ASTM D8161-17(2022)

(Test Method)Standard Test Method for Impact Resistance of Thermoplastic Pavement Marking Materials over a Highway Substrate by Means of a Striker Impacted by a Falling Weight

Standard Test Method for Impact Resistance of Thermoplastic Pavement Marking Materials over a Highway Substrate by Means of a Striker Impacted by a Falling Weight

SIGNIFICANCE AND USE

5.1 The significance of this test is to determine the thermoplastic pavement marking material’s resistance to impact over a simulated pavement substrate, under laboratory conditions, and is expressed as pass/fail or numerically. The test result can be used as a quality test or to differentiate marking materials.

5.2 Anyone attempting to perform this test should initially review Test Methods D5420 and D2794, specifically the equipment setup.

5.3 Sample preparation and equipment set-up should be followed precisely to minimize variability in the test result.

SCOPE

1.1 This test method covers the sample preparation over a road-type substrate and test methodology of thermoplastic pavement marking materials similar to the “Gardner Impact” method as listed in Test Method D5420.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8161 − 17 (Reapproved 2022)

Standard Test Method for

Impact Resistance of Thermoplastic Pavement Marking

Materials over a Highway Substrate by Means of a Striker

Impacted by a Falling Weight

This standard is issued under the fixed designation D8161; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D5628 Test Method for Impact Resistance of Flat, Rigid

Plastic Specimens by Means of a Falling Dart (Tup or

1.1 This test method covers the sample preparation over a

Falling Mass)

road-type substrate and test methodology of thermoplastic

D7307 Practice for Sampling of Thermoplastic Pavement

pavement marking materials similar to the “Gardner Impact”

Marking Materials

method as listed in Test Method D5420.

D7308 Practice for Sample Preparation of Thermoplastic

1.2 The values stated in inch-pound units are to be regarded

Pavement Marking Materials

as standard. The values given in parentheses are mathematical

E177 Practice for Use of the Terms Precision and Bias in

conversions to SI units that are provided for information only

ASTM Test Methods

and are not considered standard.

E284 Terminology of Appearance

1.3 This standard does not purport to address all of the

E691 Practice for Conducting an Interlaboratory Study to

safety concerns, if any, associated with its use. It is the Determine the Precision of a Test Method

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3. Terminology

mine the applicability of regulatory limitations prior to use.

3.1 Definitions:

1.4 This international standard was developed in accor-

3.1.1 The terms and definitions in Terminology D883 and

dance with internationally recognized principles on standard-

E284 apply to this method.

ization established in the Decision on Principles for the

3.2 Definitions of Terms Specific to This Standard:

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3.2.1 failure(oftestspecimen),n—thepresenceofanycrack

Barriers to Trade (TBT) Committee. or split created by the impact of the falling weight that can be

seen by the naked eye under normal laboratory lighting

2. Referenced Documents

conditions.

2.1 ASTM Standards:

3.2.2 Falling Weight (Gardner) Impact Tester, n—impact

D883 Terminology Relating to Plastics

tester designed as described in Test Method D5420.

D2794 Test Method for Resistance of Organic Coatings to

3.2.3 thermoplastic pavement marking, n—a highly filled

the Effects of Rapid Deformation (Impact)

100 % total solids highway marking system that when heated

D4796 Test Method for Bond Strength of Thermoplastic

toamoltenstatecanbeextrudedorsprayedontoaroadsurface

Pavement Marking Materials

and when cooled forms a solid durable delineator or marking.

D5420 Test Method for Impact Resistance of Flat, Rigid

Plastic Specimen by Means of a Striker Impacted by a

4. Summary of Test Method

Falling Weight (Gardner Impact)

4.1 In this test method, a weight falls through a guide tube

and impacts a striker resting on top of a supported specimen.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

This test method is similar to Test Methods D5420 and D2794

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.44 on Traffic Coatings.

except the impact occurs on thermoplastic pavement marking

Current edition approved Dec. 1, 2022. Published December 2022. Originally

material applied over a solid road-type substrate with minimal

approved in 2017. Last previous edition approved in 2017 as D8161-17. DOI:

deformation.

10.1520/D8161-17R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 The test result is typically pass/fail, however maximum

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

impacttocausematerialfailurecanbedeterminedasshownby

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. cracking, chipping, delaminating, etc.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D8161 − 17 (2022)

5. Significance and Use

5.1 The significance of this test is to determine the thermo-

plastic pavement marking material’s resistance to impact over

a simulated pavement substrate, under laboratory conditions,

and is expressed as pass/fail or numerically. The test result can

be used as a quality test or to differentiate marking materials.

5.2 Anyone attempting to perform this test should initially

review Test Methods D5420 and D2794, specifically the

equipment setup.

5.3 Sample preparation and equipment set-up should be

followed precisely to minimize variability in the test result.

6. Interferences

6.1 Falling-weight-impact test results are dependent on the

geometry of the falling weight, striker, and the support. Thus,

use impact tests only to obtain relative rankings of materials.

Impact values cannot be considered absolute unless the geom-

etryofthetestequipmentandspecimenconformtotheend-use

requirement. Data obtained with different geometries, cannot,

in general, be compared directly with each other

6.2 Since this method is based on the impact of a material

on a non-deformable substrate, the failure mode can come in

many different forms. This method may not cover the type of

deformation seen on some type of products. In this instance, a

determination of whether an impact causes a passing or a

FIG. 1 Impact Tester

failing deformation will then need to be determined by the

buyer and the seller.

6.3 Impact properties of thermoplastic pavement marking

materials can be very sensitive to temperature. This test can be

carried out at any reasonable temperature and humidity, thus

representing actual-use environments. However, this test

method as written is intended primarily for rating materials

under specific impact conditions and at 75 °F 6 2 °F (24 °C 6

1 °C).

6.4 It is possible that the apparatus used in this test method

will not have sufficient energy available to cause failure of

some specimens under the conditions of this procedure.

7. Apparatus

7.1 The basics of the apparatus are shown in Fig. 1 minus

the specimen support plate and support anvil. More detailed

information can be found in the Apparatus section of Test

Methods D5420 and D2794.

7.1.1 The difference being that the test sample on the road

substrate is placed under the striker, and on the base of the

apparatus instead of on the specimen support anvil as shown in FIG. 2 Specimen Support Anvil

Fig. 2.

7.2 Although there are many sizes and shapes of strikers for

this method, we are recommending that only a 0.625 in. 6

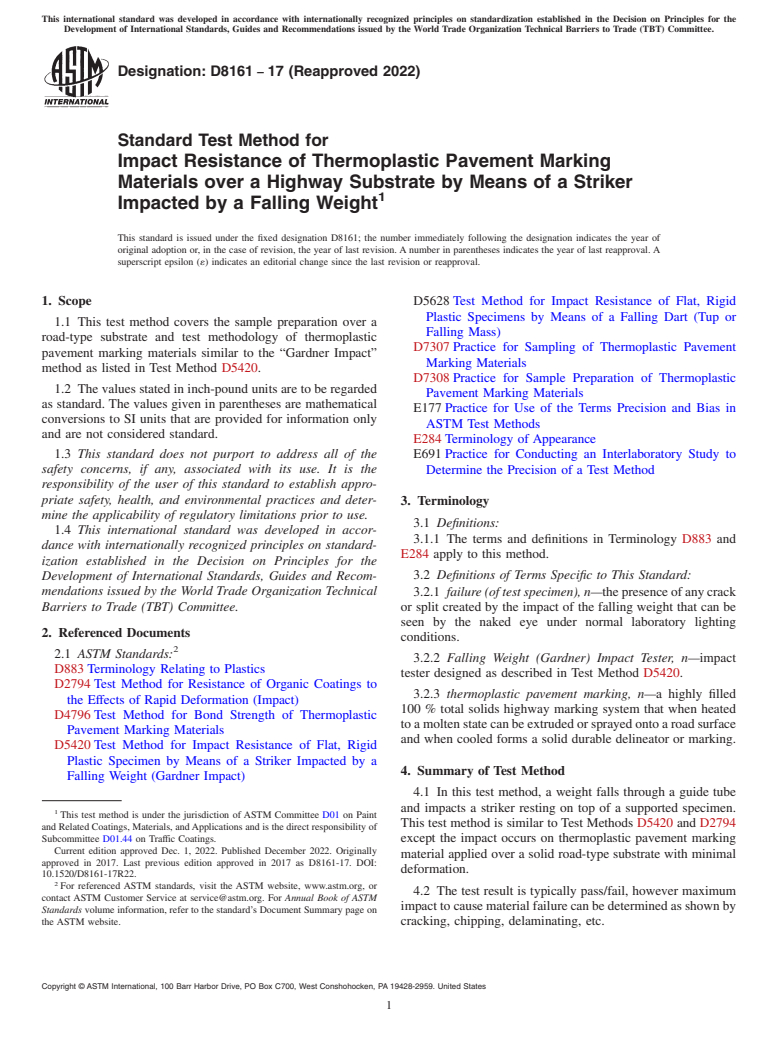

ing. Other width drawdown bars and drawdown gaps can be

0.004 in. (15.86 mm 6 0.10 mm) striker be used.

used but this is the most common for the thermoplastic

7.3 Although many weight loads can be used,a2lb (0.9 kg)

pavement marking industry (Fig. 3).

weightisthemostcommonandwillbetheonlytypeaddressed

8.2 Concrete Brick, with a minimum of 3000 psi compres-

within this method.

sion strength or substrate of choice.

8. Reagents and Materials

8.3 Asphalt Samples, cored from a road surface or made to

8.1 Four (4) in. Wide Drawdown Bar, capable of drawing a specific formulation and compressed in a Marshall testing

down a 0.125 in. thick film of thermoplastic pavement mark- device, then sawed in half. The top half of these types of

D8161 − 17 (2022)

FIG. 3 Drawdown Bar

samples can be used to simulate fresh asphalt and the cut side

worn or aged asphalt surfaces (Fig. 4).

FIG. 5 Warmed Drawdown Bar

8.4 Any other type of road surface or road surface covered

with an overlay or road marking can be used.

400 lb to the floor. Alternatively, affix testers directly to the

9. Hazards

floor. (Warning—Use of rubber mats either directly under the

9.1 Impact testing of any type can cause flying debris, so

tester or supporting apparatus is prohibite

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.