ASTM F303-78(1996)

(Practice)Standard Practices for Sampling Aerospace Fluids from Components

Standard Practices for Sampling Aerospace Fluids from Components

SCOPE

1.1 These practices cover sampling procedures for use in determining the cleanliness of liquids from components. Three practices A, B, and C, have been developed on the basis of component geometry in order to encompass the wide variety of configurations. These practices establish guidelines to be used in preparing detailed procedures for sampling specific components. Note 1-The term cleanliness used in these practices refers to solid particles in the liquid. It does not generally cover other foreign matter such as gases, liquids, and products of chemical degradation. Cleanliness with respect to particulate contamination does not necessarily give any indication of the other types of contamination.

1.2 All components, regardless of application, may be tested provided (1) the fluid medium selected is completely compatible with the materials, packing and fluid used in the test component, and test apparatus, and (2) the fluid is handled in accordance with the manufacturer's recommendations and precautions. A liquid shall be used as the test fluid medium. These test fluids may be flushing, rinsing, packing, end use operating, or suitable substitutes for end use operating fluids. (Caution.) Note 2-Practices for sampling surface cleanliness by the vacuum cleaner technique (used on clean room garments and large storage tanks) sampling gaseous fluids and handling hazardous fluids such as oxidizers, acids, propellants, etc., are not within the scope of the practices presented; however, they may be included in addendums or separate practices at a later date. Substitute fluids are recommended in place of end item fluids for preassembly cleanliness determinations on components using hazardous end item fluids. After obtaining the sample, the substitute fluid must be totally removed from the test part with particular caution given to the possibility of trapped fluid. It is hazardous to use a substitute fluid for testing assembled parts where the fluid can be trapped in dead ends, behind seals, etc. Note 3-The word fluid used in these practices shall be assumed to be a liquid unless otherwise stated.

1.3 The cleanliness of assemblies with or without moving parts may be determined at the time of test; however, movement of internal component parts during the test will create unknown quantities of contamination from wear. Practice B covers configurations requiring dynamic actuation to achieve a sample. The practice does not differentiate between built-in particles and wear particles. Note 4-Defining allowable cleanliness limits is not within the scope of these practices.

1.4 The three practices included are as follows:

1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For hazard statement, see Notes.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 303 – 78 (Reapproved 1996)

Standard Practices for

Sampling Aerospace Fluids from Components

This standard is issued under the fixed designation F 303; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope unknown quantities of contamination from wear. Practice B

covers configurations requiring dynamic actuation to achieve a

1.1 These practices cover sampling procedures for use in

sample. The practice does not differentiate between built-in

determining the cleanliness of liquids from components. Three

particles and wear particles.

practices A, B, and C, have been developed on the basis of

component geometry in order to encompass the wide variety of

NOTE 4—Defining allowable cleanliness limits is not within the scope

configurations. These practices establish guidelines to be used of these practices.

in preparing detailed procedures for sampling specific compo-

1.4 The three practices included are as follows:

nents.

Sections

Practice A—Static Fluid Sampling (Method for extract- 5-13

NOTE 1—The term cleanliness used in these practices refers to solid

ing fluid from the test article for analysis. This ap-

particles in the liquid. It does not generally cover other foreign matter such

plies to components that have a cavity from which

as gases, liquids, and products of chemical degradation. Cleanliness with

fluid may be extracted)

respect to particulate contamination does not necessarily give any indica-

Practice B—Flowing Fluid Sampling (Method for flush- 14-22

tion of the other types of contamination. ing contaminants from the test article for analysis.

This applies to components which fluid can pass (1)

1.2 All components, regardless of application, may be tested

directly through, or (2) pass into and out of by cy-

cling)

provided (1) the fluid medium selected is completely compat-

Practice C—Rinse Fluid Sampling (Method for rinsing 23-31

ible with the materials, packing and fluid used in the test

contaminants from the test article’s surfaces. The

component, and test apparatus, and (2) the fluid is handled in

rinse fluid is analyzed for contamination. This ap-

plies to components that do not have a fluid cavity

accordance with the manufacturer’s recommendations and

or for other reasons are not adaptable to Practices

precautions. A liquid shall be used as the test fluid medium.

A and B)

These test fluids may be flushing, rinsing, packing, end use

1.5 This standard does not purport to address all of the

operating, or suitable substitutes for end use operating fluids.

safety concerns, if any, associated with its use. It is the

(Caution.)

responsibility of the user of this standard to establish appro-

NOTE 2—Practices for sampling surface cleanliness by the vacuum

priate safety and health practices and determine the applica-

cleaner technique (used on clean room garments and large storage tanks)

bility of regulatory limitations prior to use. For hazard state-

sampling gaseous fluids and handling hazardous fluids such as oxidizers,

ment, see Notes.

acids, propellants, etc., are not within the scope of the practices presented;

however, they may be included in addendums or separate practices at a

2. Referenced Documents

later date.

Substitute fluids are recommended in place of end item fluids for 2.1 ASTM Standards:

preassembly cleanliness determinations on components using hazardous

D 1836 Specification for Commercial Hexanes

end item fluids. After obtaining the sample, the substitute fluid must be

F 311 Practice for Processing Aerospace Liquid Samples for

totally removed from the test part with particular caution given to the

Particulate Contamination Analysis Using Membrane Fil-

possibility of trapped fluid. It is hazardous to use a substitute fluid for

ters

testing assembled parts where the fluid can be trapped in dead ends,

F 312 Methods for Microscopical Sizing and Counting

behind seals, etc.

Particles from Aerospace Fluids on Membrane Filters

NOTE 3—The word fluid used in these practices shall be assumed to be

a liquid unless otherwise stated. F 313 Test Method for Insoluble Contamination of Hydrau-

lic Fluids by Gravimetric Analysis

1.3 The cleanliness of assemblies with or without moving

2.2 Military Standards:

parts may be determined at the time of test; however, move-

MIL-T-27602 Trichlorine Oxygen Propellant Compatibles

ment of internal component parts during the test will create

MIL-H-6083 Hydraulic Fluid Petroleum Base for Pressure

These practices are under the jurisdiction of ASTM Committee E-21 on Space

Simulation and Applications of Space Technology and are the direct responsibility Annual Book of ASTM Standards, Vol 06.04.

of Subcommittee E21.05 on Contamination. Annual Book of ASTM Standards, Vol 14.02.

Current edition approved Aug. 25, 1978. Published October 1978. Originally Annual Book of ASTM Standards, Vol 15.03.

published as D 2429–65 T. Redesignated F 303 in 1970. Last previous edition Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

F 303 – 70 (1976). Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 303

MIL-H-5606 Hydraulic Fluid Petroleum Base for Aircarrier

Missiles and Ordinance

3. Terminology

3.1 Definitions:

3.1.1 analytical membrane—a membrane filter used to col-

lect the contaminant particles for analysis.

3.1.2 blank analysis—sometimes referred to as “fluid tare,”

“control level,” “reference contamination level,” or “back-

ground level.” The blank analysis is the particulate contami-

nation level of the test fluid when the test part is omitted.

3.1.3 cleanup membrane—a membrane used to filter the

contaminant particles from the fluid medium.

3.1.4 component—an individual piece or a complete assem-

bly of individual pieces.

3.1.5 field filter holder—a throw-away or reusable cartridge

containing an analytical membrane filter.

3.1.6 initial cleanliness—the measure of contamination re-

moved from the test component at the time of test excluding

that defined by operating cleanliness.

3.1.7 membrane tare—sometimes referred to as “blank

count” or “control filter.” When applied to microscope meth-

ods, the membrane tare is the quantity of particles determined

to be on the filter before the test fluid is filtered. When applied

to gravimetric methods, the membrane tare is an amount of

weight increase imparted to the control filter when uncontami-

nated test fluid is passed through.

3.1.8 operating cleanliness—the measure of contaminants

FIG. 1 Recommended and Alternative Methods for Static Fluid

generated by moving parts in the component during a specified

Sampling (Practice A)

period of dynamic operation.

3.1.9 solvent filtering dispenser—an apparatus to dispense a

7. Significance and Use

stream of 2.0 μm or finer membrane filtered fluid.

7.1 Although a cleaning action is imparted to the test

3.1.10 system tare—The measure of contamination deter-

component, it is not the intent of this practice to serve as a

mined by replacing the test component with a connecting

cleaning procedure. Components are normally cleaner after

fitting and following the cleanliness test procedure as if

each consecutive test; thus repeated tests may be used to

checking the test component.

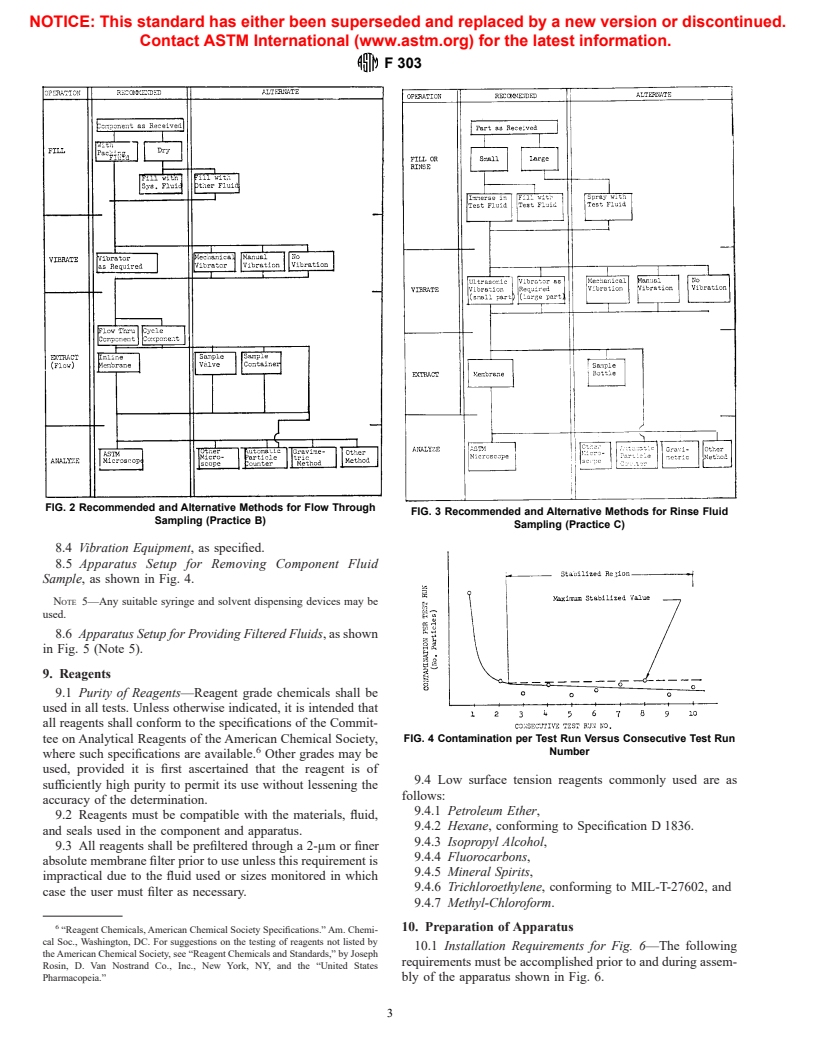

establish process limits for a given component (Fig. 4). A

4. Summary of Practices

specific set of test parameters must be supplied by the agency

4.1 Cleanliness is determined by sampling and analyzing

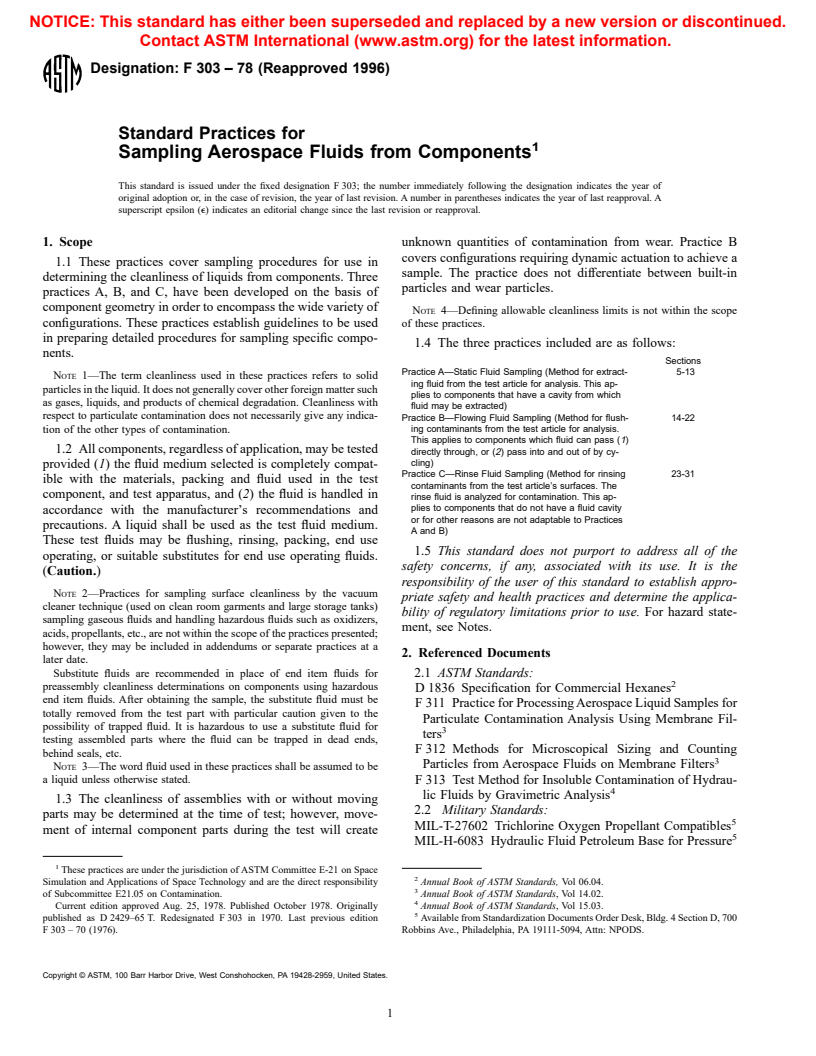

specifying cleanliness limits. Fig. 1, Fig. 2, and Fig. 3 may be

fluid that has been in contact with the surface being analyzed.

used as a guide to establish the desired parameters of test fluid,

Specific methods are recommended; however, other methods

vibration, extraction, and analysis.

have been recognized due to the wide variety of components

7.2 The curve in Fig. 4 shows the typical behavior of a

and different test equipment used by industry. Recommended

component when tested for cleanliness several consecutive

and alternative methods are given in Fig. 1, Fig. 2, and Fig. 3.

times. Stabilization generally occurs before the fifth successive

run. The stabilized region starts where a horizontal line through

PRACTICE A—STATIC FLUID SAMPLING

the maximum stabilized value intersects the curve.

7.3 The allowable cleanliness limit of a test component

5. Scope

should be based on the cleanliness requirements of the system

5.1 This practice covers procedures for determining the

in which it will be used and the assigned value should be

particulate contamination level of fluids from components that

greater than the maximum stabilized value. When defining the

have a cavity from which fluid may be extracted.

allowable cleanliness limits, an important consideration is that

6. Summary of Practice

the accuracy of the results decreases as the allowable limit

value approaches the stabilized value.

6.1 Fluid is extracted from the component and analyzed to

determine the particulate contamination level. Recommended

8. Apparatus

and alternative methods are given in Fig. 1.

6.2 It is recommended that all operations of this practice be 8.1 Apparatus, as described in Practice F 313.

conducted in a dust controlled area. Cleanliness level of the 8.2 Apparatus, as described in Test Methods F 312 or as

dust controlled area shall be consistent with the component described in Practice F 311.

contamination limits. 8.3 Automatic Particle Counter, as required.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 303

FIG. 2 Recommended and Alternative Methods for Flow Through

FIG. 3 Recommended and Alternative Methods for Rinse Fluid

Sampling (Practice B)

Sampling (Practice C)

8.4 Vibration Equipment, as specified.

8.5 Apparatus Setup for Removing Component Fluid

Sample, as shown in Fig. 4.

NOTE 5—Any suitable syringe and solvent dispensing devices may be

used.

8.6 Apparatus Setup for Providing Filtered Fluids, as shown

in Fig. 5 (Note 5).

9. Reagents

9.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

FIG. 4 Contamination per Test Run Versus Consecutive Test Run

tee on Analytical Reagents of the American Chemical Society,

Number

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

9.4 Low surface tension reagents commonly used are as

sufficiently high purity to permit its use without lessening the

follows:

accuracy of the determination.

9.4.1 Petroleum Ether,

9.2 Reagents must be compatible with the materials, fluid,

9.4.2 Hexane, conforming to Specification D 1836.

and seals used in the component and apparatus.

9.4.3 Isopropyl Alcohol,

9.3 All reagents shall be prefiltered through a 2-μm or finer

9.4.4 Fluorocarbons,

absolute membrane filter prior to use unless this requirement is

9.4.5 Mineral Spirits,

impractical due to the fluid used or sizes monitored in which

9.4.6 Trichloroethylene, conforming to MIL-T-27602, and

case the user must filter as necessary.

9.4.7 Methyl-Chloroform.

10. Preparation of Apparatus

“Reagent Chemicals, American Chemical Society Specifications.” Am. Chemi-

cal Soc., Washington, DC. For suggestions on the testing of reagents not listed by

10.1 Installation Requirements for Fig. 6—The following

the American Chemical Society, see “Reagent Chemicals and Standards,” by Joseph

requirements must be accomplished prior to and during assem-

Rosin, D. Van Nostrand Co., Inc., New York, NY, and the “United States

Pharmacopeia.” bly of the apparatus shown in Fig. 6.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 303

10.3 Installation Requirements for Fig. 7—The following

requirements must be accomplished prior to and during assem-

bly on the apparatus shown in Fig. 7 (Caution, Note 6).

10.3.1 Eject all fluid from the syringe.

10.3.2 Install the hypodermic adapter and fluid outlet needle

onto the double valve.

NOTE 8—Caution: The hypodermic adapter and fluid outlet needle

must be precleaned and the hypodermic adapter filter disk replaced prior

to each usage.

10.3.3 Exercise extreme caution to assemble the hypoder-

mic adapter in the correct configuration. Tighten sufficiently to

effect a seal.

FIG. 5 Apparatus Setup for Providing Filtered Fluids

10.4 General Requirements for Fig. 5:

10.4.1 Periodic control analysis is required in order to

guarantee an acceptable contamination level of the component

replacement fluid.

10.4.2 Prior to initial use, replace the “as received” hypo-

dermic adapter backup screen with a like diameter backup

screen, approximately 35 mesh (500-μm opening), or photo-

etched screen with 70-μm holes.

10.4.3 The addition of a field filter holder between the

double valve and fluid inlet tube will increase the filtration

capability. This application would be governed by the quality

and condition of the fluid being filtered.

NOTE 9—Caution: If utilizing a field filter holder, take caution to

assemble the apparatus with the field filter holder towards the fluid being

withdrawn.

FIG. 6 Apparatus Setup for Removing Component Fluid Sample

10.4.4 Do not utilize a field filter holder with paper back-up

NOTE 6—Caution: All connections must be finger tight only.

10.1.1 Install the double valve and fluid outlet plastic tube.

10.1.2 Remove caps or plugs, or both, from the field filter

holder and place them in a covered, precleaned, petri dish.

10.1.3 Install the field filter holder onto the double valve,

taking care to place the inlet side of the field filter holder

towards the fluid being withdrawn.

10.1.4 Install fluid inlet needle onto the monitor.

NOTE 7—Caution: The fluid inlet needle must be precleaned prior to

each usage.

10.2 General Requirements for Fig. 6:

10.2.1 A control blank must be accomplished on the appa-

ratus setup before fluid is withdrawn for component fluid

sampling.

10.2.2 It is recommended that the field filter holders be used

one time only for component fluid sampling. However, clean-

ing in sufficient numbers might warrant their reuse, provided it

is first determined that

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.