ASTM D4796-17

(Test Method)Standard Test Method for Bond Strength of Thermoplastic Pavement Marking Materials

Standard Test Method for Bond Strength of Thermoplastic Pavement Marking Materials

SIGNIFICANCE AND USE

5.1 The function of this test method is to provide numerical instrumental results indicating the cohesive and/or adhesive bond strength of thermoplastic pavement marking to a specified cement brick substrate.

5.2 The use of this test method allows the user and manufacturer to control the quality of the product and make inferences about the performance of the thermoplastic pavement marking product. Results from these tests also provide information helpful in researching and developing thermoplastic pavement marking materials.

5.3 The method has been revised to be more consistent to methodology in other ASTM bond methods for coatings in Test Methods D4541, D5179, and D7234.

5.4 Strict adherence to the procedures outlined is necessary for precision of the test method. Under no conditions should the bond strength be accepted unless there is conformance to the method.

SCOPE

1.1 This test method provides an instrumental means for the determination of thermoplastic pavement marking material bond strengths using cement bricks and loading fixtures.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4796 − 17

Standard Test Method for

Bond Strength of Thermoplastic Pavement Marking

1

Materials

This standard is issued under the fixed designation D4796; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ings on Concrete Using Portable Pull-Off Adhesion Tes-

ters

1.1 This test method provides an instrumental means for the

D7307 PracticeforSamplingofThermoplasticTrafficMark-

determination of thermoplastic pavement marking material

ing Materials

bond strengths using cement bricks and loading fixtures.

D7308 Practice for Sample Preparation of Thermoplastic

1.2 The values stated in inch-pound units are to be regarded

Pavement Marking Materials

as standard. The values given in parentheses are mathematical

E177 Practice for Use of the Terms Precision and Bias in

conversions to SI units that are provided for information only

ASTM Test Methods

and are not considered standard.

E691 Practice for Conducting an Interlaboratory Study to

1.3 This standard does not purport to address all of the Determine the Precision of a Test Method

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

priate safety, health and environmental practices and deter- 3.1 The terms and definitions in Terminology D16 apply to

this method.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

3.2 Definitions of Terms Specific to This Standard:

dance with internationally recognized principles on standard-

3.2.1 cement brick, n—a type of brick (a solid masonry unit,

ization established in the Decision on Principles for the

rectangular in shape) made from a mixture of cement and sand,

Development of International Standards, Guides and Recom-

molded under pressure and cured under steam at 200°F (93°C);

mendations issued by the World Trade Organization Technical

used as backing brick and where there is no danger of attack

Barriers to Trade (TBT) Committee.

from acid or alkaline conditions.These bricks are not colorized

and have a compressive strength of 3000 to 5000 psi.

2. Referenced Documents

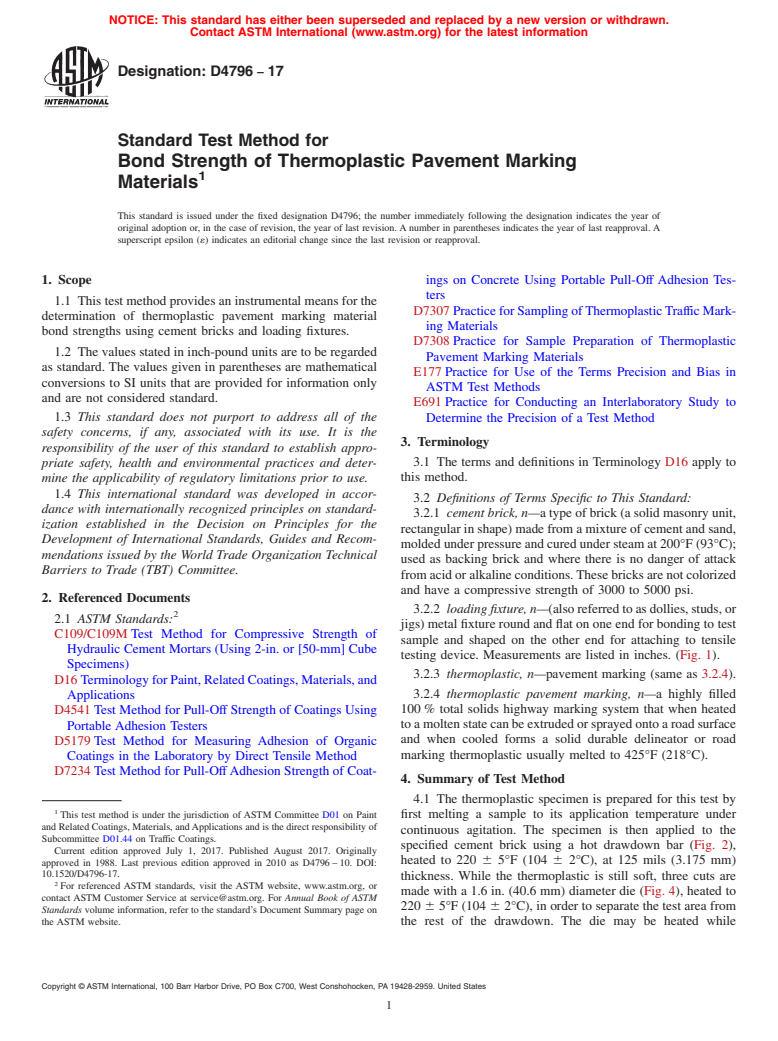

3.2.2 loadingfixture,n—(alsoreferredtoasdollies,studs,or

2

2.1 ASTM Standards:

jigs) metal fixture round and flat on one end for bonding to test

C109/C109M Test Method for Compressive Strength of

sample and shaped on the other end for attaching to tensile

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

testing device. Measurements are listed in inches. (Fig. 1).

Specimens)

3.2.3 thermoplastic, n—pavement marking (same as 3.2.4).

D16 TerminologyforPaint,RelatedCoatings,Materials,and

3.2.4 thermoplastic pavement marking, n—a highly filled

Applications

100 % total solids highway marking system that when heated

D4541 Test Method for Pull-Off Strength of Coatings Using

toamoltenstatecanbeextrudedorsprayedontoaroadsurface

Portable Adhesion Testers

and when cooled forms a solid durable delineator or road

D5179 Test Method for Measuring Adhesion of Organic

marking thermoplastic usually melted to 425°F (218°C).

Coatings in the Laboratory by Direct Tensile Method

D7234 Test Method for Pull-OffAdhesion Strength of Coat-

4. Summary of Test Method

4.1 The thermoplastic specimen is prepared for this test by

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

first melting a sample to its application temperature under

and Related Coatings, Materials, andApplications and is the direct responsibility of

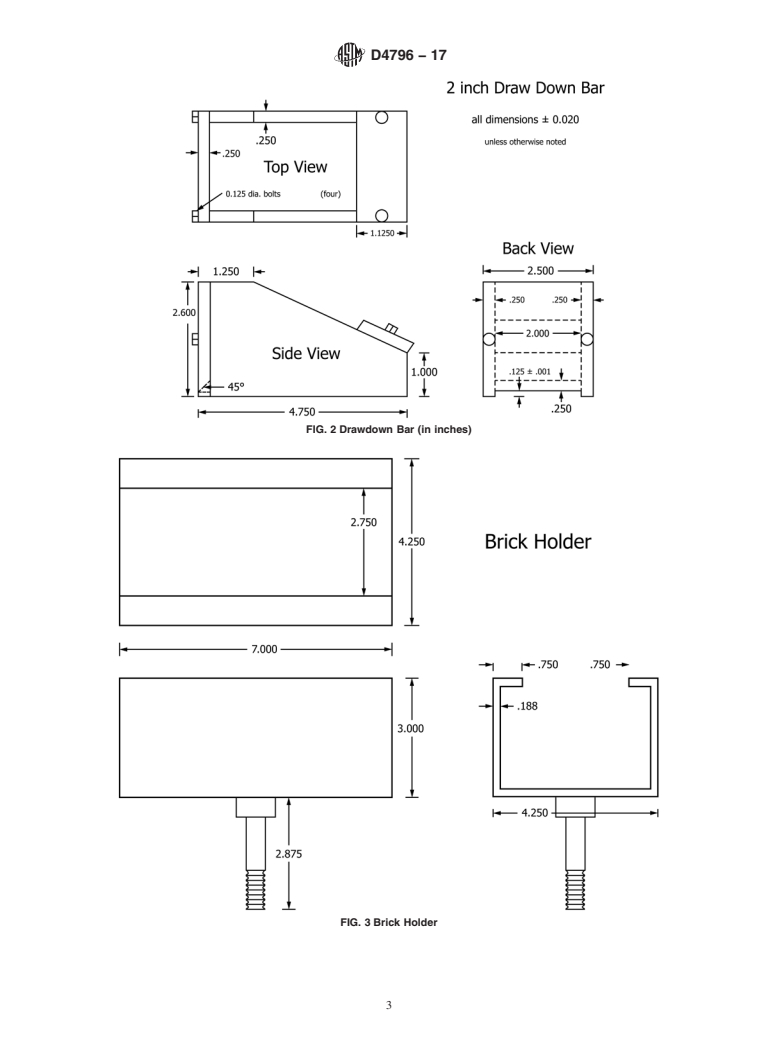

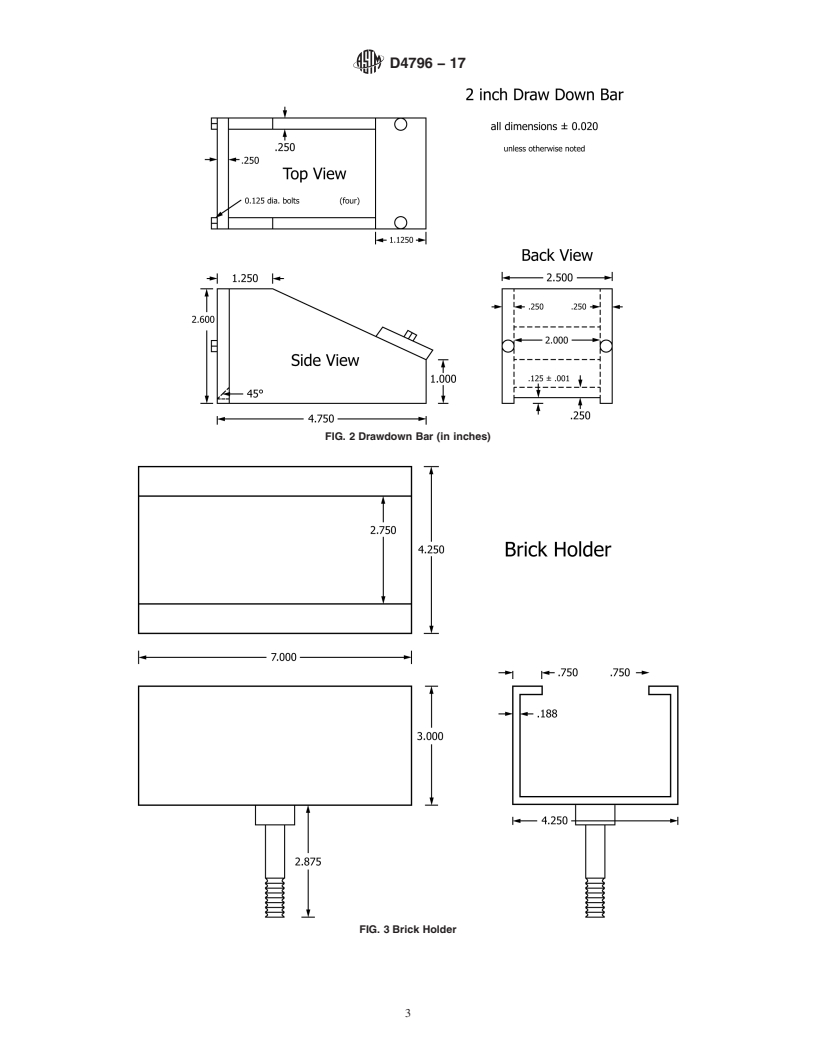

continuous agitation. The specimen is then applied to the

Subcommittee D01.44 on Traffic Coatings.

specified cement brick using a hot drawdown bar (Fig. 2),

Current edition approved July 1, 2017. Published August 2017. Originally

heated to 220 6 5°F (104 6 2°C), at 125 mils (3.175 mm)

approved in 1988. Last previous edition approved in 2010 as D4796 – 10. DOI:

10.1520/D4796-17.

thickness. While the thermoplastic is still soft, three cuts are

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

made with a 1.6 in. (40.6 mm) diameter die (Fig. 4), heated to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

220 6 5°F (104 6 2°C), in order to separate the test area from

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the rest of the drawdown. The die may be heated while

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4796 − 17

6. Types of Separation in Bond Strengt

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4796 − 10 D4796 − 17

Standard Test Method for

Bond Strength of Thermoplastic TrafficPavement Marking

1

Materials

This standard is issued under the fixed designation D4796; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides an instrumental means for the determination of thermoplastic trafficpavement marking material

bond strengths using cement bricks and loading fixtures.

1.2 The values stated in SIinch-pound units are to be regarded as the standard. The values given in parentheses are for

information only.mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

D16 Terminology for Paint, Related Coatings, Materials, and Applications

D4541 Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers

D5179 Test Method for Measuring Adhesion of Organic Coatings in the Laboratory by Direct Tensile Method

D7234 Test Method for Pull-Off Adhesion Strength of Coatings on Concrete Using Portable Pull-Off Adhesion Testers

D7307 Practice for Sampling of Thermoplastic Traffic Marking Materials

D7308 Practice for Sample Preparation of Thermoplastic Pavement Marking Materials

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 The terms and definitions in Terminology D16 apply to this method.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 cement brick, n—a brick formed by mixing cement and fine sand together and allowing to harden with 210.9 to 351.5

kg/cmtype of brick (a solid masonry unit, rectangular in shape) made from a mixture of cement and sand, molded under pressure

2

and cured under steam at 200°F (93°C); used as (3000 to 5000 psi) compression strength.backing brick and where there is no

danger of attack from acid or alkaline conditions. These bricks are not colorized and have a compressive strength of 3000 to 5000

psi.

3.2.2 loading fixture, n—(also referred to as dollies, studs, or jigs) metal fixture round and flat on one end for bonding to test

sample and shaped on the other end for attaching to tensile testing device device. Measurements are listed in inches. (Fig. 1).

3.2.3 thermoplastic, n—trafficpavement marking (same as 3.2.4).

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.44 on Traffic Coatings.

Current edition approved Dec. 1, 2010July 1, 2017. Published March 2011August 2017. Originally approved in 1988. Last previous edition approved in 20042010 as

D4796 – 88 (2004).D4796 – 10. DOI: 10.1520/D4796-10.10.1520/D4796-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4796 − 17

FIG. 1 Loading Fixture

3.2.4 thermoplastic traffıcpavement marking, n—a highly filled 100 % total solids highway marking system that when heated

to a molten state can be extruded or sprayed onto a road surface and when cooled forms a solid durable delineator or road marking

thermoplastic usually melted to 218°

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.