ASTM D788-96

(Classification)Standard Classification System for Poly(Methyl Methacrylate) (PMMA) Molding and Extrusion Compounds

Standard Classification System for Poly(Methyl Methacrylate) (PMMA) Molding and Extrusion Compounds

SCOPE

1.1 The purpose of this classification system is to provide a method of adequately identifying PMMA materials using a system consistent with that of Classification System D 4000. It further provides a means for specifying these materials by the use of a simple line callout designation.

1.2 This classification system covers poly(methyl methacrylate) molding and extrusion compounds. These compounds are polymers based on methyl methacrylate, and at least 70 % of the polymer shall be polymerized from methyl methacrylate.

1.3 The properties in this classification system are those required to identify the compositions covered. There may be other requirements necessary to identify particular characteristics important to specific applications. These shall be described by using the suffixes as given in Section 5.

1.4 Acrylic molding and extrusion compounds are used frequently in applications where extreme clarity and the ability to retain that clarity and color under severe weathering and other environmental exposures are of primary significance. While the test specimen properties of this document may be used to evaluate nonvirgin materials, the user should take precautions to ensure that parts made from these materials meet the desired end-use requirements. Accordingly, this specification allows for the use of those acrylic plastic materials that can be recycled, reconstituted, and regrounded provided the following:

1.4.1 The requirements as stated in this specification are met,

1.4.2 The material has not been modified in any way to alter its conformance to food contact regulations or similar requirements, and

1.4.3 The requirements of the particular end-use application are met.

1.5 This classification system and subsequent line callout (specification) are not intended for the selection of materials, but only as a means to call out plastic materials to be used for the manufacture of parts. The selection of these materials is to be made by personnel with expertise in the plastics field in which the environment, inherent properties of the materials, performance of the parts, part design, manufacturing process, and economics are considered.

Note 1—This classification system is similar to ISO 8257-1:1987 in title only. The technical content is significantly different.

1.6 The values stated in SI units are to be regarded as the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 788 – 96 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Classification System for

Poly(Methyl Methacrylate) (PMMA) Molding and Extrusion

Compounds

This standard is issued under the fixed designation D 788; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope be made by personnel with expertise in the plastics field in

which the environment, inherent properties of the materials,

1.1 The purpose of this classification system is to provide a

performance of the parts, part design, manufacturing process,

method of adequately identifying PMMA materials using a

and economics are considered.

system consistent with that of Classification System D 4000. It

further provides a means for specifying these materials by the

NOTE 1—This classification system is similar to ISO 8257-1:1987 in

use of a simple line callout designation. title only. The technical content is significantly different.

1.2 This classification system covers poly(methyl methacry-

1.6 The values stated in SI units are to be regarded as the

late) molding and extrusion compounds. These compounds are

standard.

polymers based on methyl methacrylate, and at least 70 % of

1.7 This standard does not purport to address all of the

the polymer shall be polymerized from methyl methacrylate.

safety concerns, if any, associated with its use. It is the

1.3 The properties in this classification system are those

responsibility of the user of this standard to establish appro-

required to identify the compositions covered. There may be

priate safety and health practices and determine the applica-

other requirements necessary to identify particular character-

bility of regulatory limitations prior to use.

istics important to specific applications. These shall be de-

scribed by using the suffixes as given in Section 5. 2. Referenced Documents

1.4 Acrylic molding and extrusion compounds are used

2.1 ASTM Standards:

frequently in applications where extreme clarity and the ability

D 149 Test Method for Dielectric Breakdown Voltage and

to retain that clarity and color under severe weathering and

Dielectric Strength of Solid Electrical Insulating Materials

other environmental exposures are of primary significance. 2

at Commercial Power Frequencies

While the test specimen properties of this document may be

D 150 Test Methods for AC Loss Characteristics and Per-

used to evaluate nonvirgin materials, the user should take

mittivity (Dielectric Constant) of Solid Electrical Insulat-

precautions to ensure that parts made from these materials meet 2

ing Materials

the desired end-use requirements. Accordingly, this specifica-

D 256 Test Methods for Impact Resistance of Plastics and

tion allows for the use of those acrylic plastic materials that can 3

Electrical Insulating Materials

be recycled, reconstituted, and regrounded provided the fol-

D 257 Test Methods for DC Resistance or Conductance of

lowing: 2

Insulating Materials

1.4.1 The requirements as stated in this specification are

D 542 Test Methods for Index of Refraction of Transparent

met, 3

Organic Plastics

1.4.2 The material has not been modified in any way to alter

D 618 Practice for Conditioning Plastics and Electrical

its conformance to food contact regulations or similar require- 3

Insulating Materials for Testing

ments, and 3

D 638 Test Method for Tensile Properties of Plastics

1.4.3 The requirements of the particular end-use application

D 790 Test Methods for Flexural Properties of Unreinforced

are met.

and Reinforced Plastics and Electrical Insulating Materi-

1.5 This classification system and subsequent line callout 3

als

(specification) are not intended for the selection of materials, 3

D 883 Terminology Relating to Plastics

but only as a means to call out plastic materials to be used for

D 1003 Test Method for Haze and Luminous Transmittance

the manufacture of parts. The selection of these materials is to 3

of Transparent Plastics

D 1238 Test Method for Flow Rates of Thermoplastics by

Extrusion Plastometer

This classification system is under the jurisdiction of ASTM Committee D-20

D 1525 Test Method for Vicat Softening Temperature of

on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermo-

plastic Materials (Section D20.15.02).

Plastics

Current edition approved April 10, 1996. Published July 1996. Originally

published as D 788 – 44T. Last previous edition D 788 – 95.

This standard was extensively revised in 1993. The current revision includes the Annual Book of ASTM Standards, Vol 10.01.

addition of 1.4, which addresses the use of recycled materials. Annual Book of ASTM Standards, Vol 08.01.

D 788

D 1600 Terminology for Abbreviated Terms Relating to shown in Table 1. A complete classification must include

Plastics reference to melt-flow rate, as discussed in 4.2 and 5.1.3.

D 1897 Practice for Injection Molding Test Specimens of

4.1.1 To facilitate the incorporation of future or special

Thermoplastic Molding and Extrusion Materials

materials, the “other/unspecified” category (0) for group, class,

D 3641 Practice for Injection Molding Test Specimens of

and grade is given in Table 1.

Thermoplastic Molding and Extrusion Materials

4.1.2 When the grade of the basic material is not shown, or

D 3892 Practice for Packaging/Packing of Plastics

is not important, the use of “0” grade classification shall be

D 4000 Classification System for Specifying Plastic Mate-

used in this classification system.

rials

4.2 The melt-flow rate can vary within a given group, class,

D 5033 Guide for the Development of Standards Relating to

and grade and can overlap classes or grades. For this reason,

the Proper Use of Recycled Plastics

the melt-flow rate shall be specified using Suffix V.

E 29 Practice for Using Significant Digits in Test Data to

4.2.1 Although the values listed in Suffix V are necessary to

Determine Conformance with Specifications

include the range of properties available in existing materials,

2.2 ISO Standards and Recommendations:

users should not infer that every melt-flow rate exists for each

ISO 178-1975 Plastics—Determination of Flexural Proper-

class or grade.

ties of Rigid Plastics

ISO 180-1982 Plastics—Determination of Izod Impact

NOTE 2—An example of this classification system is as follows:

Strength of Rigid Materials

The designation PMMA0112 indicates:

ISO 294

PMMA 5 poly(methyl methacrylate) as found in Terminology D 1600,

ISO 306-1987 Plastics—Thermoplastic Materials—

01 5 unmodified (group),

Determination of Vicat Softening Temperature

1 5 minimum 77°C Vicat, etc. (class) and

2 5 ultraviolet transmitting (grade).

ISO 489-1983 Plastics—Determination of the Refractive

(See Note 4 for a more complete example.)

Index of Transparent Plastics

ISO R 527 November 1966 Plastics—Determination of

NOTE 3—Major industries using these materials now require interna-

Tensile Properties tionally accepted test methods for product specifications. For this reason,

ISO test methods have been used in Table 1 and elsewhere in this

ISO 1133-1981 Plastics—Determination of the Melt Flow

classification system where appropriate. Similar ASTM standards have

Rate of Thermoplastics

been listed in Section 2. Many of these ASTM standards are now or soon

ISO 3167-1983 Plastics—Preparation and Use of Multipur-

will be equivalent. In future editions, a note in the ASTM standard will

pose Test Specimens

indicate the degree of equivalency with a particular international standard.

ISO 8257-1:1987 Plastics—Poly(Methyl Methacrylate)

The corresponding ASTM test method may be substituted as long as the

(PMMA) Moulding and Extrusion Materials—Part 1

specimen size and all other conditions of the test method noted in this

2.3 SAE Standards:

classification system as applying to the ISO test method are also applied

SAE J576 SEP86—SAE Recommended Practice forPlastic to the ASTM standard.

Materials for Use in Optical Parts such as Lenses and

4.3 Grade 1 materials are used where special ultraviolet

Reflectors for Motor Vehicle Lighting Devices

transmission, filtering, or stabilization characteristics are not

SAE J1885 AUG87—SAE Recommended Practice for Ac-

required.

celerated Exposure of Automotive Interior Trim Compo-

4.4 Grade 2 materials are used for those specialized appli-

nents Using a Controlled Irradiance Water Cooled Xenon

cations in which the greatest amount of transmission of UV

Arc Apparatus

light is required. The transmission properties are given in Table

SAE J1960 JUN89—SAE Standard for Accelerated Expo-

2.

sure of Automotive Exterior Materials Using a Controlled

4.5 Grade 3 materials (transparent UV stabilized or trans-

Irradiance Water Cooled Xenon Arc Apparatus

parent UV absorbing) are used when either special resistance to

3. Terminology

slight color change over long exposure times or high-intensity

UV radiation is required, or when the material is required to

3.1 Definitions—The terminology used in this classification

filter out ultraviolet light. These applications are varied and

system is in accordance with Terminologies D 883 and D 1600.

require specific light transmission or color-stability properties

4. Basis of Classification

to be specified by the user.

4.1 Poly(methyl methacrylate) molding and extrusion com-

pounds are classified into groups according to their composi- 5. Suffixes

tion. These groups are subdivided into classes and grades as

5.1 When additional requirements are needed, based on the

application, that are not covered by the basic cell-table require-

ments, they shall be indicated through the use of suffixes. In

Annual Book of ASTM Standards, Vol 08.02.

5 general, suffixes consist of a suffix letter, which gives the

Annual Book of ASTM Standards, Vol 08.03.

requirement needed, a first digit, which gives the test condition,

Annual Book of ASTM Standards, Vol 14.02.

Available from American National Standards Institute, 11 W. 42nd St., 13th

and a second digit, which gives the specific requirement.

Floor, New York, NY 10036.

5.1.1 Suffix E 5 Electrical requirements, as designated by

Available from Society of Automotive Engineers, Inc., 400 Commonwealth

Drive, Warrendale, PA 15096-0001. the following digits:

D 788

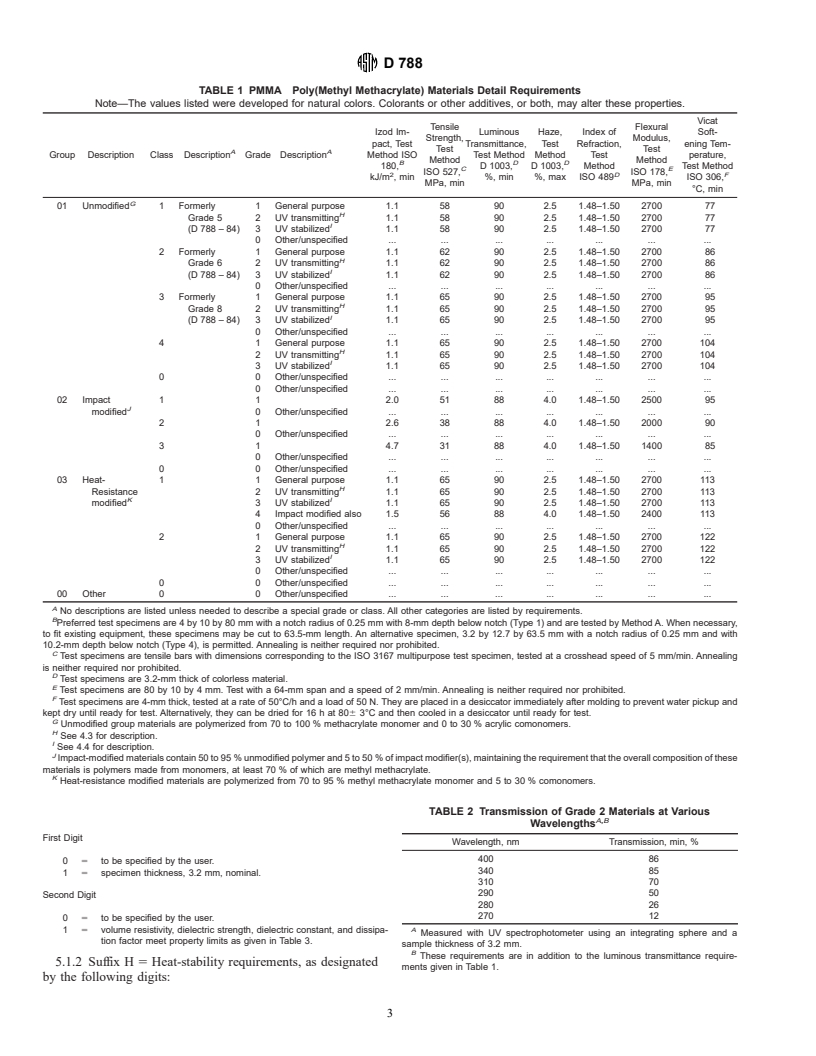

TABLE 1 PMMA Poly(Methyl Methacrylate) Materials Detail Requirements

Note—The values listed were developed for natural colors. Colorants or other additives, or both, may alter these properties.

Vicat

Tensile Flexural

Izod Im- Luminous Haze, Index of Soft-

Strength, Modulus,

pact, Test Transmittance, Test Refraction, ening Tem-

Test Test

A A

Group Description Class Description Grade Description Method ISO Test Method Method Test perature,

Method Method

B D D

180, D 1003, D 1003, Method Test Method

C E

ISO 527, ISO 178,

2 D F

kJ/m , min %, min %, max ISO 489 ISO 306,

MPa, min MPa, min

°C, min

G

01 Unmodified 1 Formerly 1 General purpose 1.1 58 90 2.5 1.48–1.50 2700 77

H

Grade 5 2 UV transmitting 1.1 58 90 2.5 1.48–1.50 2700 77

I

(D 788 – 84) 3 UV stabilized 1.1 58 90 2.5 1.48–1.50 2700 77

0 Other/unspecified . . . . . . .

2 Formerly 1 General purpose 1.1 62 90 2.5 1.48–1.50 2700 86

H

Grade 6 2 UV transmitting 1.1 62 90 2.5 1.48–1.50 2700 86

I

(D 788 – 84) 3 UV stabilized 1.1 62 90 2.5 1.48–1.50 2700 86

0 Other/unspecified . . . . . . .

3 Formerly 1 General purpose 1.1 65 90 2.5 1.48–1.50 2700 95

H

Grade 8 2 UV transmitting 1.1 65 90 2.5 1.48–1.50 2700 95

I

(D 788 – 84) 3 UV stabilized 1.1 65 90 2.5 1.48–1.50 2700 95

0 Other/unspecified . . . . . . .

4 1 General purpose 1.1 65 90 2.5 1.48–1.50 2700 104

H

2 UV transmitting 1.1 65 90 2.5 1.48–1.50 2700 104

I

3 UV stabilized 1.1 65 90 2.5 1.48–1.50 2700 104

0 0 Other/unspecified . . . . . . .

0 Other/unspecified . . . . . . .

02 Impact 1 1 2.0 51 88 4.0 1.48–1.50 2500 95

J

modified 0 Other/unspecified . . . . . . .

2 1 2.6 38 88 4.0 1.48–1.50 2000 90

0 Other/unspecified . . . . . . .

3 1 4.7 31 88 4.0 1.48–1.50 1400 85

0 Other/unspecified . . . . . . .

0 0 Other/unspecified . . . . . . .

03 Heat- 1 1 General purpose 1.1 65 90 2.5 1.48–1.50 2700 113

H

Resistance 2 UV transmitting 1.1 65 90 2.5 1.48–1.50 2700 113

K I

modified 3 UV stabilized 1.1 65 90 2.5 1.48–1.50 2700 113

4 Impact modified also 1.5 56 88 4.0 1.48–1.50 2400 113

0 Other/unspecified . . . . . . .

2 1 General purpose 1.1 65 90 2.5 1.48–1.50 2700 122

H

2 UV transmitting 1.1 65 90 2.5 1.48–1.50 2700 122

I

3 UV stabilized 1.1 65 90 2.5 1.48–1.50 2700 122

0 Other/unspecified . . . . . . .

0 0 Other/unspecified . . . . . . .

00 Other 0 0 Other/unspecified . . . . . . .

A

No descriptions are listed unless needed to describe a special grade or class. All other categories are listed by requirements.

B

Preferred test specimens are 4 by 10 by 80 mm with a notch radius of 0.25 mm with 8-mm depth below notch (Type 1) and are tested by Method A. When necessary,

to fit existing equipment, these specimens may be cut to 63.5-mm length. An alternative specimen, 3.2 by 12.7 by 63.5 mm with a notch radius of 0.25 mm and with

10.2-mm depth below notch (Type 4), is permitted. Annealing is neither required nor prohibited.

C

Test specimens are tensile bars with dimensions corresponding to the ISO 3167 multipurpose test specimen, tested at a crosshead speed of 5 mm/min. Annealing

is neither required nor prohibited.

D

Test specimens are 3.2-mm thick of colorless material.

E

Test specimens are 80 by 10 by 4 mm. Test with a 64-mm span and a speed of 2 mm/min. Annealing is neither required nor prohibited.

F

Test specimens are 4-mm thick, tested at a rate of 50°C/h and a load of 50 N. They are placed in a desiccator immediately after molding to prevent water pickup and

kept dry until ready for test. Alternatively, they can be dried for 16 h at 806 3°C and then cooled in a desiccator until ready for test.

G

Unmodified group materials are polymerized from 70 to 100 % methacrylate monomer and 0 to 30 % acrylic comonomers.

H

See 4.3 for description.

I

See 4.4 for description.

J

Impact-modified materials contain 50 to 95 % unmodified polymer and 5 to 50 % of impact modifier(s), maintaining the requirement that the overall composition of these

materials is polymers made from monomers, at least 70 % of which are methyl methacrylate.

K

Heat-resistance modified materials are polymerized f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.