ASTM A749/A749M-14(2021)

(Specification)Standard Specification for Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements for

Standard Specification for Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements for

ABSTRACT

This specification covers the general requirements for hot-rolled steel strip in coils and cut lengths. It applies to carbon steel and high-strength, low-alloy steel furnished as hot-rolled. Hot-rolled material shall be furnished hot-rolled, not annealed, or pickled. The chemical composition shall be in accordance with the applicable product specification. Where the material is used for fabrication by welding, care must be exercised in the selection of chemical composition or mechanical properties to ensure compatibility with the welding process and its effect on altering the properties. A heat analysis shall be conducted to determine the percentage of elements specified or restricted by the applicable specification. The specimens shall be subjected to bend and tension tests.

SCOPE

1.1 This specification covers the general requirements for hot-rolled steel strip in coils and cut lengths. It applies to carbon steel and high-strength, low-alloy steel furnished as hot-rolled.

1.2 This specification is not applicable to hot-rolled heavy-thickness carbon sheet and strip coils (Specification A1018/A1018M), cold-rolled carbon steel strip (Specification A109/A109M), high-strength, low-alloy cold-rolled steel (Specifications A606/A606M and A1008/A1008M) or cold-rolled high carbon steel (Specification A684/A684M).

1.3 In case of any conflict in requirements, the requirements of the individual material specification shall prevail over those of this general specification.

1.4 For the purposes of determining conformance with this and the appropriate product specification referenced under 2.1, values shall be rounded to the nearest unit in the right hand place of figures used in expressing the limiting values in accordance with the rounding method of Practice E29.

1.5 Annex A1 lists permissible variations in dimensions and mass (Note 1) in SI [metric] units. The values listed are not exact conversions of the values listed in the inch-pound tables, but instead are rounded or rationalized values. Conformance to Annex A1 is mandatory when the “M” specification is used.

Note 1: The term “weight” is used when inch-pound units are the standard; however, under SI, the preferred term is “mass.”

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.7 This specification and the applicable material specifications are expressed in both inch-pound units and SI units. However, unless the order specifies the applicable “M” specification designation (SI units), the material shall be furnished to inch-pound units.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A749/A749M −14 (Reapproved 2021)

Standard Specification for

Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-

Rolled, General Requirements for

This standard is issued under the fixed designationA749/A749M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.7 This specification and the applicable material specifica-

tions are expressed in both inch-pound units and SI units.

1.1 This specification covers the general requirements for

However, unless the order specifies the applicable “M” speci-

hot-rolled steel strip in coils and cut lengths. It applies to

fication designation (SI units), the material shall be furnished

carbon steel and high-strength, low-alloy steel furnished as

to inch-pound units.

hot-rolled.

1.8 This international standard was developed in accor-

1.2 This specification is not applicable to hot-rolled heavy-

dance with internationally recognized principles on standard-

thickness carbon sheet and strip coils (Specification A1018/

ization established in the Decision on Principles for the

A1018M), cold-rolled carbon steel strip (Specification A109/

Development of International Standards, Guides and Recom-

A109M), high-strength, low-alloy cold-rolled steel

mendations issued by the World Trade Organization Technical

(Specifications A606/A606M and A1008/A1008M) or cold-

Barriers to Trade (TBT) Committee.

rolled high carbon steel (Specification A684/A684M).

1.3 In case of any conflict in requirements, the requirements

2. Referenced Documents

of the individual material specification shall prevail over those 2

2.1 ASTM Standards:

of this general specification.

A109/A109M Specification for Steel, Strip, Carbon (0.25

1.4 For the purposes of determining conformance with this Maximum Percent), Cold-Rolled

and the appropriate product specification referenced under 2.1,

A370 Test Methods and Definitions for Mechanical Testing

values shall be rounded to the nearest unit in the right hand of Steel Products

place of figures used in expressing the limiting values in

A568/A568M Specification for Steel, Sheet, Carbon,

accordance with the rounding method of Practice E29. Structural,andHigh-Strength,Low-Alloy,Hot-Rolledand

Cold-Rolled, General Requirements for

1.5 AnnexA1 lists permissible variations in dimensions and

A606/A606M Specification for Steel, Sheet and Strip, High-

mass (Note 1) in SI [metric] units. The values listed are not

Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, with

exact conversions of the values listed in the inch-pound tables,

Improved Atmospheric Corrosion Resistance

but instead are rounded or rationalized values. Conformance to

A684/A684M Specification for Steel, Strip, High-Carbon,

Annex A1 is mandatory when the “M” specification is used.

Cold-Rolled

NOTE 1—The term “weight” is used when inch-pound units are the

A700 Guide for Packaging, Marking, and Loading Methods

standard; however, under SI, the preferred term is “mass.”

for Steel Products for Shipment

1.6 The values stated in either SI units or inch-pound units

A751 Test Methods and Practices for Chemical Analysis of

are to be regarded separately as standard. The values stated in

Steel Products

each system are not necessarily exact equivalents; therefore, to

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

ensure conformance with the standard, each system shall be

Alloys, and Ferroalloys

used independently of the other, and values from the two

A1008/A1008M Specification for Steel, Sheet, Cold-Rolled,

systems shall not be combined.

Carbon, Structural, High-Strength Low-Alloy, High-

Strength Low-Alloy with Improved Formability, Required

Hardness, Solution Hardened, and Bake Hardenable

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.19 on Steel Sheet and Strip. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2021. Published September 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1981. Last previous edition approved in 2014 as A0749/A749M – 14. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0749_A0749M-14R21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A749/A749M−14 (2021)

A1018/A1018M Specification for Steel, Sheet and Strip, 5.1.1 The chemical composition shall be in accordance with

Heavy-Thickness Coils, Hot-Rolled, Carbon, the applicable product specification. However, if other compo-

Commercial, Drawing, Structural, High-Strength Low- sitions are required for carbon steel, they shall be prepared in

Alloy, High-Strength Low-Alloy with Improved accordance with Specification A568/A568M, Appendix X2.

Formability, and Ultra-High Strength

5.1.2 Where the material is used for fabrication by welding,

E11 Specification for Woven Wire Test Sieve Cloth and Test care must be exercised in the selection of chemical composi-

Sieves

tion or mechanical properties to ensure compatibility with the

E29 Practice for Using Significant Digits in Test Data to welding process and its effect on altering the properties.

Determine Conformance with Specifications

5.2 Cast or Heat (Formerly Ladle) Analysis:

E290 Test Methods for Bend Testing of Material for Ductil-

5.2.1 An analysis of each cast or heat of steel shall be made

ity

by the manufacturer to determine the percentage of elements

2.2 Military Standards:

specified or restricted by the applicable specification.

MIL-STD-129 Marking for Shipment and Storage

5.2.2 When requested, cast or heat analysis for elements

2.3 Federal Standards:

listed or required shall be reported to the purchaser or to its

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

representative.

Fed. Std. No. 183 Continuous Identification Marking of Iron

5.3 Product, Check, or Verification Analysis:

and Steel Products

5.3.1 Nonkilled steels (such as capped or rimmed) are not

technologically suited to product analysis due to the nonuni-

3. Terminology

formcharacteroftheirchemicalcompositionandtherefore,the

3.1 Definitions of Terms Specific to This Standard:

tolerances referenced in 5.3.2 do not apply. Product analysis is

3.1.1 Product Types:

appropriate on these types of steel only when misapplication is

3.1.2 hot-rolled strip—manufacturedbyhotrollingbilletsor

apparent or for copper when copper steel is specified.

slabstotherequiredthickness;itmaybeproducedsinglewidth

5.3.2 For steels other than nonkilled (capped or rimmed),

or by rolling multiple width and slitting to the desired width; it

product analysis may be made by the purchaser. The chemical

can be supplied in coils or cut lengths as specified.

analysis shall not vary from the limits specified by more than

the amounts in Specification A568/A568M, subsection 5.3

Width, in. Thickness, in.

(Table 2 in A568/A568M). The several determinations of any

Over Through Over Through

1 element in a cast shall not vary both above and below the

... 3 ⁄2 0.044 0.203

3 ⁄2 6 0.044 0.203

specified range.

6 12 0.044 0.230 excl

5.4 Sampling for Product Analysis:

5.4.1 To indicate adequately the representative composition

Width, mm Thickness, mm

of a cast by product analysis, it is general practice to select

Over Through Over Through

samples to represent the steel, as fairly as possible, from a

... 100 1.2 5.0

100 200 1.2 5.0 minimum number of pieces as follows: three pieces for lots up

200 300 1.2 6.0, excl

to 15 tons inclusive, and six pieces for lots over 15 tons

Hot-rolled, high-strength, low-alloy strip is commonly

[15 Mg].

available by size as follows:

5.4.2 When the steel is subject to tension test requirements,

samples for product analysis may be taken either by drilling

Width, in. Thickness, in.

Over Through From Through

entirely through the used tension test specimens themselves or

Coils & Cut Coils

in accordance with 5.4.3.

Lengths Only

... 6 0.054 0.203 0.230 excl 5.4.3 When the steel is not subject to tension test

6 12 0.054 0.230 0.230 excl

requirements, the samples for analysis must be taken by

milling or drilling entirely through the strip in a sufficient

number of places so that the samples are representative of the

Width, mm Thickness, mm

entire strip. The sampling may be facilitated by folding the

Over Through Over Through

... 200 1.8 5.0

strip both ways, so that several samples may be taken at one

200 300 1.8 6.0, excl

drilling. Steel subjected to certain heating operations by the

purchaser may not give chemical analysis results that properly

4. Materials and Manufacture

represent its original composition. Therefore, users must ana-

4.1 Unless otherwise specified, hot-rolled material shall be

lyze chips taken from the steel in the condition in which it is

furnished hot-rolled, not annealed or pickled.

received from the steel manufacturer.

5.5 Specimen Preparation—Drillingsorchipsmustbetaken

5. Chemical Composition

without the application of water, oil, or other lubricant, and

5.1 Limits:

must be free of scale, grease, dirt, or other foreign substances.

They must not be overheated during cutting to the extent of

causing decarburization. Chips must be well mixed, and those

Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

Philadelphia, PA 19111-5094, http://quicksearch.dla.mil. too coarse to pass a No. 10 (2.00 mm) sieve or too fine to

A749/A749M−14 (2021)

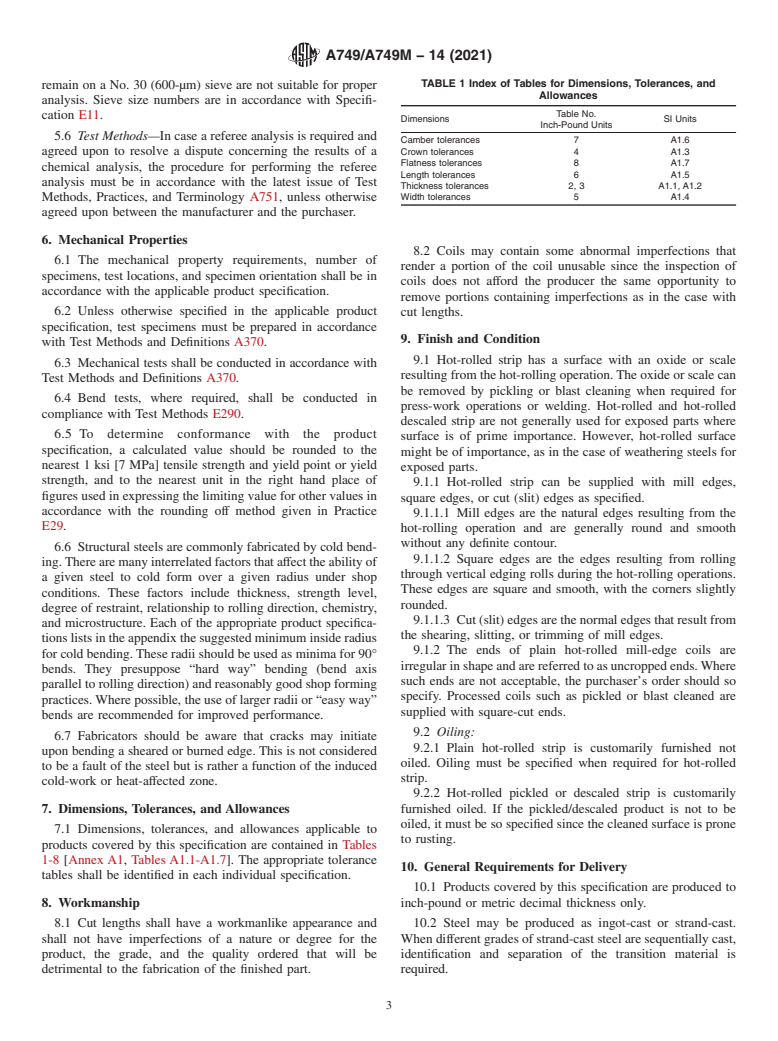

TABLE 1 Index of Tables for Dimensions, Tolerances, and

remain on a No. 30 (600-µm) sieve are not suitable for proper

Allowances

analysis. Sieve size numbers are in accordance with Specifi-

Table No.

cation E11.

Dimensions SI Units

Inch-Pound Units

5.6 Test Methods—In case a referee analysis is required and

Camber tolerances 7 A1.6

agreed upon to resolve a dispute concerning the results of a Crown tolerances 4 A1.3

Flatness tolerances 8 A1.7

chemical analysis, the procedure for performing the referee

Length tolerances 6 A1.5

analysis must be in accordance with the latest issue of Test

Thickness tolerances 2, 3 A1.1, A1.2

Width tolerances 5 A1.4

Methods, Practices, and Terminology A751, unless otherwise

agreed upon between the manufacturer and the purchaser.

6. Mechanical Properties

8.2 Coils may contain some abnormal imperfections that

6.1 The mechanical property requirements, number of

render a portion of the coil unusable since the inspection of

specimens, test locations, and specimen orientation shall be in

coils does not afford the producer the same opportunity to

accordance with the applicable product specification.

remove portions containing imperfections as in the case with

6.2 Unless otherwise specified in the applicable product

cut lengths.

specification, test specimens must be prepared in accordance

9. Finish and Condition

with Test Methods and Definitions A370.

9.1 Hot-rolled strip has a surface with an oxide or scale

6.3 Mechanical tests shall be conducted in accordance with

resulting from the hot-rolling operation. The oxide or scale can

Test Methods and Definitions A370.

be removed by pickling or blast cleaning when required for

6.4 Bend tests, where required, shall be conducted in

press-work operations or welding. Hot-rolled and hot-rolled

compliance with Test Methods E290.

descaled strip are not generally used for exposed parts where

6.5 To determine conformance with the product

surface is of prime importance. However, hot-rolled surface

specification, a calculated value should be rounded to the

might be of importance, as in the case of weathering steels for

nearest 1 ksi [7 MPa] tensile strength and yield point or yield

exposed parts.

strength, and to the nearest unit in the right hand place of

9.1.1 Hot-rolled strip can be supplied with mill edges,

figures used in expressing the limiting value for other values in

square edges, or cut (slit) edges as specified.

accordance with the rounding off method given in Practice

9.1.1.1 Mill edges are the natural edges resulting from the

E29.

hot-rolling operation and are generally round and smooth

without any definite contour.

6.6 Structural steels are commonly fabricated by cold bend-

9.1.1.2 Square edges are the edges resulting from rolling

ing.Therearemanyinterrelatedfactorsthataffecttheabilityof

through vertical edging rolls during the hot-rolling operations.

a given steel to cold form over a given radius under shop

These edges are square and smooth, with the corners slightly

conditions. These factors include thickness, strength level,

rounded.

degree of restraint, relationship to rolling direction, chemistry,

9.1.1.3 Cut (slit) edges are the normal edges that result from

and microstructure. Each of the appropriate product specifica-

the shearing, slitting, or trimming of mill edges.

tions lists in the appendix the suggested minimum inside radius

9.1.2 The ends of plain hot-rolled mill-edge coils are

for cold bending.These radii should be used as minima for 90°

irregularinshapeandarereferredtoasuncroppedends.Where

bends. They presuppose “hard way” bending (bend axis

such ends are not acceptable, the purchaser’s order should so

parallel to rolling direction) and reasonably good shop forming

specify. Processed coils such as pickled or blast cleaned are

practices. Where possible, the use of larger radii or “easy way”

supplied with square-cut ends.

bends are recommended for improved performance.

9.2 Oiling:

6.7 Fabricators should be aware that cracks may initiate

9.2.1 Plain hot-rolled strip is customarily furnished not

upon bending a sheared or burned edge. This is not considered

oiled. Oiling must be specified when required for hot-rolled

to be a fault of the steel but is rather a function of the induced

strip.

cold-work or heat-affected zone.

9.2.2 Hot-rolled pickled or descaled strip is customarily

7. Dimensions, Tolerances, and Allowances furnished oiled. If the pickled/descaled product is not to be

oiled, it must be so specified since the cleaned surface is prone

7.1 Dimensions, tolerances, and allowances applicable to

to rusting.

products covered by this specification are contained in Tables

1-8 [Annex A1, Tables A1.1-A1.7]. The appropriate tolerance

10. General Requirements for Delivery

tables shall be identified in each individ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.