ASTM F880-12(2017)

(Specification)Standard Specification for Stainless Steel Socket, Square Head, and Slotted Headless-Set Screws

Standard Specification for Stainless Steel Socket, Square Head, and Slotted Headless-Set Screws

ABSTRACT

This specification covers the requirements for austenitic grade stainless steel socket set screws (SSS), sizes M1.6 through M24, having property classes A1-50 and A1-70. The analysis of the screw material shall conform to the chemical composition specified. Socket set screw shall be subjected to torque test, Vickers hardness test, and corrosion resistance test to meet the requirements prescribed.

SCOPE

1.1 This specification covers the requirements for austenitic grade stainless steel socket-set screws (SSS) sizes 0.060 through 1.000 in. square head set screws (SHSS) sizes 0.190 through 1.500 in., and slotted headless set screws (HSS) 0.060 through 0.750 in., in two conditions, AF and CW.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

Note 1: A complete metric companion to Specification F880 has been developed—F880M; therefore, no metric equivalents are shown in this specification.

1.3 The following hazards caveat pertains only to Test Method Section, Section 12 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F880 − 12 (Reapproved 2017)

Standard Specification for

Stainless Steel Socket, Square Head, and Slotted Headless-

Set Screws

This standard is issued under the fixed designation F880; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* A342/A342M Test Methods for Permeability of Weakly

Magnetic Materials

1.1 This specification covers the requirements for austenitic

A380 Practice for Cleaning, Descaling, and Passivation of

grade stainless steel socket-set screws (SSS) sizes 0.060

Stainless Steel Parts, Equipment, and Systems

through 1.000 in. square head set screws (SHSS) sizes 0.190

A555/A555M Specification for General Requirements for

through 1.500 in., and slotted headless set screws (HSS) 0.060

Stainless Steel Wire and Wire Rods

through 0.750 in., in two conditions, AF and CW.

A751 Test Methods and Practices for Chemical Analysis of

1.2 Units—The values stated in inch-pound units are to be

Steel Products

regarded as standard. No other units of measurement are

A967 Specification for Chemical Passivation Treatments for

included in this standard.

Stainless Steel Parts

D3951 Practice for Commercial Packaging

NOTE 1—A complete metric companion to Specification F880 has been

developed—F880M; therefore, no metric equivalents are shown in this E18 Test Methods for Rockwell Hardness of Metallic Ma-

specification.

terials

1.3 The following hazards caveat pertains only to Test F593 Specification for Stainless Steel Bolts, Hex Cap

Method Section, Section 12 of this specification. This standard

Screws, and Studs

does not purport to address all of the safety concerns, if any, F788/F788M Specification for Surface Discontinuities of

associated with its use. It is the responsibility of the user of this

Bolts, Screws, Studs, and Rivets, Inch and Metric Series

standard to establish appropriate safety, health, and environ- F1470 Practice for Fastener Sampling for Specified Me-

mental practices and determine the applicability of regulatory

chanical Properties and Performance Inspection

limitations prior to use.

2.2 ASME Standard:

1.4 This international standard was developed in accor-

B 18.3 Socket Cap, Shoulder and Set Screws, Inch Series

dance with internationally recognized principles on standard-

B 18.6.2 Slotted Head Cap Screws, Square Head Set Screws,

ization established in the Decision on Principles for the

and Slotted Headless Set Screws (Inch Series)

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3. Classification

Barriers to Trade (TBT) Committee.

3.1 The designation of the alloy group and condition for the

two materials and conditions of this specification shall be

2. Referenced Documents

consistent with the stainless steel designations in Specification

2.1 ASTM Standards:

F593.

A262 Practices for Detecting Susceptibility to Intergranular

3.2 The austenitic stainless steel socket set screw shall be

Attack in Austenitic Stainless Steels

designated F880 Group 1 Condition AF (solution annealed) or

F880 Group 1 Condition CW (cold worked).

This specification is under the jurisdiction of ASTM Committee F16 on

4. Ordering Information

Fasteners and is the direct responsibility of Subcommittee F16.04 on Nonferrous

4.1 Orders for material under this specification shall include

Fasteners.

Current edition approved Dec. 1, 2017. Published December 2017. Originally

the following information:

approved in 1986. Last previous edition approved in 2012 as F880 -12. DOI:

4.1.1 Quantity (number of screws);

10.1520/F0880-12R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F880 − 12 (2017)

4.1.2 Dimensions, including nominal thread designation, 6.2 Unless otherwise specified in the inquiry and purchase

thread pitch, nominal screw length (inches) and point configu- order (see Supplementary Requirement S2), the choice of alloy

ration. A standard part number may be used for this definition; used shall be that of the fastener manufacturer as determined

4.1.3 Name of the screw (SSS, SHSS or HSS); by his fabrication methods and material availability. The

4.1.4 Condition AF/CW; specific alloy used by the manufacturer shall be clearly

4.1.5 Surface finish, if required. If a finish other than identified on all certification required in the purchase order and

passivation is required, it must be specified on the order or shall have a chemical composition conforming to the limits

product standard; specified in Table 2.

4.1.6 ASTM specification and year of issue; and

6.3 When chemical analysis is performed by the purchaser

4.1.7 Any special or supplemental requirements.

using finished fasteners representing each lot, the chemical

4.1.8 If torque testing is required for socket set screws sizes

contents obtained shall conform to the limits specified in Table

over ⁄2 inch.

2 for the specific alloy. Chemical composition shall conform to

4.2 Example—50 000 pieces 0.250-20 × 0.375 cone point the tolerances specified in Specification A555/A555M.

SSS CW ASTM F880 – XX. 6.3.1 In the event of a discrepancy, a referee analysis of the

samples for each lot as specified in 12.1 shall be made in

accordance with 11.3.1.

5. Materials and Manufacture

5.1 The screw may be forged, formed, extruded, machined,

7. Mechanical Properties

or ground to meet the dimensional characteristics and perfor-

7.1 Socket-set screws, when subjected to a torque test in

mance requirements.

accordance with 12.3.1, shall withstand application of the test

5.2 Heat Treatment—Austenitic alloys Group 1 Condition

tightening torque specified in Table 1 without evidence of the

AF screw shall be annealed by heating to 1900 6 50°F to

socket reaming or the screw bursting. Socket set screws in

obtain maximum corrosion resistance and minimum perme-

sizes in nominal diameters over ⁄2 in. are not subject to torques

ability. The screws shall be held for a sufficient time at

testing unless required by purchaser. The test torque values

temperature, then cooled at a rate sufficient to prevent precipi-

must be supplied by purchaser and agreed to by the supplier.

tation of the carbide and provide the properties in accordance

7.2 The hardness limits from 70 to 95 HRB (125 to 210

with Table 1.

DPH) for Condition AF and 96 HRB to 33 HRC (216 to 327

5.3 When condition CW is specified, the austenitic alloys

DPH) for Condition CW shall be met as determined using Test

shall be annealed as specified in 5.2, generally by the raw

Methods E18.

material manufacturer, and then cold worked to develop

specific properties.

8. Corrosion Resistance Requirements

8.1 Carbide Precipitation:

6. Chemical Composition

8.1.1 Rod, bar, and wire in the austenitic alloy groups 1, 2,

6.1 The analysis of the screw material shall conform to the and 3, except the free-machining grades, 303 and 303Se, used

to make fasteners in accordance with this specification shall be

chemical composition specified in Table 2.

A

TABLE 1 Socket Set Screw Torsional Strength Requirements

Nominal Screw Size Shortest Nominal Screw Lengths Subject to Torque Testing Test Torque, in.-lb, min

Cup and Flat Points, Cone and Oval Points Half Dog Points, in. AF CW

in.

0 0.060 0.109 0.125 0.109 0.3 0.6

1 0.073 0.125 0.141 0.125 0.7 1.2

2 0.086 0.125 0.141 0.141 0.7 1.2

3 0.099 0.141 0.156 0.156 1.6 3.3

4 0.112 0.141 0.172 0.156 1.6 3.3

5 0.125 0.172 0.188 0.172 3 5

6 0.138 0.188 0.203 0.188 3 5

8 0.164 0.188 0.219 0.203 9 16

10 0.190 0.188 0.250 0.234 16 26

⁄4 0.250 0.250 0.312 0.297 40 67

⁄16 0.312 0.312 0.391 0.359 79 135

⁄8 0.375 0.375 0.438 0.438 138 237

⁄16 0.437 0.438 0.547 0.484 220 378

⁄2 0.500 0.500 0.609 0.547 358 600

⁄8 0.625 0.625 0.875 0.875 . .

⁄4 0.750 0.750 1.000 1.000 . .

⁄8 0.875 0.875 1.000 1.000 . .

1 1.000 1.100 1.250 1.250 . .

A

For socket set screw sizes over ⁄2 inch, torsional strength testing is not required unless specified by purchaser. The test torque values must be supplied by purchaser

and agreed upon by the supplier.

F880 − 12 (2017)

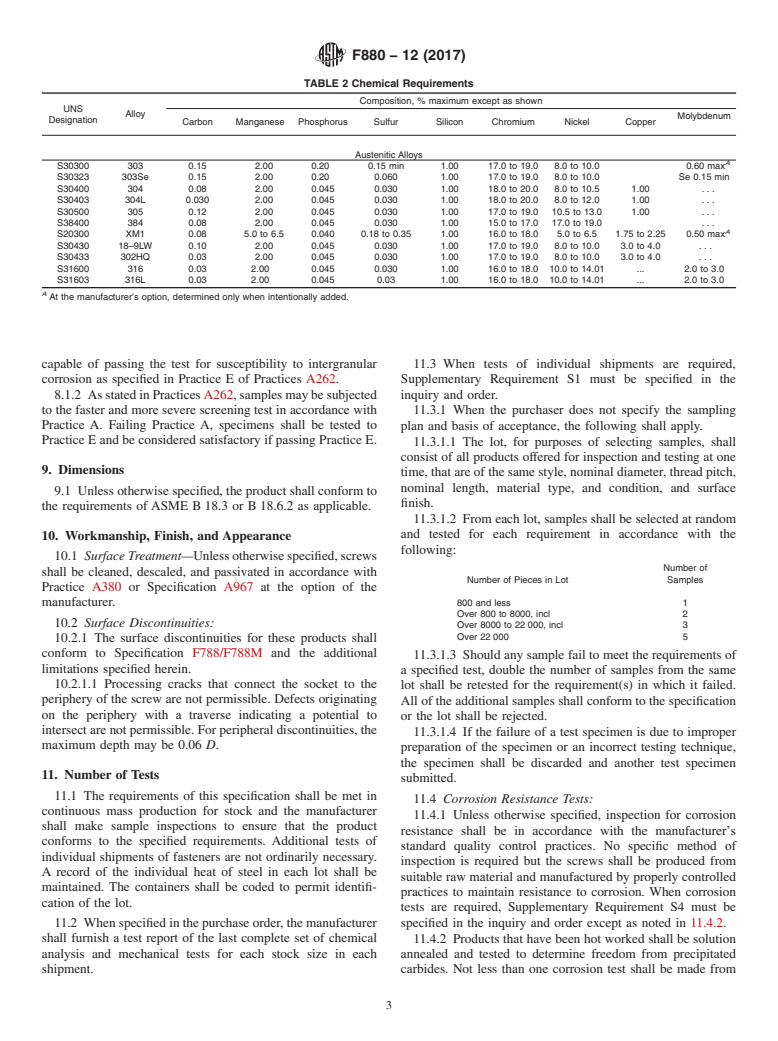

TABLE 2 Chemical Requirements

Composition, % maximum except as shown

UNS

Alloy

Molybdenum

Designation

Carbon Manganese Phosphorus Sulfur Silicon Chromium Nickel Copper

Austenitic Alloys

A

S30300 303 0.15 2.00 0.20 0.15 min 1.00 17.0 to 19.0 8.0 to 10.0 0.60 max

S30323 303Se 0.15 2.00 0.20 0.060 1.00 17.0 to 19.0 8.0 to 10.0 Se 0.15 min

S30400 304 0.08 2.00 0.045 0.030 1.00 18.0 to 20.0 8.0 to 10.5 1.00 . . .

S30403 304L 0.030 2.00 0.045 0.030 1.00 18.0 to 20.0 8.0 to 12.0 1.00 . . .

S30500 305 0.12 2.00 0.045 0.030 1.00 17.0 to 19.0 10.5 to 13.0 1.00 . . .

S38400 384 0.08 2.00 0.045 0.030 1.00 15.0 to 17.0 17.0 to 19.0 . . .

A

S20300 XM1 0.08 5.0 to 6.5 0.040 0.18 to 0.35 1.00 16.0 to 18.0 5.0 to 6.5 1.75 to 2.25 0.50 max

S30430 18–9LW 0.10 2.00 0.045 0.030 1.00 17.0 to 19.0 8.0 to 10.0 3.0 to 4.0 . . .

S30433 302HQ 0.03 2.00 0.045 0.030 1.00 17.0 to 19.0 8.0 to 10.0 3.0 to 4.0 . . .

S31600 316 0.03 2.00 0.045 0.030 1.00 16.0 to 18.0 10.0 to 14.01 . 2.0 to 3.0

S31603 316L 0.03 2.00 0.045 0.03 1.00 16.0 to 18.0 10.0 to 14.01 . 2.0 to 3.0

A

At the manufacturer’s option, determined only when intentionally added.

capable of passing the test for susceptibility to intergranular 11.3 When tests of individual shipments are required,

corrosion as specified in Practice E of Practices A262. Supplementary Requirement S1 must be specified in the

8.1.2 As stated in Practices A262, samples may be subjected inquiry and order.

to the faster and more severe screening test in accordance with

11.3.1 When the purchaser does not specify the sampling

Practice A. Failing Practice A, specimens shall be tested to plan and basis of acceptance, the following shall apply.

Practice E and be considered satisfactory if passing Practice E.

11.3.1.1 The lot, for purposes of selecting samples, shall

consist of all products offered for inspection and testing at one

9. Dimensions

time, that are of the same style, nominal diameter, thread pitch,

nominal length, material type, and condition, and surface

9.1 Unless otherwise specified, the product shall conform to

finish.

the requirements of ASME B 18.3 or B 18.6.2 as applicable.

11.3.1.2 From each lot, samples shall be selected at random

and tested for each requirement in accordance with the

10. Workmanship, Finish, and Appearance

following:

10.1 Surface Treatment—Unless otherwise specified, screws

Number of

shall be cleaned, descaled, and passivated in accordance with

Number of Pieces in Lot Samples

Practice A380 or Specification A967 at the option of the

800 and less 1

manufacturer.

Over 800 to 8000, incl 2

10.2 Surface Discontinuities:

Over 8000 to 22 000, incl 3

Over 22 000 5

10.2.1 The surface discontinuities for these products shall

conform to Specification F788/F788M and the additional

11.3.1.3 Should any sample fail to meet the requirements of

limitations specified herein.

a specified test, double the number of samples from the same

10.2.1.1 Processing cracks that connect the socket to the

lot shall be retested for the requirement(s) in which it failed.

periphery of the screw are not permissible. Defects originating

All of the additional samples shall conform to the specification

on the periphery with a traverse indicating a potential to

or the lot shall be rejected.

intersect are not permissible. For peripheral discontinuities, the

11.3.1.4 If the failure of a test specimen is due to improper

maximum depth may be 0.06 D.

preparation of the specimen or an incorrect testing technique,

the specimen shall be discarded and another test specimen

11. Number of Tests

submitted.

11.1 The requirements of this specification shall be met in

11.4 Corrosion Resistance Tests:

continuous mass production for stock and the manufacturer

11.4.1 Unless otherwise specified, inspection for corrosion

shall make sample inspections to ensure that the product

resistance shall be in accordance with the manufacturer’s

conforms to the specified requirements. Additional tests of

standard quality control practices. No specific method of

individual shipments of fasteners are not ordinarily necessary.

inspection is required but the screws shall be produced from

A record of the individual heat of steel in each lot shall be

suitable raw material and manufactured by properly controlled

maintained. The containers shall be coded to permit identifi-

practices to maintain resistance to corrosion. When corrosion

cation of the lot.

tests are required, Supplementary Requirement S4 must be

specified in the inquiry and order except as noted in 11.4.2.

11.2 When specified in the purchase order, the manufacturer

shall furnish a test report of the last complete set of chemical 11.4.2 Products that have been hot worked shall be solution

analysis and mechanical tests for each stock size in each annealed and tested to determine freedom from precipitated

shipment. carbides. Not less than one corrosion test shall be made from

F880 − 12 (2017)

each lot. Corrosion tests shall be performed in accordance with 13.2 The inspector representing the purchaser shall have

Practices A262, Practices A or E as applicable. free entry to all parts of the manufacturer’s works that concern

the manufacture of the material ordered. The manufacturer

12. Test Methods

shall afford the inspector all reasonable facilities to satisfy that

the material is being furnished in accordance with this speci-

12.1 Chemical Analysis—The chemical composition shall

be determined in accordance with Test Methods, Practices, and fication. All tests and inspection required by the specification

that are requested by the purchaser’s representative and pur-

Terminology A751.

chase order shall be made prior to shipment and shall be so

12.2 The fastener manufacturer may accept the chemi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.