ASTM F2663-07a

(Test Method)Standard Test Method for Bead Unseating of Tubeless Tires for Motor Vehicles with GVWR of 4536 kg (10 000 lb) or Less

Standard Test Method for Bead Unseating of Tubeless Tires for Motor Vehicles with GVWR of 4536 kg (10 000 lb) or Less

SIGNIFICANCE AND USE

This test method establishes a standard procedure for the test and provides data that can be related to the force required to unseat the bead of a tire inflated with a specified pressure from the rim. This test method does not establish performance limits or tolerances for tire specifications.

SCOPE

1.1 This test method covers the static non-rolling laboratory method of determination of a tubeless tire’s resistance to bead unseating. The test requires the use of a standardized fixture and load machine. The test is conducted using a defined test pressure and method of determining the resultant force to unseat the tire from the rim.

1.2 This test method is applicable for all passenger, light truck, and temporary spare tires used on motor vehicles with 4536 kg (10 000 lb) Gross Vehicle Weight Rating (GVWR) or less.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2663 −07a

StandardTest Method for

Bead Unseating of Tubeless Tires for Motor Vehicles with

1

GVWR of 4536 kg (10 000 lb) or Less

This standard is issued under the fixed designation F2663; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 bead unseating block, n—machined block of cast

aluminum (also known as “shoe”) used on the bead unseating

1.1 This test method covers the static non-rolling laboratory

fixture to press against the tire sidewall.

method of determination of a tubeless tire’s resistance to bead

3.1.3 elements, n—an isolated (totally bounded by void)

unseating. The test requires the use of a standardized fixture

projection. F538

and load machine. The test is conducted using a defined test

pressure and method of determining the resultant force to

3.1.4 manufacturer, of a tire, n—name of a company or

unseat the tire from the rim.

wholly owned subsidiary making the tire. F538

1.2 This test method is applicable for all passenger, light

3.1.5 measuring rim, n—any“rim”withawidthasspecified

truck, and temporary spare tires used on motor vehicles with

for the design or measuring rim for a particular tire size

4536 kg (10 000 lb) Gross Vehicle Weight Rating (GVWR) or

designation, and with the “bead” seat and flange dimensions in

less.

accordance with publications of tire and rim standards organi-

zations current at the time of manufacture.

1.3 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information 3.1.6 outside diameter, n—maximum diameter of the tire

only. when it is mounted and inflated. F538

1.4 This standard does not purport to address all of the 3.1.7 overall width, n—maximum cross-sectional width of a

safety concerns, if any, associated with its use. It is the tire, including protective or decorative ribs. F538

responsibility of the user of this standard to establish appro-

3.1.8 rim, n—specially shaped circular periphery to which a

priate safety and health practices and determine the applica-

tire may be mounted with appropriate bead fitment. F538

bility of regulatory limitations prior to use.

3.1.9 rim, test, n—rim having the configuration and dimen-

sions suitable for use with a test tire in accordance with

2. Referenced Documents

publications of a tire and rim standards organization current at

2

2.1 ASTM Standards:

the time of tire manufacture. F538

F538 Terminology Relating to the Characteristics and Per-

3.1.10 sidewall, of a tire, n—portion of a tire between the

formance of Tires

tread and the bead. F538

F1502 Test Method for Static Measurements on Tires for

3.1.11 specified design section width, n—width specified in

Passenger Cars, Light Trucks, and Medium Duty Vehicles

the publications of tire and rim standards organizations current

at the time of manufacture for a new tire of that size

3. Terminology

designation and type when inflated on its “measuring rim.”

3.1 Definitions:

3.1.12 tire, pneumatic, n—hollow tire that becomes load-

3.1.1 bead, of a tire, n—part of a tire that comes in contact

bearing upon inflation with air, or other gas, to a pressure

with the rim and is shaped to secure the tire to the rim. F538

above atmospheric. F538

3.1.13 tread, of a tire, n—part of the tire that comes in

1

This test method is under the jurisdiction of ASTM Committee F09 on Tires contact with the ground. F538

and is the direct responsibility of Subcommittee F09.30 on Laboratory (Non-

3.1.14 unseating, v—the dislodgment of the bead area of a

Vehicular) Testing.

tire from the portion of the rim designed to hold the bead in

Current edition approved Dec. 15, 2007. Published January 2008. Originally

approved in 2007. Last previous edition approved in 2007 as F2663 – 07. DOI:

place resulting in loss of inflation pressure.

10.1520/F2663-07A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4. Summary of Test Method

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1 This test method measures the force needed to unseat a

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tire from a clean, dry, painted test rim. The force is applied

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

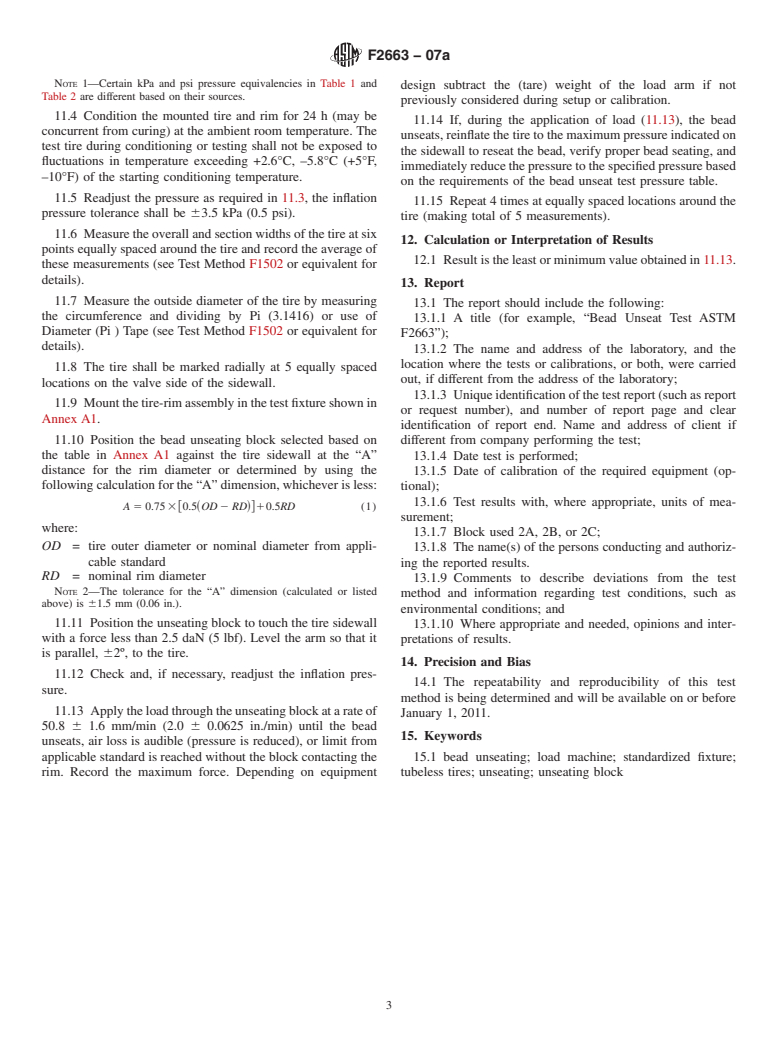

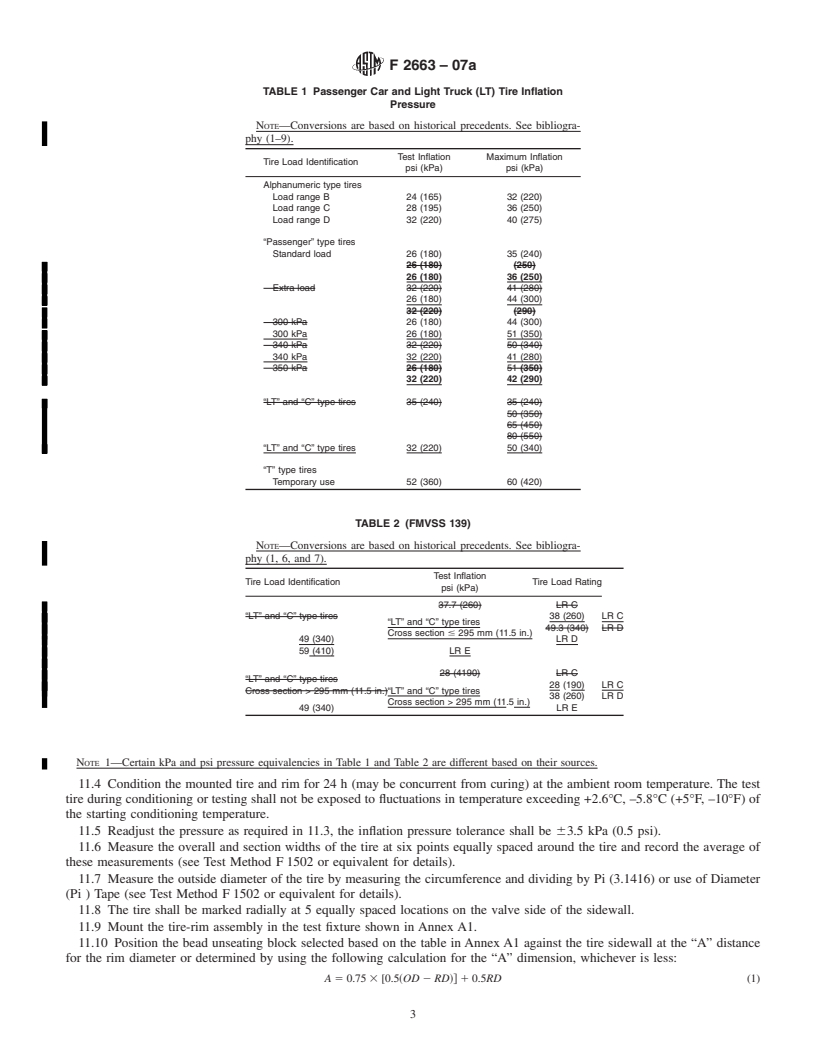

F2663−07a

throughaspecifiedbeadunseatingblockandpivotingloadarm setting and travel speeds. Calibration standard accuracy will be

set substantially parallel to the tire rim assembly at the start of ascertained by comparison of the st

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F 2663–07 Designation: F 2663 – 07a

Standard Test Method for

Bead Unseating of Tubeless Tires for Motor Vehicles with

1

GVWR of 4536 kg (10 000 lb) or Less

This standard is issued under the fixed designation F 2663; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the static non-rolling laboratory method of determination of a tubeless tire’s resistance to bead

unseating. The test requires the use of a standardized fixture and load machine. The test is conducted using a defined test pressure

and method of determining the resultant force to unseat the tire from the rim.

1.2 This test method is applicable for all passenger, light truck, and temporary spare tires used on motor vehicles with 4536 kg

(10 000 lb) Gross Vehicle Weight Rating (GVWR) or less.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

F 538 Terminology Relating to the Characteristics and Performance of Tires

F 1502 Test Method for Static Measurements on Tires for Passenger Cars, Light Trucks, and Medium Duty Vehicles

3. Terminology

3.1 Definitions:

3.1.1 bead, of a tire, n—part of a tire that comes in contact with the rim and is shaped to secure the tire to the rim. F 538

3.1.2 bead unseating block, n—machined block of cast aluminum (also known as “shoe”) used on the bead unseating fixture

to press against the tire sidewall.

3.1.3 elements, n—an isolated (totally bounded by void) projection. F 538

3.1.4 manufacturer, of a tire, n—name of a company or wholly owned subsidiary making the tire. F 538

3.1.5 measuring rim, n—any “rim” with a width as specified for the design or measuring rim for a particular tire size

designation,andwiththe“bead”seatandflangedimensionsinaccordancewithpublicationsoftireandrimstandardsorganizations

current at the time of manufacture.

3.1.6 outside diameter, n—maximum diameter of the tire when it is mounted and inflated. F 538

3.1.7 overall width, n—maximum cross-sectional width of a tire, including protective or decorative ribs. F 538

3.1.8 rim, n—specially shaped circular periphery to which a tire may be mounted with appropriate bead fitment. F 538

3.1.9 rim, test, n—rim having the configuration and dimensions suitable for use with a test tire in accordance with publications

of a tire and rim standards organization current at the time of tire manufacture. F 538

3.1.10 sidewall, of a tire, n—portion of a tire between the tread and the bead. F 538

3.1.11 specified design section width, n— width specified in the publications of tire and rim standards organizations current at

the time of manufacture for a new tire of that size designation and type when inflated on its “measuring rim.”

3.1.12 tire, pneumatic, n—hollow tire that becomes load-bearing upon inflation with air, or other gas, to a pressure above

atmospheric. F 538

3.1.13 tread, of a tire, n—part of the tire that comes in contact with the ground. F 538

3.1.14 unseating, v—the dislodgment of the bead area of a tire from the portion of the rim designed to hold the bead in place

resulting in loss of inflation pressure.

1

This test method is under the jurisdiction of ASTM Committee F09 on Tires and is the direct responsibility of Subcommittee F09.30 on Laboratory (Non-Vehicular)

Testing.

Current edition approved June 1, 2007. Published July 2007.

Current edition approved Dec. 15, 2007. Published January 2008. Originally approved in 2007. Last previous edition approved in 2007 as F 2663 – 07.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 2663 – 07a

4. Summary of Test Method

4.1 This

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.