ASTM A684/A684M-86(2002)

(Specification)Standard Specification for Steel, Strip, High-Carbon, Cold-Rolled

Standard Specification for Steel, Strip, High-Carbon, Cold-Rolled

SCOPE

1.1 This specification covers cold-rolled, high-carbon strip. It is furnished in the following types as specified:

1.1.1 Soft spheroidized annealed high-carbon steel is intended for applications requiring maximum cold forming. It is normally produced to give the lowest maximum Rockwell hardness for each grade.

1.1.2 Soft annealed high-carbon steel is intended for applications requiring moderate cold forming. It is produced to a maximum Rockwell hardness.

1.1.3 Intermediate hardness high-carbon steel is intended for applications where cold forming is slight or a stiff, springy product is needed, or both. It is produced to specified Rockwell hardness ranges, the maximum being higher than obtained for the annealed type.

1.1.4 Full hard high-carbon steel is intended for flat applications. It is produced to minimum Rockwell hardness requirements, which vary with grade, microstructure and gage. Full hard can be produced with either a pearlitic or spheroidized microstructure or a mixture of both. The minimum hardness should be established between the consumer and the producer.

1.2 This specification is applicable for orders in either inch-pound units (as A 684) or SI units (A 684M).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 684/A 684M – 86 (Reapproved 2002)

Standard Specification for

Steel, Strip, High-Carbon, Cold-Rolled

This standard is issued under the fixed designationA684/A684M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 This specification covers cold-rolled, high-carbon strip. 3.1 Number 1 or matte (dull) finish—finish without luster,

It is furnished in the following types as specified: produced by rolling on rolls roughened by mechanical or

1.1.1 Soft spheroidized annealed high-carbon steel is in- chemical means.This finish is especially suitable for lacquer or

tended for applications requiring maximum cold forming. It is paint adhesion, and is beneficial in aiding drawing operations

normally produced to give the lowest maximum Rockwell by reducing the contact friction between the die and the strip.

hardness for each grade. 3.2 Number 2 (regular bright) finish—finish produced by

1.1.2 Soft annealed high-carbon steel is intended for appli- rolling on rolls having a moderately smooth finish. It is less

cations requiring moderate cold forming. It is produced to a suitable that No. 1 (matte) finish for cold forming and may be

maximum Rockwell hardness. applicable for certain types of plating.

1.1.3 Intermediate hardness high-carbon steel is intended 3.3 spheroidizing—the heating and cooling of the strip in

for applications where cold forming is slight or a stiff, springy controlled conditions (annealing) to produce a spheroidal or

product is needed, or both. It is produced to specified Rockwell globular form of carbide microconstituent.

hardness ranges, the maximum being higher than obtained for 3.4 stretcher strains—elongated markings that appear on

the annealed type. the surface of the strip when dead soft (fully annealed) material

1.1.4 Full hard high-carbon steel is intended for flat appli- is deformed beyond its yield point (see 5.2).

cations. It is produced to minimum Rockwell hardness require-

4. Ordering Information

ments, which vary with grade, microstructure and gage. Full

4.1 Orders for material under this specification shall include

hard can be produced with either a pearlitic or spheroidized

the following information:

microstructure or a mixture of both. The minimum hardness

should be established between the consumer and the producer. 4.1.1 ASTM designation and date of issue,

4.1.2 Name, type, and steel grade number,

1.2 This specification is applicable for orders in either

inch-pound units (as A 684) or SI units (A 684M). 4.1.3 Hardness (if intermediate or restricted hardness is

specified),

2. Referenced Documents

4.1.4 Decarburization (if required),

2.1 ASTM Standards: 4.1.5 Application,

A 370 Test Methods and Definitions for MechanicalTesting 4.1.6 Dimensions,

of Steel Products 4.1.7 Coil size requirements,

A 682 Specification for Steel, Strip, High-Carbon, Cold- 4.1.8 Edge (indicate No. 1 round, square, etc.),

Rolled, Spring Quality, General Requirements for 4.1.9 Finish (indicate and specify),

A 682M Specification for Steel, Strip, High-Carbon, Cold- 4.1.10 Conditions (specify whether material is oiled or dry),

Rolled, Spring Quality, General Requirements for [Met- 4.1.11 Package (bare coils, skid, etc.),

ric] 4.1.12 Cast or heat (formerly ladle) analysis report (if

E 3 Methods of Preparation of Metallographic Specimens required), and

4.1.13 Special requirements (if required).

1 NOTE 1—A typical ordering description is as follows: ASTM A 684

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

dated ———Cold Rolled, High-Carbon Soft, Strip, Spheroidized 1064,

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee

A01.19 on Steel Sheet and Strip.

Current edition approved November 10, 2002. Published January 2003. Origi-

nally approved in 1973. Last previous edition approved in 1998 as A 684 – 86

(1998).

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 684/A 684M – 86 (2002)

0.042 in. by 6 in. by coil (16 in. ID by 40 in. OD max), No. 5 Edge, No.

7.2 Annealed is mostly a spheroidized structure, but may

2 Finish, Oiled, Bare Skid or

contain some vestiges of pearlite.

“ASTM A 684 dated ———Cold Rolled, High-Carbon, Soft, Strip,

7.3 Spheroidize annealed is essentially free of pearlite.

Spheroidized 1064, 0.6 mm by 200 mm by coil (400 mm ID by 7500 mm

7.4 At least one specimen shall be taken from each lot (see

OD max), No. 3 Edge, No. 2 Finish, Oiled, Bare Skid.”

Specification A 682 or A 682M) for microexamination.

5. Manufacture

7.4.1 The specimens shall be prepared for microscopical

examination in accordance with Methods E 3.

5.1 Condition:

5.1.1 The strip shall be furnished cold rolled spheroidized

8. Mechanical Requirements

annealed, soft annealed, intermediate hardness, or full hard, as

specified.

8.1 Hardness:

5.1.2 Intermediate hardness may be obtained by either

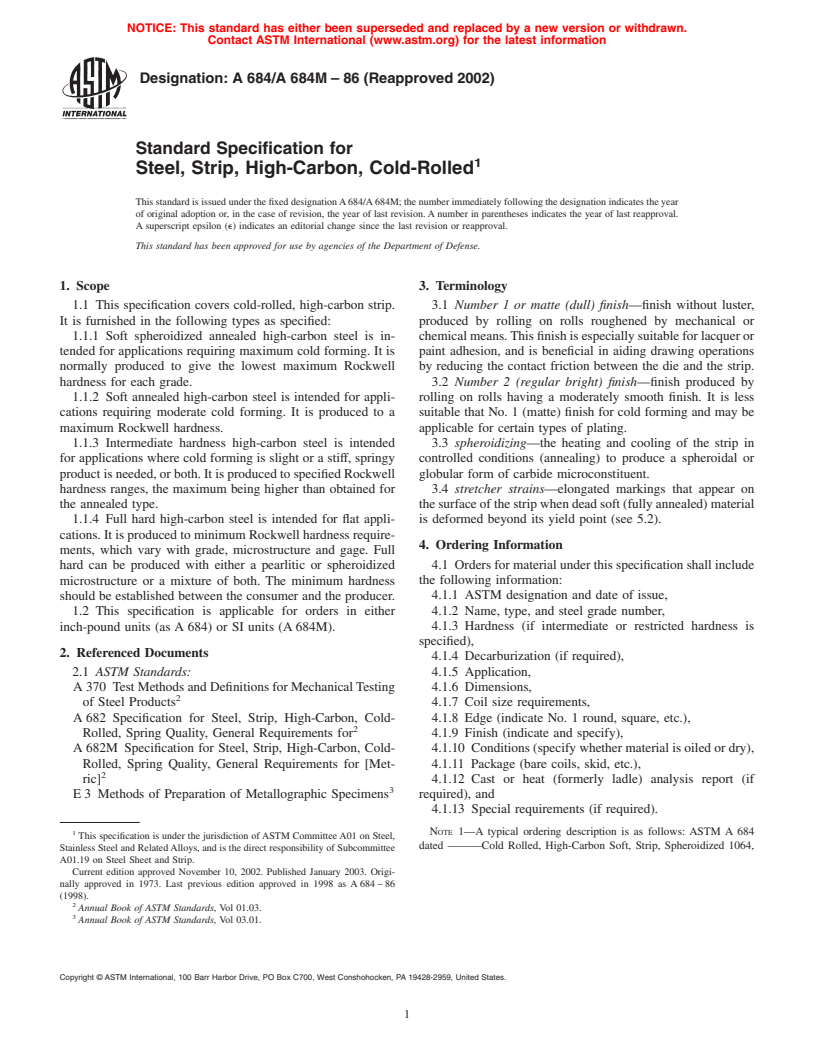

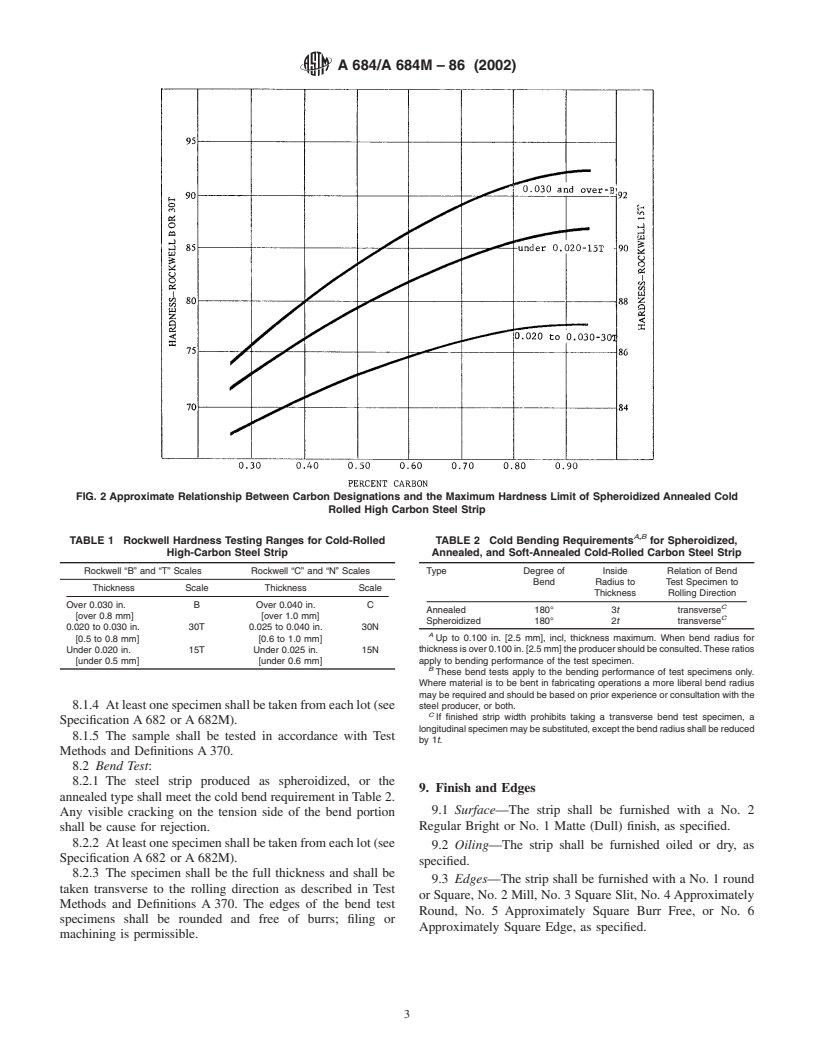

8.1.1 Spheroidized Annealed and Annealed Types—When

rolling the strip after final annealing or by varying the

furnished spheroidized annealed or annealed, the hardness of

annealing treatment, or both.

the strip shall not exceed the maximum values specified in Fig.

5.2 Pinch Pass—Spheroidized annealed and annealed ma-

1 and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.