ASTM C203-22

(Test Method)Standard Test Methods for Breaking Load and Flexural Properties of Block-Type Thermal Insulation

Standard Test Methods for Breaking Load and Flexural Properties of Block-Type Thermal Insulation

SIGNIFICANCE AND USE

5.1 These test methods are to be used to determine the resistance of some types of preformed block insulation when transverse loads are normally applied to the surface. Values are measured at the maximum load or breaking point under specified conditions or specimen size, span between supports, and rate of load application. The equations used are based on the assumption that the materials are uniform and presume that the stress-strain characteristics below the elastic limit are linearly elastic. These assumptions are not strictly applicable to thermal insulations of certain types in which crushing occurs before failure is obtained in transverse bending; however, depending upon the accuracy required, these procedures are capable of providing acceptable results.

5.2 Test Method I is especially useful when testing only for the modulus of rupture or the breaking load. This information is useful for quality control inspection and qualification for specification purposes.

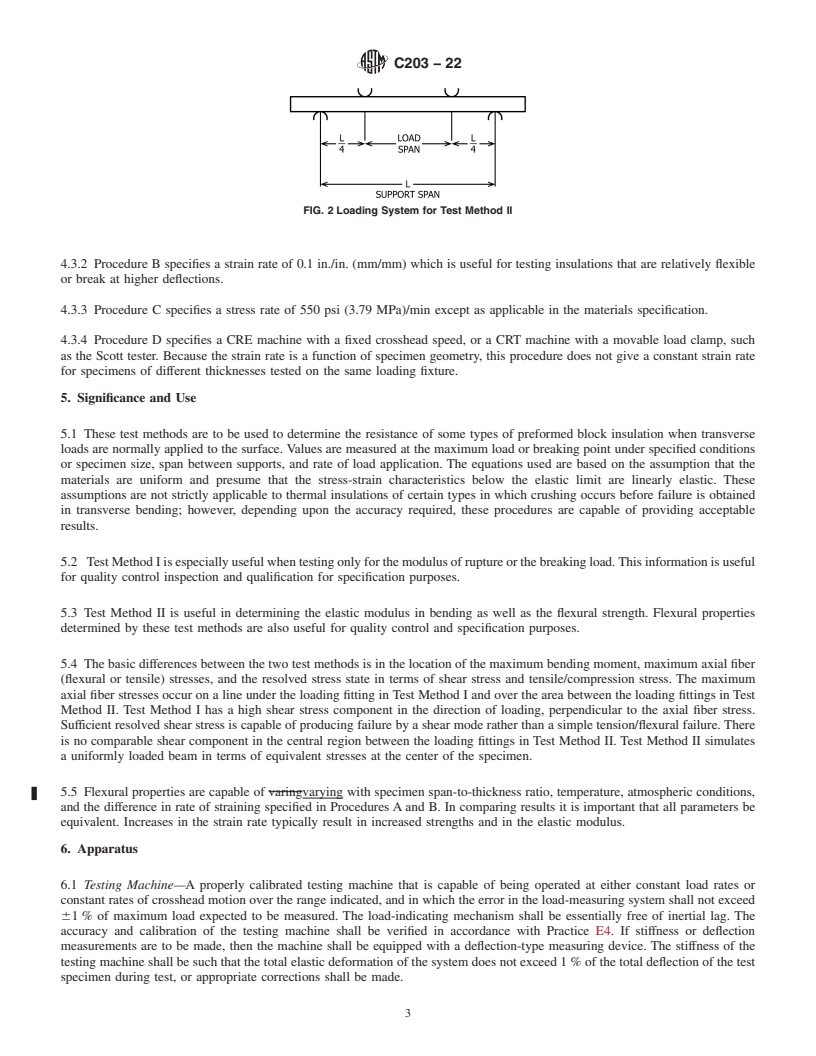

5.3 Test Method II is useful in determining the elastic modulus in bending as well as the flexural strength. Flexural properties determined by these test methods are also useful for quality control and specification purposes.

5.4 The basic differences between the two test methods is in the location of the maximum bending moment, maximum axial fiber (flexural or tensile) stresses, and the resolved stress state in terms of shear stress and tensile/compression stress. The maximum axial fiber stresses occur on a line under the loading fitting in Test Method I and over the area between the loading fittings in Test Method II. Test Method I has a high shear stress component in the direction of loading, perpendicular to the axial fiber stress. Sufficient resolved shear stress is capable of producing failure by a shear mode rather than a simple tension/flexural failure. There is no comparable shear component in the central region between the loading fittings in Test Method II. Test Method II simulates a u...

SCOPE

1.1 These test methods cover the determination of the breaking load and calculated flexural strength of a rectangular cross section of a preformed block-type thermal insulation tested as a simple beam. It is also applicable to cellular plastics. Two test methods are described as follows:

1.1.1 Test Method I—A loading system utilizing center loading on a simply supported beam, supported at both ends.

1.1.2 Test Method II—A loading system utilizing two symmetric load points equally spaced from their adjacent support points at each end with a distance between load points of one half of the support span.

1.2 Either test method is capable of being used with the four procedures that follow:

1.2.1 Procedure A—Designed principally for materials that break at comparatively small deflections.

1.2.2 Procedure B—Designed particularly for those materials that undergo large deflections during testing.

1.2.3 Procedure C—Designed for measuring at a constant stress rate, using a CRL (constant rate of loading) machine. Used for breaking load measurements only.

1.2.4 Procedure D—Designed for measurements at a constant crosshead speed, using either a CRT (constant rate of traverse) or CRE (constant rate of extension) machine. Used for breaking load measurements using a fixed crosshead speed machine.

1.3 Comparative tests are capable of being run according to either method or procedure, provided that the method or procedure is found satisfactory for the material being tested.

1.4 These test methods are purposely general in order to accommodate the widely varying industry practices. It is important that the user consult the appropriate materials specification for any specific detailed requirements regarding these test methods.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.6 This standard does not purport to address all...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C203 − 22

Standard Test Methods for

Breaking Load and Flexural Properties of Block-Type

1

Thermal Insulation

This standard is issued under the fixed designation C203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.5 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are provided for

1.1 These test methods cover the determination of the

information only.

breaking load and calculated flexural strength of a rectangular

1.6 This standard does not purport to address all of the

cross section of a preformed block-type thermal insulation

safety concerns, if any, associated with its use. It is the

testedasasimplebeam.Itisalsoapplicabletocellularplastics.

responsibility of the user of this standard to establish appro-

Two test methods are described as follows:

priate safety, health, and environmental practices and deter-

1.1.1 Test Method I—A loading system utilizing center

mine the applicability of regulatory limitations prior to use.

loading on a simply supported beam, supported at both ends.

For specific precautionary statements, see Section 10

1.1.2 Test Method II—A loading system utilizing two sym-

1.7 This international standard was developed in accor-

metric load points equally spaced from their adjacent support

dance with internationally recognized principles on standard-

points at each end with a distance between load points of one

ization established in the Decision on Principles for the

half of the support span.

Development of International Standards, Guides and Recom-

1.2 Either test method is capable of being used with the four

mendations issued by the World Trade Organization Technical

procedures that follow:

Barriers to Trade (TBT) Committee.

1.2.1 Procedure A—Designed principally for materials that

break at comparatively small deflections.

2. Referenced Documents

1.2.2 Procedure B—Designed particularly for those materi-

2

2.1 ASTM Standards:

als that undergo large deflections during testing.

C133 Test Methods for Cold Crushing Strength and Modu-

1.2.3 Procedure C—Designed for measuring at a constant

lus of Rupture of Refractories

stress rate, using a CRL (constant rate of loading) machine.

C168 Terminology Relating to Thermal Insulation

Used for breaking load measurements only.

C390 Practice for Sampling and Acceptance of Thermal

1.2.4 Procedure D—Designed for measurements at a con-

Insulation Lots

stant crosshead speed, using either a CRT (constant rate of

C870 Practice for Conditioning of Thermal Insulating Ma-

traverse) or CRE (constant rate of extension) machine. Used

terials

for breaking load measurements using a fixed crosshead speed

D76 Specification for Tensile Testing Machines for Textiles

machine.

E4 Practices for Force Calibration and Verification of Test-

1.3 Comparative tests are capable of being run according to

ing Machines

either method or procedure, provided that the method or

procedure is found satisfactory for the material being tested.

3. Terminology

1.4 These test methods are purposely general in order to

3.1 Terminology C168 applies to the terms used in this

accommodate the widely varying industry practices. It is

method.

important that the user consult the appropriate materials

4. Summary of Test Methods

specification for any specific detailed requirements regarding

these test methods.

4.1 A bar of rectangular cross section is tested in flexure as

a beam as follows:

1

These test methods are under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and are the direct responsibility of Subcommittee C16.32 on

2

Mechanical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2022. Published September 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1945. Last previous edition approved in 2017 as C203 – 05a (2017). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/C0203-22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C203 − 22

4.1.1 Test Method I—The bar rests on two supports and is

loaded by means of a loading fitting or piece midway between

the supports (see

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C203 − 05a (Reapproved 2017) C203 − 22

Standard Test Methods for

Breaking Load and Flexural Properties of Block-Type

1

Thermal Insulation

This standard is issued under the fixed designation C203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover the determination of the breaking load and calculated flexural strength of a rectangular cross section

of a preformed block-type thermal insulation tested as a simple beam. It is also applicable to cellular plastics. Two test methods

are described as follows:

1.1.1 Test Method I—A loading system utilizing center loading on a simply supported beam, supported at both ends.

1.1.2 Test Method II—A loading system utilizing two symmetric load points equally spaced from their adjacent support points at

each end with a distance between load points of one half of the support span.

1.2 Either test method is capable of being used with the four procedures that follow:

1.2.1 Procedure A—Designed principally for materials that break at comparatively small deflections.

1.2.2 Procedure B—Designed particularly for those materials that undergo large deflections during testing.

1.2.3 Procedure C—Designed for measuring at a constant stress rate, using a CRL (constant rate of loading) machine. Used for

breaking load measurements only.

1.2.4 Procedure D—Designed for measurements at a constant crosshead speed, using either a CRT (constant rate of traverse) or

CRE (constant rate of extension) machine. Used for breaking load measurements using a fixed crosshead speed machine.

1.3 Comparative tests are capable of being run according to either method or procedure, provided that the method or procedure

is found satisfactory for the material being tested.

1.4 These test methods are purposely general in order to accommodate the widely varying industry practices. It is important that

the user consult the appropriate materials specification for any specific detailed requirements regarding these test methods.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information

only.

1

These test methods are under the jurisdiction of ASTM Committee C16 on Thermal Insulation and are the direct responsibility of Subcommittee C16.32 on Mechanical

Properties.

Current edition approved Sept. 1, 2017Sept. 1, 2022. Published December 2017September 2022. Originally approved in 1945. Last previous edition approved 2012 in 2017

as C203 – 05a (2012).(2017). DOI: 10.1520/C0203-05AR17.10.1520/C0203-22.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C203 − 22

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific precautionary statements, see Section 1110

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C133 Test Methods for Cold Crushing Strength and Modulus of Rupture of Refractories

C168 Terminology Relating to Thermal Insulation

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C870 Practice for Conditioning of Thermal Insulating Materials

D76 Specification for Tensile Testing Machines for Textiles

E4 Practices for Force Calibration and Verification of Testing Machines

3. Terminology

3.1 Terminology C168 shall be considered applied applies to the terms used in this method.

4. Summary of Test Methods

4.1 A bar of rectangular cross section is tested in flexure as a beam as follows:

4.1.1 Test Method I—The bar rests on two supports and is loaded by means of a loading fitting or piece midway between the

supports (see Fig. 1).

4.1.2 Te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.