ASTM F112-00e1

(Test Method)Standard Test Method for Sealability of Enveloped Gaskets

Standard Test Method for Sealability of Enveloped Gaskets

SCOPE

1.1 This test method covers the evaluation of the sealing properties of enveloped gaskets for use with corrosion-resistant process equipment. Enveloped gaskets are described as gaskets having some corrosion-resistant covering over the internal area normally exposed to the corrosive environment. The shield material may be plastic (such as polytetrafluoroethylene) or metal (such as tantalum). A resilient conformable filler is usually used inside the envelope. The design and construction of nonmetallic gaskets is covered in Practice F 336.

1.2 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:F112–00

Standard Test Method for

1

Sealability of Enveloped Gaskets

This standard is issued under the fixed designation F 112; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Adjunct reference was corrected editorially in April 2006.

1. Scope 3. Summary of Method

1.1 This test method covers the evaluation of the sealing 3.1 An enveloped gasket is compressed between two bolted

5

propertiesofenvelopedgasketsforusewithcorrosion-resistant flanges in a special test fixture. After the specified load is

2

process equipment. Enveloped gaskets are described as gas- applied to the gasket, air at the specified pressure is introduced

kets having some corrosion-resistant covering over the internal into the test chamber and then the test chamber is sealed.

area normally exposed to the corrosive environment. The Pressure and temperature readings are taken and recorded at

shieldmaterialmaybeplastic(suchaspolytetrafluoroethylene) specified intervals.The leakage rate is measured by the change

or metal (such as tantalum). A resilient conformable filler is in the test chamber pressure over time. The flange load on the

usually used inside the envelope. The design and construction gasket is increased and the process is repeated.

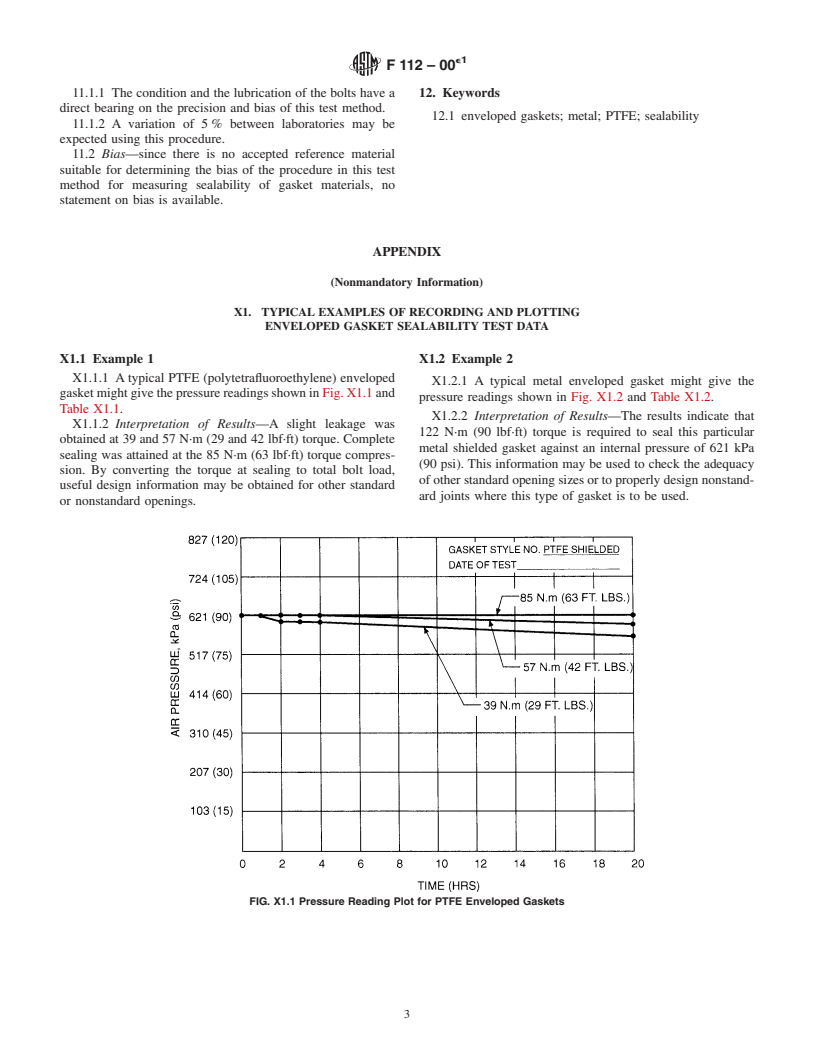

of nonmetallic gaskets is covered in Practice F 336. 3.2 Results of the sealability test are expressed as a graph of

1.2 The values stated in SI units are to be regarded as the the remaining test chamber pressure versus time for the

standard. specified conditions.

1.3 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 This test method is designed to evaluate all types of

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- enveloped gaskets under controlled conditions with respect to

leakage and to provide measurable leakage rates.

bility of regulatory limitations prior to use. For specific

precautionary statements, see Section 6. 4.2 Determining torque required to seal a given gasket is

also part of this test method. By converting the torque at

2. Referenced Documents

sealing to total bolt load, useful design information may be

3

2.1 ASTM Standards: obtained for other standard and nonstandard openings.

F 336 Practice for Design and Construction of Nonmetallic 4.3 This test method may be used as an incoming quality

Enveloped Gaskets for Corrosive Service control test to evaluate similar gaskets from different suppliers.

2.2 ASTM Adjuncts: This test method may also be used as a quality control test

4

Detailed Drawing of Test Fixture whenparametersareagreeduponbetweentheproducerandthe

user.

4.4 Leakage through the gasket or over the gasket, or both,

1

This test method is under the jurisdiction ofASTM Committee F03 on Gaskets is determined by this test method.

and is the direct responsibility of Subcommittee F03.10 on Composite Gaskets.

Current edition approved Oct. 10, 2000. Published November 2000. Originally

5. Apparatus

published as F 112 – 70. Last previous edition F 112 - 95.

5

2

5.1 Leakage Test Unit—The unit shall contain a suitable

This test method is to be used in place of ASTM Test Methods F 37, for

SealabilityofGasketMaterials(AnnualBookofASTMStandards,Vol09.02),which

pressure gage to read from 0 to 2.1 MPa (0 to 300 psig) and

applies only to single-component gasket materials and is not applicable to

mounted as shown in Fig. 1.

envelope-style gaskets. This fixture may also be used for other gasket materials or

5.2 Compressed Air Supply, capable of supplying 621 kPa

designs, with or without modification.

(90 psig) to the test unit.

Supporting data have been filed atASTM International Headquarters and may be

obtained by requesting Research Report RR: F03-1000.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM The sole source of supply of the apparatus known to the committee at this time

Standards volume information, refer to the standard’s Document Summary page on is Pfaudler Co., 1000 West Ave., Rochester, NY 14603. If you are aware of

the ASTM website. alternative suppliers, please provide this information to ASTM International

4

Available from ASTM International Headquarters. Order Adjunct No. Headquarters.Your comments will receive careful consideration at a meeting of the

1

ADJF0112. Original adjunct produced in 1970. responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Ha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.