ASTM F303-08(2023)e1

(Practice)Standard Practices for Sampling for Particles in Aerospace Fluids and Components

Standard Practices for Sampling for Particles in Aerospace Fluids and Components

SIGNIFICANCE AND USE

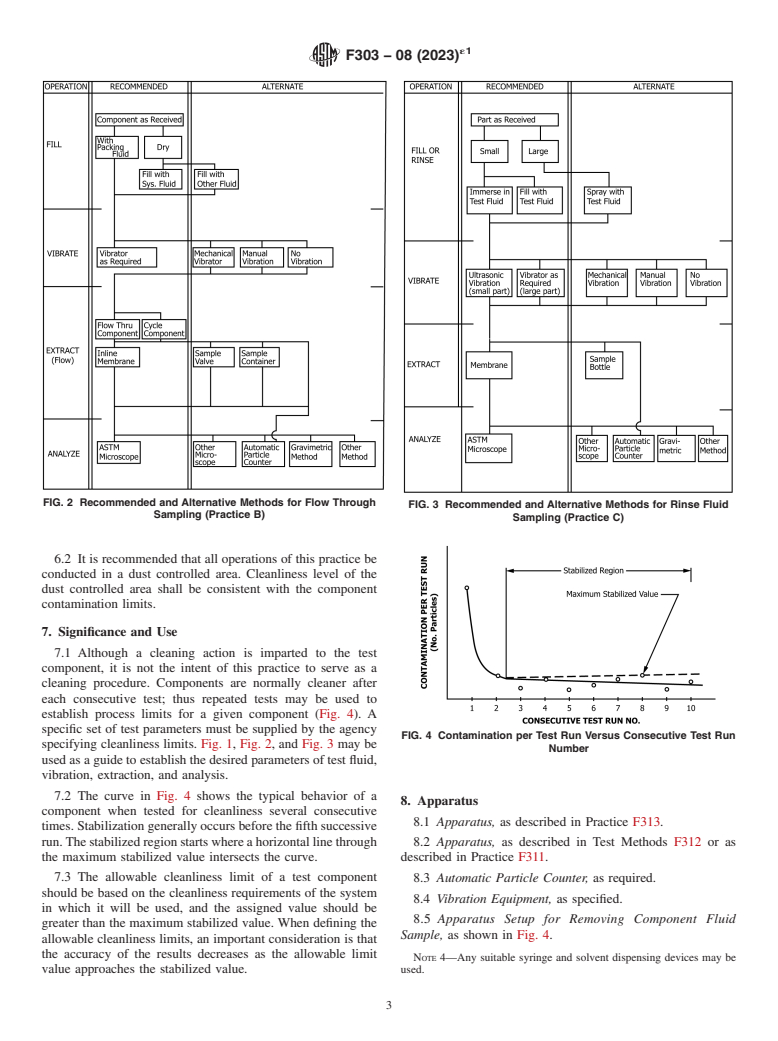

7.1 Although a cleaning action is imparted to the test component, it is not the intent of this practice to serve as a cleaning procedure. Components are normally cleaner after each consecutive test; thus repeated tests may be used to establish process limits for a given component (Fig. 4). A specific set of test parameters must be supplied by the agency specifying cleanliness limits. Fig. 1, Fig. 2, and Fig. 3 may be used as a guide to establish the desired parameters of test fluid, vibration, extraction, and analysis.

FIG. 4 Contamination per Test Run Versus Consecutive Test Run Number

7.2 The curve in Fig. 4 shows the typical behavior of a component when tested for cleanliness several consecutive times. Stabilization generally occurs before the fifth successive run. The stabilized region starts where a horizontal line through the maximum stabilized value intersects the curve.

7.3 The allowable cleanliness limit of a test component should be based on the cleanliness requirements of the system in which it will be used, and the assigned value should be greater than the maximum stabilized value. When defining the allowable cleanliness limits, an important consideration is that the accuracy of the results decreases as the allowable limit value approaches the stabilized value.

SCOPE

1.1 These practices cover sampling procedures for use in determining the particle cleanliness of liquids and liquid samples from components. Three practices, A, B, and C, have been developed on the basis of component geometry in order to encompass the wide variety of configurations. These practices establish guidelines to be used in preparing detailed procedures for sampling specific components.

Note 1: The term cleanliness used in these practices refers to solid particles in the liquid. It does not generally cover other foreign matter such as gases, liquids, and products of chemical degradation. Cleanliness with respect to particulate contamination does not necessarily give any indication of the other types of contamination.

1.2 All components, regardless of application, may be tested provided (1) the fluid medium selected is completely compatible with the materials, packing and fluid used in the test component, and test apparatus, and (2) the fluid is handled in accordance with the manufacturer's recommendations and precautions. A liquid shall be used as the test fluid medium. These test fluids may be flushing, rinsing, packing, end use operating, or suitable substitutes for end use operating fluids. (Warning—Practices for sampling surface cleanliness by the vacuum cleaner technique (used on clean room garments and large storage tanks) sampling gaseous fluids and handling hazardous fluids such as oxidizers, acids, propellants, and so forth, are not within the scope of the practices presented; however, they may be included in addendums or separate practices at a later date.

Substitute fluids are recommended in place of end item fluids for preassembly cleanliness determinations on components using hazardous end item fluids. After obtaining the sample, the substitute fluid must be totally removed from the test part with particular caution given to the possibility of trapped fluid. It is hazardous to use a substitute fluid for testing assembled parts where the fluid can be trapped in dead ends, behind seals, and so forth.)

Note 2: The word fluid used in these practices shall be assumed to be a liquid, unless otherwise stated.

1.3 The cleanliness of assemblies with or without moving parts may be determined at the time of test; however, movement of internal component parts during the test will create unknown quantities of contamination from wear. Practice B covers configurations requiring dynamic actuation to achieve a sample. The practice does not differentiate between built-in particles and wear particles.

Note 3: Defining allowable cleanliness limits is not within the scope of these practice...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: F303 − 08 (Reapproved 2023)

Standard Practices for

Sampling for Particles in Aerospace Fluids and

Components

This standard is issued under the fixed designation F303; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorially updated formatting in 13.1 and 20.3.3 in September 2023.

1. Scope It is hazardous to use a substitute fluid for testing assembled

parts where the fluid can be trapped in dead ends, behind seals,

1.1 These practices cover sampling procedures for use in

and so forth.)

determining the particle cleanliness of liquids and liquid

samples from components. Three practices, A, B, and C, have

NOTE 2—The word fluid used in these practices shall be assumed to be

been developed on the basis of component geometry in order to

a liquid, unless otherwise stated.

encompass the wide variety of configurations. These practices

1.3 The cleanliness of assemblies with or without moving

establish guidelines to be used in preparing detailed procedures

parts may be determined at the time of test; however, move-

for sampling specific components.

ment of internal component parts during the test will create

NOTE 1—The term cleanliness used in these practices refers to solid

unknown quantities of contamination from wear. Practice B

particles in the liquid. It does not generally cover other foreign matter such

covers configurations requiring dynamic actuation to achieve a

as gases, liquids, and products of chemical degradation. Cleanliness with

sample. The practice does not differentiate between built-in

respect to particulate contamination does not necessarily give any indica-

particles and wear particles.

tion of the other types of contamination.

1.2 All components, regardless of application, may be tested

NOTE 3—Defining allowable cleanliness limits is not within the scope

provided (1) the fluid medium selected is completely compat- of these practices.

ible with the materials, packing and fluid used in the test

1.4 The three practices included are as follows:

component, and test apparatus, and (2) the fluid is handled in

Sections

accordance with the manufacturer’s recommendations and

Practice A—Static Fluid Sampling (Method for 5 – 13

precautions. A liquid shall be used as the test fluid medium.

extracting fluid from the test article for analysis.

This applies to components that have a cavity from

These test fluids may be flushing, rinsing, packing, end use

which fluid may be extracted)

operating, or suitable substitutes for end use operating fluids.

Practice B—Flowing Fluid Sampling (Method for flush- 14 – 22

(Warning—Practices for sampling surface cleanliness by the ing contaminants from the test article for analysis.

This applies to components which fluid can pass (1)

vacuum cleaner technique (used on clean room garments and

directly through, or (2) pass into and out of by cy-

large storage tanks) sampling gaseous fluids and handling

cling)

hazardous fluids such as oxidizers, acids, propellants, and so Practice C—Rinse Fluid Sampling (Method for rinsing 23 – 31

contaminants from the test article’s surfaces. The

forth, are not within the scope of the practices presented;

rinse fluid is analyzed for contamination. This ap-

however, they may be included in addendums or separate

plies to components that do not have a fluid cavity

practices at a later date. or for other reasons are not adaptable to Practices

A and B)

Substitute fluids are recommended in place of end item fluids

1.5 This standard does not purport to address all of the

for preassembly cleanliness determinations on components

safety concerns, if any, associated with its use. It is the

using hazardous end item fluids. After obtaining the sample,

responsibility of the user of this standard to establish appro-

the substitute fluid must be totally removed from the test part

with particular caution given to the possibility of trapped fluid. priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accor-

1 dance with internationally recognized principles on standard-

These practices are under the jurisdiction of ASTM Committee E21 on Space

Simulation and Applications of Space Technology and are the direct responsibility

ization established in the Decision on Principles for the

of Subcommittee E21.05 on Contamination.

Development of International Standards, Guides and Recom-

Current edition approved Oct. 1, 2016. Published September 2023. Originally

mendations issued by the World Trade Organization Technical

approved in 1965 as D2429 – 65 T. Redesignated F303 in 1970. Last previous

edition approved in 2016 as F303 – 08 (2016). DOI: 10.1520/F0303-08R23E01. Barriers to Trade (TBT) Committee.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F303 − 08 (2023)

2. Referenced Documents 3.1.10 solvent filtering dispenser, n—an apparatus to dis-

2 pense a stream of 2.0 μm or finer membrane filtered fluid.

2.1 ASTM Standards:

3.1.11 system tare, n—The measure of contamination deter-

D1836 Specification for Commercial Hexanes

mined by replacing the test component with a connecting

F311 Practice for Processing Aerospace Liquid Samples for

fitting and following the cleanliness test procedure as if

Particulate Contamination Analysis Using Membrane Fil-

checking the test component.

ters

F312 Test Methods for Microscopical Sizing and Counting

4. Summary of Practices

Particles from Aerospace Fluids on Membrane Filters

F313 Test Method for Insoluble Contamination of Hydraulic

4.1 Cleanliness is determined by sampling and analyzing

Fluids by Gravimetric Analysis (Withdrawn 1988)

fluid that has been in contact with the surface being analyzed.

Specific methods are recommended; however, other methods

2.2 Military Standards:

have been recognized due to the wide variety of components

MIL-T-27602 Trichlorine Oxygen Propellant Compatibles

MIL-H-6083 Hydraulic Fluid Petroleum Base for Pressure and different test equipment used by industry. Recommended

and alternative methods are given in Fig. 1, Fig. 2, and Fig. 3.

MIL-H-5606 Hydraulic Fluid Petroleum Base for Aircarrier

Missiles and Ordinance

PRACTICE A—STATIC FLUID SAMPLING

3. Terminology

5. Scope

3.1 Definitions:

5.1 This practice covers procedures for determining the

3.1.1 analytical membrane, n—a membrane filter used to

particulate contamination level of fluids from components that

collect the contaminant particles for analysis.

have a cavity from which fluid may be extracted.

3.1.2 azeotropic mixture, n—a solution of two or more

liquids, the composition of which does not change upon

6. Summary of Practice

distillation. Also known as azeotrope.

6.1 Fluid is extracted from the component and analyzed to

3.1.3 blank analysis, n—sometimes referred to as “fluid

determine the particulate contamination level. Recommended

tare,” “control level,” “reference contamination level,” or

and alternative methods are given in Fig. 1.

“background level.” The blank analysis is the particulate

contamination level of the test fluid when the test part is

omitted.

3.1.4 cleanup membrane, n—a membrane used to filter the

contaminant particles from the fluid medium.

3.1.5 component, n—an individual piece or a complete

assembly of individual pieces.

3.1.6 field filter holder, n—a throw-away or reusable car-

tridge containing an analytical membrane filter.

3.1.7 initial cleanliness, n—the measure of contamination

removed from the test component at the time of test, excluding

that defined by operating cleanliness.

3.1.8 membrane tare, n—sometimes referred to as “blank

count” or “control filter.” When applied to microscope

methods, the membrane tare is the quantity of particles

determined to be on the filter before the test fluid is filtered.

When applied to gravimetric methods, the membrane tare is an

amount of weight increase imparted to the control filter when

uncontaminated test fluid is passed through.

3.1.9 operating cleanliness, n—the measure of contami-

nants generated by moving parts in the component during a

specified period of dynamic operation.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

The last approved version of this historical standard is referenced on

www.astm.org.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 FIG. 1 Recommended and Alternative Methods for Static Fluid

Robbins Ave., Philadelphia, PA 19111-5098, Attn: NPODS. Sampling (Practice A)

´1

F303 − 08 (2023)

FIG. 2 Recommended and Alternative Methods for Flow Through

FIG. 3 Recommended and Alternative Methods for Rinse Fluid

Sampling (Practice B)

Sampling (Practice C)

6.2 It is recommended that all operations of this practice be

conducted in a dust controlled area. Cleanliness level of the

dust controlled area shall be consistent with the component

contamination limits.

7. Significance and Use

7.1 Although a cleaning action is imparted to the test

component, it is not the intent of this practice to serve as a

cleaning procedure. Components are normally cleaner after

each consecutive test; thus repeated tests may be used to

establish process limits for a given component (Fig. 4). A

specific set of test parameters must be supplied by the agency

FIG. 4 Contamination per Test Run Versus Consecutive Test Run

specifying cleanliness limits. Fig. 1, Fig. 2, and Fig. 3 may be

Number

used as a guide to establish the desired parameters of test fluid,

vibration, extraction, and analysis.

7.2 The curve in Fig. 4 shows the typical behavior of a

8. Apparatus

component when tested for cleanliness several consecutive

8.1 Apparatus, as described in Practice F313.

times. Stabilization generally occurs before the fifth successive

run. The stabilized region starts where a horizontal line through

8.2 Apparatus, as described in Test Methods F312 or as

the maximum stabilized value intersects the curve. described in Practice F311.

7.3 The allowable cleanliness limit of a test component

8.3 Automatic Particle Counter, as required.

should be based on the cleanliness requirements of the system

8.4 Vibration Equipment, as specified.

in which it will be used, and the assigned value should be

8.5 Apparatus Setup for Removing Component Fluid

greater than the maximum stabilized value. When defining the

Sample, as shown in Fig. 4.

allowable cleanliness limits, an important consideration is that

the accuracy of the results decreases as the allowable limit

NOTE 4—Any suitable syringe and solvent dispensing devices may be

value approaches the stabilized value. used.

´1

F303 − 08 (2023)

8.6 Apparatus Setup for Providing Filtered Fluids, as shown 9.4.8 Deionized water.

in Fig. 5 (Note 4).

5 NOTE 5—Methyl-chloroform, used in these practices, is toxic, and is

9. Reagents

being phased out for many applications. Methyl-chloroform has been

replaced in this edition of these practices. The replacement solvents were

9.1 Purity of Reagents—Reagent grade chemicals shall be

selected based on tests and analyses performed by The Aerospace

used in all tests. Unless otherwise indicated, it is intended that

Corporation and described in SMC-TR-95–28.

all reagents shall conform to the specifications of the Commit-

NOTE 6—Trichloroethylene has been labeled a potential human carcino-

tee on Analytical Reagents of the American Chemical Society,

gen by the Environmental Protection Agency. Use should be restricted to

where such specifications are available. Other grades may be

limit human exposure.

used, provided it is first ascertained that the reagent is of

10. Preparation of Apparatus

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

10.1 Installation Requirements for Fig. 6—The following

requirements must be accomplished prior to and during assem-

9.2 Reagents must be compatible with the materials, fluid,

bly of the apparatus shown in Fig. 6. (Warning—All connec-

and seals used in the component and apparatus.

tions must be finger tight only.)

9.3 All reagents shall be prefiltered through a 2-μm or finer

10.1.1 Install the double valve and fluid outlet plastic tube.

absolute membrane filter prior to use unless this requirement is

10.1.2 Remove caps or plugs, or both, from the field filter

impractical due to the fluid used or sizes monitored in which

holder and place them in a covered, precleaned, petri dish.

case the user must filter as necessary.

10.1.3 Install the field filter holder onto the double valve,

9.4 Low surface tension reagents commonly used are as

taking care to place the inlet side of the field filter holder

follows:

towards the fluid being withdrawn.

9.4.1 Petroleum Ether,

10.1.4 Install fluid inlet needle onto the monitor.

9.4.2 Hexane, in accordance with Specification D1836.

(Warning—The fluid inlet needle must be precleaned prior to

9.4.3 Isopropyl Alcohol,

each usage.)

9.4.4 Fluorocarbons,

10.2 General Requirements for Fig. 6:

9.4.5 Mineral Spirits,

10.2.1 A control blank must be accomplished on the appa-

9.4.6 Trichloroethylene, in accordance with MIL-T-27602,

ratus setup before fluid is withdrawn for component fluid

and

sampling.

9.4.7 Azeotropic mixture of ethyl acetate (47 % vol) and

10.2.2 It is recommended that the field filter holders be used

cyclohexane (53 % vol).

one time only for component fluid sampling. However, clean-

ing in sufficient numbers might warrant their reuse, provided it

is first determined that the monitors are sufficiently cleaned to

A Material Safety Data Sheet (MSDS) can be obtained from the vendor. The

permit their reuse without lessening the accuracy of the

following website can also provide MSDS’s for all materials:

determination.

www.msdssearch.com/DBlinksN.htm. Note that the specific fluorocarbon must be

identified.

10.2.3 Always actuate the syringe plunger slowly when

6 6

filling or ejecting fluid.

ACS Reagent Chemicals, Specifications and Procedures for

Reagents and Standard-Grade Reference Materials, American

Chemical Society, Washington, DC. For suggestions on the

testing of reagents not listed by the American Chemical

Aerospace Corporation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.