ASTM D612-88(2007)

(Test Method)Standard Test Method for Carbonizable Substances in Paraffin Wax

Standard Test Method for Carbonizable Substances in Paraffin Wax

SIGNIFICANCE AND USE

This test method is a means for ascertaining whether pharmaceutical paraffin wax conforms to the standards for quality prescribed by the U.S. National Formulary.

SCOPE

1.1 This test method covers determination of carbonizable substances in paraffin wax. The test method is applicable to paraffin wax for pharmaceutical use, as defined by the U.S. National Formulary, with a melting point as determined in accordance with Test Method D 87, between 117 and 149°F (47 and 65°C).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in Annex A1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D612 − 88(Reapproved 2007)

Standard Test Method for

Carbonizable Substances in Paraffin Wax

This standard is issued under the fixed designation D612; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Significance and Use

4.1 This test method is a means for ascertaining whether

1.1 This test method covers determination of carbonizable

pharmaceutical paraffin wax conforms to the standards for

substances in paraffin wax. The test method is applicable to

quality prescribed by the U.S. National Formulary.

paraffin wax for pharmaceutical use, as defined by the U.S.

National Formulary, with a melting point as determined in

5. Apparatus

accordance withTest Method D87, between 117 and 149°F (47

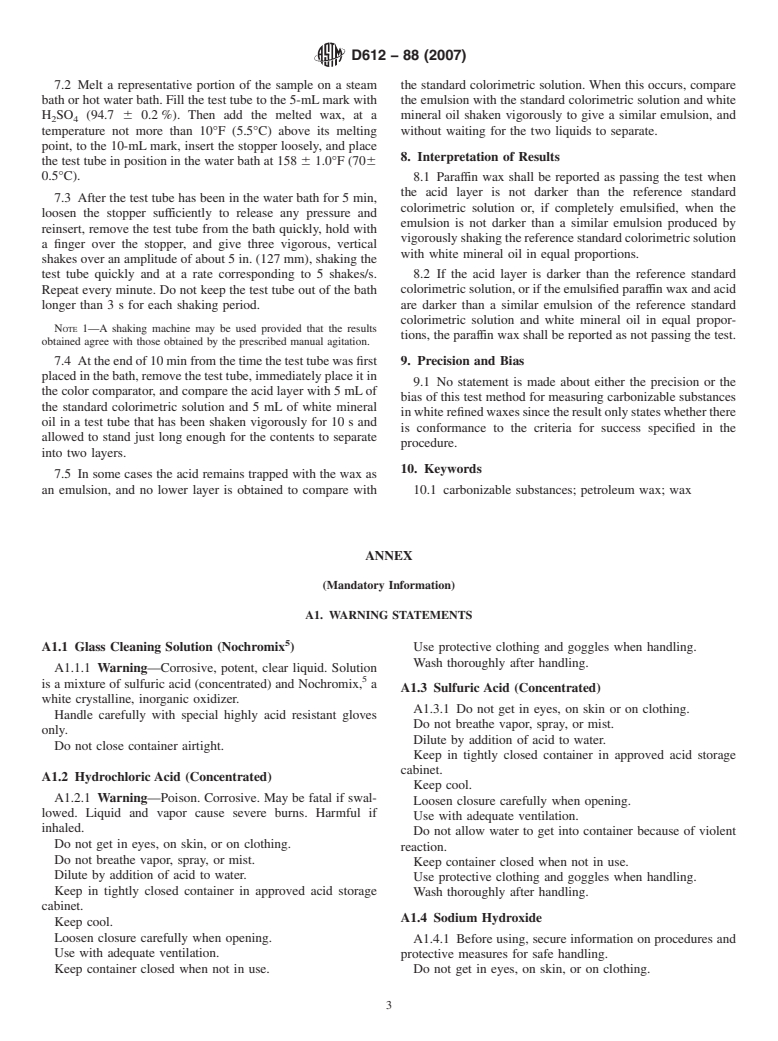

5.1 Test Tube, as shown in Fig. 1, of heat-resistant glass

and 65°C).

fittedwithawell-groundglassstopper,thestopperandthetube

1.2 The values stated in inch-pound units are to be regarded

bearing identical and indestructible numbers. The tube shall be

as standard. The values given in parentheses are mathematical

140 6 2 mm in length and between 14.5 and 15.0 mm in

conversions to SI units that are provided for information only

outside diameter, and shall be calibrated at the 5 6 0.2-mLand

and are not considered standard.

10 6 0.2-mL liquid levels. The capacity of the tube with

stopper inserted shall be between 13.6 and 15.6 mL. A rolled

1.3 This standard does not purport to address all of the

edge may be provided for suspending the tube on the cover of

safety concerns, if any, associated with its use. It is the

the water bath.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5.2 Water Bath, suitable for immersing the test tube above

bility of regulatory limitations prior to use. Specific warning

the 10-mL line and equipped to maintain a temperature of 158

statements are given in Annex A1.

6 1.0°F (70 6 0.5°C).The bath shall be provided with a cover

of any suitable material, with holes approximately 16 mm in

2. Referenced Documents

diameter through which the test tubes may be suspended.

2.1 ASTM Standards:

5.3 Color Comparator, of a suitable type for observing the

D87 Test Method for Melting Point of Petroleum Wax color of the acid layer in comparison with the reference

(Cooling Curve)

standard color solution. The size and shape of the comparator

D1193 Specification for Reagent Water are optional, but the size and shape of the apertures shall

conform to the dimensions prescribed in Fig. 1.

3. Summary of Test Method

6. Reagents

3.1 Five millilitres of melted wax are treated with 5 mL of

6.1 Purity of Reagents—Reagent grade chemicals shall be

concentrated, nitrogen-free sulfuric acid at 158°F (70°C). The

used in all tests. Unless otherwise indicated, it is intended that

color of the acid layer is compared with that of a colorimetric

all reagents shall conform to the specifications of the Commit-

reference standard. If the color is not darker than the standard,

tee onAnalytical Reagents of theAmerican Chemical Society,

the wax is reported as passing the test.

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

This test method is under the jurisdiction of ASTM Committee D02 on

accuracy of the determination.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.10.0A on Physical/Chemical Properties.

Current edition approved Nov. 1, 2007. Published January 2008. Originally Borosilicate glass has been found satisfactory for this purpose.

approved in 1941. Last previous edition approved in 2004 as D612–88(2004). DOI: Reagent Chemicals, American Chemical Society Specifications, American

10.1520/D0612-88R07. Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

For referenced ASTM standards, visit the ASTM website, www.astm.org, or listed by the American Chemical Society, see Annual Standards for Laboratory

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Standards volume information, refer to the standard’s Document Summary page on and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

the ASTM website. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D612 − 88 (2007)

FIG. 1 Color Comparator for Carbonizable Substances in Liquid Petrolatum

6.2 Purity of Water—Unless otherwise indicated, references and3gofKI.Allow the mixture to stand for 5 min, then titrate

to water shall be understood to mean distilled water, such as the liberated iodine with 0.1 N Na S O solution, using starch

2 2 3

reagent water corresponding to Specification D1193, Type III, solution as an indicator. Each millilitre of 0.1 N Na S O

2 2 3

or water of equal purity. solution is equivalent to 0.02497 g of CuSO ·5H O.Adjust the

4 2

final volume of CuSO solution by the addition of diluted HCl

6.3 Cobaltous Chloride Solution (0.5 N)—Dissolve about

(1 + 39) so that 1 mL contains 62.4 mg of CuSO ·5H O.

4 2

65 g of cobaltous chloride (CoCl ·6H O) in enough diluted

2 2

hydrochloricacid(HCl,1 + 39)(Warning—Hydrochloricacid 6.6 Ferric Chloride Solution (0.5N)—Dissolve about 55 g

(concentrated) causes burns, vapor extremely irritating. See of ferric chloride (FeCl ·6H O) in enough diluted HCl

3 2

A1.2) to make 1000 mL of solution. Transfer exactly 5 mL of (Warning—Hydrochloric acid (concentrated) causes burns,

this solution to a flask; add 15 mL of sodium hydroxide vapor extremely irritating. See A1.2) (1 + 39) to make 1000

(NaOH, 1 + 5) (Warning—Sodium hydroxide, corrosive, can mL of solution. Transfer exactly 10 mL of the solution to a

cause severe burns or blindness. Evolution of heat produces a flask, add 5 mLof HCl (sp gr 1.19), 25 mLof water, and about

violent reaction or eruption upon too rapid a mixture with 3 g of KI. Stopper and allow the mixture to stand for 5 min.

water. See A1.4), and 5 mL of hydrogen peroxide. Boil for 10 Dilutethemixturewith50mLofwater,andtitratetheliberated

min, cool, and add2gof potassium iodide (KI) and 20 mL of iodinewith0.1 NNa S O solution,usingstarchsolutionasan

2 2 3

sulfuric acid (H SO , 1+4) (Warning—Sulfuric acid (con- indicator. Each millilitre of 0.1 N Na S O solution is equiva-

2 4 2 2 3

centrated) causes burns, vapor irritating, strong oxidizer. See lentto0.02703gofFeCl ·6H O.Adjustthefinalvolumeofthe

3 2

A1.3). When the precipitate has dissolved, titrate the liberated FeCl solution by the addition of diluted HCl (1 + 39) so that

iodine with 0.1 N sodium thiosulfate (Na S O ) solution using 1 mL contains 45.0 mg of FeCl ·6H O.

2 2 3 3 2

starchsolutionasanindicator.Eachmillilitreof0.1 NNa S O

2 2 3

6.7 Sulfuric Acid (94.7 6 0.2 %)—The sulfuric acid

solution consumed is equivalent to 0.023799 g of CoCl ·6H O.

2 2

(H SO)(Warning—Sulfuric acid (concentrated) causes

2 4

Adjust the final volume of CoCl solution by the addition of

burns, vapor irritating, strong oxidizer. See A1.3) shall be

diluted HCl (1 + 39) so that 1 mL contains 59.5 mg of

nitrogen-free when analyzed in accordance with the following

CoCl ·6H O.

2 2

procedure: Dilute a small amount of the acid with an equal

6.4 Colorimetric Reference Standard Solution—Prepare a volume of water and superimpose 10 mL of the cooled liquid

referencestandardpaleambersoluti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.