ASTM D6465-99(2012)

(Guide)Standard Guide for Selecting Aerospace and General Purpose Adhesives and Sealants

Standard Guide for Selecting Aerospace and General Purpose Adhesives and Sealants

SIGNIFICANCE AND USE

The guide is to be used by anyone developing bonding or sealing requirements for specifications for manufacturing, maintenance or overhaul. This guide has been designed to be application specific for each bonding or sealing application, and allows the design engineer to rest assured that the product(s) or process(es) selected by the industrial or manufacturing engineer will be compatible with both the part material and the subsequent processes, such as adherend/substrate cleaning and preparation. It allows the industrial or manufacturing engineer to customize the selection of the adhesive or sealant product based on the materials of the parts being bonded or sealed, the conditions required for the subsequent process(es), environmental, cost, and health and safety concerns.

SCOPE

1.1 This guide is intended to assist design engineers, manufacturing/industrial engineers, and production managers in selecting the best-fit adhesive/sealant or bonding/sealing process. The guide takes into account environmental pollution prevention and occupational health and safety factors in a selection process.

1.2 This guide is not to be considered as a database of acceptable materials. It will guide the engineers and managers through the adhesive/sealant material selection process, calling for engineers to customize their selection based on the bonding or sealing performance requirements for the specified application. A comprehensive selection process will allow for the establishment of a more efficient production process, and may eliminate unnecessary process steps. A total life cycle cost analysis or performance/cost of implementation study is recommended to compare the available alternatives.

1.3 This guide is for aerospace and general purpose operations. It is not intended to be used for automotive, carpet, construction, electronics, medical/dental, optical, or structural and nonstructural wood applications. Note that this guide is not specifically for these applications, but the general methodology may be used in the selection process for these applications.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6465 − 99 (Reapproved2012)

Standard Guide for

Selecting Aerospace and General Purpose Adhesives and

Sealants

This standard is issued under the fixed designation D6465; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D896Practice for Resistance of Adhesive Bonds to Chemi-

cal Reagents

1.1 This guide is intended to assist design engineers,

D897Test Method forTensile Properties ofAdhesive Bonds

manufacturing/industrial engineers, and production managers

D903Test Method for Peel or Stripping Strength of Adhe-

in selecting the best-fit adhesive/sealant or bonding/sealing

sive Bonds

process. The guide takes into account environmental pollution

D905Test Method for Strength Properties of Adhesive

prevention and occupational health and safety factors in a

Bonds in Shear by Compression Loading

selection process.

D907Terminology of Adhesives

1.2 This guide is not to be considered as a database of

D950Test Method for Impact Strength of Adhesive Bonds

acceptable materials. It will guide the engineers and managers

D1002Test Method for Apparent Shear Strength of Single-

throughtheadhesive/sealantmaterialselectionprocess,calling

Lap-Joint Adhesively Bonded Metal Specimens by Ten-

forengineerstocustomizetheirselectionbasedonthebonding

sion Loading (Metal-to-Metal)

or sealing performance requirements for the specified applica-

D1062Test Method for Cleavage Strength of Metal-to-

tion. A comprehensive selection process will allow for the

establishment of a more efficient production process, and may Metal Adhesive Bonds

eliminate unnecessary process steps. A total life cycle cost D1084Test Methods for Viscosity of Adhesives

analysis or performance/cost of implementation study is rec-

D1144Practice for Determining Strength Development of

ommended to compare the available alternatives.

Adhesive Bonds

D1146Test Method for Blocking Point of PotentiallyAdhe-

1.3 This guide is for aerospace and general purpose opera-

sive Layers

tions. It is not intended to be used for automotive, carpet,

D1151Practice for Effect of Moisture and Temperature on

construction, electronics, medical/dental, optical, or structural

andnonstructuralwoodapplications.Notethatthisguideisnot Adhesive Bonds

specificallyfortheseapplications,butthegeneralmethodology D1183Practices for Resistance of Adhesives to Cyclic

may be used in the selection process for these applications.

Laboratory Aging Conditions

D1184Test Method for Flexural Strength of Adhesive

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the Bonded Laminated Assemblies

responsibility of the user of this standard to establish appro- D1310TestMethodforFlashPointandFirePointofLiquids

priate safety and health practices and determine the applica-

by Tag Open-Cup Apparatus

bility of regulatory limitations prior to use.

D1337Practice for Storage Life of Adhesives by Viscosity

and Bond Strength

2. Referenced Documents

D1338Practice for Working Life of Liquid or Paste Adhe-

2.1 ASTM Standards:

sives by Consistency and Bond Strength

D56Test Method for Flash Point by Tag Closed Cup Tester

D1780Practice for Conducting Creep Tests of Metal-to-

Metal Adhesives

D1781Test Method for Climbing Drum Peel for Adhesives

ThisguideisunderthejurisdictionofASTMCommitteeD14onAdhesivesand

is the direct responsibility of Subcommittee D14.60 on Adhesive Material Classi- D1828Practice for Atmospheric Exposure of Adhesive-

fication System.

Bonded Joints and Structures

Current edition approved May 1, 2012. Published May 2012. Originally

D1875Test Method for Density ofAdhesives in Fluid Form

approved in 1999. Last previous edition approved in 2005 as D6465–99(2005).

DOI: 10.1520/D6465-99R12. D1876Test Method for Peel Resistance of Adhesives (T-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Peel Test)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D1879Practice for Exposure of Adhesive Specimens to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Ionizing Radiation

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6465 − 99 (2012)

D1916Test Method for Penetration of Adhesives (With- D3310Test Method for Determining Corrosivity of Adhe-

drawn 2005) sive Materials

D1994Test Method for Determination of Acid Numbers of

D3433Test Method for Fracture Strength in Cleavage of

Hot-Melt Adhesives

Adhesives in Bonded Metal Joints

D1995Test Methods for Multi-Modal Strength Testing of

D3528Test Method for Strength Properties of Double Lap

Autohesives (Contact Adhesives)

Shear Adhesive Joints by Tension Loading

D2093Practice for Preparation of Surfaces of Plastics Prior

D3632Test Method for Accelerated Aging of Adhesive

to Adhesive Bonding

Joints by the Oxygen-Pressure Method

D2095Test Method for Tensile Strength of Adhesives by

D3762Test Method for Adhesive-Bonded Surface Durabil-

Means of Bar and Rod Specimens

ity of Aluminum (Wedge Test)

D2240Test Method for Rubber Property—Durometer Hard-

D3807Test Method for Strength Properties ofAdhesives in

ness

Cleavage Peel by Tension Loading (Engineering Plastics-

D2293Test Method for Creep Properties of Adhesives in

to-Engineering Plastics)

Shear by Compression Loading (Metal-to-Metal)

D3929Test Method for Evaluating Stress Cracking of Plas-

D2294Test Method for Creep Properties of Adhesives in

tics by Adhesives Using the Bent-Beam Method

Shear by Tension Loading (Metal-to-Metal)

D3931TestMethodforDeterminingStrengthofGap-Filling

D2295Test Method for Strength Properties ofAdhesives in

Adhesive Bonds in Shear by Compression Loading

Shear by Tension Loading at Elevated Temperatures

D3933Guide for Preparation of Aluminum Surfaces for

(Metal-to-Metal)

Structural Adhesives Bonding (Phosphoric Acid Anodiz-

D2556Test Method for Apparent Viscosity of Adhesives

ing)

Having Shear-Rate-Dependent Flow Properties

D3983Test Method for Measuring Strength and Shear

D2557TestMethodforTensile-ShearStrengthofAdhesives

Modulus of Nonrigid Adhesives by the Thick-Adherend

in the Subzero Temperature Range from −267.8 to −55°C

Tensile-Lap Specimen

(−450 to −67°F)

D4027Test Method for Measuring Shear Properties of

D2583Test Method for Indentation Hardness of Rigid Plas-

Structural Adhesives by the Modified-Rail Test

tics by Means of a Barcol Impressor

D4317Specification for Polyvinyl Acetate-Based Emulsion

D2651GuideforPreparationofMetalSurfacesforAdhesive

Adhesives

Bonding

D4339Test Method for Determination of the Odor of

D2674Methods ofAnalysis of Sulfochromate Etch Solution

Used in Surface Preparation of Aluminum Adhesives

D2918Test Method for Durability Assessment of Adhesive D4497Test Method for Determining the Open Time of Hot

Joints Stressed in Peel Melt Adhesives (Manual Method)

D2919Test Method for Determining Durability ofAdhesive D4498Test Method for Heat-Fail Temperature in Shear of

Joints Stressed in Shear by Tension Loading

Hot Melt Adhesives

D2979Test Method for Pressure-Sensitive Tack of Adhe-

D4499Test Method for Heat Stability of Hot-Melt Adhe-

sives Using an Inverted Probe Machine

sives

D3111Test Method for Flexibility Determination of Hot-

D4501Test Method for Shear Strength of Adhesive Bonds

Melt Adhesives by Mandrel Bend Test Method

Between Rigid Substrates by the Block-Shear Method

D3121Test Method for Tack of Pressure-Sensitive Adhe-

D4562Test Method for Shear Strength of Adhesives Using

sives by Rolling Ball

Pin-and-Collar Specimen

D3163Test Method for Determining Strength ofAdhesively

D4689Specification for Adhesive, Casein-Type

Bonded Rigid Plastic Lap-Shear Joints in Shear by Ten-

D4690Specification for Urea-Formaldehyde Resin Adhe-

sion Loading

sives

D3164Test Method for Strength Properties of Adhesively

D4783Test Methods for Resistance of Adhesive Prepara-

Bonded Plastic Lap-Shear Sandwich Joints in Shear by

tions in Container toAttack by Bacteria,Yeast, and Fungi

Tension Loading

D4800Guide for Classifying and Specifying Adhesives

D3165Test Method for Strength Properties ofAdhesives in

D5041Test Method for Fracture Strength in Cleavage of

Shear by Tension Loading of Single-Lap-Joint Laminated

Adhesives in Bonded Joints

Assemblies

D5267Test Method for Determination of Extrudability of

D3166Test Method for Fatigue Properties of Adhesives in

Cartridge Adhesives

Shear by Tension Loading (Metal/Metal)

D5363Specification for Anaerobic Single-Component Ad-

D3167Test Method for Floating Roller Peel Resistance of

hesives (AN)

Adhesives

D5573Practice for Classifying Failure Modes in Fiber-

D3278Test Methods for Flash Point of Liquids by Small

Reinforced-Plastic (FRP) Joints

Scale Closed-Cup Apparatus

D5648Test Method for Torque-Tension Relationship of

Adhesives Used on Threaded Fasteners (Lubricity)

3 D5649Test Method for Torque Strength ofAdhesives Used

The last approved version of this historical standard is referenced on

www.astm.org. on Threaded Fasteners

D6465 − 99 (2012)

D5656Test Method for Thick-Adherend Metal Lap-Shear the guide, which will provide appropriate guidance on evalu-

Joints for Determination of the Stress-Strain Behavior of ation criteria that should be followed in order to evaluate the

Adhesives in Shear by Tension Loading potential adhesive or sealant. Table 1 provides a summary of

D5657TestMethodforFluidTightnessAbilityofAdhesives the user-defined requirements information and the procedures

Used on Threaded Fasteners tobeprovidedbytheguide.Theorderofthestepspresentedin

D5868Test Method for Lap Shear Adhesion for Fiber Table1issuggested,butnotcrucialtothesuccessfuluseofthe

Reinforced Plastic (FRP) Bonding guide. Section 6 will provide greater details on both the user

D6195Test Methods for Loop Tack input and the guidance provided.

D6361Guide for Selecting Cleaning Agents and Processes

5. Significance and Use

E229Test Method for Shear Strength and Shear Modulus of

Structural Adhesives (Withdrawn 2003)

5.1 The guide is to be used by anyone developing bonding

or sealing requirements for specifications for manufacturing,

3. Terminology

maintenance or overhaul. This guide has been designed to be

3.1 Definitions—Fortechnicaltermspertainingtoadhesives application specific for each bonding or sealing application,

and allows the design engineer to rest assured that the

and sealants, see Terminology D907.

product(s) or process(es) selected by the industrial or manu-

3.2 Classifications—For the identification and classification

facturing engineer will be compatible with both the part

system of adhesives and sealants, see Guide D4800. (Related

material and the subsequent processes, such as adherend/

documents: Specification D4317; Specification D4689; Speci-

substrate cleaning and preparation. It allows the industrial or

fication D4690; Specification D5363; and Test Method

manufacturing engineer to customize the selection of the

D1994.)

adhesive or sealant product based on the materials of the parts

being bonded or sealed, the conditions required for the subse-

4. Summary of Guide

quent process(es), environmental, cost, and health and safety

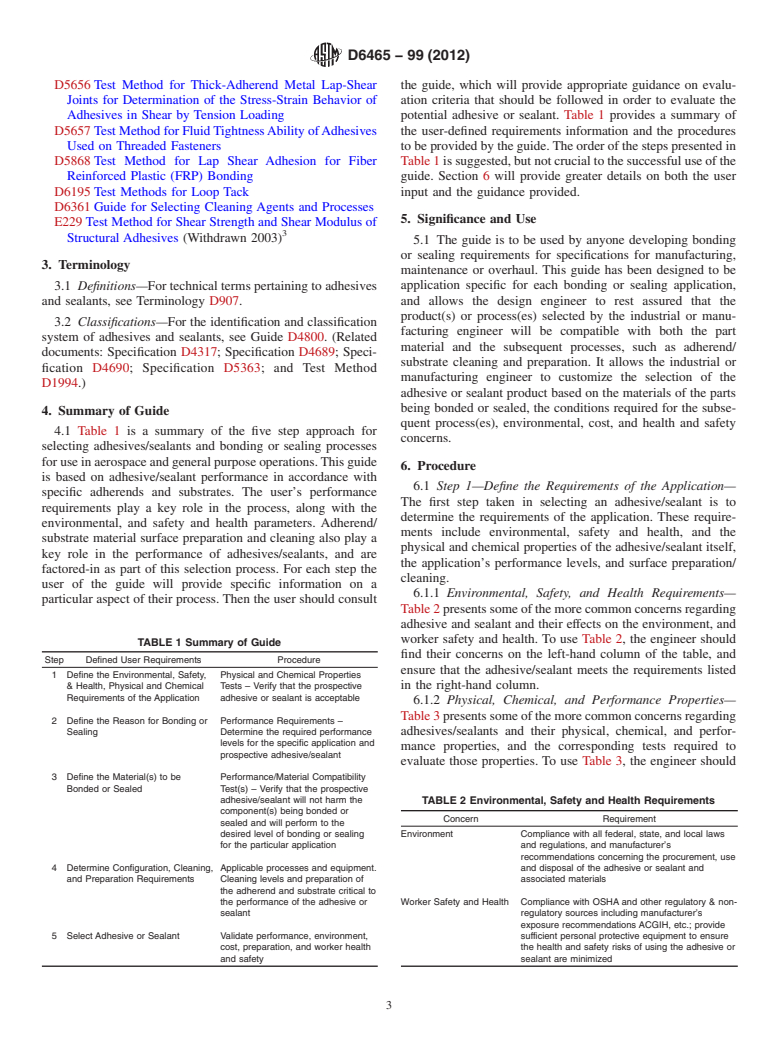

4.1 Table 1 is a summary of the five step approach for

concerns.

selecting adhesives/sealants and bonding or sealing processes

foruseinaerospaceandgeneralpurposeoperations.Thisguide

6. Procedure

is based on adhesive/sealant performance in accordance with

6.1 Step 1—Define the Requirements of the Application—

specific adherends and substrates. The user’s performance

The first step taken in selecting an adhesive/sealant is to

requirements play a key role in the process, along with the

determine the requirements of the application. These require-

environmental, and safety and health parameters. Adherend/

ments include environmental, safety and health, and the

substrate material surface preparation and cleaning also play a

physical and chemical properties of the adhesive/sealant itself,

key role in the performance of adhesives/sealants, and are

the application’s performance levels, and surface preparation/

factored-in as part of this selection process. For each step the

cleaning.

user of the guide will provide specific information on a

6.1.1 Environmental, Safety, and Health Requirements—

particular aspect of their process.Then the user should consult

Table2presentssomeofthemorecommonconcernsregarding

adhesive and sealant and their effects on the environment, and

worker safety and health. To use Table 2, the engineer should

TABLE 1 Summary of Guide

find their concerns on the left-hand column of the table, and

Step Defined User Requirements Procedure

ensure that the adhesive/sealant meets the requirements listed

1 Define the Environmental, Safety, Physical and Chemical Properties

& Health, Physical and Chemical Tests – Verify that the prospective in the right-hand column.

Requirements of the Application adhesive or sealant is acceptable

6.1.2 Physical, Chemical, and Performance Properties—

Table3presentssomeofthemorecommonconcernsregarding

2 Define the Reason for Bonding or Performance Requirements –

Sealing Determine the required performance adhesives/sealants and their physical, chemical, and perfor-

levels for the specific application and

mance properties, and the corresponding tests required to

prospective adhesive/sealant

evaluate those properties. To use Table 3, the engineer should

3 Define the Material(s) to be Performance/Material Compatibility

Bonded or Sealed Test(s) – Verify that the prospective

adhesive/sealant will not harm the

TABLE 2 Environmental, Safety and Health Requirements

component(s) being bonded or

Concern Requirement

sealed and will perform to the

desired level of bonding or sealing Environment Compliance with all federal, state, and local laws

for the particular application and regulations, and manufacturer’s

recommendations concerning the procurement, use

4 Determine Configuration, Cleaning, Applicable processes and equipment. and disposal of the adhesive or sealant and

and Preparation Requirements Cleaning levels and preparation of associated materials

the adherend and substrate critical to

the performance of the adhesive or Worker Safety and Health Compliance with OSHA and other regulatory & non-

sealant regulatory sources including manufacturer’s

exposure recommendations ACGIH, etc.; provide

5 Select Adhesive or Sealant Validate performance, environment, sufficient personal protective equipment to ensure

cost, preparation, and worker health the health and safety risks of using the ad

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.