ASTM D4950-22

(Specification)Standard Classification and Specification for Automotive Service Greases

Standard Classification and Specification for Automotive Service Greases

SCOPE

1.1 This specification covers lubricating greases suitable for the periodic relubrication of chassis systems and wheel bearings of passenger cars, trucks, and other vehicles.

1.2 This specification defines the requirements used to describe the properties and performance characteristics of chassis greases and wheel bearing greases for service-fill applications.

1.3 The test requirements (acceptance limits) given in this specification are, as the case may be, minimum or maximum acceptable values for valid duplicate test results. Apply no additional corrections for test precision, such as described in Practice D3244, inasmuch as the precision of the test methods was taken into account in the determination of the requirements.

1.4 The values stated in SI units are to be regarded as standard.

1.4.1 Exceptions—Test Method D2596 reports test results in kgf units, and Test Method D4289 reports rubber hardness in Durometer Shore A units.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D4950 −22

Standard Classification and Specification for

1,2

Automotive Service Greases

This standard is issued under the fixed designation D4950; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This specification describes current categories of lubricating greases for automotive service-fill

applications. A specific designation is assigned to each category. The system is open ended, that is,

new designations are assigned for use with new categories as each new set of grease performance

characteristics is defined. Grease categories are referenced by automotive manufacturers in making

lubrication recommendations and used by grease suppliers and users in identifying products for

specific applications.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 Thisspecificationcoverslubricatinggreasessuitablefor

the periodic relubrication of chassis systems and wheel bear-

2. Referenced Documents

ings of passenger cars, trucks, and other vehicles.

3

2.1 ASTM Standards:

1.2 This specification defines the requirements used to

D217Test Methods for Cone Penetration of Lubricating

describe the properties and performance characteristics of

Grease

chassis greases and wheel bearing greases for service-fill

D1264Test Method for Determining the Water Washout

applications.

Characteristics of Lubricating Greases

1.3 The test requirements (acceptance limits) given in this

D1742Test Method for Oil Separation from Lubricating

specification are, as the case may be, minimum or maximum

Grease During Storage

acceptable values for valid duplicate test results. Apply no

D1743Test Method for Determining Corrosion Preventive

additional corrections for test precision, such as described in

Properties of Lubricating Greases

Practice D3244, inasmuch as the precision of the test methods

D2265Test Method for Dropping Point of Lubricating

was taken into account in the determination of the require-

Grease Over Wide Temperature Range

ments.

D2266Test Method for Wear Preventive Characteristics of

1.4 The values stated in SI units are to be regarded as

Lubricating Grease (Four-Ball Method)

standard.

D2596Test Method for Measurement of Extreme-Pressure

1.4.1 Exceptions—TestMethodD2596reportstestresultsin

Properties of Lubricating Grease (Four-Ball Method)

kgf units, and Test Method D4289 reports rubber hardness in

D3244Practice for Utilization of Test Data to Determine

Durometer Shore A units.

Conformance with Specifications

D3527Test Method for Life Performance of Automotive

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard- Wheel Bearing Grease

D4170Test Method for Fretting Wear Protection by Lubri-

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- cating Greases

D4175Terminology Relating to Petroleum Products, Liquid

Fuels, and Lubricants

D4289Test Method for Elastomer Compatibility of Lubri-

1

This classification and specification is under the jurisdiction of ASTM

cating Greases and Fluids

Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the

direct responsibility of Subcommittee D02.B0.04 on Automotive Greases.

Current edition approved Dec. 1, 2022. Published January 2023. Originally

published in 1989. Last previous edition approved in 2019 as D4950–19. DOI:

3

10.1520/D4950-22. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

2

This classification and specification was developed as a cooperative effort contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

among the American Society for Testing and Materials, the National Lubricating Standards volume information, refer to the standard’s Document Summary page on

Grease Institute (NLGI), and the Society of Automotive Engineers (SAE). the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

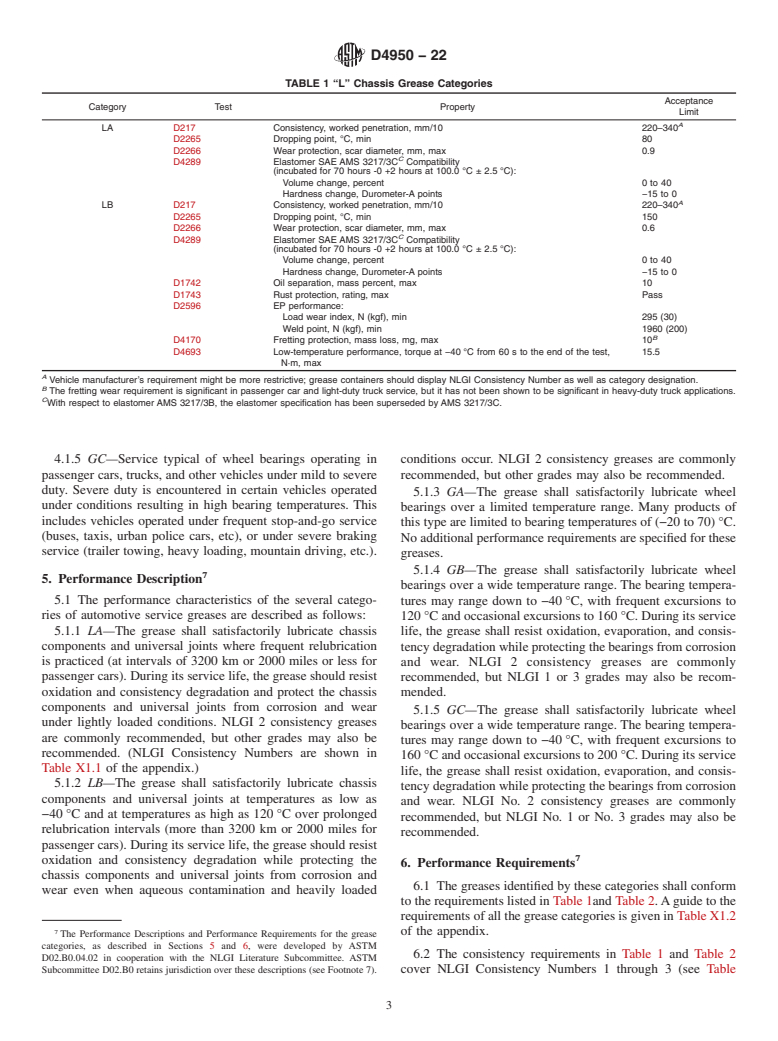

D4950−22

D4290Test Method for Determining the Leakage Tenden- 3.2.5 “G” category group, n—automotiveservicegreasesof

cies of Automotive Wheel Bearing Grease Under Accel- such composition, properties, and performance characteristics

erated Conditions as to be suitable for the service lubrication o

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4950 − 19 D4950 − 22

Standard Classification and Specification for

1,2,

Automotive Service Greases

This standard is issued under the fixed designation D4950; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This specification describes current categories of lubricating greases for automotive service-fill

applications. A specific designation is assigned to each category. The system is open ended, that is,

new designations are assigned for use with new categories as each new set of grease performance

characteristics is defined. Grease categories are referenced by automotive manufacturers in making

lubrication recommendations and used by grease suppliers and users in identifying products for

specific applications.

1. Scope*

1.1 This specification covers lubricating greases suitable for the periodic relubrication of chassis systems and wheel bearings of

passenger cars, trucks, and other vehicles.

1.2 This specification defines the requirements used to describe the properties and performance characteristics of chassis greases

and wheel bearing greases for service-fill applications.

1.3 The test requirements (acceptance limits) given in this specification are, as the case may be, minimum or maximum acceptable

values for valid duplicate test results. Apply no additional corrections for test precision, such as described in Practice D3244,

inasmuch as the precision of the test methods was taken into account in the determination of the requirements.

1.4 The values stated in SI units are to be regarded as standard.

1.4.1 Exceptions—Test Method D2596 reports test results in kgf units, and Test Method D4289 reports rubber hardness in

Durometer Shore A units.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This classification and specification is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility

of Subcommittee D02.B0.04 on Automotive Greases.

Current edition approved Nov. 1, 2019Dec. 1, 2022. Published November 2019January 2023. Originally published in 1989. Last previous edition approved in 20142019

as D4950 – 14.D4950 – 19. DOI: 10.1520/D4950-19.10.1520/D4950-22.

2

This classification and specification was developed as a cooperative effort among the American Society for Testing and Materials, the National Lubricating Grease

Institute (NLGI), and the Society of Automotive Engineers (SAE).

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4950 − 22

2. Referenced Documents

3

2.1 ASTM Standards:

D217 Test Methods for Cone Penetration of Lubricating Grease

D566 Test Method for Dropping Point of Lubricating Grease

D1264 Test Method for Determining the Water Washout Characteristics of Lubricating Greases

D1742 Test Method for Oil Separation from Lubricating Grease During Storage

D1743 Test Method for Determining Corrosion Preventive Properties of Lubricating Greases

D2265 Test Method for Dropping Point of Lubricating Grease Over Wide Temperature Range

D2266 Test Method for Wear Preventive Characteristics of Lubricating Grease (Four-Ball Method)

D2596 Test Method for Measurement of Extreme-Pressure Properties of Lubricating Grease (Four-Ball Method)

D3244 Practice for Utilization of Test Data to Determine Conformance with Specifications

D3527 Test Method for Life Performance of Automotive Wheel Bearing Grease

D4170 Test Method for Fretting Wear Protection by Lubricating Greases

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D4289 Test Method for Elastomer Compatibility of Lubricating Greases and Fluids

D4290 Test Method for Determining the Leakage Tendencies of Automotive Wheel Bearing Grease Under Accelerated

Conditions

D4693 Test Method for Low-Temperature Torque of Grease-Lubricated Wheel Bearings

4

2.2 SAE Standards:

AMS 3217A Standard Elastomer Stock-Test Sla

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.