ASTM C227-97a

(Test Method)Standard Test Method for Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)

Standard Test Method for Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)

SCOPE

1.1 This test method covers the determination of the susceptibility of cement-aggregate combinations to expansive reactions involving hydroxyl ions associated with the alkalies (sodium and potassium) by measurement of the increase (or decrease) in length of mortar bars containing the combination during storage under prescribed conditions of test.

1.2 Alkalies participating in the expansive reactions usually are derived from the cement; under some circumstances they may be derived from other constituents of the concrete or from external sources. Two types of alkali reactivity of aggregates are recognized: (1) an alkali-silica reaction involving certain siliceous rocks, minerals, and natural or artificial glasses and (2) an alkali-carbonate reaction involving dolomite in certain calcitic dolomites and dolomitic limestones. The method is not recommended as a means to detect the latter reaction because expansions produced in the mortar-bar test by the alkali-carbonate reaction (see Test Method C586) are generally much less than those produced by the alkali-silica reaction for combinations having equally harmful effects in service.

1.3 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 227 – 97a

Standard Test Method for

Potential Alkali Reactivity of Cement-Aggregate

Combinations (Mortar-Bar Method)

This standard is issued under the fixed designation C 227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C 289 Test Method for Potential Reactivity of Aggregates

(Chemical Method)

1.1 This test method covers the determination of the sus-

C 294 Descriptive Nomenclature for Constituents of Natu-

ceptibility of cement-aggregate combinations to expansive

ral Mineral Aggregates

reactions involving hydroxyl ions associated with the alkalies

C 295 Guide for Petrographic Examination of Aggregates

(sodium and potassium) by measurement of the increase (or

for Concrete

decrease) in length of mortar bars containing the combination

C 305 Practice for Mechanical Mixing of Hydraulic Cement

during storage under prescribed conditions of test.

Pastes and Mortars of Plastic Consistency

1.2 Alkalies participating in the expansive reactions usually

C 490 Practice for Use of Apparatus for the Determination

are derived from the cement; under some circumstances they

of Length Change of Hardened Cement Paste, Mortar, and

may be derived from other constituents of the concrete or from

Concrete

external sources. Two types of alkali reactivity of aggregates

C 511 Specification for Moist Cabinets, Moist Rooms, and

are recognized: (1) an alkali-silica reaction involving certain

Water Storage Tanks Used in Testing of Hydraulic Ce-

siliceous rocks, minerals, and natural or artificial glasses and

ments and Concretes

(2) an alkali-carbonate reaction involving dolomite in certain

C 586 Test Method for Potential Alkali Reactivity of Car-

calcitic dolomites and dolomitic limestones (see Standard

bonate Rocks for Concrete Aggregates (Rock Cylinder

C 294). The method is not recommended as a means to detect

Method)

the latter reaction because expansions produced in the mortar-

C 856 Practice for Petrographic Examination of Hardened

bar test by the alkali-carbonate reaction (see Test Method

Concrete

C 586) are generally much less than those produced by the

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

alkali-silica reaction for combinations having equally harmful

poses

effects in service.

1.3 The values stated in SI units are to be regarded as

3. Significance and Use

standard. The non-SI values, shown in parentheses, are for

3.1 Data correlating the results of tests performed using this

informational purposes only.

test method with performance of cement-aggregate combina-

1.4 This standard does not purport to address all of the

tions in concrete in service, results of petrographic examination

safety concerns, if any, associated with its use. It is the

of aggregates (Guide C 295), and results of tests for potential

responsibility of the user of this standard to establish appro-

reactivity of aggregates by chemical methods have been

priate safety and health practices and determine the applica-

published in Test Method C 289 and should be consulted in

bility of regulatory limitations prior to use.

connection with the use of results of tests performed using this

2. Referenced Documents test method as the basis for conclusions and recommendations

concerning the use of cement-aggregate combinations in con-

2.1 ASTM Standards:

crete.

C 33 Specification for Concrete Aggregates

3.2 The results of tests performed using this method furnish

C 109/C 109M Test Method for Compressive Strength of

information on the likelihood that a cement-aggregate combi-

Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube

3 nation is potentially capable of harmful alkali-silica reactivity

Specimens)

with consequent deleterious expansion of concrete. Criteria to

determine potential deleterious alkali-silica reactivity of

This test method is under the jurisdiction of ASTM Committee C-9 on Concrete

cement-aggregate combinations from the results of this test

and Concrete Aggregatesand is the direct responsibility of Subcommittee C09.26on

method have been given in the Appendix of Specification C 33.

Chemical Reactions of Materials.

Current edition approved Nov. 10, 1997. Published October 1998. Originally

3.3 Insignificant expansion may result when potentially

published as C 227 – 50 T. Last previous edition C 227 – 97.

Annual Book of ASTM Standards, Vol 04.02.

3 4

Annual Book of ASTM Standards, Vol 04.01. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 227

deleteriously reactive siliceous rocks are present in compara- cements, or the same cement-aggregate combination with a

tively high proportion even when a high-alkali cement is used. mineral admixture.

This may occur because the alkali-silica reaction products are

4. Apparatus

characterized by an alkali to silica ratio that is so low as to

minimize uptake of water and swelling, or because of alkali 4.1 The apparatus shall conform to Specification C 490,

leaching from the bars (see section on containers). Dolomitic except as follows:

aggregates that are deleteriously affected by the alkali- 4.2 Sieves—Square hole, woven-wire cloth sieves, shall

carbonate reaction when employed as course aggregate in conform to Specification E 11.

concrete may not produce notable expansion in this test 4.3 Mixer, Paddle, and Mixing Bowl— Mixer, paddle, and

method. Also, significant expansion may occur rarely in the test mixing bowl shall conform to the requirements of Method

for reasons other than alkali-aggregate reaction, particularly C 305, except that the clearance between the lower end of the

the presence of sulfates in the aggregate that produce a sulfate paddle and the bottom of the bowl shall be 5 to 6 mm (0.20 to

attack upon the cement paste, ferrous sulfides (pyrite, marca- 0.24 in.) .

site, or pyrrhotite) that oxidize and hydrate with the release of 4.4 Tamper and Trowel—The tamper and trowel shall con-

sulfate, and materials such as free lime (CaO) or free magnesia form to Test Method C 109.

4.5 Containers—Covered containers for storing the test

(MgO) in the cement or aggregate that progressively hydrate

and carbonate. specimens shall be constructed of material that is resistant to

corrosion under the test conditions. The wall thickness of the

3.4 When expansions in excess of those given in the

Appendix of Specification C 33 are shown in results of tests container and cover shall be less than 6 mm ( ⁄16 in.) to reduce

performed using this test method, it is strongly recommended the insulating effect and provide a rapid heat transfer for the

that supplementary information be developed to confirm that initial 14-day test period. The cover shall be constructed in a

the expansion is actually due to alkali reactivity. Sources of manner to maintain a tight seal between the cover and top of

such supplementary information include: (1) petrographic the container wall (Note 1). The container shall be arranged to

examination of the aggregate to determine if known reactive provide every surface of each specimen with approximately an

constituents are present; (2) examination of the specimens after equal exposure to an absorbent wicking material. The speci-

tests to identify the products of alkali reactivity; and (3) tests of mens shall not be in direct contact with the wicking material

the aggregate for potential reactivity by chemical methods but every surface shall be within 30 mm (1 ⁄4 in.) or less of the

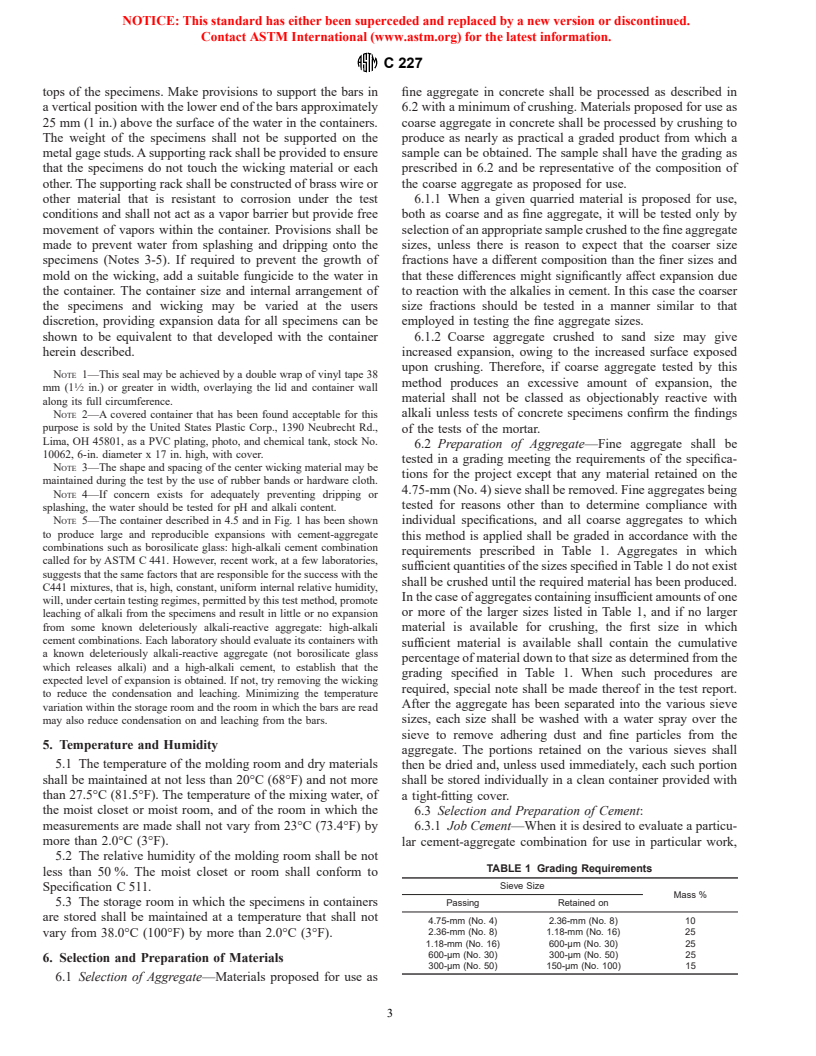

(Test Method C 289). the wicking. A typical arrangement of such a container is

3.5 When it has been concluded from the results of tests shown in Fig. 1 (Note 2). The inner sides and the center core

performed using this test method and supplementary informa- of the containers are to be lined with an absorbent material,

tion as outlined that a given cement-aggregate combination such as blotting paper or filter paper, to act as a wick and to

should be considered potentially deleteriously reactive, addi- ensure that the atmosphere in the container is quickly saturated

tional studies may be appropriate to develop information on the with water vapor when it is sealed after the specimens are

potential reactivity of other combinations containing the same placed therein (Note 2). The wicking liners will extend into the

cement with other aggregates, the same aggregate with other top of the water in the bottom of the container and above the

FIG. 1 Diagram of an Acceptable Assembled Container

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 227

tops of the specimens. Make provisions to support the bars in fine aggregate in concrete shall be processed as described in

a vertical position with the lower end of the bars approximately 6.2 with a minimum of crushing. Materials proposed for use as

25 mm (1 in.) above the surface of the water in the containers. coarse aggregate in concrete shall be processed by crushing to

The weight of the specimens shall not be supported on the produce as nearly as practical a graded product from which a

metal gage studs. A supporting rack shall be provided to ensure sample can be obtained. The sample shall have the grading as

that the specimens do not touch the wicking material or each prescribed in 6.2 and be representative of the composition of

other. The supporting rack shall be constructed of brass wire or the coarse aggregate as proposed for use.

other material that is resistant to corrosion under the test 6.1.1 When a given quarried material is proposed for use,

conditions and shall not act as a vapor barrier but provide free both as coarse and as fine aggregate, it will be tested only by

movement of vapors within the container. Provisions shall be selection of an appropriate sample crushed to the fine aggregate

made to prevent water from splashing and dripping onto the sizes, unless there is reason to expect that the coarser size

specimens (Notes 3-5). If required to prevent the growth of fractions have a different composition than the finer sizes and

mold on the wicking, add a suitable fungicide to the water in that these differences might significantly affect expansion due

the container. The container size and internal arrangement of to reaction with the alkalies in cement. In this case the coarser

the specimens and wicking may be varied at the users size fractions should be tested in a manner similar to that

discretion, providing expansion data for all specimens can be employed in testing the fine aggregate sizes.

shown to be equivalent to that developed with the container 6.1.2 Coarse aggregate crushed to sand size may give

herein described. increased expansion, owing to the increased surface exposed

upon crushing. Therefore, if coarse aggregate tested by this

NOTE 1—This seal may be achieved by a double wrap of vinyl tape 38

method produces an excessive amount of expansion, the

mm (1 ⁄2 in.) or greater in width, overlaying the lid and container wall

material shall not be classed as objectionably reactive with

along its full circumference.

alkali unless tests of concrete specimens confirm the findings

NOTE 2—A covered container that has been found acceptable for this

purpose is sold by the United States Plastic Corp., 1390 Neubrecht Rd.,

of the tests of the mortar.

Lima, OH 45801, as a PVC plating, photo, and chemical tank, stock No.

6.2 Preparation of Aggregate—Fine aggregate shall be

10062, 6-in. diameter x 17 in. high, with cover.

tested in a grading meeting the requirements of the specifica-

NOTE 3—The shape and spacing of the center wicking material may be

tions for the project except that any material retained on the

maintained during the test by the use of rubber bands or hardware cloth.

4.75-mm (No. 4) sieve shall be removed. Fine aggregates being

NOTE 4—If concern exists for adequately preventing dripping or

tested for reasons other than to determine compliance with

splashing, the water should be tested for pH and alkali content.

NOTE 5—The container described in 4.5 and in Fig. 1 has been shown individual specifications, and all coarse aggregates to which

to produce large and reproducible expansions with cement-aggregate

this method is applied shall be graded in accordance with the

combinations such as borosilicate glass: high-alkali cement combination

requirements prescribed in Table 1. Aggregates in which

called for by ASTM C 441. However, recent work, at a few laboratories,

sufficient quantities of the sizes specified in Table 1 do not exist

suggests that the same factors that are responsible for the success with the

shall be crushed until the required material has been produced.

C441 mixtures, that is, high, constant, uniform internal relative humidity,

In the case of aggregates containing insufficient amounts of one

will, under certain testing regimes, permitted by this test method, promote

or more of the larger sizes listed in Table 1, and if no larger

leaching of alkali from the specimens and result in little or no expansion

from some known deleteriously alkali-reactive aggregate: high-alkali material is available for crushing, the first size in which

cement combinations. Each laboratory should evaluate its containers with

sufficient material is available shall contain the cumulative

a known deleteriously alkali-reactive aggregate (not borosilicate glass

percentage of material down to that size as determined from the

which releases alkali) and a high-alkali cement, to establish that the

grading specified in Table 1. When such procedures are

expected level of expansion is obtained. If not, try removing the wicking

required, special note shall be made thereof in the test report.

to reduce the condensation and leaching. Minimizing the temperature

After the aggregate has been separated into the various sieve

variation within the storage room and the room in which the bars are read

may also reduce condensation on and leaching from the bars. sizes, each size shall be washed with a water spray over the

sieve to remove adhering dust and fine particles from the

5. Temperature and Humidity

aggregate. The portions retained on the various sieves shall

5.1 The temperature of the mold

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.