ASTM D4289-97

(Test Method)Standard Test Method for Elastomer Compatibility of Lubricating Greases and Fluids

Standard Test Method for Elastomer Compatibility of Lubricating Greases and Fluids

SCOPE

1.1 This test method evaluates the compatibility of lubricating greases and fluids with coupons cut from standard elastomer sheets (Practice D3182) or, optionally, from SAE Specification AMS 3217/2A (NBR-L) and AMS 3217/3A (CR) sheets. Compatibility is evaluated by determining the changes in volume and Durometer A hardness that occur when elastomer coupons are totally immersed in a lubricant sample for 70 h at either 100 or 150oC or as required by the lubricant specification.

1.1.1 Some lubricant specifications may require different test conditions, such as longer durations or lower or higher temperatures. In such instances, the repeatability and reproducibility values stated in Section 12 do not apply, and the user and supplier should agree on acceptable limits of precision.

Note 1--The scope of this test method now includes the evaluation of the elastomer compatibility of both lubricating fluids and greases. Testing of fluids was not included in Test Method D4289 - 95 and earlier versions.

1.2 This test method can also be used as a guide to evaluate the compatibility of greases with rubber products not in standard sheet form (Practice D3183).

1.3 The values stated in SI and Durometer A units shall be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Note 6, Note 7, and Note 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4289 – 97 An American National Standard

Standard Test Method for

Elastomer Compatibility of Lubricating Greases and Fluids

This standard is issued under the fixed designation D 4289; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 297 Test Methods for Rubber Products—Chemical

Analysis

1.1 This test method evaluates the compatibility of lubricat-

D 412 Test Methods for Vulcanized Rubber and Thermo-

ing greases and fluids with coupons cut from standard elas-

plastic Elastomers—Tension

tomer sheets (Practice D 3182) or, optionally, from SAE

D 471 Test Method for Rubber Property—Effect of Liq-

Specification AMS 3217/2A (NBR-L) and AMS 3217/3A (CR)

uids

sheets. Compatibility is evaluated by determining the changes

D 1193 Specification for Reagent Water

in volume and Durometer A hardness that occur when elas-

D 2240 Test Method for Rubber Property—Durometer

tomer coupons are totally immersed in a lubricant sample for

Hardness

70 h at either 100 or 150°C or as required by the lubricant

D 3182 Practice for Rubber—Materials, Equipment, and

specification.

Procedures for Mixing Standard Compounds and Prepar-

1.1.1 Some lubricant specifications may require different

ing Standard Vulcanized Sheets

test conditions, such as longer durations or lower or higher

D 3183 Practice for Rubber—Preparation of Pieces for Test

temperatures. In such instances, the repeatability and reproduc-

Purposes from Products

ibility values stated in Section 12 do not apply, and the user and

D 4175 Terminology Relating to Petroleum, Petroleum

supplier should agree on acceptable limits of precision.

Products, and Lubricants

NOTE 1—The scope of this test method now includes the evaluation of

D 4950 Classification of and Specification for Automotive

the elastomer compatibility of both lubricating fluids and greases. Testing

Service Greases

of fluids was not included in Test Method D 4289 – 95 and earlier

2.2 Federal Standard:

versions.

Federal Test Method Standard 791C, Method 3603.5,

1.2 This test method can also be used as a guide to evaluate

Swelling of Synthetic Rubbers

the compatibility of greases with rubber products not in

2.3 U.S. Air Force Specification:

standard sheet form (Practice D 3183).

539 Specification Bulletin for Standard Elastomer Stocks

1.3 The values stated in SI and Durometer A units shall be

2.4 SAE Standards:

regarded as the standard.

AMS 3217A Standard Elastomer Stocks—Test Slabs

1.4 This standard does not purport to address all of the

AMS 3217/2A Test Slabs, Acrylonitrile Butadiene (NBR-

safety concerns, if any, associated with its use. It is the

L)—Low Acrylonitrile, 65–75

responsibility of the user of this standard to establish appro-

AMS 3217/3A Test Slabs, Chloroprene (CR)—65–75

priate safety and health practices and determine the applica-

NOTE 2—USAF Specification Bulletin 539 was specified in Test

bility of regulatory limitations prior to use. For specific hazard

Method D 4289 – 94 and earlier versions. This specification is obsolete

statements, see Note 6, Note 7, and Note 8.

and has been replaced by SAE Standard AMS 3217A. USAF-539 NBR-L

has been replaced by SAE AMS 3217/2A (NBR-L), which is virtually

2. Referenced Documents

identical. USAF-539 CR has been replaced by the similar, but not

2.1 ASTM Standards:

identical, SAE AMS 3217/3A (CR). Elastomer sheets prepared to this

D 217 Test Methods for Cone Penetration of Lubricating

Grease

Annual Book of ASTM Standards, Vol 09.01.

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 05.02.

Annual Book of ASTM Standards, Vol 05.03.

1 7

This test method is under the jurisdiction of ASTM Committee D-2 on Available from Standardization Documents Order Desk, Bldg. 4, Section D,

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

D02.G0 on Lubricating Grease. USAF Specification Bulletin 539 is obsolete, but reproductions are available by

Current edition approved June 10, 1997. Published August 1997. Originally requesting RR: D02-1165 from ASTM Headquarters.

published as D 4289 – 89. Last previous edition D 4289 – 95. Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Annual Book of ASTM Standards, Vol 05.01. Warrendale, PA 15096.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4289

latter specification are not known or expected to provide test results

M1 = initial mass of coupon in air, g,

identical with those of the USAF Specification 539 counterpart.

M2 = initial mass of coupon and hanger wire in water less

mass of hanger wire partially submerged in water, g,

3. Terminology

M3 = final mass of coupon in air, g,

3.1 Definitions:

M4 = final mass of coupon and hanger wire in water less

3.1.1 elastomer, n—a natural or synthetic polymer having

mass of hanger wire partially submerged in water, g.

the rubber-like property of substantially recovering its size and

4. Summary of Test Method

shape after removal of a deforming force.

3.1.2 hardness, n—of an elastomer, the resistance to defor-

4.1 A prepared elastomer coupon is measured for initial

mation or indentation.

hardness (Durometer A), density or relative density (to ensure

3.1.2.1 Discussion—In this test method the hardness of an

that the coupon is within specified limits), and volume by water

elastomer is measured with a Shore Durometer A (see Test

displacement. The coupon is immersed in test grease or fluid

Method D 2240).

and aged for 70 h at either 100°C (for chloroprene and similar

3.1.3 lubricant, n—any material interposed between two

flex-resistant elastomers) or 150°C (for nitrile and similar

surfaces that reduces the friction or wear between them.

heat-resistant elastomers) or at other conditions as required by

D 4175

the lubricant specification. The resulting changes in hardness

3.1.4 lubricating grease, n—a semifluid to solid product of

and volume are determined.

a dispersion of a thickener in a liquid lubricant.

5. Significance and Use

3.1.4.1 Discussion—The dispersion of the thickener forms a

two-phase system and immobilizes the liquid lubricant by 5.1 Measurement of the changes in the volume and hardness

surface tension and other physical forces. Other ingredients

of an elastomer that occur from immersion in a lubricating

imparting special properties are often included. D 217 grease or fluid provides a means for evaluating relative

3.1.5 relative density, n—the ratio of the density of a

compatibility. Much of this test method was derived from

material at temperature, t , to the density of water at a reference procedures described in Test Method D 471 and Federal Test

temperature, t .

Method 791C/3603.5. In contrast to these two test methods,

3.1.5.1 Discussion—In this test method relative density is which emphasize the evaluation of rubber and rubber-like

determined with the temperature of the elastomer and water compounds, Test Method D 4289 was developed specifically to

being equal and within the range from 20 to 25°C, and the evaluate lubricating greases and fluids, especially those used in

temperature correction for the density of water is not applied. automotive applications, although the test method can be

The term, relative density, replaces the synonymous, depre- applied to lubricants used in industrial applications as well.

cated term, specific gravity, used in some earlier editions of this Excepting the Shore Durometer A, this test method requires no

test method. specialized, rubber-testing equipment. Virtually all other

3.1.6 thickener, n—in a lubricating grease, a substance equipment and supplies specified in the procedure are stock

composed of finely divided particles dispersed in a liquid items in lubricants laboratories.

lubricant to form the product’s structure. 5.2 The volume and hardness-change values determined by

this test method do not duplicate similar changes that occur in

3.1.6.1 Discussion—The thickener can be fibers (such as

various metallic soaps) or plates or spheres (such as certain elastomeric seals under actual service conditions. However,

they can be correlated in many instances. In one such instance,

non-soap thickeners) which are insoluble or, at most, only very

the volume-change values determined by the antecedent of this

slightly soluble in the liquid lubricant. The general require-

test method correlated (r = 0.99) with those that occurred

ments are that the solid particles be extremely small, uniformly

during a vehicle test. Because of wide variations in service

dispersed, and capable of forming a relatively stable, gel-like

conditions and differences in grease and elastomer formula-

structure with the liquid lubricant. D 217

tions, correlations between the results obtained with this test

3.2 Definitions of Terms Specific to This Standard:

method and particular applications should be determined on an

3.2.1 coupon, n—a test piece of specified dimensions cut

individual basis.

from standard elastomer sheets (Practice D 3182).

5.3 When the optional Reference Elastomers AMS 3217/2A

3.3 Symbols:

(acrylonitrile-butadiene, NBR-L) and AMS 3217/3A (chloro-

3.3.1 Symbols used in the calculation of hardness change

prene, CR) are used to evaluate compatibility, the results can be

(see Eq 1 in 10.1):

used to judge a service characteristic of lubricants. In this

respect, this test method is useful for lubricant specifications

DH = hardness change, Durometer A units,

(for example, Specification D 4950). Similarly, this test method

H = initial hardness, Durometer A units,

i

can be used in specifications for lubricating fluids as well.

H = final hardness, Durometer A units.

f

5.4 With specifications requiring elastomers other than Ref-

3.3.2 Symbols used in the calculation of relative density

erence Elastomers AMS 3217/2A or AMS 3217/3A, coupons

(see Eq 2 in 10.2) and volume change (see Eq 3 in 10.3):

cut from standard sheets (Practice D 3182) should be used.

RD = relative density,

Verdura, T. M., “Evaluating Compatibility of Greases with Elastomeric Seals,”

DV = volume change, %,

NLGI Spokesman, Vol 42, 1978, pp. 20–29.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4289

When the preparation of such coupons is not feasible, or the (approximately 8-mm gape) at the other.

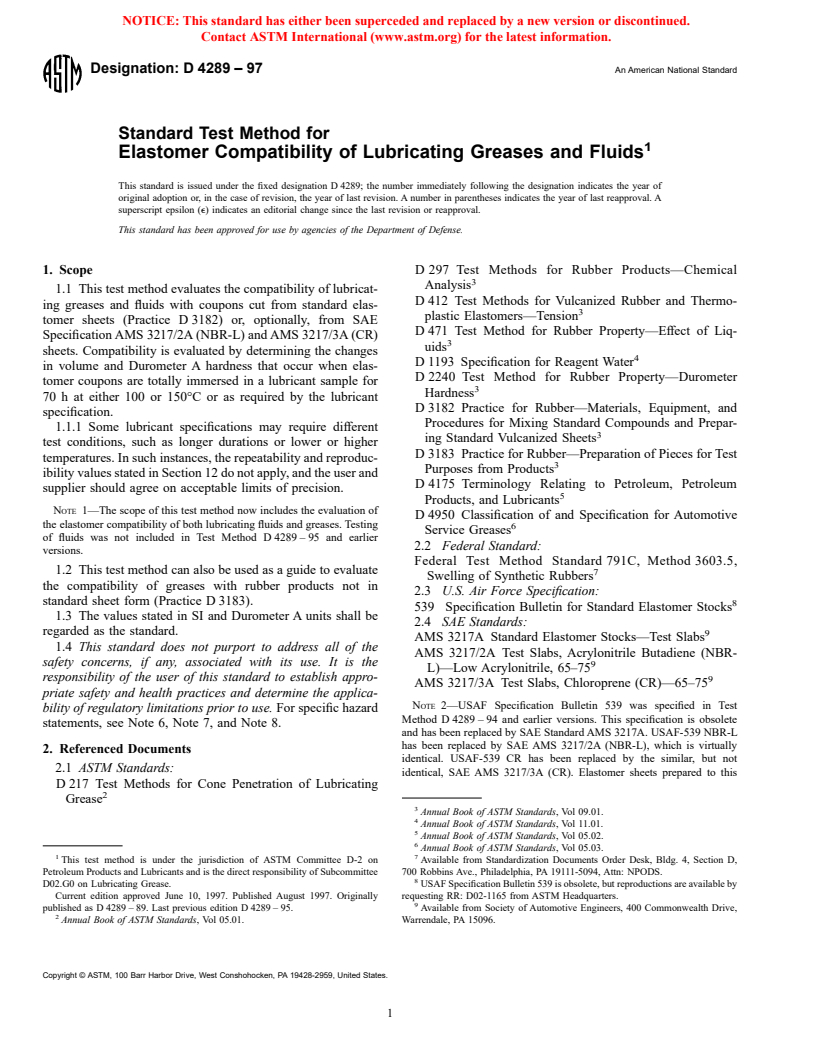

lubricant specification requires the use of rubber products that 7.5 Coupon Suspension Wire, stainless steel, about 0.71 to

do not have a suitable size or configuration for use in preparing 0.72-mm diameter (No. 22 U.S. Steel Wire Gage or Imperial

coupons for testing (Practice D 3183), this test method can be Wire Gage), configured as shown in Fig. 1, to suspend the

used as a guide for evaluating compatibility. coupon below the surface of a fluid sample.

7.6 Laboratory Oven, circulating-air type, capable of main-

NOTE 3—Inasmuch as the precision values apply only to the elastomers

taining the test temperature within6 2.5°C and equipped with

specified in Annex A1 of Test Method D 4289, when a lubricant

one or more grill-type, wire shelves.

specification requires some other elastomer, the user and supplier of the

7.7 Shore Durometer A, stand-mounted type (see Test

lubricant should agree to the values of acceptable precision. Such values

may or may not be the same as those of Test Method D 4289. It is

Method D 2240).

recommended that the agreed upon precision values be stated in the user’s

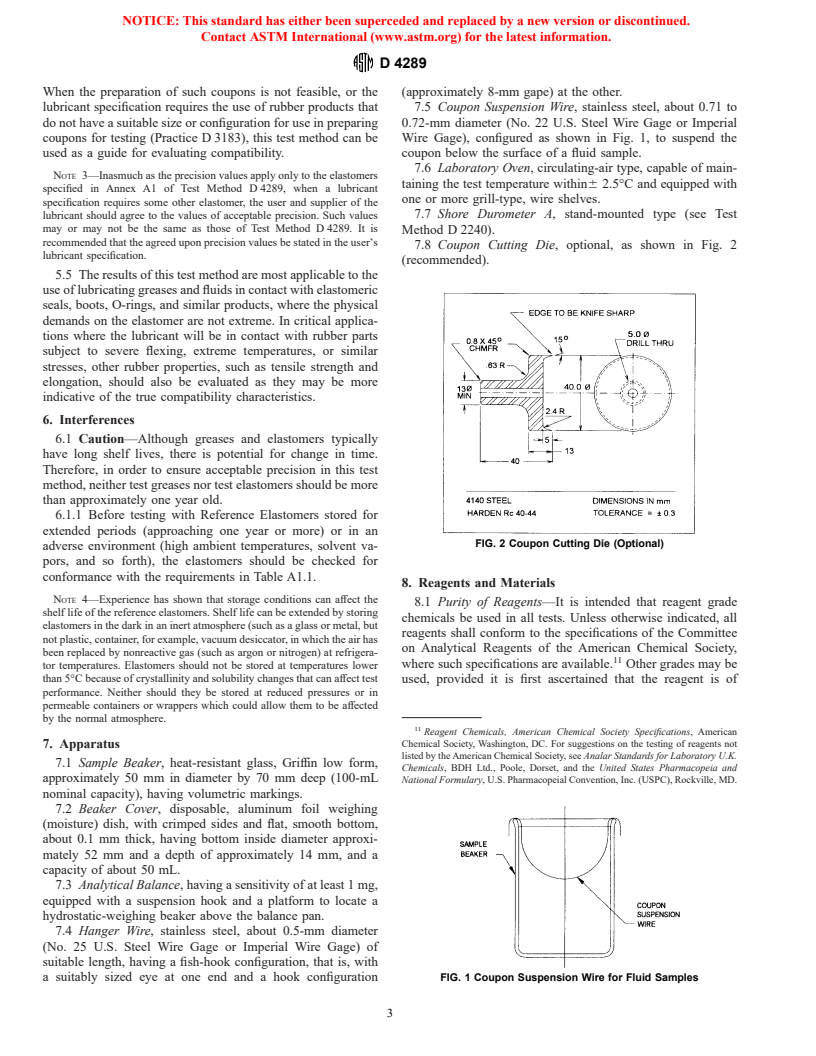

7.8 Coupon Cutting Die, optional, as shown in Fig. 2

lubricant specification.

(recommended).

5.5 The results of this test method are most applicable to the

use of lubricating greases and fluids in contact with elastomeric

seals, boots, O-rings, and similar products, where the physical

demands on the elastomer are not extreme. In critical applica-

tions where the lubricant will be in contact with rubber parts

subject to severe flexing, extreme temperatures, or similar

stresses, other rubber properties, such as tensile strength and

elongation, should also be evaluated as they may be more

indicative of the true compatibility characteristics.

6. Interferences

6.1 Caution—Although greases and elastomers typically

have long shelf lives, there is potential for change in time.

Therefore, in order to ensure acceptable precision in this test

method, neither test greases nor test elastomers should be more

than approximately one year old.

6.1.1 Before testing with Reference Elastomers stored for

extended periods (approaching one year or more) or in an

FIG. 2 Coupon Cutting Die (Optional)

adverse environment (high ambient temperatures, solvent va-

pors, and so forth), the elastomers should be checked for

conformance with the requirements in Table A1.1.

8. Reagents and Materials

NOTE 4—Experience has shown that storage conditions can affect the

8.1 Purity of Reagents—It is intended that reagent grade

shelf life of the reference elastomers. Shelf life can be extended by storing

chemicals be used in all tests. Unless otherwise indicated, all

elastomers in the dark in an inert atmosphere (such as a glass or metal, but

reagents shall conform to the specifications of the Committee

not plastic, container, for example, vacuum desiccator, in which the air has

on Analytical Reagents of the American Chemical Society,

been replaced by nonreactive gas (such as argon or nitrogen) at refrigera-

where such specifications are available. Other grades may be

tor temperatures. Elastomers should not be stored at temperatures lower

than 5°C because of crystallinity and solubility changes that can affect test

used, provided it is first ascertained that the reagent is of

performance. Neither should they be stored at reduced pressures or in

permeable containers or wrappers which could allow them to be affected

by the normal atmosphere.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

7. Apparatus

listed by the American Chemical Society, see Analar Standards for Laboratory U.K.

7.1 Sample Beaker, heat-resistant glass, Griffin low form,

Chemicals, BDH Ltd., Poole, Dorset, and the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.