ASTM G64-99(2005)

(Classification)Standard Classification of Resistance to Stress-Corrosion Cracking of Heat-Treatable Aluminum Alloys

Standard Classification of Resistance to Stress-Corrosion Cracking of Heat-Treatable Aluminum Alloys

SCOPE

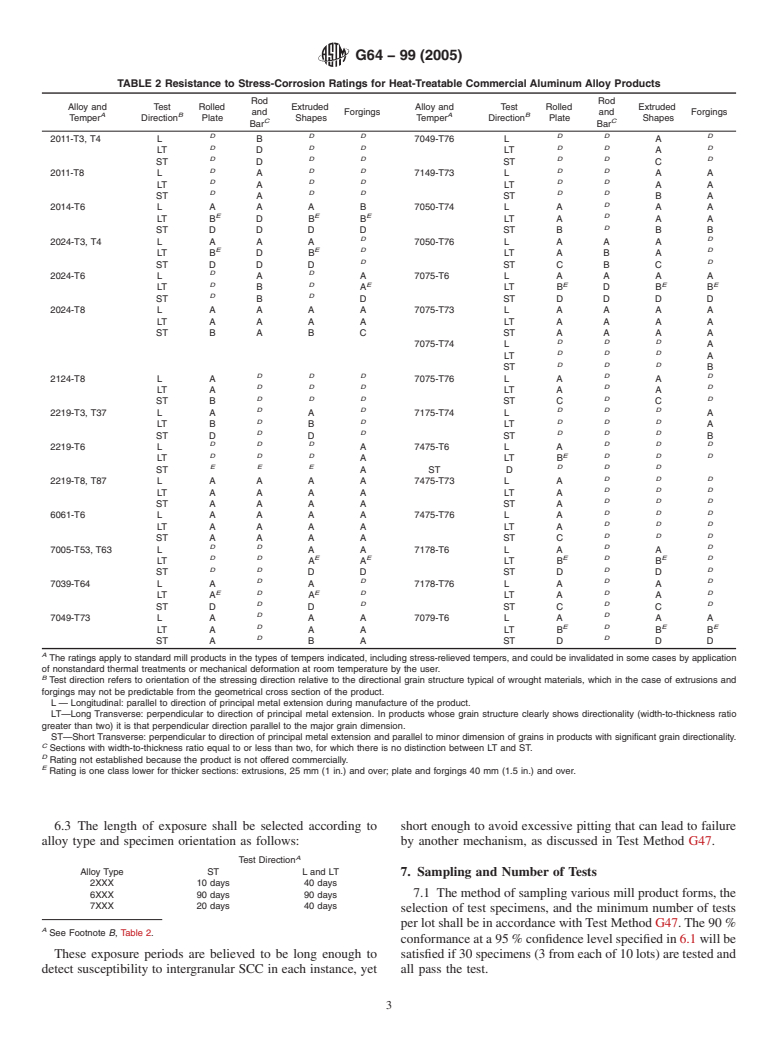

1.1 This classification covers alphabetical ratings of the relative resistance to SCC of various mill product forms of the wrought 2XXX, 6XXX, and 7XXX series heat-treated aluminum alloys and the procedure for determining the ratings.

1.2 The ratings do not apply to metal in which the metallurgical structure has been altered by welding, forming, or other fabrication processes.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G64 −99(Reapproved2005)

Standard Classification of

Resistance to Stress-Corrosion Cracking of Heat-Treatable

Aluminum Alloys

ThisstandardisissuedunderthefixeddesignationG64;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Stresscorrosionbehaviorisanimportantcharacteristictobeconsideredwhenoptimizingthechoice

of material for an engineering structure. Unfortunately, there is no generally accepted scale for

measuring it, and stress corrosion tendencies are difficult to define because of the complex

interdependence of the material, tensile stress, environment, and time. Conventional test-dependent

types of laboratory stress corrosion data have only very limited applicability in mathematical models

used for materials selection.

This standard is intended to provide a qualitative classification of the relative resistance to stress

corrosion cracking (SCC) of high-strength aluminum alloys to assist in the selection of materials. The

classification is based on a combination of service experience and a widely accepted laboratory

corrosion test.

It is cautioned, however, that any such generalized classification of alloys can involve an

oversimplification in regard to their behavior in unusual environments. Moreover, the quantitative

prediction of the service performance of a material in a specific situation is outside the scope of this

standard.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This classification covers alphabetical ratings of the

G44 PracticeforExposureofMetalsandAlloysbyAlternate

relative resistance to SCC of various mill product forms of the

Immersion in Neutral 3.5 % Sodium Chloride Solution

wrought 2XXX, 6XXX, and 7XXX series heat-treated alumi-

G47 Test Method for Determining Susceptibility to Stress-

num alloys and the procedure for determining the ratings.

Corrosion Cracking of 2XXX and 7XXX Aluminum

1.2 The ratings do not apply to metal in which the metal- Alloy Products

lurgical structure has been altered by welding, forming, or 2.2 Other Documents:

MIL-HANDBOOK-5 Metallic Materials and Elements for

other fabrication processes.

Aerospace Vehicle Structures

1.3 The values stated in SI units are to be regarded as the

MIL-STD-1568 Materials and Processes for Corrosion Pre-

standard. The values given in parentheses are for information

vention and Control in Aerospace Systems

only.

MSFC-SPEC-522A Design Criteria for Controlling Stress

Corrosion Cracking

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This classification is under the jurisdiction of ASTM Committee G01 on Standards volume information, refer to the standard’s Document Summary page on

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on the ASTM website.

Environmentally Assisted Cracking. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Current edition approved May 1, 2005. Published May 2005. Originally Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098

approved in 1980. Last previous edition approved in 1999 as G64 – 99. DOI: Available from NationalAeronautics and SpaceAdministration (NASA), 300 E

10.1520/G0064-99R05. St. SW, Washington, D.C.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G64−99(2005)

TABLE 1 Practical Interpretation of Ratings for Resistance to SCC

NOTE 1—The stress levels mentioned below and the test stresses mentioned in 6.2 are not to be interpreted as “threshold” stresses, and are not

recommended for design. Other documents, such as MIL-HANDBOOK-5, MIL-STD-1568, NASC SD-24, and MSFC-SPEC-522A, should be consulted

for design recommendations.

Rating Interpretation

A

A Very high. SCC not anticipated in general applications if the total sustained tensile stress is less than 75 % of the minimum specified yield strength for

the alloy, heat treatment, product form, and orientation.

A

B High. SCC not anticipated if the total sustained tensile stress is less than 50 % of the minimum specified yield strength.

A

C Intermediate. SCC not anticipated if the total sustained tensile stress is less than 25 % of the minimum specified yield strength. This rating is designated

for the short transverse direction in improved products used primarily for high resistance to exfoliation corrosion in relatively thin structures where appre-

ciable short transverse stresses are unlikely.

A

D Low. SCC failures have occurred in service or would be anticipated if there is any sustained tensile stress in the designated test direction. This rating cur-

rently is designated only for the short transverse direction in certain materials.

A

The sum of all stresses including those from service loads (applied), heat treatement, straightening, forming, and so forth.

3. Terminology specimens for susceptibility at specified stress levels. The

3.5 % NaCl alternate immersion test (Practice G44) was

3.1 Definitions:

chosen for the laboratory test because it is widely used for

3.1.1 lot—an identifiable quantity of material of the same

aluminum alloys and is capable of detecting materials that

mill form, alloy, temper, section, and size (or thickness, in the

would be likely to be susceptible to SCC in natural environ-

case of sheet and plate) traceable to a heat treat lot or lots, and

ments.

subjected to inspection at one time.

5.2 Other types of tests using precracked specimens or

3.1.2 stress-corrosion cracking (SCC)—a cracking process

dynamic loading have promise as alternative or supplemen-

that requires the simultaneous action of a corrodent and

tary methods, but they presently require better understanding

sustained tensile stress. SCC in aluminum alloy products

and standardization.

historically has been observed to follow an intergranular path

leading to the ultimate fracture. Thus, for the purpose of this

6. Test Method

standard, a fractured test specimen that reveals only pitting

6.1 To rate a new material and test direction, stress-

corrosion or pitting plus transgranular cracking shall not be

corrosion tests shall be performed on at least ten random lots.

considered as an SCC failure (Test Method G47).

The highest rating assigned shall be that for which the test

4. Significance and Use

results show 90 % conformance at the 95 % confidence level

when tested at the following stresses:

4.1 Thisclassificationinvolvesalphabeticalratingsintended

A—Equal to or greater than 75 % of the specified minimum

only to provide a qualitative guide for materials selection. The

yield strength.

ratings are based primarily on the results of standard corrosion

B—Equal to or greater than 50 % of the specified minimum

tests.

yield strength.

4.2 Interpretations of the SCC ratings in terms of typical

C—Equal to or greater than 25 % of the specified minimum

problem areas including service experience are given in Table

yield strength or 100 MPa (14.5 ksi), whichever is higher.

1. Practical experience has shown that SCC problems with

D—Fails to meet the criterion for rating C.

aluminum alloys generally have involved situations where the

6.2 Specimens shall be exposed by alternate immersion in

direction and magnitude of the tensile stresses

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.