ASTM E1782-14

(Test Method)Standard Test Method for Determining Vapor Pressure by Thermal Analysis

Standard Test Method for Determining Vapor Pressure by Thermal Analysis

SIGNIFICANCE AND USE

5.1 Vapor pressure is a fundamental thermophysical property of a liquid. Vapor pressure data are useful in process design and control, in establishing environmental regulations for safe handling and transport, for estimation of volatile organic content (VOC), and in deriving hazard assessments. Vapor pressure and boiling temperature data are required for Material Safety Data Sheets (MSDS). The enthalpy of vaporization may also be estimated from the slope of the vapor pressure curve (see Practice E2071).

SCOPE

1.1 This test method describes a procedure for the determination of the vapor pressure of pure liquids or melts from boiling point measurements made using differential thermal analysis (DTA) or differential scanning calorimetry (DSC) instrumentation operated at different applied pressures.

1.2 This test method may be used for the temperature range 273 to 773 K (0 to 500°C) and for pressures between 0.2 kPa to 2 MPa. These ranges may differ depending upon the instrumentation used and the thermal stability of materials tested. Because a range of applied pressures is required by this test method, the analyst is best served by use of instrumentation referred to as high pressure differential thermal instrumentation (HPDSC or HPDTA).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. (See also IEEE/ASTM SI 10.)

1.4 There is no ISO standard equivalent to this test method.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1782 − 14

Standard Test Method for

1

Determining Vapor Pressure by Thermal Analysis

This standard is issued under the fixed designation E1782; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E967Test Method for Temperature Calibration of Differen-

tial Scanning Calorimeters and Differential ThermalAna-

1.1 This test method describes a procedure for the determi-

lyzers

nation of the vapor pressure of pure liquids or melts from

E1142Terminology Relating to Thermophysical Properties

boiling point measurements made using differential thermal

E2071Practice for Calculating Heat of Vaporization or

analysis (DTA) or differential scanning calorimetry (DSC)

Sublimation from Vapor Pressure Data

instrumentation operated at different applied pressures.

IEEE/ASTM SI10Standard for Use of the International

1.2 This test method may be used for the temperature range

System of Units (SI) The Modern Metric System

273 to 773 K (0 to 500°C) and for pressures between 0.2 kPa

to 2 MPa. These ranges may differ depending upon the

3. Terminology

instrumentation used and the thermal stability of materials

3.1 Definitions:

tested. Because a range of applied pressures is required by this

3.1.1 The following terms are applicable to this test method

test method, the analyst is best served by use of instrumenta-

and can be found in either Terminology E473 or Terminology

tionreferredtoashighpressuredifferentialthermalinstrumen-

E1142:boilingpressure,boilingtemperature,differentialscan-

tation (HPDSC or HPDTA).

ning calorimetry (DSC), differential thermal analysis (DTA),

1.3 The values stated in SI units are to be regarded as

vapor pressure, vaporization point, vaporization temperature.

standard. No other units of measurement are included in this

3.2 Symbols:

3

standard. (See also IEEE/ASTM SI10.)

3.2.1 A, B, C—Antoine vapor pressure equation (1) con-

stants (log , kPa, K):

1.4 There is no ISO standard equivalent to this test method.

10

Antoinevaporpressureequation:Log P 5 A 2 B/ T1C

1.5 This standard does not purport to address all of the ~ !

10

safety concerns, if any, associated with its use. It is the

where:

responsibility of the user of this standard to establish appro-

P = vapor pressure, kPa, and

priate safety and health practices and determine the applica-

T = temperature, K.

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 A specimen in an appropriate container is heated at a

2

2.1 ASTM Standards:

constant rate within a DTAor DSC instrument operated under

E177Practice for Use of the Terms Precision and Bias in

an applied constant vacuum/pressure between 0.2 kPa and 2

ASTM Test Methods

MPauntilaboilingendothermisrecorded.Boilingisobserved

E473Terminology Relating to Thermal Analysis and Rhe-

at the temperature where the specimen partial pressure equals

ology

the pressure applied to the test chamber. The pressure is

E691Practice for Conducting an Interlaboratory Study to

recorded during observation of the boiling endotherm and the

Determine the Precision of a Test Method

boiling temperature is recorded as the extrapolated onset

temperature. This measurement is repeated using new speci-

mens for each of five or more different pressures covering the

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

pressure range of interest. The pressure-temperature data are

Measurements and is the direct responsibility of Subcommittee E37.01 on Calo-

−1

fitted as Log P and 1/T (K ) to the Antoine vapor pressure

10

rimetry and Mass Loss.

equation (see Fig. 1). Vapor pressure values required for

Current edition approved March 15, 2014. Published April 2014. Originally

approved in 1996. Last previous edition approved in 2008 as E1782–08. DOI:

specific reports are then computed from the derived equation.

10.1520/E1782-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to a list of references at the end of

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

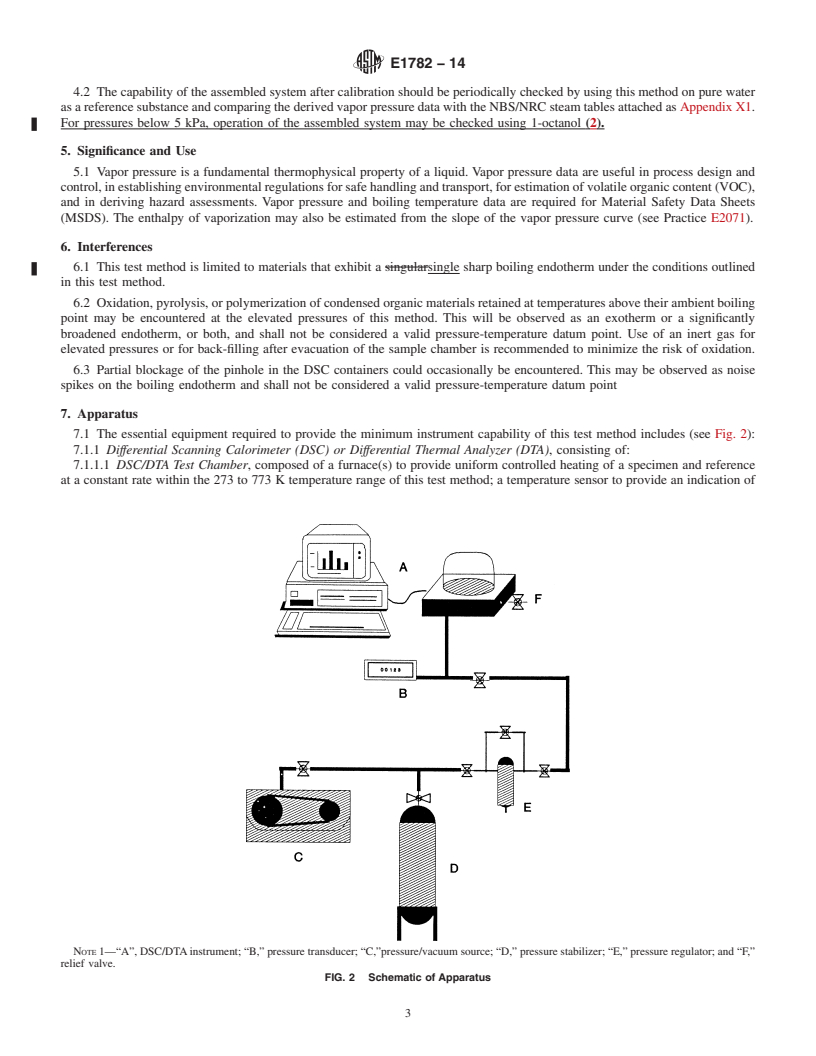

E1782 − 14

NOTE 1—“A”, DSC/DTA instrument; “B,” pressure transducer; “C,

”pressure/vacuum source; “D,” pressure stabilizer; “E,” pressure regula-

tor; and “F,” relief valve.

FIG. 1 Vapor Pressure Curve with Experimental Data and An-

FIG.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1782 − 08 E1782 − 14

Standard Test Method for

1

Determining Vapor Pressure by Thermal Analysis

This standard is issued under the fixed designation E1782; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes a procedure for the determination of the vapor pressure of pure liquids or melts from boiling point

measurements made using differential thermal analysis (DTA) or differential scanning calorimetry (DSC) instrumentation operated

at different applied pressures.

1.2 This test method may be used for the temperature range 273 to 773 K (0 to 500 °C)500°C) and for pressures between 50.2

kPa to 2 MPa. These ranges may differ depending upon the instrumentation used and the thermal stability of materials tested.

Because a range of applied pressures is required by this test method, the analyst is best served by use of instrumentation referred

to as high pressure differential thermal instrumentation (HPDSC or HPDTA).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

(See also IEEE/ASTM SI 10.)

1.4 There is no ISO standard equivalent to this test method.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E473 Terminology Relating to Thermal Analysis and Rheology

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E967 Test Method for Temperature Calibration of Differential Scanning Calorimeters and Differential Thermal Analyzers

E1142 Terminology Relating to Thermophysical Properties

E2071 Practice for Calculating Heat of Vaporization or Sublimation from Vapor Pressure Data

IEEE/ASTM SI 10 Standard for Use of the International System of Units (SI) The Modern Metric System

3. Terminology

3.1 Definitions:

3.1.1 The following terms are applicable to this test method and can be found in either Terminology E473 or Terminology

E1142: boiling pressure, boiling temperature, differential scanning calorimetry (DSC), differential thermal analysis (DTA), vapor

pressure, vaporization point, vaporization temperature.

3.2 Symbols:

1

This test method is under the jurisdiction of ASTM Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on Calorimetry

and Mass Loss.

Current edition approved March 1, 2008March 15, 2014. Published June 2008April 2014. Originally approved in 1996. Last previous edition approved in 20032008 as

E1782 – 03.E1782 – 08. DOI: 10.1520/E1782-08.10.1520/E1782-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1782 − 14

3

3.2.1 A, B, C—Antoine vapor pressure equation (1) constants (log , kPa, K):

10

Antoine vapor pressure equation:Log P 5 A 2 B/~T1C!

10

where:

P = vapor pressure, kPa, and

T = temperature, K.

3.2 Symbols:

3

3.2.1 A, B, C—Antoine vapor pressure equation (1) constants (log , kPa, K):

10

Antoine vapor pressure equation:Log P 5 A 2 B/ T1C

~ !

10

where:

P = vapor pressure, kPa, and

T = temperature, K.

4. Summary of Test Method

4.1 A specimen in an appropriate container is heated at a constant rate within a DTA or DSC instrument operated under an

applied constant vacuum/pressure between 50.2 kPa and 2 MPa until a boiling endotherm is recorded. Boiling is observed at the

temperature where the specimen partial pressure equals the pressure applied to the test chamber. The pressure is recorded during

observanceobservation of the boiling endotherm and the boiling temperature is recorded as the extrapolated onset temperature. This

measurement is repeated using new specimens for each of five or more dif

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.