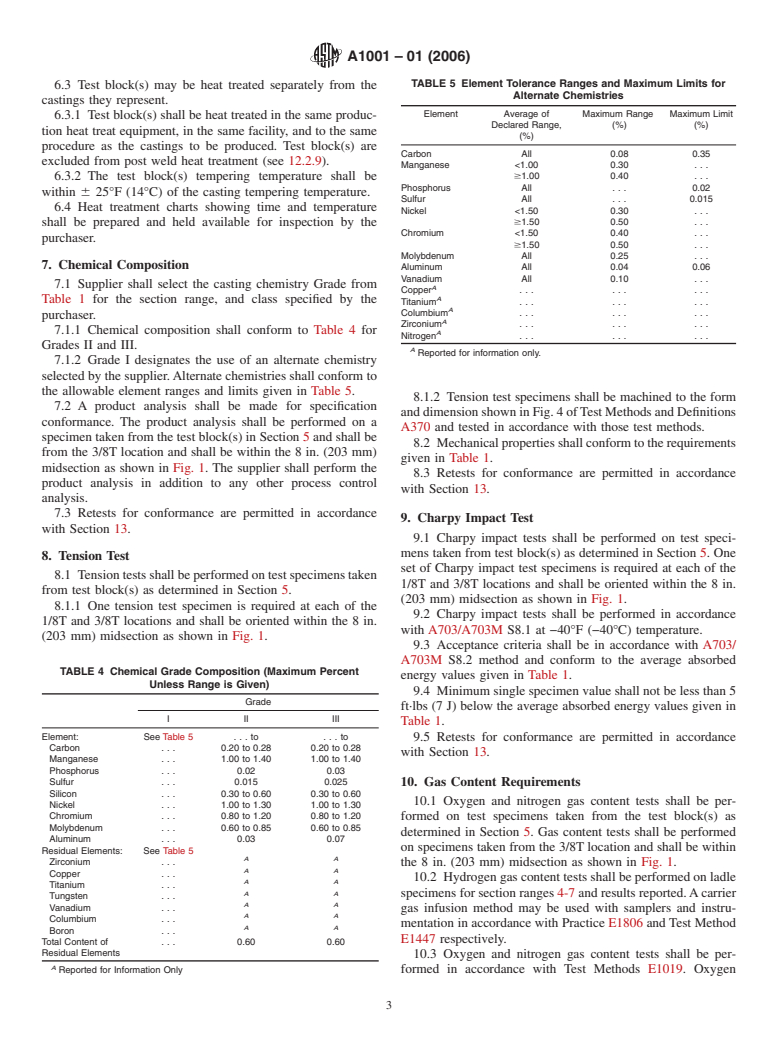

2. Referenced Documents

all requirements that are necessary for material ordered under

2.1 ASTM Standards:

this specification. Such requirements to be considered include,

A370 Test Methods and Definitions for Mechanical Testing

but are not limited to, the following:

of Steel Products

4.1.1 A description of the casting by pattern number or a

A609/A609M Practice for Castings, Carbon, Low-Alloy,

fully dimensional and toleranced drawing,

and Martensitic Stainless Steel, Ultrasonic Examination

4.1.2 ASTM designation and year of issue,

Thereof

4.1.3 Section range and class of steel (see Table 1),

A703/A703M Specification for Steel Castings, General Re-

4.1.4 Definition of inspection methods, extent of examina-

quirements, for Pressure-Containing Parts

tion, frequency, casting quality zones, and acceptance criteria

E94 Guide for Radiographic Examination

(see Section 11).

E165 PracticeforLiquidPenetrantExaminationforGeneral

4.1.5 Product marking locations (see Section 15),

Industry

4.1.6 Certification report options (see Section 14),

4.1.7 Options in the specification (see 1.4 and 11.6), and

1

4.1.8 The supplementary requirements desired.

This specification is under the jurisdiction of ASTM Committee A01 onSteel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.18 on Castings.

Current edition approved March 1, 2006. Published March 2006. Originally

2

approved in 1999. Last previous edition approved in 2001 as A1001-01. DOI: AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

10.1520/A1001-01R06. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A1001 – 01 (2006)

TABLE 1 Required Mechanical Properties

Chemistry Tensile Strength Yield Strength,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.