ASTM B483/B483M-03

(Specification)Standard Specification for Aluminum and Aluminum-Alloy Drawn Tube and Pipe for General Purpose Applications (Withdrawn 2012)

Standard Specification for Aluminum and Aluminum-Alloy Drawn Tube and Pipe for General Purpose Applications (Withdrawn 2012)

ABSTRACT

This specification covers aluminum and aluminum-alloy drawn tube and pipe, of specified nominal composition and tempers, in straight lengths and tube in coils for general purpose applications. Coiled tubes are generally available only as round tubes with a prescribed wall thickness and only in non-heat-treatable alloys. The tube may be produced by drawing tube stock produced by extrusion through a bridge-type die or by die and mandrel methods. The ends of coils shall be crimped or otherwise sealed to avoid contamination during shipment. In addition to conformance with tensile requirements, coiled tube in the annealed temper only shall be capable of being expanded on a hardened ground tapered steel pin and shall be subject to inside cleanliness test.

SCOPE

1.1 This specification covers aluminum and aluminum-alloy drawn tubes in straight lengths and coils for general purpose applications in the alloys (Note 0), and tempers shown in . Coiled tubes are generally available only as round tubes with a wall thickness not exceeding 0.083 in. [2.00 mm] and only in non-heat-treatable alloys.

Note 1—For drawn seamless tubes, see Specifications B 210 and B 210M, for tubes to be used in condensers and heat exchangers, Specifications B 234 and B 234M, and for seamless pipe, Specification B 241/B 241M.

Note 2—Throughout this specification use of the term alloyin the general sense includes aluminum as well as aluminum alloy.

1.2 Alloy and temper designations are in accordance with ANSI H35.1 and H35.1M. The equivalent Unified Number System alloy designations are those of preceded by A9, for example A91060 for aluminum 1060 in accordance with Practice E 527.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

WITHDRAWN RATIONALE

Formerly under the jurisdiction of Committee B07 on Light Metals and Alloys, this specification was withdrawn in January 2012 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B483/B483M – 03

Standard Specification for

Aluminum and Aluminum-Alloy Drawn Tube and Pipe for

1

General Purpose Applications

This standard is issued under the fixed designation B483/B483M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

2

1. Scope* 2.2 ASTM Standards:

B210 Specification for Aluminum and Aluminum-Alloy

1.1 Thisspecificationcoversaluminumandaluminum-alloy

Drawn Seamless Tubes

drawn tube and pipe in straight lengths and tube in coils for

B210M Specification for Aluminum and Aluminum-Alloy

general purpose applications in the alloys (Note 2), and

Drawn Seamless Tubes (Metric)

tempers shown in Tables 1 and 2. Coiled tubes are generally

B234 Specification for Aluminum and Aluminum-Alloy

available only as round tubes with a wall thickness not

DrawnSeamlessTubesforCondensersandHeatExchang-

exceeding 0.083 in. [2.00 mm] and only in non-heat-treatable

ers

alloys.

B234M Specification for Aluminum and Aluminum-Alloy

NOTE 1—For drawn seamless tubes, see Specifications B210 and

DrawnSeamlessTubesforCondensersandHeatExchang-

B210M, for tubes to be used in condensers and heat exchangers,

ers (Metric)

Specifications B234 and B234M, and for seamless pipe, Specification

B241/B241M Specification for Aluminum and Aluminum-

B241/B241M. For extruded structural tube and pipe, see Specification

Alloy Seamless Pipe and Seamless Extruded Tube

B429/B429M.

B429/B429M Specification for Aluminum-Alloy Extruded

NOTE 2—Throughout this specification use of the term alloy in the

general sense includes aluminum as well as aluminum alloy.

Structural Pipe and Tube

B557 Test Methods for Tension Testing Wrought and Cast

1.2 Alloy and temper designations are in accordance with

Aluminum- and Magnesium-Alloy Products

ANSI H35.1 and H35.1M. The equivalent Unified Number

B557M TestMethodsforTensionTestingWroughtandCast

SystemalloydesignationsarethoseofTable3precededbyA9,

Aluminum- and Magnesium-Alloy Products (Metric)

for example A91060 for aluminum 1060 in accordance with

3

B597 Practice for Heat Treatment of Aluminum Alloys

Practice E527.

B660 Practices for Packaging/Packing of Aluminum and

1.3 For acceptance criteria for inclusion of new aluminum

Magnesium Products

and aluminum alloys in this specification, see Annex A2.

B666/B666M Practice for Identification Marking ofAlumi-

1.4 The values stated in either inch-pound units or SI units

num and Magnesium Products

are to be regarded separately as standard. Within the text, the

E29 Practice for Using Significant Digits in Test Data to

SI units are shown in brackets. The values stated in each

Determine Conformance with Specifications

system may not be exact equivalents; therefore, each system

E34 Test Methods for ChemicalAnalysis ofAluminum and

shall be used independently of the other. Combining values

Aluminum-Base Alloys

from the two systems may result in nonconformance with the

E55 Practice for SamplingWrought Nonferrous Metals and

standard.

Alloys for Determination of Chemical Composition

2. Referenced Documents

E215 PracticeforStandardizingEquipmentforElectromag-

netic Testing of Seamless Aluminum-Alloy Tube

2.1 The following documents of the issue in effect on date

E527 Practice for Numbering Metals and Alloys in the

of order acceptance form a part of this specification to the

Unified Numbering System (UNS)

extent referenced herein:

1 2

This specification is under the jurisdiction ofASTM Committee B07 on Light For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Aluminum Alloy Wrought Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 10, 2003. Published August 2003. Originally the ASTM website.

3

approved in 1983. Last previous edition approved in 2000 as B483–00. DOI: Withdrawn. The last approved version of this historical standard is referenced

10.1520/B0483_B0483M-03. on www.astm.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

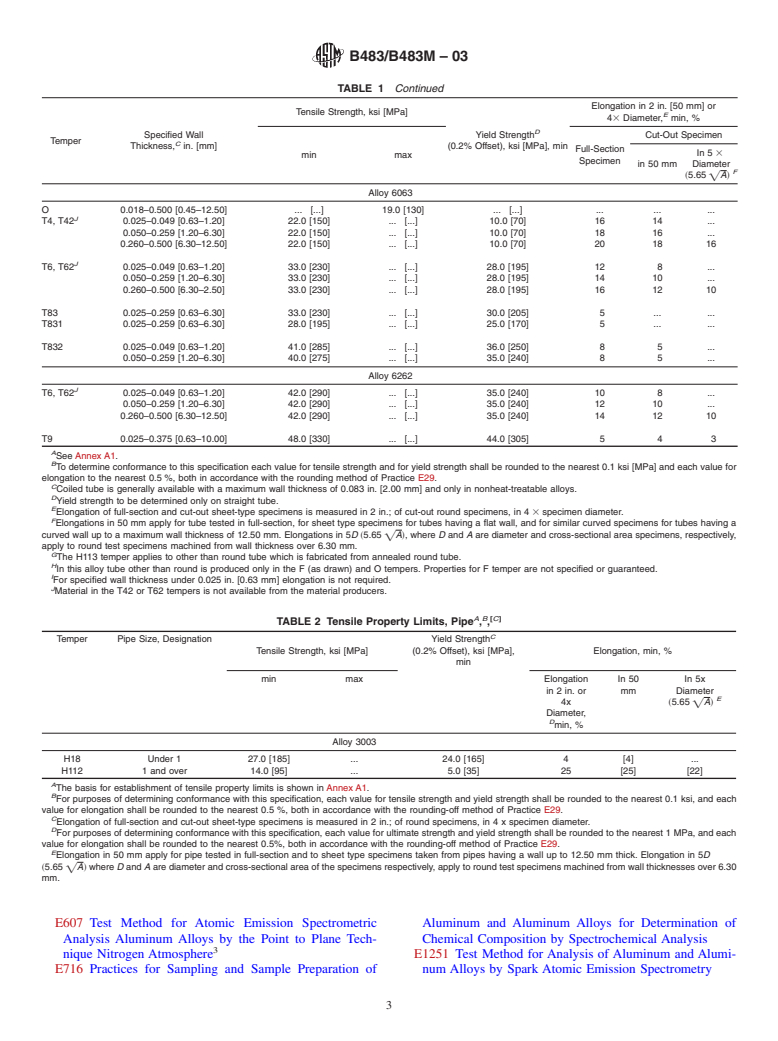

B483/B483M – 03

A,B

TABLE 1 Tensile Property Limits, Tube

Elongation in 2 in. [50 mm] or

Tensile Strength, ksi [MPa]

E

43 Diameter, min, %

D

Specified Wall Yield Strength Cut-Out Specimen

Temper

C

Thickness, in. [mm] (0.2% Offset), ksi [MPa], min

Full-Section

In 5 3

min max

Specimen

in 50 mm Diameter

F

~5.65 A!

=

Aluminum

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.