ASTM D6687-01

(Guide)Standard Guide for Testing Printing Ink Vehicles and Components Thereof

Standard Guide for Testing Printing Ink Vehicles and Components Thereof

SCOPE

1.1 This guide covers a list of test methods, practices, guides, and specifications that can be used for the testing and evaluation of printing ink vehicles and components thereof (see Table 1).

1.2 This guide includes methods that were developed to test impact and non-impact inks and vehicles associated with letterpress, lithography, flexography and gravure. Tests on raw materials and analytical tests in general have been included.

1.3 Other ASTM standards not specified here may also be applicable.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6687 – 01

Standard Guide for

Testing Printing Ink Vehicles and Components Thereof

This standard is issued under the fixed designation D 6687; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope composition that is applied by printing machinery.

2.1.1.1 Discussion—Printing inks may contain vehicles,

1.1 This guide covers a list of test methods, practices,

colorants, waxes, solvents, and other additives. Bulk inks are

guides, and specifications that can be used for the testing and

tested for dispersion, tinting strength, density, heat and storage

evaluation of printing ink vehicles and components thereof (see

stability, rheology, and printing properties.

Table 1).

2.1.2 vehicle, n—the portion of a printing ink that excludes

1.2 This guide includes methods that were developed to test

the colorant.

impact and non-impact inks and vehicles associated with

2.1.2.1 Discussion—Ink vehicles typically include the resin/

letterpress, lithography, flexography and gravure. Tests on raw

solvent portion of the printing ink. Other printing ink additives,

materials and analytical tests in general have been included.

generally not included in the vehicle, are waxes, antioxidants

1.3 Other ASTM standards not specified here may also be

and driers.

applicable.

1.4 This standard does not purport to address all of the

3. Test Categories

safety concerns, if any, associated with its use. It is the

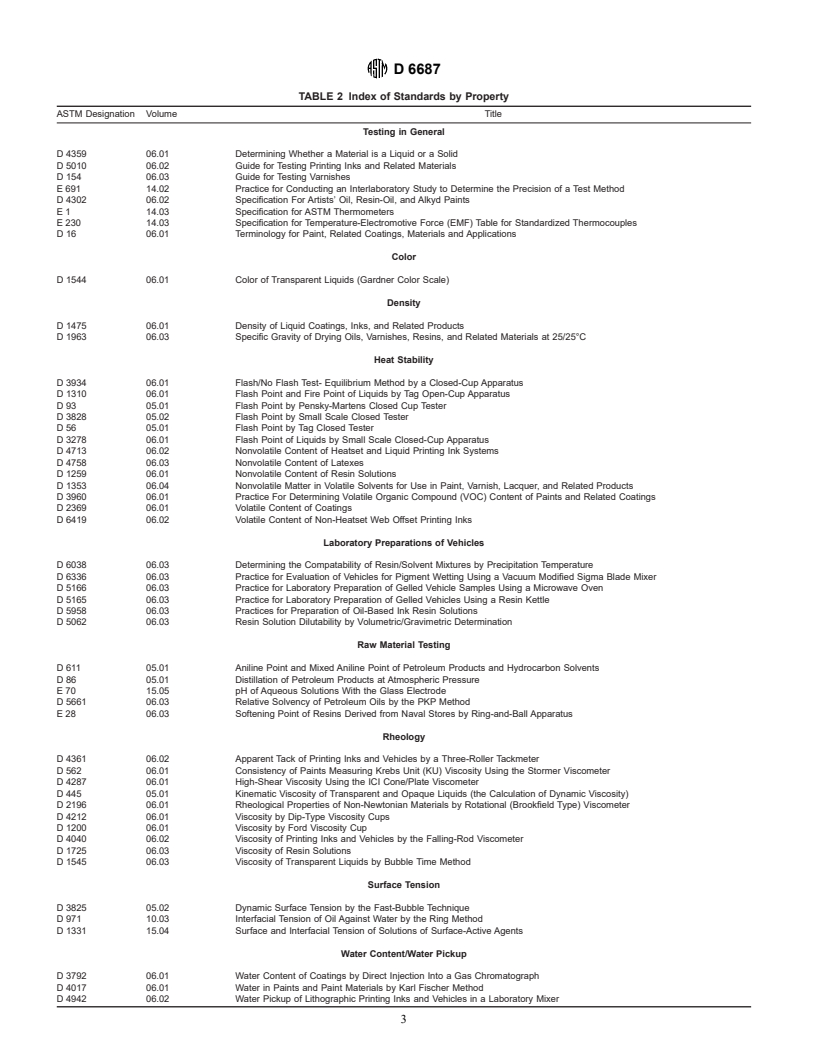

3.1 For convenience in selection, the test methods, prac-

responsibility of the user of this standard to establish appro-

tices, guides, and specifications listed in this guide are listed

priate safety and health practices and determine the applica-

numerically (see Table 1) and by property of interest (see Table

bility of regulatory requirements prior to use.

2).

2. Terminology

4. Precision and Bias

2.1 Definitions:

4.1 If available, precision for each test method listed can be

2.1.1 printing ink, n—a colored or pigmented liquid or paste

found in the latest revision of that test method.

1 5. Keywords

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of

5.1 printing inks; printing ink vehicles; test methods and

Subcommittee D01.37 on Ink Vehicles.

practices (tabulation of); vehicles

Current edition approved June 10, 2001. Published August 2001.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 6687

TABLE 1 Numerical Listing of Ink Vehicle Related Standards

ASTM Designation Volume Title

D 16 06.01 Terminology for Paint, Related Coatings, Materials and Applications

D 56 05.01 Test Method for Flash Point by Tag Closed Tester

D 86 05.01 Test Method for Distillation of Petroleum Products at Atmospheric Pressure

D 93 05.01 Test Method for Flash Point by Pensky-Martens Closed Cup Tester

D 154 06.03 Guide for Testing Varnishes

D 445 05.01 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (the Calculation of Dynamic Viscosity)

D 562 06.01 Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using the Stormer Viscometer

D 611 05.01 Test Methods for Aniline Point and Mixed Aniline Point of Petroleum Products and Hydrocarbon Solvents

D 971 10.03 Test Method for Interfacial Tension of Oil Against Water by the Ring Method

D 1200 06.01 Test Method for Viscosity by Ford Viscosity Cup

D 1259 06.01 Test Method for Nonvolatile Content of Resin Solutions

D 1310 06.01 Test Method for Flash Point and Fire Point of Liquids by Tag Open-Cup Apparatus

D 1331 15.04 Test Methods for Surface and Interfacial Tension of Solutions of Surface-Active Agents

D 1353 06.04 Test Method for Nonvolatile Matter in Volatile Solvents for Use in Paint, Varnish, Lacquer, and Related Products

D 1475 06.01 Test Method for Density of Liquid Coatings, Inks, and Related Products

D 1544 06.01 Test Method for Color of Transparent Liquids (Gardner Color Scale)

D 1545 06.03 Test Method for Viscosity of Transparent Liquids by Bubble Time Method

D 1725 06.03 Test Method for Viscosity of Resin Solutions

D 1963 06.03 Test Method for Specific Gravity of Drying Oils, Varnishes, Resins, and Related Materials at 25/25°C

D 2196 06.01 Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational (Brookfield Type) Viscometer

D 2369 06.01 Test Method for Volatile Content of Coatings

D 3278 06.01 Test Method for Flash Point of Liquids by Small Scale Closed-Cup Apparatus

D 3792 06.01 Test Method for Water Content of Coatings by Direct Injection Into a Gas Chromatograph

D 3825 05.02 Test Method for Dynamic Surface Tension by the Fast-Bubble Technique

D 3828 05.02 Test Method for Flash Point by Small Scale Closed Tester

D 3934 06.01 Test Method for Flash/No Flash Test- Equilibrium Method by a Closed-Cup Apparatus

D 3960 06.01 Practice For Determining Volatile Organic Compound (VOC) Content of Paints and Related Coatings

D 4017 06.01 Test Method for Water in Paints and Paint Materials by Karl Fischer Method

D 4040 06.02 Test Method for Viscosity of Printing Inks and Vehicles by the Falling-Rod Viscometer

D 4212 06.01 Test Method for Viscosity by Dip-Type Viscosity Cups

D 4287 06.01 Test Method for High-Shear Viscosity Using the ICI Cone/Plate Viscometer

D 4302 06.02 Specification For Artists’ Oil, Resin-Oil, and Alkyd Paints

D 4359 06.01 Test Method for Determining Whether a Material is a Liquid or a Solid

D 4361 06.02 Test Method for Apparent Tack of Printing Inks and Vehicles by a Three-Roller Tackmeter

D 4713 06.02 Test Methods for Nonvolatile Content of Heatset and Liquid Printing Ink Systems

D 4758 06.03 Test Method for Nonvolatile Content of Latexes

D 4942 06.02 Test Methods for Water Pickup of Lithographic Printing Inks and Vehicles in a Laboratory Mixer

D 5010 06.02 Guide for Testing Printing Inks and Related Materials

D 5062 06.03 Test Method for Resin Solution Dilutability by Volumetric/Gravimetric Determination

D 5165 06.03 Practice for Laboratory Preparation of Gelled Vehicles Using a Resin Kettle

D 5166 06.03 Practice for Laboratory Prep

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.