ASTM G64-99

(Classification)Standard Classification of Resistance to Stress-Corrosion Cracking of Heat-Treatable Aluminum Alloys

Standard Classification of Resistance to Stress-Corrosion Cracking of Heat-Treatable Aluminum Alloys

SCOPE

1.1 This standard contains alphabetical ratings of the relative resistance to SCC of various mill product forms of the wrought 2XXX, 6XXX, and 7XXX series heat-treated aluminum alloys and the procedure for determining the ratings.

1.2 The ratings do not apply to metal in which the metallurgical structure has been altered by welding, forming, or other fabrication processes.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 64 – 99

Standard Classification of

Resistance to Stress-Corrosion Cracking of Heat-Treatable

Aluminum Alloys

ThisstandardisissuedunderthefixeddesignationG 64;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Stresscorrosionbehaviorisanimportantcharacteristictobeconsideredwhenoptimizingthechoice

of material for an engineering structure. Unfortunately, there is no generally accepted scale for

measuring it, and stress corrosion tendencies are difficult to define because of the complex

interdependence of the material, tensile stress, environment, and time. Conventional test-dependent

types of laboratory stress corrosion data have only very limited applicability in mathematical models

used for materials selection.

This standard is intended to provide a qualitative classification of the relative resistance to

stresscorrosioncracking(SCC)ofhigh-strengthaluminumalloystoassistintheselectionofmaterials.

The classification is based on a combination of service experience and a widely accepted laboratory

corrosion test.

It is cautioned, however, that any such generalized classification of alloys can involve an

oversimplification in regard to their behavior in unusual environments. Moreover, the quantitative

prediction of the service performance of a material in a specific situation is outside the scope of this

standard.

1. Scope 3. Terminology

1.1 This standard contains alphabetical ratings of the rela- 3.1 Definitions:

tive resistance to SCC of various mill product forms of the 3.1.1 lot—an identifiable quantity of material of the same

wrought 2XXX, 6XXX, and 7XXX series heat-treated alumi- mill form, alloy, temper, section and size (or thickness, in the

num alloys and the procedure for determining the ratings. case of sheet and plate) traceable to a heat treat lot or lots, and

1.2 The ratings do not apply to metal in which the metal- subjected to inspection at one time.

lurgical structure has been altered by welding, forming, or 3.1.2 stress-corrosion cracking (SCC)—a cracking process

other fabrication processes. that requires the simultaneous action of a corrodent and

sustained tensile stress. SCC in aluminum alloy products

2. Referenced Documents

historically has been observed to follow an intergranular path

2.1 ASTM Standards: leading to the ultimate fracture. Thus, for the purpose of this

G 44 Practice for Evaluating Stress Corrosion Cracking

standard, a fractured test specimen that reveals only pitting

ResistanceofMetalsandAlloysbyAlternateImmersionin

corrosion or pitting plus transgranular cracking shall not be

3.5 % Sodium Chloride Solution considered as an SCC failure (Test Method G 47).

G 47 Test Method for Determining Susceptibility to Stress-

4. Significance and Use

Corrosion Cracking of High-Strength Aluminum Alloy

Products 4.1 Thisclassificationinvolvesalphabeticalratingsintended

only to provide a qualitative guide for materials selection. The

ratings are based primarily on the results of standard corrosion

tests.

This classification is under the jurisdiction of ASTM Committee G-1 on

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on

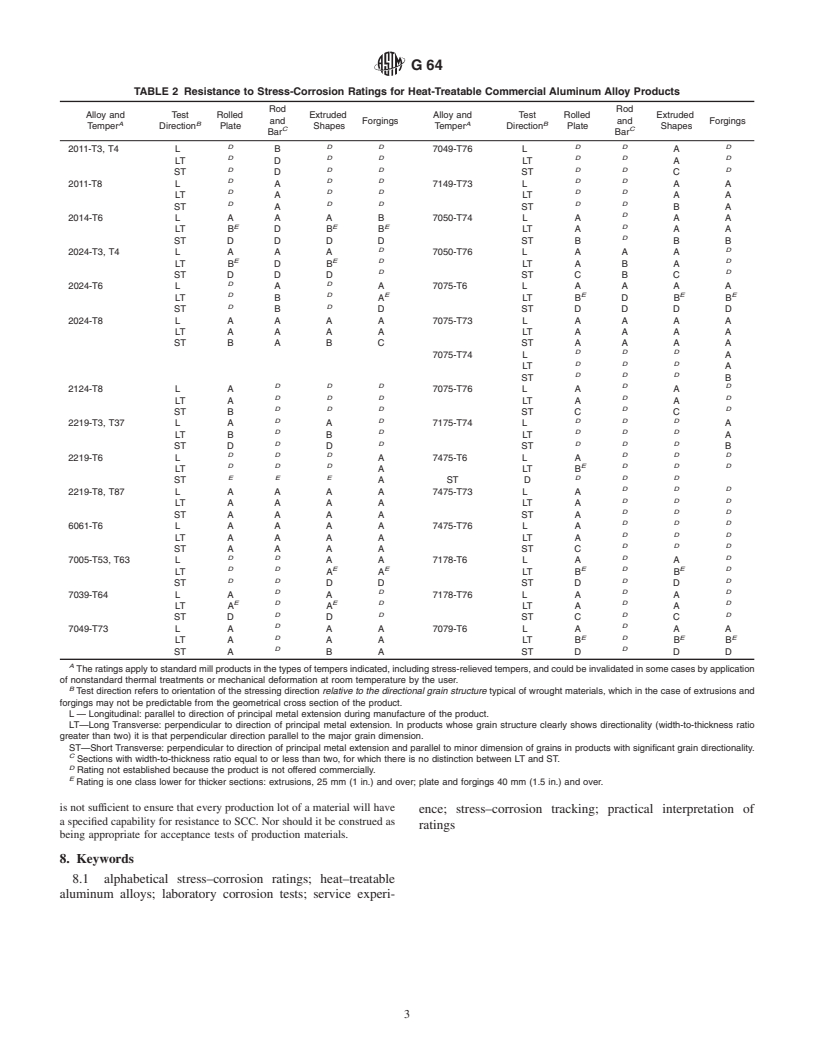

4.2 Interpretations of the SCC ratings in terms of typical

Stress Corrosion Cracking and Corrosion Fatigue.

problem areas including service experience are given in Table

Current edition approved Aug. 10, 1999. Published September 1999. Originally

e1 1. Practical experience has shown that SCC problems with

published as G 64 – 80. Last previous edition G 64 –91 (1997) .

Annual Book of ASTM Standards, Vol 03.02. aluminum alloys generally have involved situations where the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G64

TABLE 1 Practical Interpretation of Ratings for Resistance to SCC

NOTE 1—The stress levels mentioned below and the test stresses mentioned in 6.2 are not to be interpreted as “threshold” stresses, and are not

recommended for design. Other documents, such as MIL-HANDBOOK-5, MIL-STD-1568, NASC SD-24, and MSFC-SPEC-522A, should be consulted

for design recommendations.

Rating Interpretation

A

A Very high. SCC not anticipated in general applications if the total sustained tensile stress is less than 75 % of the minimum specified yield strength for

the alloy, heat treatment, product form, and orientation.

A

B High. SCC not anticipated if the total sustained tensile stress is less than 50 % of the minimum specified yield strength.

A

C Intermediate. SCC not anticipated if the total sustained tensile stress is less than 25 % of the minimum specified yield strength. This rating is designated

for the short transverse direction in improved products used primarily for high resistance to exfoliation corrosion in relatively thin structures where appre-

ciable short transverse stresses are unlikely.

A

D Low. SCC failures have occurred in service or would be anticipated if there is any sustained tensile stress in the designated test direction. This rating cur-

rently is designated only for the short transverse direction in certain materials.

A

The sum of all stresses including those from service loads (applied), heat treatement, straightening, forming, and so forth.

direction and magnitude of the tensile stresses resulting from A—Equal to or greater than 75 % of the specified minimum

manufacturing or use, or both, of the material were not yield strength.

recognized. B—Equal to or greater than 50 % of the specified minimum

4.3 AlistoftheSCCratingsfortheheat-treatablealuminum yield strength.

alloyproductsisgiveninTable2.Revisionstothetablewillbe C—Equal to or greater than 25 % of the specified minimum

required as new materials become available and additional test yield strength or 100 MPa (14.5 ksi), whichever is higher.

results are accumulated. D—Fails to meet the criterion for rating C.

4.4 These alphabetical ratings are not suitable for direct use 6.2 Specimens shall be exposed by alternate immersion in

in mathematical models for material selection, but numerical 3.5 % sodium chloride solution in accordance with Practice

weights and confidence factors can be devised on thebasis of G 44.

experience and judgment of the materials engineer. 6.3 The length of exposure shall be selected according to

alloy type and specimen orientation as follows:

A

5. Basis of Classification

Test Direction

Alloy Type ST L and LT

5.1 The stress corrosion ratings for new or additional

2XXX 10 days 40 days

materials shall be based on laboratory tests of standard smooth

6XXX 90 days 90 days

7XXX 20 days 40 days

specimens for susceptibility at specified stress levels. The

A

See Footnote B, Table 2.

3.5 % NaCl alternate immersion test (Practice G 44) was

These exposure periods are believed to be long enough to

chosen for the laboratory test because it is widely used for

detect susceptibility to intergranular SCC in each instance, yet

aluminum alloys and is capable of detecting mate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.