ASTM D7466-08

(Test Method)Standard Test Method for Measuring the Asperity Height of Textured Geomembrane

Standard Test Method for Measuring the Asperity Height of Textured Geomembrane

SIGNIFICANCE AND USE

The asperity height is an index property used to quantify one of the physical attributes related to the surface roughness of textured geomembranes.

This test method is applicable to all currently available textured geomembranes that are deployed as manufactured geomembrane sheets.

SCOPE

1.1 TThis test method covers a procedure to measure the asperity height of textured geomembranes.

1.2 This test method does not provide for measurement of the spacing between the asperities nor of the complete profile of the textured surface.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7466–08

Standard Test Method for

Measuring the Asperity Height of Textured Geomembrane

This standard is issued under the fixed designation D7466; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers a procedure to measure the 4.1 The asperity height of a textured geomembrane is

asperity height of textured geomembranes. measured with a depth gage, the setting block of which rests on

1.2 This test method does not provide for measurement of the top of the asperities while the contact point extends to the

the spacing between the asperities nor of the complete profile sheet’s core surface.

of the textured surface. 4.2 The asperity height of a textured geomembrane is

1.3 This standard does not purport to address all of the calculated as the average value of ten (10) individual measure-

safety concerns, if any, associated with its use. It is the ments taken across the roll width of the sample under investi-

responsibility of the user of this standard to establish appro- gation.

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 The asperity height is an index property used to quantify

2. Referenced Documents

one of the physical attributes related to the surface roughness

2.1 ASTM Standards: of textured geomembranes.

D4439 Terminology for Geosynthetics 5.2 This test method is applicable to all currently available

D5994 Test Method for Measuring Core Thickness of textured geomembranes that are deployed as manufactured

Textured Geomembrane geomembrane sheets.

3. Terminology 6. Apparatus

3.1 Definitions: 6.1 Depth Gage— The depth gage shall consist of three

3.1.1 asperity, n—the individual projections of polyethyl- components that conform the requirements of this section; a

ene that extend above the core surface of a textured geomem- dial indicator, a setting block and a contact point with exten-

brane resulting in the textured surface profile. sion.

3.1.2 core thickness,, n—the average thickness of a textured 6.1.1 Dial Indicator —capable of measuring to depth of at

geomembrane as measured using Test Method D5994. least 2.5 mm (0.10 in.) with an accuracy of 60.025 mm (0.001

3.1.3 geomembrane), n—an essentially impermeable geo- in.).

synthetic composed of one or more synthetic sheets. D4439 6.1.2 Setting Block—the setting block shall have a base

3.1.4 thickness gage contact point, n—the tip of a thickness dimension of 50 mm to 63.5 mm long x 20 mm to 12.7 mm

gage which contacts the base sheet of the geomembrane wide (2.0 in. to 2.5 in long x 0.75 in. to 0.50 in wide) and a

surface. height of 15 mm (0.60 in.)

3.1.5 setting block, n—the component part of a depth gage 6.1.3 Contact Point with Extension —– The contact point is

that rests on top of the asperities. 1.3 mm (0.051 in.) in diameter with the tip tapered to a point.

3.1.6 thickness, n— the perpendicular distance between one An extension of approximately 17 mm (0.66 in.) is required to

surface and its opposite. achieve the necessary travel beyond the base surface of the

3.2 For definitions of other terms used in this test method, setting block.The contact point should protrude at least 10 mm

refer to Terminology D4439. below the setting block when not in use in order to ensure that

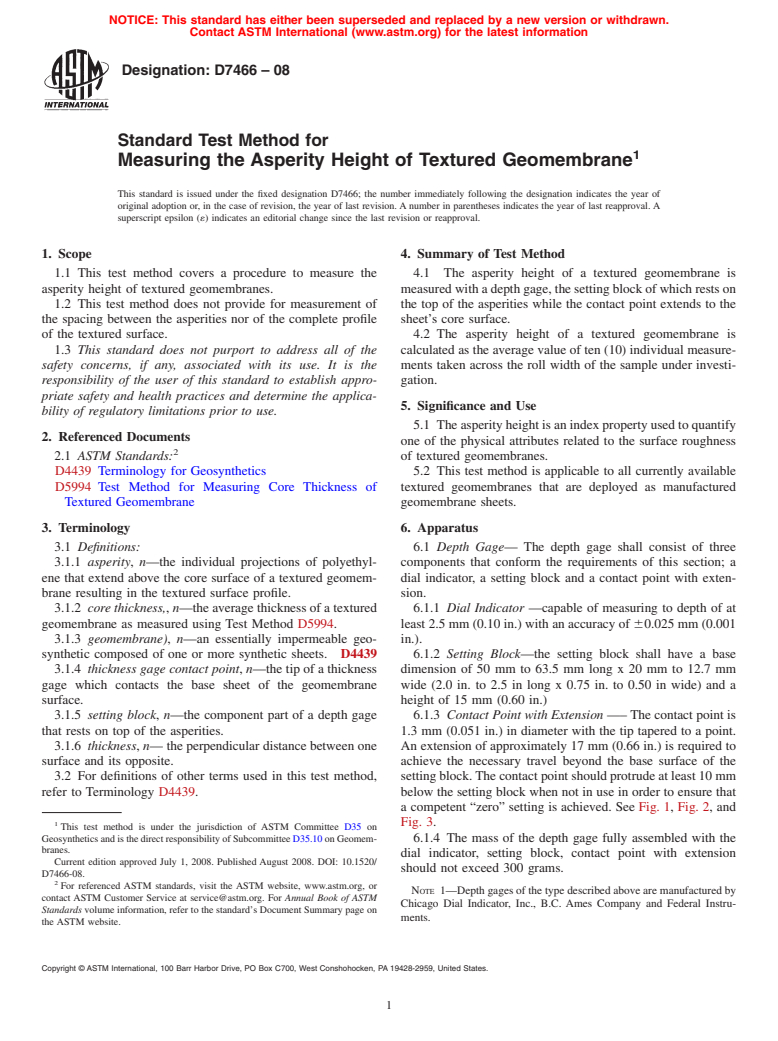

a competent “zero” setting is achieved. See Fig. 1, Fig. 2, and

Fig. 3.

This test method is under the jurisdiction of ASTM Committee D35 on

Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomem- 6.1.4 The mass of the depth gage fully assembled with the

branes.

dial indicator, setting block, contact point with extension

Current edition approved July 1, 2008. Published August 2008. DOI: 10.1520/

should not exceed 300 grams.

D7466-08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 1—Depth gages of the type described above are manufactured by

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Chicago Dial Indicator, Inc., B.C. Ames Company and Federal Instru-

Standards volume information, refer to the standard’s Document Summary page on

ments.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7466–08

FIG. 1 The Asperity Height Test Gage

8. Conditioning and Testing

8.1 Bring the specimens to temperature equilibrium at 21 6

2°C (70 6 4°F) and at a relative humidity of 60 6 10 %.

9. Procedure

9.1 Test the conditioned specimens in the standard labora-

tory atmosphere specified in 8.1.

9.2 Place the depth gage on a flat, rigid supporting surface

to zero the contact point with the botto

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.