ASTM D3799-95

(Test Method)Standard Test Method for Purity of Styrene by Freezing Point Method (Withdrawn 2000)

Standard Test Method for Purity of Styrene by Freezing Point Method (Withdrawn 2000)

SCOPE

1.1 This test method is used for determining the purity of styrene expressed as weight percent. All impurities are considered to be ethylbenzene.

1.2 The following applies to all specified limits in this standard: for purposes of determining conformance with this standard, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E29.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 5 and 7.5.

General Information

Standards Content (Sample)

~

ASTM D3799 95 m 0759510 0556849 273 m

AMERICAN SOCIETY FOR TESTING AND MATERIALS

Designation: D 3799 - 95

191 6 Race St Philadelphia. Pa 191 03

#Tb

Reprinted from the Annual Book of Ash Standards. Copyright ASTM

If not Iited in the current combined inde? will appear in the ne>d edition.

Standard Test Method for

Purity of Styrene by Freezing Point Method'

This standard is issued under the fixed designation D 3799; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope of impurities causes a depression of the freezing point which

is proportional to the molal concentration of the contami-

1.1 This test method is used for determining the purity of

nating substances. The freezing point is the highest tempera-

styrene expressed as weight percent. All impunties are

ture obtained after the supercooling of the liquid. For

considered to be ethylbenzene.

purities over 99 % it is not necessary to plot a time-

1.2 The following applies to all specified limits in this

temperature curve.

standard: for purposes of determining conformance with this

3.2 The freezing point methods, Test Methods D 1015

standard, an observed value or a calculated value shall be

and D 1016, specified a platinum resistance thermometer for

rounded off "to the nearest unit" in the last right-hand digit

measuring the temperature. For routine work, mercury-

used in expressing the specification limit, in accordance with

in-glass thermometers are used. Other temperature-mea-

the rounding-off method of Practice E 29.

suring devices can be utilized in this method provided that

1.3 The values stated in SI units are to be regarded as the

they have temperature resolution to 0.0i"C or better. They

standard. The values given in parentheses are for informa-

must be calibrated since small differences in the temperature

tion only.

readings are significant. They must be recalibrated about

1.4 This standard does not purport to address all of the

once per week to correct for differences which may develop

safity concerns, if any, associated with its use. It is the

with age and handling. To simplify the multiple calibrations

responsibility of the user of this standard to establish appro-

the freezing point of a large sample of styrene is determined

priate safety and health practices and determine the applica-

with a platinum resistance thermometer and the mercury-

of regulatory limitations prior to use. Specific hazard

bility

in-glass or other thermometers calibrated against the stan-

statements are given in Section 5 and 7.5.

dard styrene. Styrene may be kept in a deep freeze for several

months with no appreciable change in the freezing point.

2. Referenced Documents

2.1 ASTM Standards: 4. Significance and Use

D 1015 Test Method for Freezing Points of High-Purity

4.1 Purity can be calculated by measuring the freezing

Hydrocarbons2

point and relating to a freezing point for zero impurities.

D1016 Test Method for Punty of Hydrocarbons from

4.2 This test method is in wide use for both producer and

Freezing Points2

consumer for determining purity and is suitable for estab-

D 1193 Specification for Reagent Water3

lishing specifications.

D 3437 Practice for Sampling and Handling Liquid Cyclic

4.3 All impurities are considered to be ethylbenzene.

Products4

E 29 Practice for Using Significant Digits in Test Data to

5. Hazards

Determine Conformance with Specifications5

5.1 Consult current OSHA regulations, supplier's Mate-

2.2 Other Document:

rial Safety Data Sheets, and local regulations for all materials

OSHA Regulations, 29 CFR, paragraphs 19 10.1000 and

used in this test method.

19 10.1 2006

6. Apparatus

3. Summary of Test Method

6.1 Temperature-Measuring Devices-Temperature-mea-

3.1 The purity of the styrene is determined by a measure-

suring devices can be used, provided they have temperature

ment of the freezing point of the sample in equilibrium with

resolution to 0.01"C or better, are operable in the range from

air at atmospheric pressure. The presence of small amounts

-20 to -40"C, and are calibrated against a platinum

resistance thermometer.

6.2 Styrene Freezing Point Thermometer'-Special de-

This test method is under the jurisdiction of ASTM Committee D-i6 on

sign for determination of the freezing point of styrene as

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

shown in Fig. I and described in Table 1 specification.

Subcommittee D16.OH on Styrene, Ethylbenzene, and C9 and Cio Aromatic

Hydrocarbons.

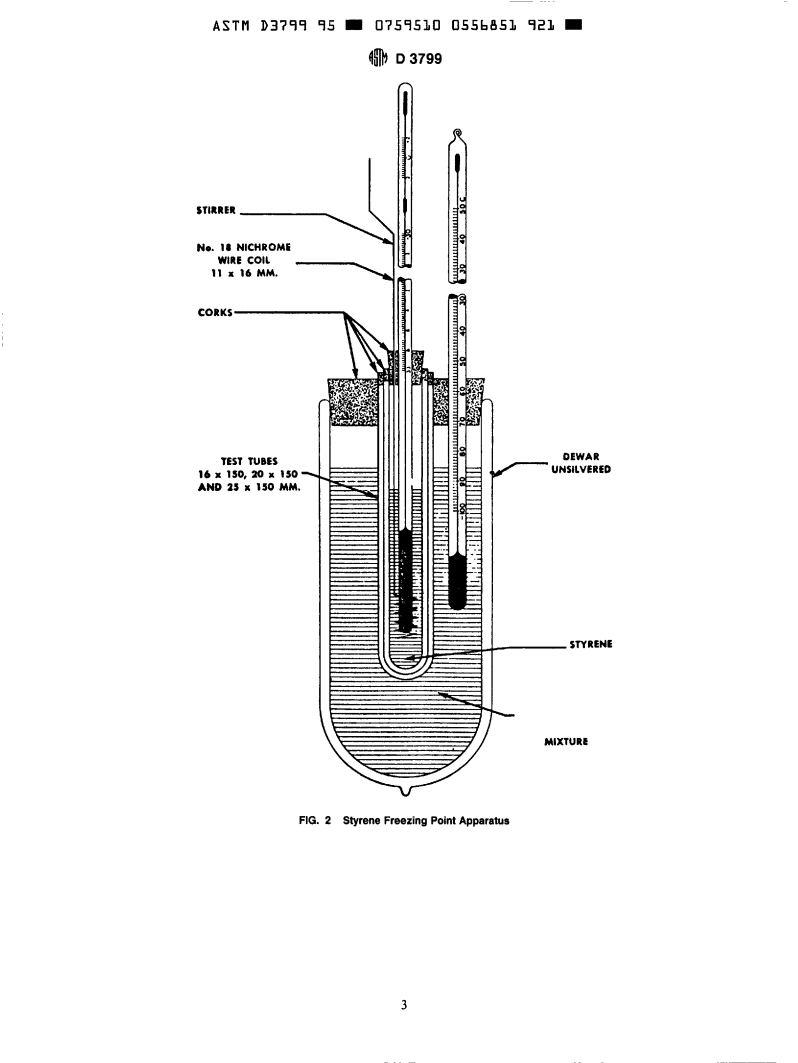

6.3 Freezing Point Apparatus-See Fig. 2 which consists

Current edition approved April 15, 1995. Published June 1995. Originally

of a 665-mL Dewar flask of borosilicate glass, a nest of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.