ASTM A931-96(2002)

(Test Method)Standard Test Method for Tension Testing of Wire Ropes and Strand

Standard Test Method for Tension Testing of Wire Ropes and Strand

SIGNIFICANCE AND USE

Wire rope tests are generally to be performed on new rope. The use of wire rope in any application can reduce individual wire strengths due to abrasion and nicking that will result in the wire rope strength being reduced. Damage to the outer wires will also lower the maximum strength achieved during tension testing.

The modulus of elasticity of wire rope is not considered to be a standard requirement at this time. The determination of this material property requires specialized equipment and techniques.

Rope to be tested should be thoroughly examined to verify that no external wire damage is present. If present, it should be noted. When possible, a new undamaged sample should be obtained for testing.

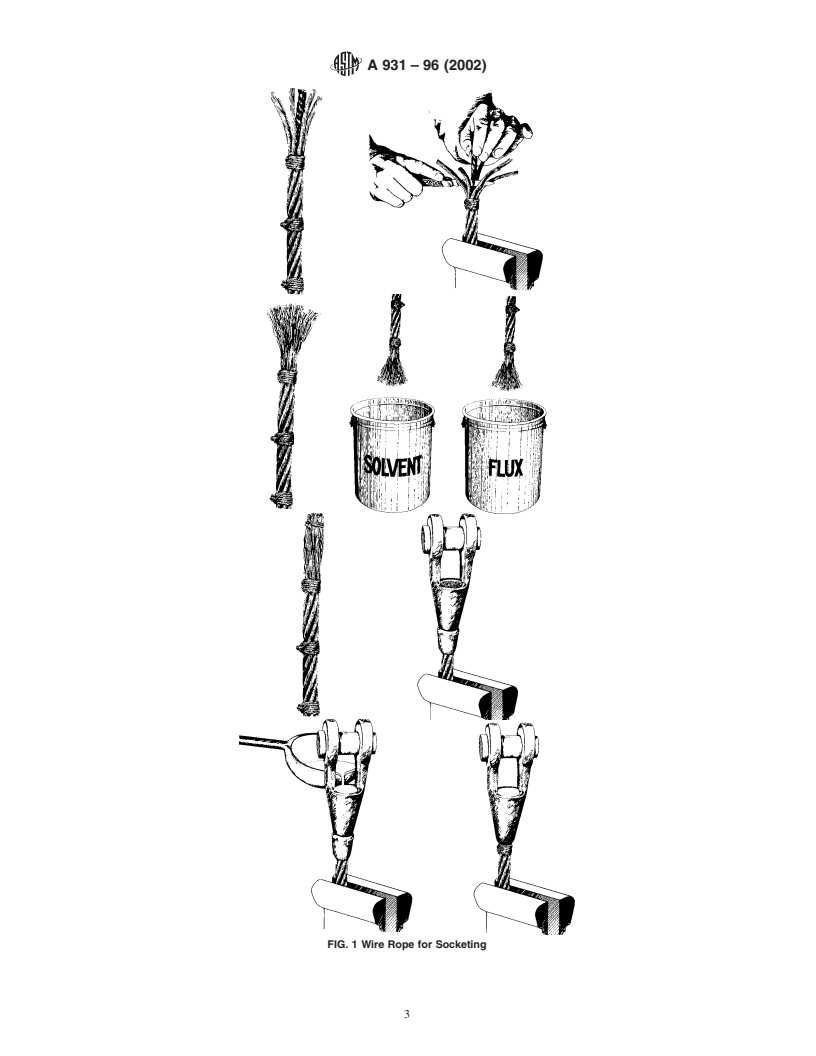

End attachments and their installation can directly affect breaking strength achieved during testing. Any attachment that can be used to directly achieve the required rope breaking strength can be used. Standard testing with a poured socket, using zinc, white metal or thermoset resin, has been considered the most efficient. Proficiency in attachment of any fitting can have a direct effect on the final test results.

SCOPE

1.1 This test method covers the tension testing of wire ropes and strand at room temperature, specifically to determine the minimum acceptance strength or nominal strength, yield strength, elongation, and modulus of elasticity.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 1, Note 2, Note 3, and Note 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A 931–96 (Reapproved 2002)

Standard Test Method for

Tension Testing of Wire Ropes and Strand

This standard is issued under the fixed designation A 931; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 abrasion—frictional surface wear on the wires of a

wire rope.

1.1 This test method covers the tension testing of wire ropes

3.2.2 aggregate area—see area, metallic.

and strand at room temperature, specifically to determine the

3.2.3 aggregate strength—the strength derived by totalling

minimum acceptance strength or nominal strength, yield

the individual breaking strengths of the elements of the strand

strength, elongation, and modulus of elasticity.

or rope. This strength does not give recognition to the

1.2 The values stated in inch-pound units are to be regarded

reduction in strength resulting from the angularity of the

as the standard. The SI units given in parentheses are for

elements in the rope, or other factors that may affect efficiency.

information only.

3.2.4 area, metallic—sum of the cross-sectional areas of all

1.3 This standard does not purport to address all of the

wires either in a wire rope or in a strand.

safety concerns, if any, associated with its use. It is the

3.2.5 breaking strength—theultimateloadatwhichatensile

responsibility of the user of this standard to establish appro-

failure occurs in the sample of wire rope being tested.

priate safety and health practices and determine the applica-

3.2.6 Discussion—The term breaking strength is synony-

bility of regulatory limitations prior to use. Specific precau-

mous with actual strength.

tionary statements are given in Note 1, Note 2, Note 3, and

3.2.7 cable—a term loosely applied to wire rope, wire

Note 5.

strand, and electrical conductors.

2. Referenced Documents

3.2.8 center—the axial member of a strand about which the

wires are laid.

2.1 ASTM Standards:

3.2.9 classification—group or family designation based on

A 586 Specification for Zinc-Coated Parallel and Helical

wire rope constructions with common strengths and weights

Steel Wire Structural Strand and Zinc-Coated Wire for

listed under the broad designation.

Spun-In-Place Structural Strand

3.2.10 construction—geometric design description of the

A 603 Specification for Zinc-Coated Steel Structural Wire

wire rope’s cross section. This includes the number of strands,

Rope

the number of wires per strand, and the pattern of wire

B 6 Specification for Zinc

arrangement in each strand.

E 4 Practices for Force Verification of Test Machines

3.2.11 core—the axial member of a wire rope about which

E 6 Terminology Relating to Methods of Mechanical Test-

the strands are laid.

ing

3.2.12 fiber core—cord or rope of vegetable or synthetic

E 8 Test Methods forTensionTesting of Metallic Materials

fiber used as the core of a rope.

3. Terminology

3.2.13 galvanized rope—wire rope made up of galvanized

wire.

3.1 The terminology relating to tensile testing in Terminol-

3.2.14 galvanized strand—strand made up of galvanized

ogy E 6 applies to this test method. In addition, the following

wire.

definitions for wire rope will apply:

3.2.15 grade—wire rope or strand classification by strength

3.2 Definitions:

or type of material, that is, Class 3, Type 302 stainless,

phosphor bronze, etc. It does not apply to strength of the

This test method is under the jurisdiction of ASTM Committee A01 on Steel,

individual wires used to manufacture the rope or strand.

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

3.2.16 independent wire rope core (IWRC)—a wire rope

A01.03 on Steel Rod and Wire.

used as the core of a larger wire rope.

Current edition approved March 10, 1996. Published May 1996. Originally

published as A 931 – 94. Last previous edition A 931 – 94. 3.2.17 inner wires—all wires of a strand except the outer or

Annual Book of ASTM Standards, Vol 01.06.

cover wires.

Annual Book of ASTM Standards, Vol 02.04.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 931–96 (2002)

3.2.18 lay—(a) the manner in which the wires in a strand or 5.3 The length of test specimen shall not be less than 3 ft,

the strands in a rope are helically laid, or (b) the distance (0.91 m) between sockets for wire ropes up to 1 in. (25.4 mm)

measured parallel to the axis of the rope (or strand) in which a diameter, inclusive, and not less than 5 ft (1.52 m) between

strand (or wire) makes one complete helical convolution about sockets for wire ropes 1 ⁄8 in. (28.6 mm) to 3 in. (77 mm)

the core (or center). In this connection, lay is also referred to as diameter. On wire ropes larger than 3 in. (77 mm), the clear

lay length or pitch. length of the test specimen shall be at least 20 times the rope

3.2.19 minimum acceptance strength—thatstrengththatis2 diameter.

1 2 % lower than the catalog or nominal strength. This

/

6. Apparatus

tolerance is used to offset variables that occur during sample

6.1 Testing Machines—Machines used for tension testing

preparation and actual physical test of a wire rope.

shall conform to the requirements of Practices E 4. The loads

3.2.20 modulus of elasticity—theslopeoftheelasticportion

used in determining tensile strength and yield strength shall be

of the stress-strain curve. The ratio of stress to corresponding

within loading range of the tensile machine as defined in

strain below the proportional limit. This value is generally

Practices E 4.

taken between 20 and 50 % of the nominal strength.

6.2 Gripping Devices:

3.2.21 nominal strength—the published (catalog) strength

calculated by a standard procedure that is accepted by the wire 6.2.1 General—Various types of gripping devices may be

used to transmit the measured load applied by the testing

rope industry.The wire rope manufacturer designs wire rope to

this strength, and the user should consider this strength when machine to test specimens.To ensure axial tensile stress within

the gage length, the axis of the test specimen should coincide

making design calculations.

3.2.22 socket—generic name for a type of wire rope fitting. with the center line of the heads of the machine.Any departure

from this requirement may introduce bending stresses that are

3.2.23 strand—a plurality of round or shaped wires heli-

cally laid about a center. not included in the usual stress computation.

6.2.2 Wedge Grips—Testing machines usually are equipped

3.2.24 wire rope—strands helically laid around a core.

with wedge grips. These wedge grips generally furnish a

3.2.25 wire strand core (WSC)—a wire strand used as the

satisfactorymeansofgrippinglongspecimensofductilemetal.

core of a wire rope.

If, however, for any reason, one grip of a pair advances farther

4. Significance and Use

than the other as the grips tighten, an undesirable bending

4.1 Wire rope tests are generally to be performed on new stress may be introduced. When liners are used behind the

rope. The use of wire rope in any application can reduce wedges, they must be of the same thickness and their faces

individual wire strengths due to abrasion and nicking that will must be flat and parallel. For best results, the wedges should be

result in the wire rope strength being reduced. Damage to the supported over their entire lengths by the heads of the testing

outer wires will also lower the maximum strength achieved machine. This requires that liners of several thicknesses be

during tension testing. available to cover the range of specimen thickness. For proper

4.2 The modulus of elasticity of wire rope is not considered gripping, it is desirable that the entire length of the serrated

to be a standard requirement at this time. The determination of face of each wedge be in contact with the specimen. Specially-

this material property requires specialized equipment and designed round-shaped grips may have to be used for testing

techniques. rope or strand. It is essential that all wires in the rope or strand

4.3 Rope to be tested should be thoroughly examined to are uniformly gripped when the load is applied.

verify that no external wire damage is present. If present, it 6.2.3 Conical Grips—Conical grips are constructed so that

should be noted. When possible, a new undamaged sample when they are fitted together, a conical-shaped cavity exists

should be obtained for testing. which will hold a cone socket wire rope or strand and

4.4 End attachments and their installation can directly affect attachment (fitting).

breaking strength achieved during testing.Any attachment that

7. Sample Preparation and Preparation of End

can be used to directly achieve the required rope breaking

Attachments

strength can be used. Standard testing with a poured socket,

7.1 Poured sockets are considered to be the most efficient

using zinc, white metal or thermoset resin, has been considered

and should be used due to their ability to distribute the load

the most efficient. Proficiency in attachment of any fitting can

evenly in the wire rope when installed properly. Procedures for

have a direct effect on the final test results.

the proper installation of poured end attachments can be found

5. Interferences

in socketing procedures.

5.1 Visual examination of the sample for any damage to 7.2 Other end attachments such as grips may be used

outer wires should be done. If any damage is evident, the provided the required loading is achieved.

sample should not be used. The purpose of this test method is 7.3 Sample Preparation Procedures:

to verify the nominal or maximum strength the wire rope or 7.3.1 Socketing

strand can achieve. Zinc-Poured Socketing:

5.2 Measurement of the rope or strand sample is necessary 7.3.1.1 Measuring the Rope Ends to be Socketed—The rope

to document the size, length between end attachments, and end should be of sufficient length so that the ends of the unlaid

length of lay of the rope if necessary. Further details regarding wires (from the s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.