ASTM C311/C311M-22

(Test Method)Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete

Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete

SIGNIFICANCE AND USE

4.1 These test methods are used to develop data for comparison with the requirements of Specification C618 or Specification C1697. These test methods are based on standardized testing in the laboratory and are not intended to simulate job conditions.

4.1.1 Strength Activity Index—The test for strength activity index is used to determine whether fly ash or natural pozzolan results in an acceptable level of strength development when used with hydraulic cement in concrete. Since the test is performed with mortar, the results may not provide a direct correlation of how the fly ash or natural pozzolan will contribute to strength in concrete.

4.1.2 Chemical Tests—The chemical component determinations and the limits placed on each do not predict the performance of a fly ash or natural pozzolan with hydraulic cement in concrete, but collectively help describe composition and uniformity of the material.

SCOPE

1.1 These test methods cover procedures for sampling and testing fly ash and raw or calcined pozzolans for use in portland-cement concrete.

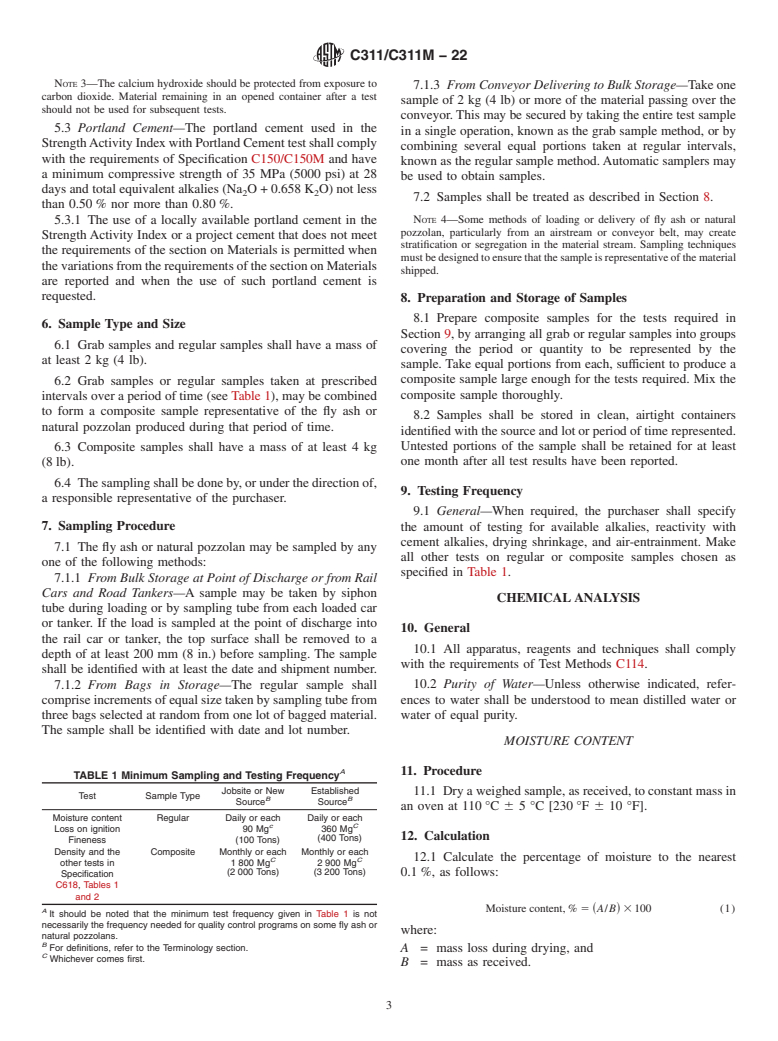

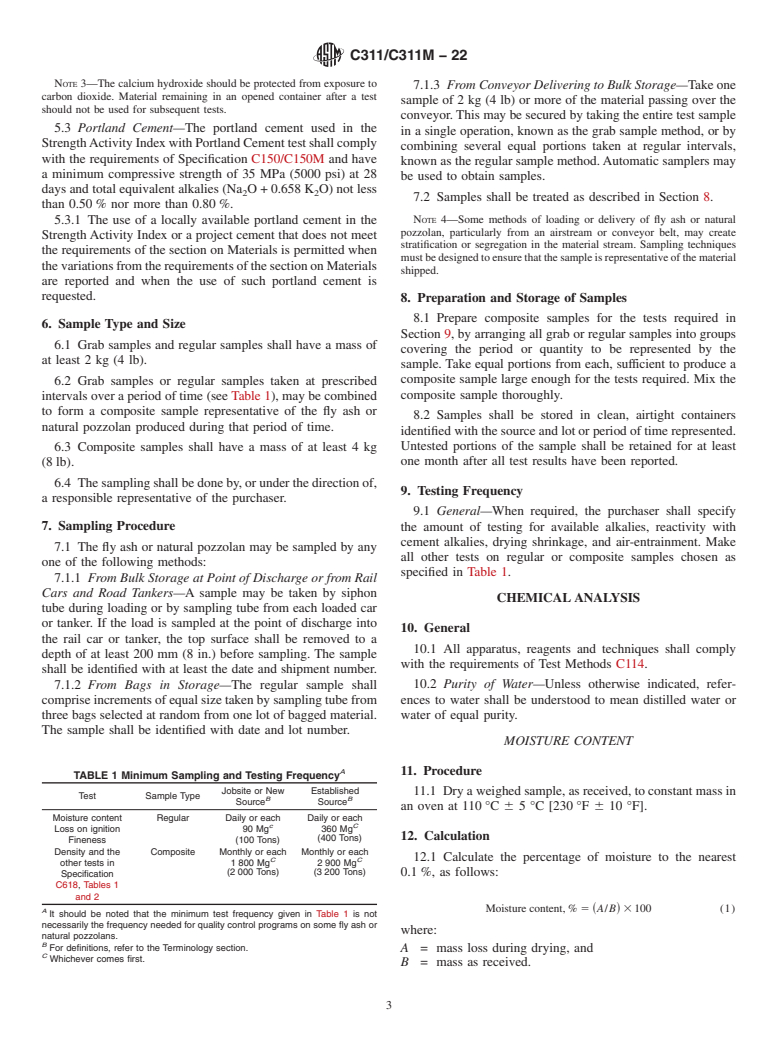

1.2 The procedures appear in the following order:

Sections

Sampling

7

CHEMICAL ANALYSIS

Reagents and apparatus

10

Moisture content

11 and 12

Loss on ignition

13 and 14

Silicon dioxide, aluminum oxide, iron oxide,

calcium oxide, magnesium oxide, sulfur

trioxide, sodium oxide and potassium

oxide

15

Available alkali

16 and 17

Ammonia

18

PHYSICAL TESTS

Density

19

Fineness

20

Increase of drying shrinkage of mortar bars

21 – 23

Soundness

24

Air-entrainment of mortar

25 and 26

Strength activity index with portland cement

27 – 30

Water requirement

31

Effectiveness of Fly Ash or Natural Pozzolan in

Controlling Alkali-Silica Reactions

32

Effectiveness of Fly Ash or Natural Pozzolan in

Contributing to Sulfate Resistance

34

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

Note 1: Sieve size is identified by its standard designation in Specification E11. The alternative designation given in parentheses is for information only and does not represent a different standard sieve size.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 The text of this standard references notes and footnotes that provide explanatory information. These notes and footnotes (excluding those in tables) shall not be considered as requirements of this standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C311/C311M − 22

Standard Test Methods for

Sampling and Testing Fly Ash or Natural Pozzolans for Use

1

in Portland-Cement Concrete

This standard is issued under the fixed designation C311/C311M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

Effectiveness of Fly Ash or Natural Pozzolan in

32

1.1 These test methods cover procedures for sampling and

Controlling Alkali-Silica Reactions

testing fly ash and raw or calcined pozzolans for use in

Effectiveness of Fly Ash or Natural Pozzolan in

portland-cement concrete.

34

Contributing to Sulfate Resistance

1.2 The procedures appear in the following order:

1.3 The values stated in either SI units or inch-pound units

Sections

are to be regarded separately as standard. The values stated in

each system are not necessarily exact equivalents; therefore, to

Sampling 7

ensure conformance with the standard, each system shall be

CHEMICAL ANALYSIS

used independently of the other, and values from the two

systems shall not be combined.

Reagents and apparatus 10

NOTE 1—Sieve size is identified by its standard designation in Speci-

Moisture content 11 and 12

fication E11. The alternative designation given in parentheses is for

Loss on ignition 13 and 14 information only and does not represent a different standard sieve size.

1.4 This standard does not purport to address all of the

Silicon dioxide, aluminum oxide, iron oxide,

calcium oxide, magnesium oxide, sulfur safety concerns, if any, associated with its use. It is the

15

trioxide, sodium oxide and potassium

responsibility of the user of this standard to establish appro-

oxide

priate safety, health, and environmental practices and deter-

Available alkali 16 and 17 mine the applicability of regulatory limitations prior to use.

1.5 The text of this standard references notes and footnotes

Ammonia 18

that provide explanatory information. These notes and foot-

PHYSICAL TESTS notes (excluding those in tables) shall not be considered as

requirements of this standard.

Density 19

1.6 This international standard was developed in accor-

Fineness 20

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Increase of drying shrinkage of mortar bars 21–23

Development of International Standards, Guides and Recom-

Soundness 24

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

Air-entrainment of mortar 25 and 26

Strength activity index with portland cement 27–30

2. Referenced Documents

2

Water requirement 31

2.1 ASTM Standards:

C109/C109MTest Method for Compressive Strength of

1

These test methods are under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregatesand are the direct responsibility of Subcommit-

2

tee C09.24 on Supplementary Cementitious Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2022. Published February 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1953. Last previous edition approved in 2018 as C311/C311M–18. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/C0311_C0311M-22. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C311/C311M − 22

Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube 3.2.1 composite sample, n—a sample that is constructed by

Specimens) combining equal portions of grab or regular samples.

C114Test Methods for Chemical Analysis of Hydraulic

3.2.2 established source, n—a source for which at least six

Cement

months of continuous production quality assurance records

C125Terminology Relating to Concrete and Concrete Ag-

from a test frequency required for a new source are available,

gregates

sampled at the source.

C150/C150MSpecification for Portland Cement

3.2.3 grab sample, n—a sample that is taken in a single

C151/C151MTest Method for Autoclave Expansion of Hy-

operation from a conveyor delivering to bulk storage, from

draulic Cement

bags, or from a bulk shipment.

C157/C157MTest Method for Length Change of Hardened

3.2.3.1 Discussion—A grab sa

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C311/C311M − 18 C311/C311M − 22

Standard Test Methods for

Sampling and Testing Fly Ash or Natural Pozzolans for Use

1

in Portland-Cement Concrete

This standard is issued under the fixed designation C311/C311M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 These test methods cover procedures for sampling and testing fly ash and raw or calcined pozzolans for use in portland-cement

concrete.

1.2 The procedures appear in the following order:

Sections

Sampling 7

CHEMICAL ANALYSIS

Reagents and apparatus 10

Moisture content 11 and 12

Loss on ignition 13 and 14

Silicon dioxide, aluminum oxide, iron oxide,

calcium oxide, magnesium oxide, sulfur

15

trioxide, sodium oxide and potassium

oxide

Available alkali 16 and 17

Ammonia 18

PHYSICAL TESTS

Density 19

Fineness 20

Increase of drying shrinkage of mortar bars 21 – 23

Soundness 24

1

These test methods are under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and are the direct responsibility of Subcommittee C09.24

on Supplementary Cementitious Materials.

Current edition approved Dec. 1, 2018Feb. 1, 2022. Published February 2019February 2022. Originally approved in 1953. Last previous edition approved in 20172018

as C311/C311M – 17.C311/C311M – 18. DOI: 10.1520/C0311_C0311M-18.10.1520/C0311_C0311M-22.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C311/C311M − 22

Air-entrainment of mortar 25 and 26

Strength activity index with portland cement 27 – 30

Water requirement 31

Effectiveness of Fly Ash or Natural Pozzolan in

32

Controlling Alkali-Silica Reactions

Effectiveness of Fly Ash or Natural Pozzolan in

34

Contributing to Sulfate Resistance

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other, and values from the two systems shall not be combined.

NOTE 1—Sieve size is identified by its standard designation in Specification E11. The alternative designation given in parentheses is for information only

and does not represent a different standard sieve size.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 The text of this standard references notes and footnotes that provide explanatory information. These notes and footnotes

(excluding those in tables) shall not be considered as requirements of this standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens)

C114 Test Methods for Chemical Analysis of Hydraulic Cement

C125 Terminology Relating to Concrete and Concrete Aggregates

C150/C150M Specification for Portland Cement

C151/C151M Test Method for Autoclave Expansion of Hydraulic Cement

C157/C157M Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete

C185 Test Method for Air Content of Hydraulic Cement Mortar

C188 Test Method for Density of Hydraulic Cement

C204 Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus

C219 Terminology Relating to Hydraulic and Other Inorganic Cements

C226 Specification for Air-Entraining Additions for Use in the Manufacture of Air-Entraining Hydraulic Cement

3

C227 Test Method for Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method) (Withdrawn 2018)

C430 Tes

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C311/C311M − 22

Standard Test Methods for

Sampling and Testing Fly Ash or Natural Pozzolans for Use

1

in Portland-Cement Concrete

This standard is issued under the fixed designation C311/C311M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

Effectiveness of Fly Ash or Natural Pozzolan in

32

1.1 These test methods cover procedures for sampling and

Controlling Alkali-Silica Reactions

testing fly ash and raw or calcined pozzolans for use in

Effectiveness of Fly Ash or Natural Pozzolan in

portland-cement concrete.

34

Contributing to Sulfate Resistance

1.2 The procedures appear in the following order:

1.3 The values stated in either SI units or inch-pound units

Sections

are to be regarded separately as standard. The values stated in

each system are not necessarily exact equivalents; therefore, to

Sampling 7

ensure conformance with the standard, each system shall be

CHEMICAL ANALYSIS

used independently of the other, and values from the two

systems shall not be combined.

Reagents and apparatus 10

NOTE 1—Sieve size is identified by its standard designation in Speci-

Moisture content 11 and 12

fication E11. The alternative designation given in parentheses is for

Loss on ignition 13 and 14

information only and does not represent a different standard sieve size.

1.4 This standard does not purport to address all of the

Silicon dioxide, aluminum oxide, iron oxide,

calcium oxide, magnesium oxide, sulfur safety concerns, if any, associated with its use. It is the

15

trioxide, sodium oxide and potassium

responsibility of the user of this standard to establish appro-

oxide

priate safety, health, and environmental practices and deter-

Available alkali 16 and 17 mine the applicability of regulatory limitations prior to use.

1.5 The text of this standard references notes and footnotes

Ammonia 18

that provide explanatory information. These notes and foot-

PHYSICAL TESTS notes (excluding those in tables) shall not be considered as

requirements of this standard.

Density 19

1.6 This international standard was developed in accor-

Fineness 20

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Increase of drying shrinkage of mortar bars 21 – 23

Development of International Standards, Guides and Recom-

Soundness 24

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

Air-entrainment of mortar 25 and 26

Strength activity index with portland cement 27 – 30

2. Referenced Documents

2

Water requirement 31

2.1 ASTM Standards:

C109/C109M Test Method for Compressive Strength of

1

These test methods are under the jurisdiction of ASTM Committee C09 on

Concrete and Concrete Aggregates and are the direct responsibility of Subcommit-

2

tee C09.24 on Supplementary Cementitious Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2022. Published February 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1953. Last previous edition approved in 2018 as C311/C311M – 18. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/C0311_C0311M-22. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C311/C311M − 22

Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube 3.2.1 composite sample, n—a sample that is constructed by

Specimens) combining equal portions of grab or regular samples.

C114 Test Methods for Chemical Analysis of Hydraulic

3.2.2 established source, n—a source for which at least six

Cement

months of continuous production quality assurance records

C125 Terminology Relating to Concrete and Concrete Ag-

from a test frequency required for a new source are available,

gregates

sampled at the source.

C150/C150M Specification for Portland Cement

3.2.3 grab sample, n—a sample that is taken in a single

C151/C151M Test Method for Autoclave Expansion of Hy-

operation from a conveyor delivering to bulk storage, from

draulic Cement

bags, or from a bulk shipment.

C157/C157M Test Method for Length Change of Hardened

3.2.3.1 Discussion—A grab sample may or may not reflect

Hydraulic-Cement Mortar and Concrete

the composition or physical properties of a single lot of fly ash

C185

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.